Beruflich Dokumente

Kultur Dokumente

E 102 3 - Rev 0.00

Hochgeladen von

dineshsirasat0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten3 Seitendwg3

Originaltitel

E-102-3_Rev-0.00

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldendwg3

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

21 Ansichten3 SeitenE 102 3 - Rev 0.00

Hochgeladen von

dineshsirasatdwg3

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

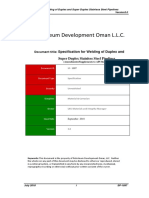

Project

Process Data Sheet Location

Document No. E-102-3 -0.00

Date 26/9/2017

Condenser

Client: Rev 0.00

Equipment Tag: E-102-3

General Specifications

S.N. Specification UOM Value Sketch

1 Equipment ID E-102-3

2 Application/Usage Solvent Condensation

3 Qty No. 1

4 Orientation Horizontal

5 Slope NA

6 Design Codes TEMA-C/ASME Section 8 Div 1

7 TEMA Heat Exchanger Type BEM

8 Location Indoor

9 Support Saddle

10 MOC of Wetted Parts SS-316

11 Heat Transfer Area m2 8.74

12 Effective HT Area m2 8.44

13 Empty Weight kg *

14 Water Filled Weight kg *

15 Radiography NA

16 Hazardous Area Classification Class 1, Div 1, Group D

17

18 Construction Data

19 Shell Side (Process) Tube Side (Utility)

20 UOM Value UOM Value

o o

21 Design Temperature C 180 Design Temperature C 180

o o

22 Operating Temperature C 50 Operating Temperature C 50

23 Design Pressure kg/cm2g FV to 4 Design Pressure kg/cm2g FV to 4

24 Operating Pressure kg/cm2g FV to 1 Operating Pressure kg/cm2g FV to 1

25 Hydro Test Pressure kg/cm2g As per Code Hydro Test Pressure kg/cm2g AS per Code

26 Shell OD mm 273.1 Tube Length mm 2000

27 Baffle Type SSEG No of Tubes No 73

28 No of Baffles No 7 Tube OD mm 19.05

29 Baffle Cut % 21 No of Tube Side Passes No 2

30 Baffle Cut Basis Dia Tube Pitch mm 23.813

31 Inlet Baffle Spacing mm 243.75 Pitch Pattern TRI60

32 Baffle Spacing C/C mm 243.75 Tube Type Bare

33 Outlet Baffle Spacing mm 243.75 Corrosion Allowance mm -

34 First Baffle Cut Orientation Horizontal

35 Baffle Cut Orientation Vertical

36 Baffle Clearance mm 3.2

37 V-Notch mm 25

38 No. of Tie Rods No 4

39 Bonnet OD mm 273.1

40 Bonnet Length (Rear Side) mm 228

41 Bonnet Length (Front Side) mm 200

42 Impingement Plate Not Required

43 Corrosion Allowance mm 2

44

45 Material of Construction

46 Component MOC Thickness (mm) Remarks

47 Tube SA213TP316 1.65 Seamless Tube

48 Tube Sheet Thickness and OD SA240TP316 25/373.1 5mm extra material shall be fabricate for RF

49 Shell SA240TP316 5

50 Bonnet SA285GrB 5

51 Baffles SA240TP316 4.8

52 Tie Rods SA479TP316 9.5 Six numbers

53 Spacer Tube SA213TP316 19.05

54 Impingement Plate NA NA

55 Process Nozzles SA312TP316 Sch 40/Sch10 Seamless Pipe

56 Service Nozzles A106GrB Sch 40 Seamless Pipe

57 Process Flanges SA240TP316 ASA150

58 Service Flanges SA285GrB ASA150

59 Body Flanges SA285GrB 30 SS-316 Lining, 3 mm thick

60 Saddle IS2062 8 Refer Fabrication Drawings

61 Saddle Foot IS2062 10

62 Lifting Hooks SS-304 12.5 Two numbers

Project

Process Data Sheet Location

Document No. E-102-3 -0.00

Date 26/9/2017

Condenser

Client: Rev 0.00

Equipment Tag: E-102-3

63 Bolts GI Std

64 NutS Gi Std

65 Gaskets CAF-PTFE Enveloped Std

66 Earthing Boss SS-304 25 Two numbers

67 Partition Plate SS-304 5

68

69 Nozzle Schedule

70 ID Size (NB) Rating Proj(mm) Pipe Schedule Flange Type Usage Location

71 N1 100 150# 150 40 SORF Vapour Inlet Shell

72 N2 25 150# 150 40 SORF Condensate Outlet Shell

73 N3 50 150# 150 40 SORF Vent Shell

74 N4 80 150# 150 40 SORF Cooling Water Inlet Bonnet

75 N5 80 150# 150 40 SORF Cooling Water Outlet Bonnet

76

77

78

79

80 Identification Plate

81 Size of Name Plate 200 mm x 200 mm Equipment Id: E-102-3

82 MOC SS-316 Effective HTA: 8.44 m2

83 Letter Size 12 mm Client:

84 Qty:

85 Locations

86 Date:

87 Reference Drawings

88 P&ID No. P&ID-102-3-0.00

89 GA Drawing No. NA

90

91 General Notes

92 1 * indicates that the information shall be provided by the Vendor.

93 2 All nozzles up to 80 NB shall be fabricated out of 40Sch Seamless pipe.

94 3 All nozzles above 80 NB shall be fabricated out of 10Sch Seamless pipe.

95 4 All nozzles up to 50 NB shall be provided with Support and Pad plate.

96 5 All nozzles above 50 NB shall be provided with Pad plate.

97 6 Nozzles standout shall be 150 mm.

98 7 Flange drilling as per ASA150, ANSI B16.5.

99 8 Vendor to provide detailed fabrication drawing.

100 9 Buffing of all external parts required to Grit 180 (Matt Finish).

101 10 Exchanger to be provided with Earthing boss.

102 11 Exchanger shall have two Lifting Hooks.

103 12 Name plate shall be designed as given in the side bar.

104 13 Documentation, Drawings and Test Certificate

105 The following test certificates shall be needed

106 Material of Construction

107 Hydraulic Test Certificate

108 PO Acceptance Copy

109 Three sets of drawings for approval

110 Three sets of approved drawings

111

112 14 Inspection

113 Stage wise Inspection shall be carried.

114 Inspection terms shall be decided by the Client.

115

116 15 Surface Finishing

117 All MS Parts shall be sand blasted followed by two coats of PU Primer and two coats of PU paint.

118 External buffing of all parts.

119 External and internal surfaces shall be free from welding flux,crevices and slug.

120

121 16 Packaging

122 The equipment shall be properly packed as not to damage during transit, Loading and Unloading.

123 Nozzles shall be properly blinded.

124

125 17 Ground Clearence

126 The bottom nozzle shall have 450 mm clearance from ground. Thus, the shall and ground clearence shall be 600 mm.

Project

Process Data Sheet Location

Document No. E-102-3 -0.00

Date 26/9/2017

Condenser

Client: Rev 0.00

Equipment Tag: E-102-3

127 Center to Center clearance between the saddle shall be 1500 mm

128

129 18 Make of Standard Items:

130 Steel Pipes/Tubes: Jindal/Tata/Corus/Ratnamani/Maharashtra Seamless.

131 Temperature/Vacuum Gauge: Waree/Tempsens/GIC

132 Welding Rods: Adwani/Esab/L&T

133 Insulation Material: Loyeds/Sait-Gobin/Temperlite

134

135

136

137

138

139

140

141

142

143 Revision History

144 Rev Date Change Summary Issued For

145 0 26/9/2017 Specifications Prepared For Comments

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

Rev 1 Rev 2

Prepared by/Date

Checked by/Date

Approved by/Date

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Sacred Heart Kindergarten, Nashik Interaction Schedule List 2019-20Dokument5 SeitenSacred Heart Kindergarten, Nashik Interaction Schedule List 2019-20dineshsirasatNoch keine Bewertungen

- DrSavkar HealthDokument2 SeitenDrSavkar HealthdineshsirasatNoch keine Bewertungen

- Roll No.: Venue Code: Registration No.: Progarmme Applied For: Name and Address: Venue of ExaminationDokument2 SeitenRoll No.: Venue Code: Registration No.: Progarmme Applied For: Name and Address: Venue of ExaminationdineshsirasatNoch keine Bewertungen

- Commented - Atmanirbhar Bharat in Archery - FinalDokument3 SeitenCommented - Atmanirbhar Bharat in Archery - FinaldineshsirasatNoch keine Bewertungen

- Union Public Service Commission: La?K Yksd Lsok VK KSX) /kksyiqj GKML) 'KKGTGK¡ JKSM) Ubz FnyyhDokument1 SeiteUnion Public Service Commission: La?K Yksd Lsok VK KSX) /kksyiqj GKML) 'KKGTGK¡ JKSM) Ubz FnyyhdineshsirasatNoch keine Bewertungen

- Diat Rules and Regulations For The Award of The Degree of Doctor of Philosophy (2016)Dokument48 SeitenDiat Rules and Regulations For The Award of The Degree of Doctor of Philosophy (2016)dineshsirasatNoch keine Bewertungen

- To 2Dokument2 SeitenTo 2dineshsirasatNoch keine Bewertungen

- Vatavruksha Apartment: Ravishankar Marg, Vidhate Nagar, Behind INOX, Nasik Pune Road, Nasik - 422006Dokument3 SeitenVatavruksha Apartment: Ravishankar Marg, Vidhate Nagar, Behind INOX, Nasik Pune Road, Nasik - 422006dineshsirasatNoch keine Bewertungen

- Tips For Filling MAH-LL.B.-3 Yrs. CET - 2020 On Line Application FormDokument6 SeitenTips For Filling MAH-LL.B.-3 Yrs. CET - 2020 On Line Application FormdineshsirasatNoch keine Bewertungen

- 1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSDokument1 Seite1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSdineshsirasatNoch keine Bewertungen

- 1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSDokument1 Seite1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSdineshsirasatNoch keine Bewertungen

- Using The ETDR Word Template: Masters Theses and ReportsDokument22 SeitenUsing The ETDR Word Template: Masters Theses and ReportsdineshsirasatNoch keine Bewertungen

- Maharashtra State Road Transport Corpora On E-Reserva On TicketDokument1 SeiteMaharashtra State Road Transport Corpora On E-Reserva On TicketdineshsirasatNoch keine Bewertungen

- FIR SubmissionDokument1 SeiteFIR SubmissiondineshsirasatNoch keine Bewertungen

- Zoom MeetingDokument2 SeitenZoom MeetingdineshsirasatNoch keine Bewertungen

- ApprciationDokument1 SeiteApprciationdineshsirasatNoch keine Bewertungen

- ToDokument1 SeiteTodineshsirasatNoch keine Bewertungen

- Model No. Modelling Details TaskDokument1 SeiteModel No. Modelling Details TaskdineshsirasatNoch keine Bewertungen

- Is Valid Only With Original Photo ID: Mechanic Motor VehicleDokument2 SeitenIs Valid Only With Original Photo ID: Mechanic Motor VehicledineshsirasatNoch keine Bewertungen

- GST Invoice Format 1Dokument1 SeiteGST Invoice Format 1dineshsirasatNoch keine Bewertungen

- Illustration For Your HDFC Life Click 2 Protect PlusDokument2 SeitenIllustration For Your HDFC Life Click 2 Protect PlusdineshsirasatNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Under Floor Trunking CatalogueDokument60 SeitenUnder Floor Trunking CatalogueARUNDAS572Noch keine Bewertungen

- Bite Type FittingsDokument42 SeitenBite Type FittingsWilson JustinoNoch keine Bewertungen

- ITP Check List HVAC Piping WorksDokument5 SeitenITP Check List HVAC Piping WorksResearcherNoch keine Bewertungen

- Automatic Sprinkler System DesignDokument2 SeitenAutomatic Sprinkler System DesignAli AimranNoch keine Bewertungen

- Boiler Magnetite Exfoliation Report June 2005Dokument23 SeitenBoiler Magnetite Exfoliation Report June 2005lacoste11111100% (1)

- Specification For Dual-Layer FBEDokument19 SeitenSpecification For Dual-Layer FBEali saidNoch keine Bewertungen

- 1 - HV Bushing - GOM - Technical Guide - ABBDokument12 Seiten1 - HV Bushing - GOM - Technical Guide - ABBTrần Minh TríNoch keine Bewertungen

- ECO 410 DG Index A PDFDokument127 SeitenECO 410 DG Index A PDFKaren Baker100% (1)

- Blucher VamzdziaiDokument32 SeitenBlucher VamzdziaigmlopesNoch keine Bewertungen

- Pheonwj M Spe 0025 1Dokument48 SeitenPheonwj M Spe 0025 1Iksan Adityo Mulyo100% (1)

- SP-1097 DSS Welding Specs PDFDokument48 SeitenSP-1097 DSS Welding Specs PDFHari Prakash GrandheyNoch keine Bewertungen

- Drainage Handbook: Optional Pipe MaterialsDokument38 SeitenDrainage Handbook: Optional Pipe MaterialsedgarabrahamNoch keine Bewertungen

- D3350Dokument7 SeitenD3350Luis Fernando Morales100% (1)

- Material Submittal HANDRAILDokument6 SeitenMaterial Submittal HANDRAILManu Mohan0% (1)

- Approved MES 19-6-12Dokument48 SeitenApproved MES 19-6-12Anonymous 7ZYHilDNoch keine Bewertungen

- Pipe Sizing LunaDokument10 SeitenPipe Sizing LunaYasin EgeNoch keine Bewertungen

- Frame 7fa Stop Ratio ValveDokument56 SeitenFrame 7fa Stop Ratio ValveJJNoch keine Bewertungen

- Copper TubesDokument10 SeitenCopper TubesJade Atkinson PhellaineNoch keine Bewertungen

- Expansion Calculation and Loop Sizing001Dokument2 SeitenExpansion Calculation and Loop Sizing001Joseph R. F. DavidNoch keine Bewertungen

- QCP KOC-VME 1221006120-PART 1 Rev 2Dokument49 SeitenQCP KOC-VME 1221006120-PART 1 Rev 2Alireza GolpesarNoch keine Bewertungen

- And Owner'S Manual: Installation InstructionsDokument40 SeitenAnd Owner'S Manual: Installation InstructionsSérgio PortuNoch keine Bewertungen

- Holdtite BrochureDokument20 SeitenHoldtite BrochureThanhnam PhanNoch keine Bewertungen

- LG Air Conditioner Remote Control ManualDokument9 SeitenLG Air Conditioner Remote Control ManualAlinson CarvajalNoch keine Bewertungen

- Industrial Refrigeration: Components and ControlsDokument1.094 SeitenIndustrial Refrigeration: Components and ControlsSudharshan ReddyNoch keine Bewertungen

- Types of Pipes, Classification of PipesDokument4 SeitenTypes of Pipes, Classification of PipeschkibiNoch keine Bewertungen

- Pre-Owned Equipment - Grundoburst 400G Pipe BursterDokument1 SeitePre-Owned Equipment - Grundoburst 400G Pipe BurstercharneNoch keine Bewertungen

- 10 Componentes de La Torre de PerforacionDokument4 Seiten10 Componentes de La Torre de PerforacionMauricio Flores VidaurreNoch keine Bewertungen

- Venn AirDokument24 SeitenVenn AirpepeNoch keine Bewertungen

- PTS Gas Driven Compressor300807Dokument114 SeitenPTS Gas Driven Compressor300807sumit kumarNoch keine Bewertungen

- Standard DesriptionDokument6 SeitenStandard Desriptionroshan jaiswalNoch keine Bewertungen