Beruflich Dokumente

Kultur Dokumente

Sistema Electrico TR-Elec - Axera5

Hochgeladen von

RimbertOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Sistema Electrico TR-Elec - Axera5

Hochgeladen von

RimbertCopyright:

Verfügbare Formate

TRAINING MANUAL

TECHNICAL TRAINING MANUAL

ELECTRICAL DIAGRAM

AXERA 5

660 240V

550 230V

500 220V

CABLE 440 Id 30mA

REEL 0

1 380

Q100

F320

0

380

L1

L2

L3

440 1

500

1

1

0

0

550 380V

600

3 F230 F240

24 V P.S.R.

KM2 KM1 KM3 K230 K240

U1 V1 W1 U1 V1 W1 U1 V1 W1

M1 M3 M4

3 3 3

U2 V2 W2 Comp.

F452.1

F452.2

F454.2

F450

F451

K471

ac

battery charger

dc

K425 A0

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

2 ( 36 )

TRAINING MANUAL

1 GENERAL SYMBOLS 4

1/1 BREAKER 4

1/2 CONTACTORS, RELAYS 4

1/3 OVERLOAD 4

1/4 STAR/DELTA STARTER 5

1/5 PHASE CONTROL RELAY 6

1/6 TRANSFORMER 7

1/7 RECTIFIER 7

1/8 BUTTON, SWITCHES AND COIL 8

1/9 TIME DELAY RELAY 9

1/10 SPECIAL CONTACTS 9

1/11 SWITCHES, COILS 10

1/12 SENSOR 10

2 POWER SELECTION 12

2/1 NEUTRAL 12

2/2 MAIN POWER 14

2/3 DIESEL MODE 16

3 DIESEL CIRCUIT 18

3/1 SAFETY POSITION 19

3/2 DIESEL READY 20

3/3 STARTING 21

3/4 DIESEL RUNNING 22

3/5 TRAMMING ENGAGED 23

4 DRILLING 24

4/1 POWER ON 26

4/2 STARTING STEP 1 28

4/3 STARTING STEP 2 29

4/4 STAR MODE 30

4/5 DELTA MODE 31

4/6 DRILLING 32

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 3 ( 36 )

TRAINING MANUAL

5 COMPONENT LOCATION 34

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

4 ( 36 )

TRAINING MANUAL

GENERAL SYMBOLS

MODULE 1) GENERAL SYMBOLS

1.1 BREAKER

Main Switch: its name starts by letter Q

Q100 Example: Q100

BREAKERS :

Those breakers can include:

Overload - overload-tripping device, set to the amps consumed by the

receptor (motor, transformer, lights .....) named Ir

1 0 - magnetic tripping device, in the event of a short circuit named

F100 Irm

The setting of each breaker is indicated on the electric diagram

magnetic

according to Voltage and the type of receptor.

Overload

Basic low for setting:

- overload ---> Amps stamp on the motor plate. NOTE: some

motors are suitable for several voltage and frequencies that

could increase the setting by 10% of the nominal Amps.

- magnetic ---> 13 to 15 time the nominal Amps, according to

the type of receptor.

1.2 CONTACTORS, RELAYS

Name starts by letter K

The contactor beside includes , 3 large Amp contacts and two

low Amp.

KM Some contactors could include overload protection.

1.3 OVERLOAD

Name starts by letter F.

1 3 5 This device controls maximum Amps directed to the motor or

the circuit they are protecting.

KM

2 4 6

1 3 5

F1

2 4 6

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 5 ( 36 )

TRAINING MANUAL

GENERAL SYMBOLS

1.4 STAR/DELTA STARTER

Purpose of star delta starter

AMPERE CONSUMPTION

The curves in the diagram show the Ampere

consumption and the torque available when starting of

DELTA an electric motor from 0 to the normal RPM running

speed.

NOTE: in delta starting configuration The Amp.

STAR consumption can reach up to 6 time the nominal

DELTA running Amps stamp on the motor plate.

Example: a 60 A electric motor will need 360 A when

0 maximum starting.

SPEED

This high Amp consumption will result in a large drop

TORQUE AVAILABLE in voltage.

SPEED

As the torque available is reduced while running in

star mode, all electric motors should not be loaded

when starting.

This picture shows the resistances when they are

connected: top, in STAR mode; bottom, in DELTA

mode.

STAR

Connecting box

At the right end side, the drawing shows the way the

SYMBOL

copper plates are used to achieve both modes in the

electric motor connecting box.

DELTA

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

6 ( 36 )

TRAINING MANUAL

GENERAL SYMBOLS

KM1: directs the 3 phases to the motor

KMY1: together with KM1 ---> STAR position

KMD1: together with KM1 ---> DELTA position.

KM2 KM1 KM3

NOTE: Due to the physical location of the overload

U1 V1 W1 relay, THE SETTING OF THE OVERLOAD RELAY

SHOULD BE:THE NOMINAL AMPS (stamp on the

M1

motor plate) DIVIDE BY THE SQUARE ROOT

3

OF3

U2 V2 W2 SETTING = ( Ir ) ( 3 )

1.5 PHASE CONTROL RELAY

380V This relay closes the contacts when the 3 phases are

correctly connected, to ensure the proper direction of

rotation for all the motors.

This relay is connected to a 380 Volt source.

3

P.S.R.

K320

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 7 ( 36 )

TRAINING MANUAL

GENERAL SYMBOLS

24V

1.6 TRANSFORMER

660

+

550 20V

Inlet power: from 380 up to 660 Volt.

300VA

500

440 0 Adjustment can be made from nominal voltage

380 - using the connecting pin plus or minus 20 Volt.

1300 VA

24V

-20 20V

1000VA

0

+20 0

This 3 phases transformer includes its rectifier

and a output controler.

3 -PH 1000 VA 24 V

380/440/500/550/660 V 42 A +

1.7 RECTIFIER

The rectifier combines a diode bridge and a

capacitor.

Note the location of the wire connected to the

ground.

Note: diode starts by letter V.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

8 ( 36 )

TRAINING MANUAL

GENERAL SYMBOLS

1.8 BUTTON, SWITCHES AND COIL

S11: Contact Key Switch used on diesel diagram.

0 1 15

S11 pin Nb

30

12

Wire Nb

X2 6

connecting

terminal x2

R3 pin 6

KA0

R4

S12: 3 positions switch, used to control pre-heat and the

diesel starter.

15

Position one: glow plugs are energized (pin 19)

Position two: glow plugs and starter energized

S12

50a 17 19

For each switch, the pin Nb is indicated on the diagram.

1 2 3

S9: Push button

S9 Contact symbols:

contact 1&3: low Amps normally open

contact 2: low Amps normally closed

S1: Emergency stop button

S1 F1

Note the symbol of the locking device

locking device indexing F1: contact of an overload relay.

Note: the contact stays in position due to the index device, it

should be reset.

27

27: end of travel switch.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 9 ( 36 )

TRAINING MANUAL

GENERAL SYMBOLS

1.9 TIME DELAY RELAY

There are two types of timed relay.

ON DELAY (timed to work): when the coil is energized, the

contacts shift after that the delay is exhausted.

Note the special symbol of the coil. To make the diagram as

simple as possible a standard symbol of the coil is used.

OFF RELAY (timed to neutral): When the coil is energized,

the contacts shift immediately. When the coil is no longer

energized, the contacts move back to neutral when the

delay is exhausted.

1.10 SPECIAL CONTACTS

To prevent lost in power at the outlet of the relay KAO, we install

special contacts 75/76 and 87/88. The symbol is not the standard one.

KAO just engaged:

the basic contacts shift: R1/R2, 61/62 and 53/54

the linked contact 87/88 shifts immediately

After a delay less than 0.2 second :

The linked contact 75/76 shifts to open position.

Those two linked contacts ensure that power is always supplied to any

receiver.

It is normaly used when a solenoid or a coil must never lost power

when the relay is shifting.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

10 ( 36 )

TRAINING MANUAL

GENERAL SYMBOLS

1.11 SWITCHES, COILS

PRESSURE SWITCH

Name starts by letter E.

The symbol shows a pressure switch using a contact

normally open. 13 and 14 are the wiring pins.

The pressure setting is 2 bar.

TEMPERATURE SWITCH

The symbol shows a temperature switch using a

contact normally open.

The temperature which activates the switch is 120

Celsius.

RELAY or CONTACTOR COIL

Name starts by letter K

KA1 is the relay number.

A1 and A2 are the wiring pins.

SOLENOID

Name starts by letter B.

HOURMETER

Name starts by letter P.

LIQUID LEVEL SWITCH

1.12 SENSOR

G WK This symbol shows a double function block.

It includes a sensor and a contact.

P

T On Diesel there are two sensor one for the temperature the othe

monitors the oil pressure.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 11 ( 36 )

TRAINING MANUAL

GENERAL SYMBOLS

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

12 ( 36 )

TRAINING MANUAL

POWER SELECTION

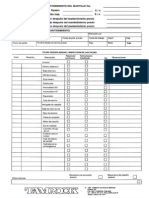

MODULE 2) POWER SELECTION

2.1 NEUTRAL

660 240V

550 230V

500 220V

CABLE 440 Id 30mA

REEL 0

1 380

Q100

F320

0

380

L1

L2

L3

440 1

500

1

0

0

550 380V

600

3 F230 F240

24 V P.S.R.

KM2 KM1 KM3 K230 K240

U1 V1 W1 U1 V1 W1 U1 V1 W1

M1 M3 M4

3 3 3

U2 V2 W2 Comp.

F452.1

F452.2

F454.2

F450

F451

K471

ac

battery charger

dc

K425 A0

IGN. KEY

10A

BATTERY

ALARM

IN 4 S

IN 3 S

IN 4 -

IN 3 -

STOP

1

50A

F454.3

30

P 0 I II III

S2 50a 15 19 17 58

S1A K78

+

K77

forward

reverse KT1

PLC Inputs

PLC Com

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 13 ( 36 )

TRAINING MANUAL

POWER SELECTION

From the cable reel main lines runs to the main switch Q100.

The 3 phases supply power to

transformers 220volt

transformer 24 volt.

all motors

Motor M1 : main power pack

Motor M3 : water booster

Motor M4 : compressor.

From the 24 Volt transformer, a 380 Volt output supplies the phase control relay.

The 24 Volt outlet includes a rectifier (6 diodes and a capacitor

A 30mA safety relay protects the outlet of the 220 Volt transformer.

24 Volt DC circuit.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

14 ( 36 )

TRAINING MANUAL

POWER SELECTION

2.2 MAIN POWER

660 240V

550 230V

500 220V

CABLE 440 Id 30mA

REEL 0

1 380

Q100

F320

0

L1

L2

L3

380

440 1

500

1

0

0

550 380V

600

3 F230 F240

24 V P.S.R.

KM2 KM1 KM3 K230 K240

U1 V1 W1 U1 V1 W1 U1 V1 W1

M1 M3 M4

3 3 3

U2 V2 W2 Comp.

F452.1

F452.2

F454.2

F450

F451

K471

ac

battery charger

dc

K425 A0

10A

2 IGN. KEY

1 BATTERY

3 ALARM

IN 4 S

IN 3 S

IN 4 -

IN 3 -

STOP

4

50A

F454.3 H617

30

P 0 I II III

S2 50a 15 19 17 58

S1A K78

+

K77

forward

reverse KT1

PLC Inputs

PLC Com

P S85 Y1

fire sup.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 15 ( 36 )

TRAINING MANUAL

POWER SELECTION

When the main power is connected to the machine, 220 Volts supplies :

the battery charger

the relay K471.

K471 energized :

disable 24 VDC to the Diesel contact key

powers the green light H617 at the control panel

allows 24Volt DC to the PLC (programmable logical control) if there is no emergency button engaged.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

16 ( 36 )

TRAINING MANUAL

POWER SELECTION

2.3 DIESEL MODE

660 240V

550 230V

500 220V

CABLE 440 Id 30mA

REEL 0

1 380

Q100

F320

0

L1

L2

L3

380

440 1

500

1

0

0

550 380V

600

3 F230 F240

24 V P.S.R.

KM2 KM1 KM3 K230 K240

U1 V1 W1 U1 V1 W1 U1 V1 W1

M1 M3 M4

3 3 3

U2 V2 W2 Comp.

F452.1

F452.2

F454.2

F450

F451

K471

ac

battery charger

dc

K425 A0

10A

1 BATTERY

2 IGN. KEY

3 ALARM

IN 4 S

IN 3 S

STOP

IN 4 -

IN 3 -

4

50A

F454.3

P 0

I II III 30

S2 50a 15 19 17 58

S1A K78

+

K77

forward

reverse KT1

PLC Inputs

PLC Com

P S85 Y1

fire sup.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 17 ( 36 )

TRAINING MANUAL

POWER SELECTION

In Diesel mode the operator should :

Rotate he batteries master switch S1A. Bottom contact grounds the circuit.

Place the contact key in position 1.

Breaker F454.3 supplies 24 VDC to the contact key.

The Diesel shut-off solenoid get 24VDC power through the following contacts :

breaker F450

contact of emergency relay K77

batteries master-switch S1A

fire suppression pressure switch S85

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

18 ( 36 )

TRAINING MANUAL

DIESEL CIRCUIT

MODULE 3) DIESEL CIRCUIT

A0

INST. LIGHT

OUT 7.5 V

OUT GND

BATTERY

IGN. KEY

ALARM

232 TxD

232 RsD

IN 4 S

IN 3 S

IN 2 S

IN 1 S

STOP

IN 4 -

IN 3 -

IN 2 -

IN 1 -

31 (-)

IN 6

IN 4

IN 2

IN 7

IN 5

IN 3

IN 1

10

15

16

22

23

11

12

13

14

17

18

19

20

21

24

25

1

2

3

4

5

6

7

8

9

OIL PRESSURE TEMP.

Fuel

G WK G WK

SP12

P T

F25 25 A

D+ B+ W

K2

15 TK 50 30

timer

G

OPTION K31T

KR1

31 H R L

FIRE

P S85 Y1

KT1

+ 30 D+ 50e

30 50

K1

31

M

+

50e

D+

S1A

50f

30

50f 31

31

Power ON

F10.2 K425

50A

forward

F454.3 0

backward Y386

0 Y385

Fast

Y176 E13

H13

P S56

H21 brakes 145b

P S57

F452 H23

F451

H18

S35

F450

30

P 0 I II III

S2 50a 15 19 17 58

K77

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 19 ( 36 )

TRAINING MANUAL

DIESEL CIRCUIT

3.1 SAFETY POSITION

ALA

BAT

STO

IN 4

IN 4

IN 3

IN 3

IN 7

IN 5

IN 3

IN 2

IN 2

IGN

INS

31 (

232

232

OU

OU

IN

IN

IN

IN

IN

IN

10

15

16

22

23

11

12

13

14

17

18

19

20

21

24

25

1

2

3

4

5

6

7

8

9

OIL PRESSURE TEMP.

Fuel

G WK G WK

SP12

P T

F25 25 A

D+ B+ W

K2

15 TK 50 30

timer

G

OPTION K31T

KR1

31 H R L

FIRE

P S85 Y1

KT1

+ 30 D+ 50e

30 50

K1

S1A

31

M

+

50e

D+

50f

30

50f 31

31

Diesel mode

F10.2 K425

50A

forward

F454.3 0

backward Y386

0 Y385

Fast

Y176 E13

H13

P S56

H21 brakes 145b

P S57

F452 H23

F451

H18

S35

F450

P 0

I II

III

30

S2 50a 15 19 17 58

K77

The diagram shows the situation when one emergency button in pushed down. Relay K77 stays in neutral position.

From its NC (normally closed) contact through the diode that powers the relay KT1.

The starter cannot be engaged.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

20 ( 36 )

TRAINING MANUAL

DIESEL CIRCUIT

3.2 DIESEL READY

A0

INST. LIGHT

OUT 7.5 V

OUT GND

BATTERY

IGN. KEY

ALARM

232 TxD

232 RsD

IN 4 S

IN 3 S

IN 2 S

IN 1 S

STOP

IN 4 -

IN 3 -

IN 2 -

IN 1 -

31 (-)

IN 6

IN 4

IN 2

IN 7

IN 5

IN 3

IN 1

10

15

16

22

23

11

12

13

14

17

18

19

20

21

24

25

1

2

3

4

5

6

7

8

9

OIL PRESSURE TEMP.

Fuel

G WK G WK

SP12

P T

F25 25 A

D+ B+ W

K2

15 TK 50 30

timer

G

OPTION K31T

KR1

31 H R L

FIRE

P S85 Y1

KT1

+ 30 D+ 50e

30 50

K1

S1A

31

M

+

50e

D+

50f

30

50f 31

31

Diesel mode

F10.2 K425

50A

forward

F454.3 0

backward Y386

0 Y385

Fast

Y176 E13

H13

P S56

H21 brakes 145b

P S57

F452 H23

F451

H18

S35

F450

P 0

I II

III

30

S2 50a 15 19 17 58

K77

The emergency button back to running position, the Diesel is ready to start. The automatic heating relay KR1

energizes the glow plug in case of cold temperature. The charge light is ON, it is grounded through the alternator.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 21 ( 36 )

TRAINING MANUAL

DIESEL CIRCUIT

3.3 STARTING

A0

INST. LIGHT

OUT 7.5 V

OUT GND

BATTERY

IGN. KEY

ALARM

232 TxD

232 RsD

IN 4 S

IN 3 S

IN 2 S

IN 1 S

STOP

IN 4 -

IN 3 -

IN 2 -

IN 1 -

31 (-)

IN 6

IN 4

IN 2

IN 7

IN 5

IN 3

IN 1

10

15

16

22

23

11

12

13

14

17

18

19

20

21

24

25

1

2

3

4

5

6

7

8

9

OIL PRESSURE TEMP.

Fuel

G WK G WK

SP12

P T

F25 25 A

D+ B+ W

K2

15 TK 50 30

timer

G

OPTION K31T

KR1

31 H R L

FIRE

P S85 Y1

KT1

+ 30 D+ 50e

30 50

K1

S1A 31

M

+

50e

D+

50f

30

50f 31

31

Diesel mode

F10.2 K425

50A

forward

F454.3 0

backward Y386

0 Y385

Fast

Y176 E13

H13

P S56

H21 brakes 145b

P S57

F452 H23

F451

H18

S35

F450

P 0

I II

III

30

S2 50a 15 19 17 58

K77

The contact-key is now in position III. From contact 50a through NC contact KT1, 24VDC runs to the special relay K1.

It includes a timer preventing using the starter for long period and it also disable the use of the starter when the Diesel

is already running.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

22 ( 36 )

TRAINING MANUAL

DIESEL CIRCUIT

3.4 DIESEL RUNNING

A0

INST. LIGHT

OUT 7.5 V

OUT GND

BATTERY

IGN. KEY

ALARM

232 TxD

232 RsD

IN 4 S

IN 3 S

IN 2 S

IN 1 S

STOP

IN 4 -

IN 3 -

IN 2 -

IN 1 -

31 (-)

IN 6

IN 4

IN 2

IN 7

IN 5

IN 3

IN 1

10

15

16

22

23

11

12

13

14

17

18

19

20

21

24

25

1

2

3

4

5

6

7

8

9

OIL PRESSURE TEMP.

Fuel

G WK G WK

SP12

P T

F25 25 A

D+ B+ W

K2

15 TK 50 30

timer

G

OPTION K31T

KR1

31 H R L

FIRE

P S85 Y1

KT1

+ 30 D+ 50e

30 50

K1

S1A

31

M

+

50e

D+

50f

30

50f 31

31

Diesel mode

F10.2 K425

50A

forward

F454.3 0

backward Y386

0 Y385

Fast

Y176 E13

H13

P S56

H21 brakes 145b

P S57

F452 H23

F451

H18

S35

F450

P 0

I II

III

30

S2 50a 15 19 17 58

K77

When Diesel starts, the alternator is running. From pin D+ the charge light get 24 VDC from both side, it turns OFF.

Same line powers as well the pin 30 of the relay K1. Its contact moves to open position, the starter is no longer

engaged. Same line powers the relay K2.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 23 ( 36 )

TRAINING MANUAL

DIESEL CIRCUIT

3.5 TRAMMING ENGAGED

A0

INST. LIGHT

OUT 7.5 V

OUT GND

BATTERY

IGN. KEY

ALARM

232 TxD

232 RsD

IN 4 S

IN 3 S

IN 2 S

IN 1 S

STOP

IN 4 -

IN 3 -

IN 2 -

IN 1 -

31 (-)

IN 6

IN 4

IN 2

IN 7

IN 5

IN 3

IN 1

10

15

16

22

23

11

12

13

14

17

18

19

20

21

24

25

1

2

3

4

5

6

7

8

9

OIL PRESSURE TEMP.

Fuel

G WK G WK

SP12

P T

F25 25 A

D+ B+ W

K2

15 TK 50 30

timer

G

OPTION K31T

KR1

31 H R L

FIRE

P S85 Y1

KT1

+ 30 D+ 50e

30 50

K1

S1A 31

M

+

50e

D+

50f

30

50f 31

31

Diesel mode

F10.2 K425

50A

forward

F454.3 0

backward Y386

0 Y385

Fast

Y176 E13

H13

P S56

H21 brakes 145b

P S57

F452 H23

F451

H18

S35

F450

P 0

I II

III

30

S2 50a 15 19 17 58

K77

Relay K2 activated grounds all tramming direction solenoids and light.

In reverse as shown here, reverse solenoid Y385 warning light E13 and buzzer H13 are all powered.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

24 ( 36 )

TRAINING MANUAL

DRILLING

MODULE 4) DRILLING

660 240V K471

550 230V

500 220V

Id 30mA

440

K78

380

F450 H614

K77

F454.2

PLC com H603

KM2

K320 Phase control

P S428

15b

water ON

S520

by-pass press switch.

P S422 P S421 S420 F230

2b 2b

230 = water F240

water

level

240 = compressor

air

K230

K240 S424 S180

T P H611

T S441 30

compres. oil filter HP

115 H610

75

S505 H606

P. Switches reset

H605

S502 H619

Compres. On - Manual H618

P400

H

H604

S501

Water On - Manual

SOURCE

L1 L2/N COM0 01 03 05 07 09 11 01 03 05

100-240VAC 50/60Hz 60VA NC 00 02 04 06 08 10 00 02 04

0CH 1CH IN : 24VDC 5mA / 12mA

0CH

IN 00 01 02 03 04 05 06 07 08 09 10 11

1CH

00 01 02 03 04 05

10CH OMRON

OUT 00 01 02 03 04 05 06 07

11CH CPM1A-30CDR-A-V1

00 01 02 03 PROGRAMMABLE CONTROLLER

PWR LOT n 25X4N Batch N xxxxxxxxx

OMRON MANUFACTURING IN THE NETHERLANDS

RUN MADE IN THE NETHERLAND

ERR ALM LISTED

95M8

IND. CONT EQ

COMM N< .APP<97A107>

OUT : 24VDC (RES) / 250V AC(GEN)

10CH 11CH 2A max /P,4A max/C,16A max/U

24VDC 0.3A OUTPUT + 00 01 02 04 05 07 00 02 NC NC

COM0 COM1 COM2 03 COM3 06 COM4 01 03 NC NC

24VDC

compressor K240

H601 water- low pressure water K230

SH520 blinking 220 VAC - IN

H609 air - low pressure

S578 main relay K424

H602 OIL LEVEL continuous = oil low level

blinking = oiler low level

K445

thermistor

K112 KM2

H612

main motor overload

delta KM1

F100

K101

H613

P S190 star Y KM3

P100 percussion

H

24VDC

joystick magnets

F451.1

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 25 ( 36 )

TRAINING MANUAL

DRILLING

Diagram in neutral position.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

26 ( 36 )

TRAINING MANUAL

DRILLING

4.1 POWER ON

660 240V K471

550 230V

500 220V

Id 30mA

440

K78

380

F450 H614

K77

F454.2

PLC com H603

KM2

K320 Phase control

P S428

15b

water ON

S520

by-pass press switch.

P S422 P S421 S420 F230

2b 2b

230 = water F240

water

level

240 = compressor

air

K230

K240 S424 S180

T P H611

T S441 30

compres. oil filter HP

115 H610

75

S505 H606

P. Switches reset

H605

S502 H619

Compres. On - Manual H618

P400

H

S501 H604

Water On - Manual

SOURCE

L1 L2/N COM0 01 03 05 07 09 11 01 03 05

100-240VAC 50/60Hz 60VA NC 00 02 04 06 08 10 00 02 04

0CH 1CH IN : 24VDC 5mA / 12mA

0CH

IN 00 01 02 03 04 05 06 07 08 09 10 11

1CH

00 01 02 03 04 05

10CH OMRON

OUT 00 01 02 03 04 05 06 07

11CH CPM1A-30CDR-A-V1

00 01 02 03 PROGRAMMABLE CONTROLLER

PWR LOT n 25X4N Batch N xxxxxxxxx

OMRON MANUFACTURING IN THE NETHERLANDS

RUN MADE IN THE NETHERLAND

ERR ALM LISTED

95M8

IND. CONT EQ

COMM N< .APP<97A107>

OUT : 24VDC (RES) / 250V AC(GEN)

10CH 11CH 2A max /P,4A max/C,16A max/U

24VDC 0.3A OUTPUT + 00 01 02 04 05 07 00 02 NC NC

COM0 COM1 COM2 03 COM3 06 COM4 01 03 NC NC

24VDC

compressor K240

H601 water- low pressure water K230

SH520 blinking 220 VAC - IN

H609 air - low pressure

S578 main relay K424

H602 OIL LEVEL continuous = oil low level

blinking = oiler low level

K445

thermistor

K112 KM2

H612

main motor overload

delta KM1

F100

K101

H613

P S190 star Y KM3

P100 percussion

H

24VDC

joystick magnets

F451.1

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 27 ( 36 )

TRAINING MANUAL

DRILLING

Machine is powered.

All emergency button are in running position.

Due to the relay K77, 24VCD powers the all COM pins of the PLC.

At a first step, if all phases are correctly set, the contact of phase control relay K320 shifts as shown.

The red light H603 turns OFF.

24VDC runs to the inlet pin 10 of the PLC through : the compressor oil temperature S441, the overload F230

(water pump) and the overload F240 (compressor).

a correct level in the drilling reservoir closes the level switch S420, that powers the inlet pin 02.

NOTE : a 3s timer allows some delay on oil level caution device prior to stop all powerpacks.

hydraulic oil at temperature below 75C

All of the above correct, the PLC powers the caution relay K424.

When one of the overload on water pump or compressor has been activated, it should be reset to neutral manually.

if water pump and compressor switches S501 & S502 are both in automatic mode (position 1) PLC pins 03 and

pin 04 are powered.

WARNING AND CAUTION PANEL

H613 H613 H613 H618 H619 H620

H612 H612 H612 H605 H606 H615

H611 H611 H611 H609 H601 H604

H602 H610 H614 H621 H617 H622

H608 H607 H603 H616 H623 H624

RUNNING CLOGGED CAUTION

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

28 ( 36 )

TRAINING MANUAL

DRILLING

4.2 STARTING STEP 1 te

115 H610

75

S505 H606

P. Switches reset

H605

S502 H619

Compres. On - Manual H618

P400

H

S501 H604

Water On - Manual

SOURCE

L1 L2/N COM0 01 03 05 07 09 11 01 03 05

100-240VAC 50/60Hz 60VA NC 00 02 04 06 08 10 00 02 04

0CH 1CH IN : 24VDC 5mA / 12mA

0CH

IN 00 01 02 03 04 05 06 07 08 09 10 11

1CH

00 01 02 03 04 05

10CH OMRON

OUT 00 01 02 03 04 05 06 07

11CH CPM1A-30CDR-A-V1

00 01 02 03 PROGRAMMABLE CONTROLLER

PWR LOT n 25X4N Batch N xxxxxxxxx

OMRON MANUFACTURING IN THE NETHERLANDS

RUN MADE IN THE NETHERLAND

ERR ALM LISTED

95M8

IND. CONT EQ

COMM N< .APP<97A107>

OUT : 24VDC (RES) / 250V AC(GEN)

10CH 11CH 2A max /P,4A max/C,16A max/U

24VDC 0.3A OUTPUT + 00 01 02 04 05 07 00 02 NC NC

COM0 COM1 COM2 03 COM3 06 COM4 01 03 NC NC

24VDC

compressor K240

H601 water- low pressure water K230

SH520 blinking 220 VAC - IN

H609 air - low pressure

S578

main relay K424

H602 OIL LEVEL continuous = oil low level

blinking = oiler low level

K445

thermistor

K112 KM2

H612

main motor overload

delta KM1

F100

K101

H613

P S190 star Y KM3

P100 percussion

H

24VDC

joystick magnets

F451.1

Main caution relay K424 is powered.

220 VAC powers :

inlet pin COM4.

normally open contact K101.

The operator rotates the switch S578 to middle position.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 29 ( 36 )

TRAINING MANUAL

DRILLING

4.3 STARTING STEP 2

75

S505 H606

P. Switches reset

H605

S502 H619

Compres. On - Manual H618

P400

H

S501 H604

Water On - Manual

SOURCE

L1 L2/N COM0 01 03 05 07 09 11 01 03 05

100-240VAC 50/60Hz 60VA NC 00 02 04 06 08 10 00 02 04

0CH 1CH IN : 24VDC 5mA / 12mA

0CH

IN 00 01 02 03 04 05 06 07 08 09 10 11

1CH

00 01 02 03 04 05

10CH OMRON

OUT 00 01 02 03 04 05 06 07

11CH CPM1A-30CDR-A-V1

00 01 02 03 PROGRAMMABLE CONTROLLER

PWR LOT n 25X4N Batch N xxxxxxxxx

OMRON MANUFACTURING IN THE NETHERLANDS

RUN MADE IN THE NETHERLAND

ERR ALM LISTED

95M8

IND. CONT EQ

COMM N< .APP<97A107>

OUT : 24VDC (RES) / 250V AC(GEN)

10CH 11CH 2A max /P,4A max/C,16A max/U

24VDC 0.3A OUTPUT + 00 01 02 04 05 07 00 02 NC NC

COM0 COM1 COM2 03 COM3 06 COM4 01 03 NC NC

24VDC

compressor K240

H601 water- low pressure water K230

SH520 blinking 220 VAC - IN

H609 air - low pressure

S578

main relay K424

H602 OIL LEVEL continuous = oil low level

blinking = oiler low level

K445

thermistor

K112 KM2

H612

main motor overload

delta KM1

F100

K101

H613

P S190 star Y KM3

P100 percussion

H

24VDC

joystick magnets

F451.1

The operator gives a pulse with the switch S578 in position run.

relay K101 get power

220VAC runs to the main motor control circuit. As a first step contactor KM3 is energized.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

30 ( 36 )

TRAINING MANUAL

DRILLING

4.4 STAR MODE te

115 H610

75

S505 H606

P. Switches reset

H605

S502 H619

Compres. On - Manual H618

P400

H

S501 H604

Water On - Manual

SOURCE

L1 L2/N COM0 01 03 05 07 09 11 01 03 05

100-240VAC 50/60Hz 60VA NC 00 02 04 06 08 10 00 02 04

0CH 1CH IN : 24VDC 5mA / 12mA

0CH

IN 00 01 02 03 04 05 06 07 08 09 10 11

1CH

00 01 02 03 04 05

10CH OMRON

OUT 00 01 02 03 04 05 06 07

11CH CPM1A-30CDR-A-V1

00 01 02 03 PROGRAMMABLE CONTROLLER

PWR LOT n 25X4N Batch N xxxxxxxxx

OMRON MANUFACTURING IN THE NETHERLANDS

RUN MADE IN THE NETHERLAND

ERR ALM LISTED

95M8

IND. CONT EQ

COMM N< .APP<97A107>

OUT : 24VDC (RES) / 250V AC(GEN)

10CH 11CH 2A max /P,4A max/C,16A max/U

24VDC 0.3A OUTPUT + 00 01 02 04 05 07 00 02 NC NC

COM0 COM1 COM2 03 COM3 06 COM4 01 03 NC NC

24VDC

compressor K240

H601 water- low pressure water K230

SH520 blinking 220 VAC - IN

H609 air - low pressure

S578

main relay K424

H602 OIL LEVEL continuous = oil low level

blinking = oiler low level

K445

thermistor

K112 KM2

H612

main motor overload

delta KM1

F100

K101

H613

P S190 star Y KM3

P100 percussion

H

24VDC

joystick magnets

F451.1

The operator releases the starting switch S578. It returns to middle position.

K101 stays powered by its own contact.

Main motor control, 220VAC circuit :

When KM3 closes its NO contact closes, that powers KM2. The main motor start running in STAR mode.

Timers start running.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 31 ( 36 )

TRAINING MANUAL

DRILLING

4.5 DELTA MODE

compres. oil filter HP

115 H610

75

S505 H606

P. Switches reset

H605

S502 H619

Compres. On - Manual H618

P400

H

S501 H604

Water On - Manual

SOURCE

L1 L2/N COM0 01 03 05 07 09 11 01 03 05

100-240VAC 50/60Hz 60VA NC 00 02 04 06 08 10 00 02 04

0CH 1CH IN : 24VDC 5mA / 12mA

0CH

IN 00 01 02 03 04 05 06 07 08 09 10 11

1CH

00 01 02 03 04 05

10CH OMRON

OUT 00 01 02 03 04 05 06 07

11CH CPM1A-30CDR-A-V1

00 01 02 03 PROGRAMMABLE CONTROLLER

PWR LOT n 25X4N Batch N xxxxxxxxx

OMRON MANUFACTURING IN THE NETHERLANDS

RUN MADE IN THE NETHERLAND

ERR ALM LISTED

95M8

IND. CONT EQ

COMM N< .APP<97A107>

OUT : 24VDC (RES) / 250V AC(GEN)

10CH 11CH 2A max /P,4A max/C,16A max/U

24VDC 0.3A OUTPUT + 00 01 02 04 05 07 00 02 NC NC

COM0 COM1 COM2 03 COM3 06 COM4 01 03 NC NC

24VDC

compressor K240

H601 water- low pressure water K230

SH520 blinking 220 VAC - IN

H609 air - low pressure

S578

main relay K424

H602 OIL LEVEL continuous = oil low level

blinking = oiler low level

K445

thermistor

K112 KM2

H612

main motor overload

delta KM1

F100

K101

H613

P S190 star Y KM3

P100 percussion

H

24VDC

joystick magnets

F451.1

KM2 timer delay expires. Both contacts shift.

KM3 returns to neutral, KM1 is now powered. Motor runs now in DELTA mode.

If the compressor control switch is in automatic position , the compressor starts due to relay K240.

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

32 ( 36 )

TRAINING MANUAL

DRILLING

4.6 DRILLING

660 240V K471

550 230V

500 220V

Id 30mA

440

K78

380

F450 H614

K77

F454.2

PLC com H603

KM2

K320 Phase control

P S428

15b

water ON

S520

by-pass press switch.

P S422 P S421 S420 F230

2b 2b

230 = water F240

water

level

240 = compressor

air

K230

K240 S424 S180

T P H611

T S441 30

compres. oil filter HP

115 H610

75

S505 H606

P. Switches reset

H605

S502 H619

Compres. On - Manual H618

P400

H

S501 H604

Water On - Manual

SOURCE

L1 L2/N COM0 01 03 05 07 09 11 01 03 05

100-240VAC 50/60Hz 60VA NC 00 02 04 06 08 10 00 02 04

0CH 1CH IN : 24VDC 5mA / 12mA

0CH

IN 00 01 02 03 04 05 06 07 08 09 10 11

1CH

00 01 02 03 04 05

10CH OMRON

OUT 00 01 02 03 04 05 06 07

11CH CPM1A-30CDR-A-V1

00 01 02 03 PROGRAMMABLE CONTROLLER

PWR LOT n 25X4N Batch N xxxxxxxxx

OMRON MANUFACTURING IN THE NETHERLANDS

RUN MADE IN THE NETHERLAND

ERR ALM LISTED

95M8

IND. CONT EQ

COMM N< .APP<97A107>

OUT : 24VDC (RES) / 250V AC(GEN)

10CH 11CH 2A max /P,4A max/C,16A max/U

24VDC 0.3A OUTPUT + 00 01 02 04 05 07 00 02 NC NC

COM0 COM1 COM2 03 COM3 06 COM4 01 03 NC NC

24VDC

compressor K240

H601 water- low pressure water K230

SH520 blinking 220 VAC - IN

H609 air - low pressure

S578

main relay K424

H602 OIL LEVEL continuous = oil low level

blinking = oiler low level

K445

thermistor

K112 KM2

H612

main motor overload

delta KM1

F100

K101

H613

P S190 star Y KM3

P100 percussion

H

24VDC

joystick magnets

F451.1

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 33 ( 36 )

TRAINING MANUAL

DRILLING

Water inlet hose is connected to the mine line.

If the pressure is higher than 2.5 bar the pressure switch S422 closes. That powers the PLC inlet pin 00.

Compressor is running, in correct situation air pressure higher than 2.5 bar closes the pressure switch S421 that

powers the inlet pin 01.

When the operator engage the water flushing, hydraulic pilot pressure operates the pressure switch S428. It powers

the PLC inlet 1CH pin 04. The water pump will start running.

CAUTIONS :

H613 H613 H613 H618 H619 H620

H612 H612 H612 H605 H606 H615

H601 : Low water inlet. If below

2.5 for longer than 4 seconds,

joystick magnet are turned OFF,

water pump stops.

H611 H611 H611 H609 H601 H604

Reset the function by pushing

button S505, re-start the pump

H602 H610 H614 H621 H617 H622 manually after faulty has been

engaged.

H608 H607 H603 H616 H623 H624

H609 : low air pressure, if pres-

sure stay below 2.5 bar for

longer than 10 seconds, joystick

RUNNING CLOGGED CAUTION magnet are turned OFF, com-

pressor stops.

SOURCE

L1 L2/N COM0 01 03 05 07 09

10

11 01 03 05 Reset the function by pushing

100-240VAC 50/60Hz 60VA NC 00 02 04 06 08 00 02 04

0CH 1CH IN : 24VDC 5mA / 12mA button S505, re-start the com-

pressor manually.

0CH

IN 00 01 02 03 04 05 06 07 08 09 10 11

1CH

10CH

00 01 02 03 04 05

OMRON

Timer adjustment :

OUT

11CH

00

00

01

01

02

02

03

03

04 05 06 07

CPM1A-30CDR-A-V1

PROGRAMMABLE CONTROLLER

: water timer

: air timer

PWR LOT n 25X4N Batch N xxxxxxxxx

OMRON MANUFACTURING IN THE NETHERLANDS

RUN MADE IN THE NETHERLAND

ERR ALM LISTED

95M8

IND. CONT EQ

COMM N< .APP<97A107>

OUT : 24VDC (RES) / 250V AC(GEN)

10CH 11CH 2A max /P,4A max/C,16A max/U

24VDC 0.3A OUTPUT + 00 01 02 04 05 07 00 02 NC NC

COM0 COM1 COM2 03 COM3 06 COM4 01 03 NC NC

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

34 ( 36 )

TRAINING MANUAL

COMPONENT LOCATION

MODULE 5) COMPONENT LOCATION

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S 35 ( 36 )

TRAINING MANUAL

COMPONENT LOCATION

Main panel

Top relays

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

TR_ELECTRIC-AXERA5-- EN 01 2006 F S

36 ( 36 )

TRAINING MANUAL

COMPONENT LOCATION

K101 X111 K77 F230 F310

K424

K112 K445 K78 K471 K471 F320

SH.520 K240 K401

A100

K230 K400

Q100

A420

T310

F100

KM1 KM3

KM2

SANDVIK TAMROCK SECOMA S.A.

19 avenue De Lattre-de-Tassigny - ZI

B.P. 46 - 69881 MEYZIEU Cedex

Tel : (33) 472 45 22 00 Fax : (33) 478 31 79 80

Das könnte Ihnen auch gefallen

- Delkom Grup: K DrifterDokument11 SeitenDelkom Grup: K Drifteronur tezmanNoch keine Bewertungen

- Everdigm Ecd40-Ecd40e Yedek ParçaDokument610 SeitenEverdigm Ecd40-Ecd40e Yedek Parçaonur tezman100% (1)

- 900-DS Electrical Systems (Engine Starting Circuit) - 1Dokument14 Seiten900-DS Electrical Systems (Engine Starting Circuit) - 1THONY100% (1)

- SLU 1/2/3 Operation and Maintenance: B 63250 - 8 en 1102 / JAS 1Dokument11 SeitenSLU 1/2/3 Operation and Maintenance: B 63250 - 8 en 1102 / JAS 1Gabo Luna MorenoNoch keine Bewertungen

- SLU 1 Shank Lubricator PDFDokument2 SeitenSLU 1 Shank Lubricator PDFMax RojasNoch keine Bewertungen

- Service Parts & Drilling ToolsDokument7 SeitenService Parts & Drilling ToolsOzan SahinNoch keine Bewertungen

- DiagramsDokument54 SeitenDiagramsHaianh ChauNoch keine Bewertungen

- dx-800 TechDokument3 Seitendx-800 TechUgurNoch keine Bewertungen

- Electrical Systems: HCR1200-EDIIDokument28 SeitenElectrical Systems: HCR1200-EDIIErmias100% (4)

- Dust CollectorDokument23 SeitenDust CollectorIgnacio Alejandro Jose Helo VarelaNoch keine Bewertungen

- Control PanelDokument40 SeitenControl PanelHaianh ChauNoch keine Bewertungen

- S03 Pressure Accumulator For HydraulicDokument18 SeitenS03 Pressure Accumulator For HydraulicjoseNoch keine Bewertungen

- 8991 3546 00 L2C Diagrams & DrawingsDokument213 Seiten8991 3546 00 L2C Diagrams & Drawingshaimay118100% (2)

- 9840 0422 92 Electrical DiagramDokument15 Seiten9840 0422 92 Electrical DiagramAldo Quiroga100% (2)

- 8997 6217 00 Diagrams and Drawings MT6020MKII PDFDokument127 Seiten8997 6217 00 Diagrams and Drawings MT6020MKII PDFFrancisco Rojas100% (1)

- Hydraulic Rock Drill HL 800 T Lifting Instructions: Incorrect CorrectDokument88 SeitenHydraulic Rock Drill HL 800 T Lifting Instructions: Incorrect Correctcristian100% (2)

- Perforadora Montabert HC-108 PDFDokument24 SeitenPerforadora Montabert HC-108 PDFRepmin SpaNoch keine Bewertungen

- System DescriptionDokument103 SeitenSystem Descriptionroland100% (3)

- Power Pack 760d PDFDokument524 SeitenPower Pack 760d PDFjesus manuel morales alvidrez100% (1)

- Manual de JD-1500E PDFDokument117 SeitenManual de JD-1500E PDFVladimir Vera0% (1)

- Sandvik dd320Dokument6 SeitenSandvik dd320Ozan SahinNoch keine Bewertungen

- UnitDokument16 SeitenUnitdefiunikasungti100% (2)

- S03 AccumulatorDokument12 SeitenS03 AccumulatorRaphael Ruiz RamosNoch keine Bewertungen

- Delkom Grup: KU DrifterDokument5 SeitenDelkom Grup: KU Drifteronur tezmanNoch keine Bewertungen

- S02 Rock Drill 2014Dokument14 SeitenS02 Rock Drill 2014Miguel Angel RicapaNoch keine Bewertungen

- Pneumatic ComponentsDokument30 SeitenPneumatic ComponentsatertemizNoch keine Bewertungen

- Microsoft PowerPoint - ECM660 III ADokument48 SeitenMicrosoft PowerPoint - ECM660 III AJannie van Staden100% (1)

- Electric EquipmentDokument232 SeitenElectric Equipmentangel alvarezNoch keine Bewertungen

- Sandvik DX780: Surface Top Hammer DrillsDokument3 SeitenSandvik DX780: Surface Top Hammer DrillsJesusFloresRodriguez100% (1)

- Pantera Dpi Compressor and Air Circuit: Original InstructionsDokument89 SeitenPantera Dpi Compressor and Air Circuit: Original InstructionsLewis NemanangaNoch keine Bewertungen

- Rod ChangerDokument27 SeitenRod ChangerHaianh ChauNoch keine Bewertungen

- Rod Handler RH 714: Ranger, ScoutDokument20 SeitenRod Handler RH 714: Ranger, ScoutcristianNoch keine Bewertungen

- 10Dokument76 Seiten10defiunikasungti100% (1)

- 8991 4448 00 Diagrams and Drawings PDFDokument44 Seiten8991 4448 00 Diagrams and Drawings PDFROboii Favela100% (2)

- CarrierDokument49 SeitenCarrierIgnacio Alejandro Jose Helo VarelaNoch keine Bewertungen

- Rock DrillDokument72 SeitenRock Drilljosue100% (3)

- Ed150 Eng Drifter Rev002-凿岩机Dokument52 SeitenEd150 Eng Drifter Rev002-凿岩机jiaozhongxing100% (1)

- Sistema Principal: Panel de Operador APP I / O APPDokument23 SeitenSistema Principal: Panel de Operador APP I / O APPRuben Castro Quispe100% (2)

- HL1560T-80 CatalogoDokument38 SeitenHL1560T-80 CatalogoAlma100% (3)

- Control PanelDokument48 SeitenControl PanelIgnacio Alejandro Jose Helo VarelaNoch keine Bewertungen

- 05Dokument97 Seiten05defiunikasungtiNoch keine Bewertungen

- Section7 - Service Information and Maintenance ECM 585Dokument26 SeitenSection7 - Service Information and Maintenance ECM 585Michael A Fourie100% (1)

- Electrical Schematic Diagram - 1 of 5 (Engine Control) : Switch BXDokument5 SeitenElectrical Schematic Diagram - 1 of 5 (Engine Control) : Switch BXAlbeiro Rodriguez100% (1)

- Rock Drill & SluDokument59 SeitenRock Drill & SluRıfat BingülNoch keine Bewertungen

- Rock DrillDokument15 SeitenRock DrillESRANoch keine Bewertungen

- Supplement ECD45Dokument35 SeitenSupplement ECD45Aprizal AzisNoch keine Bewertungen

- 8991 4813 00 Diagrams and Drawings PDFDokument94 Seiten8991 4813 00 Diagrams and Drawings PDFphong100% (1)

- Electrical System (HCR1500-EDII, D20II)Dokument20 SeitenElectrical System (HCR1500-EDII, D20II)Wa Toke100% (2)

- DD310 26 PDFDokument94 SeitenDD310 26 PDFmegamNoch keine Bewertungen

- Atlas Copco: ROC DMK-II TH (With Bosal Cabin) System DescriptionDokument27 SeitenAtlas Copco: ROC DMK-II TH (With Bosal Cabin) System DescriptionLUIS HERNANDONoch keine Bewertungen

- FeedDokument45 SeitenFeedcristianNoch keine Bewertungen

- Powerview : Model Pv101-C User'S GuideDokument52 SeitenPowerview : Model Pv101-C User'S GuideYipper ShnipperNoch keine Bewertungen

- Electric EquipmentDokument76 SeitenElectric EquipmentESRANoch keine Bewertungen

- Drill Rigs Safety PowerROC T50Dokument46 SeitenDrill Rigs Safety PowerROC T50Seno AgusNoch keine Bewertungen

- 9852 1458 01 L2C Mark4 Maintenance InstructionsDokument376 Seiten9852 1458 01 L2C Mark4 Maintenance Instructionshaimay118Noch keine Bewertungen

- Diagram AsDokument116 SeitenDiagram AsMariano Perez IbarraNoch keine Bewertungen

- Rd10 Partes Drill EVERDIGMDokument240 SeitenRd10 Partes Drill EVERDIGMLuisAntonioVegaParangueoNoch keine Bewertungen

- Power KSC-570Dokument1 SeitePower KSC-570Lucie Pavlíčková100% (1)

- NPT10 Avr Sx460.sx440.sa465.sx421Dokument8 SeitenNPT10 Avr Sx460.sx440.sa465.sx421engmohsen.ramadanhotmail.comNoch keine Bewertungen

- Schematic PS Star ToneDokument1 SeiteSchematic PS Star ToneRahmat Elektronika97Noch keine Bewertungen

- Planos Hidraulicos dd311 PDFDokument11 SeitenPlanos Hidraulicos dd311 PDFRimbertNoch keine Bewertungen

- Manual de Partes TS 32Dokument84 SeitenManual de Partes TS 32RimbertNoch keine Bewertungen

- Manual de Partes TS 32Dokument84 SeitenManual de Partes TS 32RimbertNoch keine Bewertungen

- TS20 de 200 A 250HP Ingles 270010-960R00Dokument99 SeitenTS20 de 200 A 250HP Ingles 270010-960R00ingenieria_377024831100% (2)

- TS20 de 200 A 250HP Ingles 270010-960R00Dokument99 SeitenTS20 de 200 A 250HP Ingles 270010-960R00ingenieria_377024831100% (2)

- Hydraulic Diagram PDFDokument10 SeitenHydraulic Diagram PDFElio Custodio HuachacaNoch keine Bewertungen

- Welcome To My SadvikDokument1 SeiteWelcome To My SadvikRimbertNoch keine Bewertungen

- Brazo TB PDFDokument67 SeitenBrazo TB PDFRimbertNoch keine Bewertungen

- Brazo TB PDFDokument67 SeitenBrazo TB PDFRimbertNoch keine Bewertungen

- Planos Hidraulicos dd311 PDFDokument11 SeitenPlanos Hidraulicos dd311 PDFRimbertNoch keine Bewertungen

- Diagrama Hidraulico PDFDokument12 SeitenDiagrama Hidraulico PDFRimbert100% (1)

- BoomDokument67 SeitenBoomBruno Almeida Carvalho100% (1)

- Diagrama Hidraulico PDFDokument12 SeitenDiagrama Hidraulico PDFRimbert100% (1)

- Especificaciones Del Jumbo DD 311Dokument4 SeitenEspecificaciones Del Jumbo DD 311RimbertNoch keine Bewertungen

- EEC DetroitDokument92 SeitenEEC DetroitRimbert100% (4)

- Manual de Partes RT 670 ActualizadoDokument245 SeitenManual de Partes RT 670 ActualizadoRimbert100% (4)

- Compresor TuFlo 750-RepDokument40 SeitenCompresor TuFlo 750-RepRimbert100% (1)

- Corona RT 46 164 SimpleDokument94 SeitenCorona RT 46 164 SimpleRimbert100% (1)

- Embrague EatonDokument42 SeitenEmbrague EatonRimbertNoch keine Bewertungen

- Detroitdiesel Lube Oil Fuel RequirementsDokument50 SeitenDetroitdiesel Lube Oil Fuel RequirementsSteven J Baynes100% (1)

- Air Brake Hand BookDokument67 SeitenAir Brake Hand BookPrajoy Janardhanan100% (8)

- Corona RT 46 160Dokument120 SeitenCorona RT 46 160Rimbert100% (2)

- Torque Pernos PDFDokument5 SeitenTorque Pernos PDFRimbertNoch keine Bewertungen

- Corona RT 46 164 SimpleDokument94 SeitenCorona RT 46 164 SimpleRimbert100% (1)

- MANUAL Slurry MAX PUMP RM150 KM04579Dokument61 SeitenMANUAL Slurry MAX PUMP RM150 KM04579Rimbert100% (1)

- Part List AtlasDokument46 SeitenPart List AtlasRimbertNoch keine Bewertungen

- MANUAL Slurry MAX PUMP RM150 KM04579Dokument61 SeitenMANUAL Slurry MAX PUMP RM150 KM04579Rimbert100% (1)

- Compresor TuFlo 750-RepDokument40 SeitenCompresor TuFlo 750-RepRimbert100% (1)

- Detroit RefrigDokument35 SeitenDetroit RefrigDanny M Hurtado TaypeNoch keine Bewertungen

- Diagra Hidraulico 793CDokument15 SeitenDiagra Hidraulico 793CRimbertNoch keine Bewertungen

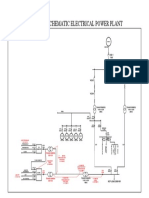

- Plan 1 Schematic Electrical Power PlantDokument1 SeitePlan 1 Schematic Electrical Power PlantEdi Santoni NababanNoch keine Bewertungen

- PicoKeyer Plus 080501Dokument10 SeitenPicoKeyer Plus 080501diney m e willemenNoch keine Bewertungen

- ANT-ATD451800-1774 DatasheetDokument2 SeitenANT-ATD451800-1774 DatasheetАнтонNoch keine Bewertungen

- SDN-C Compact DIN Rail Series: Power SuppliesDokument5 SeitenSDN-C Compact DIN Rail Series: Power SuppliesVickocorp SlpNoch keine Bewertungen

- ESP ManualDokument25 SeitenESP ManualAnoop Tiwari100% (4)

- Silicon Controlled-RectifierDokument6 SeitenSilicon Controlled-RectifierAecer MedinaNoch keine Bewertungen

- Technical Details: Complementary Metal-Oxide-Semiconductor (CMOS)Dokument4 SeitenTechnical Details: Complementary Metal-Oxide-Semiconductor (CMOS)Testing toolsNoch keine Bewertungen

- BomDokument8 SeitenBomPritam SinghNoch keine Bewertungen

- Conveyor Auxiliaries - WPDokument47 SeitenConveyor Auxiliaries - WPPaulNoch keine Bewertungen

- Piezoelectric Pressure Transducer RDokument20 SeitenPiezoelectric Pressure Transducer RKaren BastidasNoch keine Bewertungen

- KBR009 SLDDokument1 SeiteKBR009 SLDGhufran Ud DinNoch keine Bewertungen

- Arihant, Ncert ExemplarDokument269 SeitenArihant, Ncert Exemplarhghhbg100% (7)

- Client - Consultant - Contractor - Project: Package-Ii: Doc. Name: Design Calculation Sheet For HT Power Cable Document No.Dokument2 SeitenClient - Consultant - Contractor - Project: Package-Ii: Doc. Name: Design Calculation Sheet For HT Power Cable Document No.Pramod B.WankhadeNoch keine Bewertungen

- Application of Digital Relay Protection On APUA.....Dokument50 SeitenApplication of Digital Relay Protection On APUA.....Sharmaine MeranoNoch keine Bewertungen

- Guantes Dielectricos CATUDokument3 SeitenGuantes Dielectricos CATUWilliam RaicoNoch keine Bewertungen

- LTE Radio Link Budgeting and RF PlanningDokument5 SeitenLTE Radio Link Budgeting and RF PlanningloukotaNoch keine Bewertungen

- Bảng thông số sản phẩm: Micrologic 5.0 A - for Masterpact NT - drawoutDokument2 SeitenBảng thông số sản phẩm: Micrologic 5.0 A - for Masterpact NT - drawoutair VNoch keine Bewertungen

- Machine Tutorial 1Dokument3 SeitenMachine Tutorial 1Rajeev YadavNoch keine Bewertungen

- WaveguidesDokument2 SeitenWaveguidesRaweed UllahNoch keine Bewertungen

- Wca-21 Rolls Royce - Umas V PDFDokument365 SeitenWca-21 Rolls Royce - Umas V PDFANoch keine Bewertungen

- Distance Protection F23Dokument54 SeitenDistance Protection F23Hossam Eldin TalaatNoch keine Bewertungen

- Magnetic Moment: Classical Concept Review 27Dokument2 SeitenMagnetic Moment: Classical Concept Review 27Md Rizwan AhmadNoch keine Bewertungen

- Manual CarretillaDokument158 SeitenManual Carretillaroboperrin89% (9)

- Cable H07RN-F 19013 PDFDokument6 SeitenCable H07RN-F 19013 PDFAlejandroNoch keine Bewertungen

- Surface Mounting Enclosure, Yellow, 1 Mounting Location Part No. M22-IY1 Catalog No. 216536 Alternate Catalog No. M22-IY1Q EL-Nummer (Norway) 4355384Dokument3 SeitenSurface Mounting Enclosure, Yellow, 1 Mounting Location Part No. M22-IY1 Catalog No. 216536 Alternate Catalog No. M22-IY1Q EL-Nummer (Norway) 4355384MonicaNoch keine Bewertungen

- Cbip Manual On Transformer Publication No 295Dokument422 SeitenCbip Manual On Transformer Publication No 295satyaprasadkolliNoch keine Bewertungen

- Corrsion AssessmentDokument27 SeitenCorrsion Assessmentanilsmg09Noch keine Bewertungen

- 12 Physics PP 23Dokument36 Seiten12 Physics PP 23Pro HackerNoch keine Bewertungen

- Gottlieb Super Soccer Startup SequenceDokument2 SeitenGottlieb Super Soccer Startup SequencekdopsonNoch keine Bewertungen

- DCS43PA05F10Dokument2 SeitenDCS43PA05F10culeros1Noch keine Bewertungen