Beruflich Dokumente

Kultur Dokumente

Equipment Tuning Procedure For Boilers

Hochgeladen von

Shiva Prakasam PernetiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Equipment Tuning Procedure For Boilers

Hochgeladen von

Shiva Prakasam PernetiCopyright:

Verfügbare Formate

RULE 4304 EQUIPMENT TUNING PROCEDURE FOR BOILERS, STEAM GENERATORS,

AND PROCESS HEATERS (Adopted October 19, 1995)

1.0 Purpose

The purpose of this rule is to provide an equipment tuning procedure for boilers, steam

generators and process heaters to control visible emissions and emissions of both nitrogen

oxides (NOx) and carbon monoxide (CO).

2.0 Applicability

This procedure applies to any boiler, steam generator, or process heater that requires tuning

pursuant to District regulations or permit conditions.

3.0 Incorporation by Reference

The provisions of Attachment 4304-A and Attachment 4304-B are hereby adopted by

reference and made a part hereof.

SJVUAPCD 4304 - 1 10/19/95

Attachment 4304-A

Equipment Tuning Procedure1

for Mechanical Draft Boilers, Steam Generators, and Process Heaters

Nothing in this Tuning Procedure shall be construed to require any act or omission that would result

in unsafe conditions or would be in violation of any regulation or requirement established by

Factory Mutual, Industrial Risk Insurers, National Fire Prevention Association, the California

Department of Industrial Relations (Occupational Safety and Health Division), the Federal

Occupational Safety and Health Administration, or other relevant regulations and requirements.

A different tuning procedure may be used if it produces equivalent results. Should a different tuning

procedure be used, a copy of this procedure should be kept with the unit records for two years and

made available to the District personnel on request.

1. Operate the unit at the firing rate most typical of normal operation. If the unit experiences

significant load variations during normal operation, operate it at its average firing rate.

2. At this firing rate, record stack gas temperature, oxygen concentration, and CO

concentration (for gaseous fuels) or smoke spot number2 (for liquid fuels), and observe

flame conditions after unit operation stabilizes at the firing rate selected. If the excess

oxygen in the stack gas is at the lower end of the range of typical minimum values3, and if

CO emissions are low and there is no smoke, the unit is probably operating at near optimum

efficiency - at this particular firing rate. However, complete the remaining portion of this

procedure to determine whether still lower oxygen levels are practical.

3. Increase combustion air flow to the furnace until stack gas oxygen levels increase by one to

two percent over the level measured in Step 2. As in Step 2, record the stack gas

temperature, CO concentration (for gaseous fuels) or smoke spot number (for liquid fuels),

and observe flame conditions for these higher oxygen levels after boiler operation stabilizes.

4. Decrease combustion air flow until the stack gas oxygen concentration is at the level

measured in step 2. From this level gradually reduce the combustion air flow, in small

increments. After each increment, record the stack gas temperature, oxygen concentration,

1

This tuning procedure is based on a tune-up procedure developed by KVB, Inc. for EPA.

2

The smoke-spot number can be determined with ASTM test method D-2156 or with the Bacharach method.

ASTM test method D-2156 is included is included in a tune-up kit that can be purchased from the

Bacharach Company.

3

Typical minimum oxygen levels for boilers at high firing rates are:

1. For natural gas: 0.5 - 3%

2. For liquid fuels: 2 - 4%

SJVUAPCD 4304 - 2 10/19/95

CO concentration (for gaseous fuels) and smoke-spot number (for liquid fuels). Also,

observe the flame and record any changes in its condition.

5. Continue to reduce combustion air flow stepwise, until one of these limits is reached:

a. Unacceptable flame conditions - such as flame impingement on furnace walls or

burner parts, excessive flame carryover, or flame instability.

b. Stack gas CO concentrations greater than 400 ppm.

c. Smoking at the stack.

d. Equipment-related limitations - such as low windbox/furnace pressure differential,

built in air-flow limits, etc.

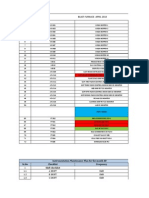

6. Develop an O2/CO curve (for gaseous fuels) or O2/smoke curve (for liquid fuels) similar to

those shown in Figures 1 and 2 using the excess oxygen and CO or smoke-spot number data

obtained at each combustion air flow setting.

7. From the curves prepared in Step 6, find the stack gas oxygen levels where the CO

emissions or smoke-spot number equal the following values:

Fuel Measurement Value

Gaseous CO Emissions 400 ppm

#1 and #2 oils smoke-spot number number 1

#4 oil smoke-spot number number 2

#5 oil smoke-spot number number 3

Other oils smoke-spot number number 4

The above conditions are referred to as the CO or smoke thresholds, or as the minimum

excess oxygen levels.

Compare this minimum value of excess oxygen to the expected value provided by the

combustion unit manufacturer. If the minimum level found is substantially higher than the

value provided by the combustion unit manufacturer, burner adjustments can probably be

made to improve fuel and air mix, thereby allowing operations with less air.

8. Add 0.5 to 2.0 percent to the minimum excess oxygen level found in Step 7 and reset burner

controls to operate automatically at this higher stack gas oxygen level. This margin above

the minimum oxygen level accounts for fuel variations, variations in atmospheric

conditions, load changes, and nonrepeatability or play in automatic controls.

SJVUAPCD 4304 - 3 10/19/95

9. If the load of the combustion unit varies significantly during normal operation, repeat Steps

1-8 for firing rates that represent the upper and lower limits of the range of the load.

Because control adjustments at one firing rate may affect conditions at other firing rates, it

may not be possible to establish the optimum excess oxygen level at all firing rates. If this

is the case, choose the burner control settings that give best performance over the range of

firing rates.If one firing rate predominates, setting should optimize conditions at the rate.

10. Verify that the new settings can accommodate the sudden load changes that may occur in

daily operation without adverse effects. Do this by increasing and decreasing load rapidly

while observing the flame and stack. If any of the conditions in step 5 result, reset the

combustion controls to provide a slightly higher level of excess oxygen at the affected firing

rates. Next verify these new settings in a similar fashion. Then make sure that the final

control settings are recorded at steady-state operating conditions for future reference.

SJVUAPCD 4304 - 4 10/19/95

Attachment 4304-B

Equipment Tuning Procedure

for Natural and Induced Draft-Boilers, Steam Generators, and Process Heaters.

Nothing in this Tuning Procedure shall be construed to require any act or omission that would result

in unsafe conditions or would be in violation of any regulation or requirement established by

Factory Mutual, Industrial Risk Insurers, National Fire Prevention Association, the California

Department of Industrial Relations (Occupational Safety and Health Division), the Federal

Occupational Safety and Health Administration, or other relevant regulations and requirements.

A different tuning procedure may be used if it produces equivalent results. Should a different tuning

procedure be used, a copy of this procedure should be kept with the unit records for two years and

made available to the District personnel on request.

1. Preliminary Analysis

a. Check the Operating Pressure or Temperature. Operate the boiler, steam generator,

or process heater at the lowest acceptable pressure or temperature that will satisfy

the load demand. This will minimize heat and radiation losses. Determine the

pressure or temperature that will be used as a basis for comparative combustion

analysis before and after tuneup.

b. Check Operating Hours. Plan the workload so that the boiler, steam generator, or

process heater operates only the minimum hours and days necessary to perform the

work required. Fewer operating hours will reduce fuel use and emissions. For units

requiring a tuneup to comply with the rule, a totalizing non-resettable fuel meter will

be required for each fuel used and for each boiler, steam generator, and process

heater to prove fuel consumption is less than the heat input limit in Btu per year

specified in the rule.

c. Check Air Supply. Sufficient fresh air supply is essential to ensure optimum

combustion and the area of air supply openings must be in compliance with

applicable codes and regulations. Air openings must be kept wide open when the

burner is firing and clean from restriction to flow.

d. Check Vent. Proper venting is essential to assure efficient combustion. Insufficient

draft or overdraft promotes hazards and inefficient burning. Check to be sure that

vent is in good condition, sized properly and with no obstructions.

e. Combustion Analysis. Perform an "as is" flue gas analysis (O2, CO, CO2, etc.) at

high and low fire, if possible. In addition to data obtained from combustion

analysis, also record the following:

i. Inlet fuel pressure at burner (at high and low fire)

SJVUAPCD 4304 - 5 10/19/95

ii. Draft above draft hood or barometric damper

1) Draft hood: high, medium, and low

2) Barometric damper: high, medium, and low

iii. Steam pressure, water temperature, or process fluid pressure or

temperature entering and leaving the boiler, steam generator, or

process heater.

iv. Unit rate if meter is available.

With above conditions recorded, make the following checks and corrective actions as necessary:

2. Checks and Corrections

a. Check burner Condition. Dirty burners or burner orifices will cause boiler, steam

generator, or process heater output rate and thermal efficiency to decrease. Clean

burners and burner orifices thoroughly. Also, ensure that fuel filters and moisture

traps in place, clean , and operating properly, to prevent plugging of gas orifices.

Confirm proper location and orientation of burner diffuser spuds, gas canes, etc.

Look for any burned-off or missing burner parts, and replace as needed.

b. Check for Clean Boiler, Steam Generator, or Process Heater Tubes and Heat

transfer Surfaces. External and internal build-up of sediment and scale of the

heating surfaces creates an insulating effect that quickly reduces unit efficiency.

Excessive fuel cost will result if the units is not kept clean. Clean tube surfaces,

remove scale and soot, assure proper fluid flow, and flue gas flow.

c. Check Water Treatment & Blowdown Program. Soft water and the proper water or

process fluid treatment must be uniformly used to minimized scale and corrosion.

Timely flushing and periodic blowdown must be employed to eliminate sediment

and scale build-up on a boiler, steam generator, or process heater.

d. Check for Steam Hot Water or Process Fluid Leaks. Repair all leaks immediately

since even small high pressure leaks quickly lead to considerate fuel, water and

steam losses. Be sure there are no leaks through the blow-off drains, safety valve,

by-pass lines or at the feed pump, if used.

3. Safety Checks

a. Test primary and secondary low water level controls.

b. Check operating and limit pressure and temp. controls.

c. Check safety valve pressure and capacity to meet boiler, steam generator, or process

heater requirements.

SJVUAPCD 4304 - 6 10/19/95

d. Check limit safety control and spill switch.

4. Adjustments

While taking combustion readings with a warmed up boiler, steam generator, or process

heater at high fire perform checks and adjustments as follows:

a. Adjust unit to fire at rated capacity. Record fuel manifold pressure.

b. Adjust draft and/or fuel pressure to obtain acceptable, clean combustion at both

high, medium and low fire. Carbon monoxide value should always be below 400

ppm at 3% O2. If CO is high make necessary adjustment. Check to ensure boiler,

steam generator, or process heater light offs are smooth and safe. A reduced fuel

pressure test at both high and low fire should be conducted in accordance with the

manufacturers instructions and maintenance manuals.

c. Check and adjust operation of modulation controller. Ensure, proper efficient and

clean combustion through range of firing rates. When above adjustments and

corrections have been made, record all data.

5. Final Test

Perform a final combustion analysis with a warmed up boiler, steam generator, or process

heater at high, medium, and low fire, whenever possible. In addition to data from

combustion analysis, also check and record:

a. Fuel pressure at burner (High, Medium, and Low).

b. Draft above draft hood or barometric damper (High, Medium, and Low).

c. Steam pressure or water temperature entering and leaving boiler, steam generator, or

process heater.

d. Unit rate if meter is available.

When the above checks and adjustments have been made, record data and attach

combustion analysis data to boiler, steam generator, or process heater records indicating

name and signature of person, title, company name, company address and date the tuneup

was performed.

SJVUAPCD 4304 - 7 10/19/95

Figure 1 Oxygen/CO Characteristic Curve

Figure 2 Oxygen/Smoke Characteristic Curve

SJVUAPCD 4304 - 8 10/19/95

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- MCK Appointment LetterDokument1 SeiteMCK Appointment LetterShiva Prakasam PernetiNoch keine Bewertungen

- BF Proper Thermocouple HistoryDokument67 SeitenBF Proper Thermocouple HistoryShiva Prakasam PernetiNoch keine Bewertungen

- Fmea - Main Air CompressorDokument78 SeitenFmea - Main Air CompressorShiva Prakasam Perneti100% (1)

- Rca SopDokument4 SeitenRca SopShiva Prakasam PernetiNoch keine Bewertungen

- Cable Used For Redundency SupplyDokument2 SeitenCable Used For Redundency SupplyShiva Prakasam PernetiNoch keine Bewertungen

- BFRV and Chute Operation/Troubleshooting Method I. Servo Drive Start Up Procedure After Power FailureDokument5 SeitenBFRV and Chute Operation/Troubleshooting Method I. Servo Drive Start Up Procedure After Power FailureShiva Prakasam PernetiNoch keine Bewertungen

- List of ISO Standards PDFDokument20 SeitenList of ISO Standards PDFKristal Newton80% (5)

- R F Admittance Point Level Switch ' Rfa'.: Instruction & Maintenance Manual FORDokument4 SeitenR F Admittance Point Level Switch ' Rfa'.: Instruction & Maintenance Manual FORShiva Prakasam PernetiNoch keine Bewertungen

- Temperature Viscosity Viscosity Temperature ViscosityDokument12 SeitenTemperature Viscosity Viscosity Temperature ViscosityShiva Prakasam PernetiNoch keine Bewertungen

- BF Inst Mis Report December 2016Dokument30 SeitenBF Inst Mis Report December 2016Shiva Prakasam PernetiNoch keine Bewertungen

- Job Description: Send Me Jobs Like ThisDokument1 SeiteJob Description: Send Me Jobs Like ThisShiva Prakasam PernetiNoch keine Bewertungen

- Francesco Borghesan: Advanced Process Control Engineer at EvonikDokument3 SeitenFrancesco Borghesan: Advanced Process Control Engineer at EvonikShiva Prakasam PernetiNoch keine Bewertungen

- Electrical 1Dokument1 SeiteElectrical 1Shiva Prakasam PernetiNoch keine Bewertungen

- Blast Furnace - April 2014: SR - No Checklist Frequency Shift Checklist Instrumentation Maintenance Plan For The month-BFDokument11 SeitenBlast Furnace - April 2014: SR - No Checklist Frequency Shift Checklist Instrumentation Maintenance Plan For The month-BFShiva Prakasam PernetiNoch keine Bewertungen

- 1 C. I. Weights 2 C. I. Weights 3 C. I. Weights 4 C. I. WeightsDokument19 Seiten1 C. I. Weights 2 C. I. Weights 3 C. I. Weights 4 C. I. WeightsShiva Prakasam PernetiNoch keine Bewertungen

- FC151Dokument24 SeitenFC151Shiva Prakasam PernetiNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Railway Engineering-1 - Railway Engineering & Its DevelopmentDokument22 SeitenRailway Engineering-1 - Railway Engineering & Its Developmentraghav VarmaNoch keine Bewertungen

- Solocup CatalogueDokument96 SeitenSolocup CatalogueJames LoewenNoch keine Bewertungen

- Telegarten Coaxial Bulk CablesDokument4 SeitenTelegarten Coaxial Bulk CablesFirmansyah PanduNoch keine Bewertungen

- Strategies For Operations of Vertical Shaft Kilns PDFDokument7 SeitenStrategies For Operations of Vertical Shaft Kilns PDFKalai SelvanNoch keine Bewertungen

- Procedures For Inspection and Assessment of Fixed Timber DocksDokument75 SeitenProcedures For Inspection and Assessment of Fixed Timber DocksstillifeNoch keine Bewertungen

- Radial Piston JeshDokument13 SeitenRadial Piston JeshmargarettNoch keine Bewertungen

- 1921 AJS E3 E5 B B1 B2 B5 Instruction Service Manual PDFDokument25 Seiten1921 AJS E3 E5 B B1 B2 B5 Instruction Service Manual PDFAndrew MoncrieffNoch keine Bewertungen

- Stabilized Uav Flight System Design Using Raspberry Pi: PG Scholar, E &C Dept., DBIT, Bangalore, Karnataka, IndiaDokument7 SeitenStabilized Uav Flight System Design Using Raspberry Pi: PG Scholar, E &C Dept., DBIT, Bangalore, Karnataka, IndialambanaveenNoch keine Bewertungen

- New Holland T7 150Dokument2 SeitenNew Holland T7 150junaifaNoch keine Bewertungen

- 18 07 2014 NGMA Library List of BooksDokument18 Seiten18 07 2014 NGMA Library List of BooksRamyasri KovvuriNoch keine Bewertungen

- ME6402 MT-II - by Civildatas - Com 12Dokument14 SeitenME6402 MT-II - by Civildatas - Com 12Muhammed SalmanNoch keine Bewertungen

- The Big Bag MistakeDokument7 SeitenThe Big Bag MistakePipe'steam CastrillonNoch keine Bewertungen

- Chemrite 303 SPDokument3 SeitenChemrite 303 SPICPL-RWPNoch keine Bewertungen

- Quot 250kva With Amf PanelDokument4 SeitenQuot 250kva With Amf PanelTiffany NunezNoch keine Bewertungen

- Tender Doc TAS at Bhatinda PDFDokument237 SeitenTender Doc TAS at Bhatinda PDFkalai100% (1)

- BySmart Fiber (New) Datasheet Eng OriginalDokument2 SeitenBySmart Fiber (New) Datasheet Eng Originalaaa a sadNoch keine Bewertungen

- Hidraulic Servovalve SystemDokument111 SeitenHidraulic Servovalve SystemJc MenjívarNoch keine Bewertungen

- Pnumatic TestDokument27 SeitenPnumatic TestV_Santhanakrishnan100% (1)

- 111 GT200N - GT200EN'suzukiDokument147 Seiten111 GT200N - GT200EN'suzukiFaberth Jonas Angel VergaraNoch keine Bewertungen

- Noise and Vibration: Toolbox Talk: NuisanceDokument5 SeitenNoise and Vibration: Toolbox Talk: Nuisancejameel babooramNoch keine Bewertungen

- D1640D1640M 24001Dokument4 SeitenD1640D1640M 24001Sandra AriasNoch keine Bewertungen

- Art Is A Diverse Range of Human Activities in Creating Visual, AuditoryDokument17 SeitenArt Is A Diverse Range of Human Activities in Creating Visual, AuditorydklvemlmmclsNoch keine Bewertungen

- EP-1 Manual 21851 en V1.6-WebDokument48 SeitenEP-1 Manual 21851 en V1.6-WebFirda Ratna Safitri100% (1)

- Actuation Sizing ChartDokument12 SeitenActuation Sizing ChartBùi Cảnh TrungNoch keine Bewertungen

- NGR Routine Test ProcedureDokument6 SeitenNGR Routine Test Procedurezaheer ahamedNoch keine Bewertungen

- Industrial UPS SuppliersDokument7 SeitenIndustrial UPS SuppliershubnetixNoch keine Bewertungen

- OperationsDokument5 SeitenOperationsArun PandeyNoch keine Bewertungen

- Machine Drawing Digital Material PPT ASHOKDokument76 SeitenMachine Drawing Digital Material PPT ASHOKashok junapudiNoch keine Bewertungen

- GolanProducts Catalog 2012Dokument40 SeitenGolanProducts Catalog 2012Raul PetersenNoch keine Bewertungen

- Bar Chart For Structural Activity: 29 November 2017Dokument2 SeitenBar Chart For Structural Activity: 29 November 2017Nilay GandhiNoch keine Bewertungen