Beruflich Dokumente

Kultur Dokumente

Properties Value: Ug-23 Maximum Allowable Stress Values

Hochgeladen von

Mohamad Faiz Zulkipli0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

84 Ansichten2 SeitenThis document discusses the material properties and uses of ASTM A516 Grade 60 carbon steel. It states that ASTM A516 Grade 60 has greater yield and tensile strength compared to ASTM A516 Grade 65, and can be used in lower temperature services as it has good weldability, notch toughness, and atmospheric corrosion resistance. It also has more reasonable prices than stainless steel. The typical mechanical properties of ASTM A516 Grade 60 are then outlined, listing the tensile strength and yield stress.

Originalbeschreibung:

carbon steele

Originaltitel

Carbon Steel

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document discusses the material properties and uses of ASTM A516 Grade 60 carbon steel. It states that ASTM A516 Grade 60 has greater yield and tensile strength compared to ASTM A516 Grade 65, and can be used in lower temperature services as it has good weldability, notch toughness, and atmospheric corrosion resistance. It also has more reasonable prices than stainless steel. The typical mechanical properties of ASTM A516 Grade 60 are then outlined, listing the tensile strength and yield stress.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

84 Ansichten2 SeitenProperties Value: Ug-23 Maximum Allowable Stress Values

Hochgeladen von

Mohamad Faiz ZulkipliThis document discusses the material properties and uses of ASTM A516 Grade 60 carbon steel. It states that ASTM A516 Grade 60 has greater yield and tensile strength compared to ASTM A516 Grade 65, and can be used in lower temperature services as it has good weldability, notch toughness, and atmospheric corrosion resistance. It also has more reasonable prices than stainless steel. The typical mechanical properties of ASTM A516 Grade 60 are then outlined, listing the tensile strength and yield stress.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

1. Determine/suggest the materials use.

Carbon Steel SA-516 Grade 60 because of its offers a greater Yield and Tensile

strength when compared to ASTM A516 Grade 65 and can operate in lower

temperatures. ASTM A516 Grade 60 is a boiler pressure vessel quality steel that

has good weld- ability and excellent notch toughness and is perfect for moderate

and lower temperature services. ASTM A516 Grade 60 also has a high

atmospheric corrosion resistance and the price are more reasonable than stainless

steel.

The mechanical properties of ASTM A516 Grade 60 and ASME SA516 Grade 60

carbon steel plate are outlined in table 1.

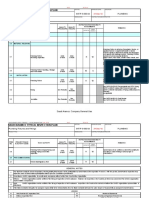

Table 1. Typical Mechanical Values of ASTM A516 Grade 60/ASME SA516

Grade 60.

Properties Value

Tensile strength (N/mm2) 415/580

Yield stress/ min (N/mm2) 265

UG-23 MAXIMUM ALLOWABLE STRESS

VALUES

(a) The maximum allowable stress value is the maximum unit stress permitted in a

given material used in a vessel constructed under these rules. The maximum

allowable tensile stress values permitted for different materials are given in

Subpart 1 of Section II, Part D. Section II, Part D is published as two separate

publications. One publication contains values only in the U.S. Customary units

and the other contains values only in SI units. The selection of the version to use

is dependent on the set of units selected for construction. A listing of these

materials is given in the following tables, which are included in Subsection C. For

material identified as meeting more than one material specification and/or grade,

the maximum allowable tensile stress value for either material specification and/or

grade may be used provided all requirements and limitations for the material

specification and grade are met for the maximum allowable tensile stress value

chosen.

27-5 HEAT TREATMENT OF TEST

SPECIMENS

(a) Except when impact testing per UCS-66 is required, and in lieu of the

requirements of UCS-85, the plate, forging, pipe, and strip steels used in the

production of glasslined vessels may be represented by test specimens that meet

the following requirements:

(2) the materials shall be limited to SA-106, SA-285, SA-414, SA-516, and SA-

836; and

(3) the multiple temperature cycles used in the glassing operation shall be within

the range of 1450F to 1700F (790C to 925C), with at least one cycle being

above the upper transformation temperature of the material. The vessel is to be

held at temperature approximately 1/2 hr/in. (1/2 hr/25 mm) of thickness, and

stillaircooled to ambient.

Das könnte Ihnen auch gefallen

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysVon EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNoch keine Bewertungen

- Age-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsDokument4 SeitenAge-Hardening Alloy Steel Forgings For Pressure Vessel ComponentsGustavo SuarezNoch keine Bewertungen

- TFP and TFT Back in Town (Tight Fit CRA Lined Pipe and Tubing)Dokument12 SeitenTFP and TFT Back in Town (Tight Fit CRA Lined Pipe and Tubing)Deadnightvikernes100% (1)

- 1999 OMAE99 PIPE-5037 Bai - Bending Moment Capacity of PipesDokument13 Seiten1999 OMAE99 PIPE-5037 Bai - Bending Moment Capacity of Pipesdmlsfmm100% (1)

- 1 Vegetated Swale Technical GuidanceDokument4 Seiten1 Vegetated Swale Technical GuidanceAnkit KodinariyaNoch keine Bewertungen

- Section 2 - Shut Off ValvesDokument30 SeitenSection 2 - Shut Off ValvesNovica BanicevicNoch keine Bewertungen

- Recommended storage procedures for packaged production equipmentDokument3 SeitenRecommended storage procedures for packaged production equipmentJuan Pablo Chavez IxtepanNoch keine Bewertungen

- EA Trash ScreensDokument102 SeitenEA Trash Screensfester100Noch keine Bewertungen

- Om Stop LogsDokument6 SeitenOm Stop LogsiculasiNoch keine Bewertungen

- Hydrogen CrackingDokument26 SeitenHydrogen CrackingmmkattaNoch keine Bewertungen

- Liner 1 PDFDokument4 SeitenLiner 1 PDFAjit AroteNoch keine Bewertungen

- AISI Designation: Stainless Tool Steels Killed Carbon SteelsDokument14 SeitenAISI Designation: Stainless Tool Steels Killed Carbon SteelsShankar JhaNoch keine Bewertungen

- What Is HDPE PIPEDokument7 SeitenWhat Is HDPE PIPEKarthikeyan MoorthyNoch keine Bewertungen

- Characterization of landfilled materials: assessing enhanced landfill mining potentialDokument12 SeitenCharacterization of landfilled materials: assessing enhanced landfill mining potentialTri diahNoch keine Bewertungen

- Reducer DimensionsDokument7 SeitenReducer DimensionsadnansirajNoch keine Bewertungen

- HDT SHA Space Heater Artic ManualDokument228 SeitenHDT SHA Space Heater Artic ManualBecky LivingstonNoch keine Bewertungen

- Piercing of Low-Carbon SteelDokument3 SeitenPiercing of Low-Carbon SteelRicardo PaceNoch keine Bewertungen

- (J. Gilbert Kaufman) Parametric Analyses of High-T (BookFi) PDFDokument170 Seiten(J. Gilbert Kaufman) Parametric Analyses of High-T (BookFi) PDFLiviu BadeaNoch keine Bewertungen

- Predicting Weld Resid Stres Dissimilar Metal Girth Weld Pipe Using 3D FEM With A Simplified Heat SourceDokument9 SeitenPredicting Weld Resid Stres Dissimilar Metal Girth Weld Pipe Using 3D FEM With A Simplified Heat SourceAngelo GontijoNoch keine Bewertungen

- Icg2013 Bookofabstracts WWWDokument326 SeitenIcg2013 Bookofabstracts WWWCAMELIA Neagu-COGALNICEANUNoch keine Bewertungen

- Nuclear Weld ConditionsDokument130 SeitenNuclear Weld ConditionsAdrian DavidNoch keine Bewertungen

- SeismicGuidelines WaterPipelines P4Dokument33 SeitenSeismicGuidelines WaterPipelines P4Dipankar BasakNoch keine Bewertungen

- A review on concrete surface treatment mechanismsDokument13 SeitenA review on concrete surface treatment mechanismsaldi sophianNoch keine Bewertungen

- LCC Literature Review ReportDokument94 SeitenLCC Literature Review ReportNabendu LodhNoch keine Bewertungen

- Microstructural and Mechanical Properties Analysis of Plasma ARC Welded 316L Austenitic Stainless Steel Joints Without Addition of Filler MaterialDokument17 SeitenMicrostructural and Mechanical Properties Analysis of Plasma ARC Welded 316L Austenitic Stainless Steel Joints Without Addition of Filler MaterialEditor IJTSRDNoch keine Bewertungen

- Pintu KlepDokument12 SeitenPintu KlepAndri KwinNoch keine Bewertungen

- Mechanics - Case Study Solution: Stress Transformation Equations Principal StressesDokument31 SeitenMechanics - Case Study Solution: Stress Transformation Equations Principal StressesPaldexNoch keine Bewertungen

- Charles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelDokument66 SeitenCharles E. Smith - Feasibility of Thermite Sparking With Impact of Rusted Steel Onto Aluminum Coated SteelAlarmakNoch keine Bewertungen

- m571c XL Cat d7g Web Spec SheetDokument2 Seitenm571c XL Cat d7g Web Spec SheetRahmat RiskiNoch keine Bewertungen

- Bisso Marine Pipeline Burial Excavation OverviewDokument14 SeitenBisso Marine Pipeline Burial Excavation OverviewyeNoch keine Bewertungen

- Carbon Steel s45cDokument4 SeitenCarbon Steel s45ctam200Noch keine Bewertungen

- Ipc2012 90736Dokument8 SeitenIpc2012 90736Marcelo Varejão CasarinNoch keine Bewertungen

- Rock Stacked Retaining Walls t01-10Dokument6 SeitenRock Stacked Retaining Walls t01-10williamvargasmongeNoch keine Bewertungen

- ASTM A153 Guide for Galvanized Hardware & FastenersDokument5 SeitenASTM A153 Guide for Galvanized Hardware & FastenersMekhmanNoch keine Bewertungen

- ASTM G 17-07 Standard Test Method For Penetration Resistance of Pipeline Coatings (Blunt Rod) 1Dokument6 SeitenASTM G 17-07 Standard Test Method For Penetration Resistance of Pipeline Coatings (Blunt Rod) 1daempi100% (2)

- Sound Insulation - NRCDokument372 SeitenSound Insulation - NRCKhader Abu-daggaNoch keine Bewertungen

- Acom 3 2015Dokument13 SeitenAcom 3 2015Joshua WalkerNoch keine Bewertungen

- Heat - Treatment of SteelDokument39 SeitenHeat - Treatment of Steel113314Noch keine Bewertungen

- BS en Iso 13760 - 2000Dokument14 SeitenBS en Iso 13760 - 2000Kim WongNoch keine Bewertungen

- Standard Guide For Selection of Weirs and Flumes For Open-Channel Flow Measurement of WaterDokument7 SeitenStandard Guide For Selection of Weirs and Flumes For Open-Channel Flow Measurement of WaterdrakenhavenNoch keine Bewertungen

- Iiw 1693 05Dokument19 SeitenIiw 1693 05Pradip Goswami100% (1)

- Fatigue of Concrete Under Uniaxial Compression Cyclic LoadingDokument7 SeitenFatigue of Concrete Under Uniaxial Compression Cyclic LoadingHCStepNoch keine Bewertungen

- Design and Construction of Grouted RiprapDokument16 SeitenDesign and Construction of Grouted Ripraptomaustin100% (1)

- 06 VD Mee-Welding of Super Duplex Stainless SteelsDokument12 Seiten06 VD Mee-Welding of Super Duplex Stainless SteelsKareem AbdelazizNoch keine Bewertungen

- 330MW Shrinagar Hydroelectric Project Penstock Intake DataDokument2 Seiten330MW Shrinagar Hydroelectric Project Penstock Intake Datasrigirisetty208Noch keine Bewertungen

- Residual Stresses and Fatigue at Tubular Welded StructuresDokument12 SeitenResidual Stresses and Fatigue at Tubular Welded StructuresElias KapaNoch keine Bewertungen

- A Review of Hydrogen Embrittlement of Martensitic Advanced High Strength SteelsDokument35 SeitenA Review of Hydrogen Embrittlement of Martensitic Advanced High Strength SteelsAndress SsalomonnNoch keine Bewertungen

- ASME Section VIII Div 1 Pressure Vessel Design GuideDokument103 SeitenASME Section VIII Div 1 Pressure Vessel Design GuideJaeup YouNoch keine Bewertungen

- Equipment Qualification in Operational Nuclear Power PlantsDokument126 SeitenEquipment Qualification in Operational Nuclear Power PlantsAnonymous l2sT4aENoch keine Bewertungen

- STD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXDokument2 SeitenSTD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXAkshay KalraNoch keine Bewertungen

- Materials Challenges in Nuclear EnergyDokument24 SeitenMaterials Challenges in Nuclear EnergyW.t. HanNoch keine Bewertungen

- Alterations Made To Saudi Aramco Standards From 1985 - 2004Dokument265 SeitenAlterations Made To Saudi Aramco Standards From 1985 - 2004Saad AshrafNoch keine Bewertungen

- ms123-2 2011preDokument5 Seitenms123-2 2011preKimi KononNoch keine Bewertungen

- A06 Guidelines For Evaluation of Water Control Gates Draft Version FEMADokument416 SeitenA06 Guidelines For Evaluation of Water Control Gates Draft Version FEMATimothy McmillanNoch keine Bewertungen

- Weholite: The Basics ofDokument24 SeitenWeholite: The Basics ofbetopagoadaNoch keine Bewertungen

- Composites Part B: Zhonggang Wang TDokument11 SeitenComposites Part B: Zhonggang Wang TAkash PrajapatiNoch keine Bewertungen

- Ejma 10th Edition The Latest Revision 5 PDF FreeDokument2 SeitenEjma 10th Edition The Latest Revision 5 PDF FreeSgk ManikandanNoch keine Bewertungen

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesVon EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesNoch keine Bewertungen

- Rectilinear Control SystemDokument15 SeitenRectilinear Control SystemMohamad Faiz ZulkipliNoch keine Bewertungen

- Plant Energy Efficiency TutorialsDokument34 SeitenPlant Energy Efficiency TutorialsMohamad Faiz ZulkipliNoch keine Bewertungen

- Heat Pump Lab Report PDFDokument12 SeitenHeat Pump Lab Report PDFMohamad Faiz ZulkipliNoch keine Bewertungen

- HSE Rules and Regulations in the WorkshopDokument4 SeitenHSE Rules and Regulations in the WorkshopMohamad Faiz ZulkipliNoch keine Bewertungen

- Asgnmnt Last 3DDokument7 SeitenAsgnmnt Last 3DMohamad Faiz ZulkipliNoch keine Bewertungen

- Analysis Data CivilDokument12 SeitenAnalysis Data CivilMohamad Faiz ZulkipliNoch keine Bewertungen

- Plant Energy Efficiency TutorialsDokument34 SeitenPlant Energy Efficiency TutorialsMohamad Faiz ZulkipliNoch keine Bewertungen

- Mechanics of Fluids Lab Impact of A JetDokument10 SeitenMechanics of Fluids Lab Impact of A JetpatrickNX942088% (17)

- Mechanical Vibrations Tse Morse HinkleDokument201 SeitenMechanical Vibrations Tse Morse HinkleHarshit DwivediNoch keine Bewertungen

- Chapter 2 TWDokument1 SeiteChapter 2 TWMohamad Faiz ZulkipliNoch keine Bewertungen

- Heat Pump Lab Report PDFDokument12 SeitenHeat Pump Lab Report PDFMohamad Faiz ZulkipliNoch keine Bewertungen

- Agitator Design and Selection GuideDokument33 SeitenAgitator Design and Selection GuideBANGGANoch keine Bewertungen

- Agitator Design and Selection GuideDokument33 SeitenAgitator Design and Selection GuideBANGGANoch keine Bewertungen

- Air Compressors (Thermo)Dokument9 SeitenAir Compressors (Thermo)Mohamad Faiz ZulkipliNoch keine Bewertungen

- Intro and EffencienciDokument7 SeitenIntro and EffencienciMohamad Faiz ZulkipliNoch keine Bewertungen

- Analysis Data CivilDokument12 SeitenAnalysis Data CivilMohamad Faiz ZulkipliNoch keine Bewertungen

- Feedforward and Ratio ControlDokument37 SeitenFeedforward and Ratio ControlFresi Yuliana Pta100% (1)

- Lecture 2 Equivalent SystemDokument8 SeitenLecture 2 Equivalent SystemMohamad Faiz ZulkipliNoch keine Bewertungen

- To Verify Boy Les LawDokument3 SeitenTo Verify Boy Les LawMohamad Faiz ZulkipliNoch keine Bewertungen

- Light Emitting DiodeDokument4 SeitenLight Emitting DiodeMohamad Faiz ZulkipliNoch keine Bewertungen

- Pid Legend PDFDokument1 SeitePid Legend PDFSocMed Dtk UI0% (1)

- NanoGrout CFGDokument3 SeitenNanoGrout CFGimzee25100% (2)

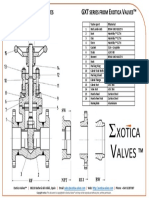

- Gate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimDokument1 SeiteGate Valve Forged B564 UNS N10276 Body, Hastelloy™ C276 TrimGiovanni PetrizzoNoch keine Bewertungen

- Ecoquip 2: Vapor Abrasive Blast EquipmentDokument20 SeitenEcoquip 2: Vapor Abrasive Blast EquipmentdimasjosesmithNoch keine Bewertungen

- Ningbo Feitian Electron Technology Co.,Ltd Product Component DiagramDokument13 SeitenNingbo Feitian Electron Technology Co.,Ltd Product Component DiagramesjomabaNoch keine Bewertungen

- Production Technology - GATE 2020Dokument54 SeitenProduction Technology - GATE 2020Saravana Mahe-ShanNoch keine Bewertungen

- Quality Improvement of Corn Husk As Raw Material For Textile ProductsDokument5 SeitenQuality Improvement of Corn Husk As Raw Material For Textile ProductsSophie BaromanNoch keine Bewertungen

- OSOS OMBLIGO AmigurumiDokument12 SeitenOSOS OMBLIGO AmigurumiANDREA ULTENGONoch keine Bewertungen

- Hydrothermal MethodDokument16 SeitenHydrothermal Methodavni vatsNoch keine Bewertungen

- SATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalDokument2 SeitenSATIP-S-060-04 REV 8 Plumbing Fixtures and Fittings FinalmominNoch keine Bewertungen

- 35 - 01 Introduction Training AidsDokument100 Seiten35 - 01 Introduction Training AidsElliank QueirozNoch keine Bewertungen

- 3 Marks (Metals and Non-Metals)Dokument13 Seiten3 Marks (Metals and Non-Metals)simrannehraa2Noch keine Bewertungen

- Aise TR9 91Dokument123 SeitenAise TR9 91Juan Carlos Lasdica100% (3)

- BMW Center Show Room Final-01Dokument43 SeitenBMW Center Show Room Final-01QC MEPNoch keine Bewertungen

- Coating, Laminating and Testing CapabilitiesDokument28 SeitenCoating, Laminating and Testing CapabilitiesrabiulfNoch keine Bewertungen

- Carbon FibersDokument1.130 SeitenCarbon Fibersaagun1Noch keine Bewertungen

- Upper FloorsDokument41 SeitenUpper FloorsTeoh Zhi Tong60% (5)

- Color Index Story PDFDokument4 SeitenColor Index Story PDFAsim khandual50% (2)

- KUWS&DBoard SR 2018-19Dokument63 SeitenKUWS&DBoard SR 2018-19Radhakrishna KPNoch keine Bewertungen

- Feasibility Biomass Fuel Briquettes From Banana Plant WasteDokument21 SeitenFeasibility Biomass Fuel Briquettes From Banana Plant WasteTuan Pham100% (1)

- Laying and Jointing Water PipesDokument15 SeitenLaying and Jointing Water Pipesashish reddyNoch keine Bewertungen

- GGFHJDokument1 SeiteGGFHJanon_791172439Noch keine Bewertungen

- Cat CatalystDokument7 SeitenCat Catalystkhaled fathyNoch keine Bewertungen

- Chemguard C306-MS-C 3% AFFF Concentrate: DescriptionDokument2 SeitenChemguard C306-MS-C 3% AFFF Concentrate: DescriptionChyeAmshariYumanNoch keine Bewertungen

- Tolerance of Performance Curves According To UNI EN ISO 9906: 2002 NormsDokument2 SeitenTolerance of Performance Curves According To UNI EN ISO 9906: 2002 NormsJuan AcostaNoch keine Bewertungen

- Ultralight, Scalable, and High-Temperature, Resilient Ceramic Nanofiber SpongesDokument4 SeitenUltralight, Scalable, and High-Temperature, Resilient Ceramic Nanofiber SpongesCj Labadan100% (1)

- Aes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowDokument1 SeiteAes Lab Qra Tories (P) Lti2: Analyzing Today FBR An Assured TomorrowShreyansh SinghNoch keine Bewertungen

- GL XX Mobil Rarus SHC 1020 SeriesDokument3 SeitenGL XX Mobil Rarus SHC 1020 SeriesHitesh MahajanNoch keine Bewertungen

- Rockwood 2013 Price BookDokument80 SeitenRockwood 2013 Price BookSecurity Lock DistributorsNoch keine Bewertungen

- 201 enDokument2 Seiten201 enRyan ZhangNoch keine Bewertungen

- Catalog Osg Vol 5 2017Dokument976 SeitenCatalog Osg Vol 5 2017Cosmin IonutNoch keine Bewertungen