Beruflich Dokumente

Kultur Dokumente

Asphalt Lab

Hochgeladen von

Asad NawazCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Asphalt Lab

Hochgeladen von

Asad NawazCopyright:

Verfügbare Formate

ASPHALT LAB

ABSTRACT

The basic objective of this lab is to test the compressive strength of asphalt. Asphalt

is merged combination of aggregates, filler and binder material. It is used for the

construction and repairing of all categories of roads. It acts as a binder in order to

bind aggregates in cohesive mixture. It form hard solid surface when it is settled.

Apparatus is used to measure deflection and force (measured in pounds) needed

to break the asphalt.

OBJECTIVES/INTRODUCTION

This lab gives idea about the application of asphalt and how it is applied on the road

surfaces. Tensile of asphalt is measured because in pavement design, the tensile

strength of asphalt concrete is a fundamental engineering property. Durable and

sustainable asphalt pavements require high-quality asphalt materials.

MATERIALS AND APPARATUS

1. Testing machine producing uniform vertical movement of 50.8 mm per

minute (2in/min).

2. Breaking heads having an inside radius of curvature of 2in.

3. Load cell or ring dynamometer and strip chart recorder of flow meter.

PROCEDURE

1. Asphalt is placed in testing machine in such a way it produced uniform

vertical movement of 50.8 mm per minute. (2 in/min).

2. Asphalt is smashed 75 time on each side.

3. Asphalt is removed from the machine and placed in to the dynamometer.

4. In order to record deflection and pound force of asphalt the dynamometer

is activated.

EXPERIMENTAL DATA

Deflection Pound force

1026 inch 9650 lb

RESULTS AND DISCUSSION

2. Where does asphalt come from?

The most of asphalt used is obtained from petroleum. It also occur in nature in

concentrated form where it formed from remains of ancient microscopic algae.

3. Did asphalt cylinder fails? Why do you think it failed?

The initial sample failed. The cylinder was compressed 25 times which was not

enough to form a strong bond.

4. Did asphalt cylinder fails? If not, then why do you think it was successfully

compacted and formed?

Because the cylinder was compacted 75 times on each sides which make it strong.

1. What is the stability of first batch of asphalt?

First batch was not stable.

2. What is the stability of second batch of asphalt?

The deflection was 1026 inch and 9650 lb-force.

3. What do you think made difference between two batches of asphalt?

The number of times compacted made all the difference.

4. What recommendations do you have for compacting ready-made cold

asphalt?

The more times compacted the stronger the asphalt will be.

CONCLUSION

Compaction method has major effect on the strength of asphalt. A good

quality asphalt may not have good strength if is not well compacted. In our

experiment our first asphalt sample was compacted 25 times and it could

gain strong bond. As we increased the number of compaction up to 75 time

it becomes stronger.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Weighted Histogram Analysis Method (WHAM) : Michael AndrecDokument14 SeitenThe Weighted Histogram Analysis Method (WHAM) : Michael AndrecWilliam AgudeloNoch keine Bewertungen

- CHEC001231-Bridge Bearing and Expansion JointsDokument78 SeitenCHEC001231-Bridge Bearing and Expansion JointsRaymond Payne100% (1)

- How Much Time To EngineerDokument3 SeitenHow Much Time To EngineerAsad NawazNoch keine Bewertungen

- Multimeter Project PlanDokument3 SeitenMultimeter Project PlanAsad NawazNoch keine Bewertungen

- Parts of TrussDokument1 SeiteParts of TrussAsad NawazNoch keine Bewertungen

- TestsDokument1 SeiteTestsAsad NawazNoch keine Bewertungen

- SheetDokument1 SeiteSheetAsad NawazNoch keine Bewertungen

- Course Completion Form MSCDokument1 SeiteCourse Completion Form MSCشاہد یونسNoch keine Bewertungen

- 6 Types of EngineersDokument5 Seiten6 Types of EngineersAsad NawazNoch keine Bewertungen

- Engineering Purpose For StudyDokument2 SeitenEngineering Purpose For StudyAsad NawazNoch keine Bewertungen

- Best Engineering Courses in IndiaDokument3 SeitenBest Engineering Courses in IndiaAsad NawazNoch keine Bewertungen

- Building Materials 5-8Dokument17 SeitenBuilding Materials 5-8Asad NawazNoch keine Bewertungen

- Firms To RegistrerdDokument11 SeitenFirms To RegistrerdAsad NawazNoch keine Bewertungen

- Multimeter Project PlanDokument3 SeitenMultimeter Project PlanAsad NawazNoch keine Bewertungen

- Firms To RegistrerdDokument11 SeitenFirms To RegistrerdAsad NawazNoch keine Bewertungen

- Engineering Ethics and Technical NotesDokument11 SeitenEngineering Ethics and Technical NotesAsad NawazNoch keine Bewertungen

- Traits Needed for Success as a Civil EngineerDokument1 SeiteTraits Needed for Success as a Civil EngineerAsad NawazNoch keine Bewertungen

- Traits Needed for Success as a Civil EngineerDokument1 SeiteTraits Needed for Success as a Civil EngineerAsad NawazNoch keine Bewertungen

- Traits Needed for Success as a Civil EngineerDokument1 SeiteTraits Needed for Success as a Civil EngineerAsad NawazNoch keine Bewertungen

- NameDokument1 SeiteNameIrfan SiswantoNoch keine Bewertungen

- Traits Needed for Success as a Civil EngineerDokument1 SeiteTraits Needed for Success as a Civil EngineerAsad NawazNoch keine Bewertungen

- Traits Needed for Success as a Civil EngineerDokument1 SeiteTraits Needed for Success as a Civil EngineerAsad NawazNoch keine Bewertungen

- Traits Needed for Success as a Civil EngineerDokument1 SeiteTraits Needed for Success as a Civil EngineerAsad NawazNoch keine Bewertungen

- NameDokument1 SeiteNameIrfan SiswantoNoch keine Bewertungen

- PrintDokument9 SeitenPrintAsad NawazNoch keine Bewertungen

- CoalDokument1 SeiteCoalAsad NawazNoch keine Bewertungen

- SimpleDokument1 SeiteSimpleAsad NawazNoch keine Bewertungen

- ActivationDokument1 SeiteActivationAsad NawazNoch keine Bewertungen

- SulfateDokument1 SeiteSulfateAsad NawazNoch keine Bewertungen

- The New Seven Wonders of The World: 1.taj MahalDokument5 SeitenThe New Seven Wonders of The World: 1.taj MahalJulieth AlvarezNoch keine Bewertungen

- One Way Slab - NptelDokument25 SeitenOne Way Slab - Npteljindal_bharatNoch keine Bewertungen

- A First Course in Linear Algebra PDFDokument424 SeitenA First Course in Linear Algebra PDFShelvin Naidu100% (1)

- TFA 1 2 3 4 5 6 7 8 9 10 in Nozzles Sizes: OptionDokument1 SeiteTFA 1 2 3 4 5 6 7 8 9 10 in Nozzles Sizes: OptionrajkumarfNoch keine Bewertungen

- Inverse Time Characteristics RelaysDokument1 SeiteInverse Time Characteristics Relayssuperthambi100% (1)

- JEE Class Companion Physics: Module-9Dokument227 SeitenJEE Class Companion Physics: Module-9RupakNoch keine Bewertungen

- Ewald SphereDokument57 SeitenEwald SphereMohammad Rameez0% (1)

- The Mystery of Relationship Charts RevealedDokument5 SeitenThe Mystery of Relationship Charts RevealedPhalgun Balaaji0% (1)

- Control System (136-248) PDFDokument113 SeitenControl System (136-248) PDFmuruganNoch keine Bewertungen

- Amateur's Telescope Was First Published in 1920. However, Unlike Ellison's TimeDokument4 SeitenAmateur's Telescope Was First Published in 1920. However, Unlike Ellison's Timemohamadazaresh0% (1)

- Make a castable lab test mixDokument16 SeitenMake a castable lab test mixthaituan237Noch keine Bewertungen

- Aditya and VarahaDokument7 SeitenAditya and VarahaVibhats VibhorNoch keine Bewertungen

- Marking Scheme Physics Trial SPM SBP 2016 Paper 3Dokument6 SeitenMarking Scheme Physics Trial SPM SBP 2016 Paper 3Anonymous UypCttWNoch keine Bewertungen

- Field-Weakening Control Algorithm For Interior Permanent Magnet Synchronous Motor Based On Space-Vector Modulation TechniqueDokument9 SeitenField-Weakening Control Algorithm For Interior Permanent Magnet Synchronous Motor Based On Space-Vector Modulation TechniqueArpan GayenNoch keine Bewertungen

- Internal Resistance and Combinations of CellsDokument10 SeitenInternal Resistance and Combinations of CellsSukoon Sarin67% (3)

- Bhavans Public School, Doha - Qatar: Model Question Paper 2016-17 MathematicsDokument4 SeitenBhavans Public School, Doha - Qatar: Model Question Paper 2016-17 MathematicsSanthosh KrishnanNoch keine Bewertungen

- Chapter 1 - Introduction To Differential EquationsDokument16 SeitenChapter 1 - Introduction To Differential EquationsnawidwardakNoch keine Bewertungen

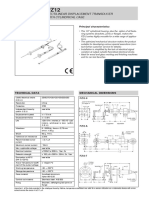

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDokument2 SeitenRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926Noch keine Bewertungen

- MIT2 080JF13 Lecture2 PDFDokument26 SeitenMIT2 080JF13 Lecture2 PDFAbhilashJanaNoch keine Bewertungen

- Teknik Menjawab KIMIA 2011Dokument73 SeitenTeknik Menjawab KIMIA 2011Nur HakimNoch keine Bewertungen

- Partition Coefficients and Their UsesDokument92 SeitenPartition Coefficients and Their UsesquelenigNoch keine Bewertungen

- KIT-DISSOLVED OXYGEN CHEMets® Refills, ULR CHEMets®-KITDokument2 SeitenKIT-DISSOLVED OXYGEN CHEMets® Refills, ULR CHEMets®-KITSorinNoch keine Bewertungen

- Centrifugal CastingDokument266 SeitenCentrifugal Castinguzairmetallurgist100% (2)

- Three-Dimensional Effects For Supported Excavations in ClayDokument7 SeitenThree-Dimensional Effects For Supported Excavations in ClayrkNoch keine Bewertungen

- ROCKYDokument4 SeitenROCKYNelson Alexander Aponte SimbronNoch keine Bewertungen

- A Simple Lamina Flow Engine PDFDokument2 SeitenA Simple Lamina Flow Engine PDFSelva KumarNoch keine Bewertungen

- MIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma ComplexesDokument7 SeitenMIT OCW Principles of Inorganic Chemistry II Lecture on Octahedral ML6 Sigma Complexessanskarid94Noch keine Bewertungen

- A2 Chapter 14 OscillationDokument61 SeitenA2 Chapter 14 OscillationkwaikunNoch keine Bewertungen

- Worksheet: ProofsDokument3 SeitenWorksheet: ProofsPCHANFANNoch keine Bewertungen