Beruflich Dokumente

Kultur Dokumente

WSMW Mudline Running Procedure

Hochgeladen von

Mahmoud Ahmed Ali AbdelrazikOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

WSMW Mudline Running Procedure

Hochgeladen von

Mahmoud Ahmed Ali AbdelrazikCopyright:

Verfügbare Formate

mudline equipment

running procedure

WMSW Mudline Running

Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Running, Abandonment and Tieback Procedures

Surface Wellhead Proposals Publication RP-603

April 2000

WMSW Mudline RP-603

Running Procedure Page 55

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Table of Contents

Bill of Materials .................................................................................................. 1

System Drawing Stage 1 Running ......................................................... 2

Section 1 30" Conductor ............................................................................ 3

Install the 30" Landing Ring ...................................................................................................................... 3

Section 2 20" Casing ................................................................................... 4

Hang off the Casing .................................................................................................................................. 4

Contingency ............................................................................................................................................. 7

Section 3 13-3/8" Casing ............................................................................ 8

Hang off the Casing .................................................................................................................................. 8

Contingency ............................................................................................................................................ 11

Run the Latch Brush/Jetting Tool ............................................................................................................ 12

Section 4 9-5/8" Casing............................................................................. 13

Hang off the Casing ................................................................................................................................ 13

Contingency ........................................................................................................................................... 17

Run the Latch Brush/Jetting Tool ............................................................................................................ 18

Section 5 7" Casing ................................................................................... 19

Hang off the Casing ................................................................................................................................ 19

Contingency ........................................................................................................................................... 22

System Drawing Stage 2 Temporary Abandonment......................... 23

Section 1 7" Casing Temporary Abandonment..................................... 24

Install the Temporary Abandonment Cap ................................................................................................ 24

Section 2 9-5/8" Casing Temporary Abandonment .............................. 26

Install the Temporary Abandonment Cap ................................................................................................ 26

Section 3 13-3/8" Casing Temporary Abandonment ............................ 28

Install the Temporary Abandonment Cap ................................................................................................ 28

Section 4 20" Casing Temporary Abandonment .................................. 30

Install the Temporary Abandonment Cap ................................................................................................ 30

WMSW Mudline RP-603

Running Procedure Page 51

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Table of Contents (con't)

System Drawing Stage 3 Tieback ........................................................ 32

Section 1 20" Casing Tieback.................................................................. 33

Cleanout Procedure ............................................................................................................................... 33

Remove the Abandonment Cap ............................................................................................................. 35

Tap the Running Threads ....................................................................................................................... 36

Install the Tieback Tool............................................................................................................................ 38

Section 2 13-3/8" Casing Tieback ............................................................ 39

Remove the Abandonment Cap ............................................................................................................. 39

Tap the Running Threads ....................................................................................................................... 40

Install the Tieback Tool............................................................................................................................ 42

Section 3 9-5/8" Casing Tieback ............................................................. 43

Remove the Abandonment Cap ............................................................................................................. 43

Tap the Running Threads ....................................................................................................................... 44

Install the Tieback Tool............................................................................................................................ 46

Section 3 7" Casing Tieback .................................................................... 47

Remove the Abandonment Cap ............................................................................................................. 47

Tap the Running Threads ....................................................................................................................... 48

Install the Tieback Tool............................................................................................................................ 50

WMSW Mudline RP-603

Running Procedure Page 53

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Bill of Materials

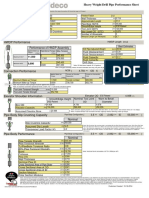

MUDLINE HANGERS TIEBACK TOOLS SERVICE TOOLS

Item Qty Description Item Qty Description Item Qty Description

A1 1 Landing Ring, WMSW, 30" x 1" C1 1 Tieback Tool, threaded, for 20" ST1 1 Casing Hanger Running Tool,

buttweld prep casing hanger WMSW, for 20" WMSW casing

Part# 647592-05 Part# 2165798-01 hanger

Part# 605142-01

A2 1 Mudline Hanger, WMSW, 30" x C2 1 Tieback Tool for 13-3/8" cas-

20" with a slip on adapter ring ing hanger ST2 1 Casing Hanger Running Tool,

and ID profile for 13-3/8" Part# 2124864-01 WMSW, for 13-3/8" WMSW

WMSW casing hanger casing hanger

C3 1 Tieback Tool for 9-5/8" casing

Part# 647594-01 Part# 604937-01-01

hanger

A3 1 Mudline Hanger, WMSW, 20" x Part# 2124865-01 ST3 1 13-3/8" Latch Brush/Jetting

13-3/8" with an ID profile for a Tool for 9-5/8" hanger profile

C4 1 Tieback Tool for 7" casing

9-5/8" WMSW casing hanger Part# 2019774-01

hanger

Part# 605037-01-01

Part# 2155415-01 ST4 1 Casing Hanger Running Tool,

A4 1 Mudline Hanger, WMSW, WMSW, for 9-5/8" WMSW cas-

13-3/8" x 9-5/8" ID profile for a ing hanger

7" WMSW casing hanger Part# 604938-01-01

Part# 647673-02

ST5 1 9-5/8" Latch Brush/Jetting Tool

A5 1 Mudline Hanger, WMSW, for 7" hanger profile

9-5/8" x 7" Part# 2019809-01

Part# 647676-02

ST6 1 Casing Hanger Running Tool,

WMSW, for 7" WMSW casing

hanger

T/A CAPS

Part# 604939-01

ST7 1 Temporary Abandonment

Item Qty Description Cap Running Tool with J-slots

B1 1 Temporary Abandonment and stinger

Cap, nonsealing for 20" cas- Part# 667811-06-02

ing hanger

Part# 647031-02 ST8 1 24" Cleanout Tool with 4-1/2"

IF box top and junk basket

B2 1 Temporary Abandonment Part# 2044723-01

Cap, nonsealing for 13-3/8"

casing hanger ST9 1 Tap Tool for 20" WMSW cas-

Part# 605193-02 ing Hanger

Part# 646677-01

B3 1 Temporary Abandonment

Cap, sealing for 9-5/8" casing ST10 1 Tap Tool for 13-3/8" WMSW

hanger casing Hanger

Part# 605080-02 Part# 646664-01

B4 1 Temporary Abandonment ST11 1 Tap Tool for 9-5/8" WMSW cas-

Cap, sealing for 7" casing ing Hanger

hanger Part# 646663-01

Part# 605174-01 ST12 1 Tap Tool for 7" WMSW casing

Hanger

Part# 646438-04

WMSW Mudline RP-603

Running Procedure Page 1

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

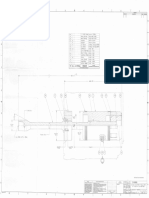

System Drawing Stage 1 Running

20"

Running Tool

13-3/8"

Running Tool

9-5/8"

Running Tool

7"

Running Tool

20" Casing

Hanger

13-3/8" Casing

Hanger

9-5/8" Casing

Hanger

30" Landing

Ring

7" Casing

Hanger

RP000286

RP-603 WMSW Mudline

Page 2 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 1 30" Conductor

Install the 30" Landing Ring

1. Run the 30" conductor string as re-

30" WMSW Landing Ring

quired

2. Examine the 30" Landing Ring (Item

A1). Verify that it is clean and undam- 6.00" 26.36"

aged.

NOTE: The WMSW Landing Ring is sym-

metrical, therefore there is no top or bot-

tom and may be installed either way. 30.00"

RP000199

3. At a predetermined position in the

string, install the Landing Ring land-

ing joint.

4. Continue running the conductor

string and position the Landing Ring

at 25' 5' below the seabed or as 30" Conductor

required. Record this dimension.

5. Cut the 30" conductor at the desired

elevation above the cellar deck and

prepare the stub for diverter installa-

tion. 30" Landing

Ring

6. Install the diverter and test as re-

quired.

RP000200

WMSW Mudline RP-603

Running Procedure Page 3

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 2 20" Casing

Hang Off the Casing

21.91" Max

1. Run the 20" casing as required.

20" WMSW Casing

2. At a predetermined position in the Hanger Running Tool

20" Casing Thread

casing string, hang off the casing in

the floor slips.

O-Ring

3. Examine the Casing Hanger Run-

17.25"

ning Tool (Item ST1). Verify the fol- Washport

lowing:

bore is clean and free of debris 1" Pitch LH

18.87" Min Thread

all seals are clean and undam-

aged

27.41" Max

all threads are clean and un-

damaged 20" WMSW

Casing Hanger

washports are clean and unob-

structed 1" Pitch LH

Thread

4. Orient the Running Tool with the

running threads down.

23.50"

5. Make up a joint of casing to the top of

the Tool. 17.72" DIA.

Min

6. Examine the Mudline Hanger (Item Fluted

Adapter Ring

A2). Verify the following:

Retainer

bore is clean and free of debris 20" Casing Thread Wire

adapter ring is properly installed RP000287

and retained

all threads are clean and un-

damaged

7. Orient the Hanger with the internal

running threads up.

RP-603 WMSW Mudline

Page 4 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 2 20" Casing

NOTE: The Hanger and Tool will usually

be delivered already made up with cas-

ing pup joints made up into each compo-

nent and the overall length equivalent to

standard casing length. Always verify, Landing Joint

prior to picking up, that the Hanger/Tool

connection is properly made up by verify-

ing that the mark across the interface is

properly aligned. If the mark across the

Hanger/Tool interface is not aligned, dis-

assemble the components and continue

with this procedure. 20"

Running Tool

8. Wipe the running threads of both the 20" Casing

Tool and Hanger and the o-rings of Hanger

the Tool with a light coat of oil or

grease.

WARNING: Do not apply pipe dope or

other metal based compounds to the

running threads of either the Tool or

Hanger.

20" Casing

9. Make up the Running Tool to the

Casing Hanger with left hand rota-

tion five full turns to a positive stop.

RP000288

10. Install the Hanger/Tool joint into the

casing string as a normal joint would

be installed.

11. Lower the Hanger and Tool through

the diverter.

12. Approximately 5 feet from the antici-

pated landing point, slow the rate of

decent.

13. Land the Hanger on the load shoul-

der of the Landing Ring.

14. Cement as required.

15. If reciprocation is required, with the

Hanger fully landed, make a hori-

zontal mark on the landing joint, level

with the rig floor.

16. Lift the Hanger approximately 5 feet.

17. Reciprocate the casing as required

during cementing, never allowing

the mark on the landing joint to go

below the rig floor.

18. Once cementing operations are

complete, land the Hanger on the

Landing Ring following the same

procedure as described earlier.

WMSW Mudline RP-603

Running Procedure Page 5

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 2 20" Casing

19. Immediately following cementing

operations, it is necessary to wash-

out the annulus.

20. Balancing the string weight, rotate 20"

the landing joint to the right 3 full Running Tool

turns. This will expose the washports

of the Running Tool. Washports

21. Begin pumping wash fluid, per rig Exposed

procedure, through the casing, until

returns are clean and free of debris.

22. Continue to pump wash fluid until an 20" Casing

amount 2 times that of the mudline Hanger

to surface annular volume has been

displaced.

NOTE: During this process, high pump 30" Conductor

rates and a pressure of between 400 and

500 psi must be maintained.

23. Once a satisfactory washout is com- 30" Landing

pleted, close the washports by rotat- Ring

ing the landing joint to the left 3 full

turns to a positive stop.

24. Pressure test the casing string

through the cement head to 80% of

casing burst pressure or as indi- 20" Casing

cated by the Drilling Supervisor.

RP000289

RP-603 WMSW Mudline

Page 6 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 2 20" Casing

Contingency

Unable to Close Washports on

20" Running Tool or Test Fails

20"

25. Rotate the casing string to the right Running Tool

until the Running Tool is released

from the Hanger, this will be a maxi-

mum of 5 turns. (Mark the casing

clearly prior to recovery). The run-

ning string should be balanced dur-

ing this operation such that the Run-

ning Tool is unloaded.

26. Recover the Running Tool to the

surface visually inspect the seals,

sealing areas and threaded areas.

27. Replace the o-rings. Apply a light

coat of sea water resistant lubri-

20" Casing

cant. Hanger

NOTE: Do Not apply Pipe Dope or other

metal based compounds to the Hanger/

Running Tool thread connection.

28. Run the Tapping Tool to clean out

the internal threads in the Hanger, if

the Running Tool Washout port can 30" Landing

not be closed. Ring

29. Rerun the Running Tool on the cas-

ing string torqued to the maximum

allowable torque.

30. When the Running Tool is 5 feet

from the Hanger top slow the rate of 20" Casing

descent and stab the Running Tool RP000290

into the Hanger. (Watch the casing

mark carefully)

31. Land the Running Tool into the

Hanger and rotate 5 turns to the left

to a positive stop, balancing the

weight as the Running Tool moves

down such that it is unloaded. It will

take 5 turns to make up.

32. Pressure test the casing string

through the cement head to 80% of

casing burst pressure, or as indi-

cated by the company representa-

tive.

WMSW Mudline RP-603

Running Procedure Page 7

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 13-3/8" Casing

Hang Off the Casing

15.15" Max

1. Run the 13-3/8" casing as required. 13-3/8" WMSW Casing

Hanger Running Tool

2. At a predetermined position in the 13-3/8"

casing string, hang off the casing in Casing Thread

the floor slips.

3. Examine the Casing Hanger Run- O-Ring

ning Tool (Item ST2). Verify the fol- 16.50" Washport

lowing:

bore is clean and free of debris

12.74" Min

all seals are clean and undam- 1" Pitch LH

Threads

aged

all threads are clean and un-

damaged

18.53" Max

washports are clean and unob- 13-3/8" WMSW

structed Casing Hanger

4. Orient the Running Tool with the

running threads down.

5. Make up a joint of casing to the top of 1" Pitch LH

the Tool. Threads

6. Examine the Mudline Hanger (Item

A3). Verify the following: 24.00"

bore is clean and free of debris

12.78" Min

all threads are clean and un-

damaged

7. Orient the Hanger with the internal 13-3/8"

running threads up. Casing Thread

RP000291

RP-603 WMSW Mudline

Page 8 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 13-3/8" Casing

NOTE: The Hanger and Tool will usually be delivered already

made up with casing pup joints made up into each component 13-3/8"

and the overall length equivalent to standard casing length. Landing Joint

Always verify, prior to picking up, that the Hanger/Tool connec-

tion is properly made up by verifying that the mark across the

interface is properly aligned. If the mark across the Hanger/

Tool interface is not aligned, disassemble the components 13-3/8"

and continue with this procedure. Running Tool

8. Wipe the running threads of both the Tool and Hanger and

the o-rings of the Tool with a light coat of oil or grease.

WARNING: Do not apply pipe dope or other metal based

compounds to the running threads of either the Tool or Hanger.

9. Make up the Running Tool to the Casing Hanger with left

13-3/8" Casing

hand rotation five full turns to a positive stop. Hanger

10. Install the Hanger/Tool joint into the casing string as a

normal joint would be installed.

11. Lower the hanger and Tool through the BOP stack.

12. Approximately 5 feet from the anticipated landing point,

slow the rate of decent.

13. Land the Hanger on the load shoulder of the 20" Hanger. 13-3/8"

Casing

14. Cement as required.

RP000293

15. If reciprocation is required, with the Hanger fully landed,

make a horizontal mark on the landing joint, level with the

rig floor.

16. Lift the Hanger approximately 5 feet. 20" Landing Joint

17. Reciprocate the casing as required during cementing, 20"

Running Tool

never allowing the mark on the landing joint to go below the

rig floor. 13-3/8"

Running Tool

18. Once cementing operations are complete, land the Hanger

on the landing profile of the 20" Hanger following the same 20" Casing

procedure as described earlier. Hanger

13-3/8" Casing

Hanger

30" Landing

Ring

20" Casing

RP000292

WMSW Mudline RP-603

Running Procedure Page 9

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 13-3/8" Casing

19. Immediately following cementing

operations, it is necessary to wash-

13-3/8"

out the annulus. Running Tool

20. Balancing the string weight, rotate

the landing joint to the right 3 full

turns. This will expose the washports

of the Running Tool. Washports Exposed

21. Begin pumping wash fluid, per rig

procedure, through the casing, until

returns are clean and free of debris.

22. Continue to pump wash fluid until an

amount 2 times that of the mudline

to surface annular volume has been

displaced.

NOTE: During this process, high pump 13-3/8" Casing

rates and a pressure of between 400 and Hanger

500 psi must be maintained.

23. Once a satisfactory washout is com-

pleted, close the washports by rotat-

ing the landing joint to the left 3 full

turns to a positive stop.

24. Pressure test the casing string

through the cement head to 80% of RP000294

casing burst pressure or as indi-

cated by the Drilling Supervisor.

RP-603 WMSW Mudline

Page 10 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 13-3/8" Casing

Contingency

Unable to Close Washports on 13-3/8"

13-3/8" Running Tool or Test Fails Landing Joint

25. Rotate the casing string to the right

until the Running Tool is released 13-3/8"

from the Hanger, this will be a maxi- Running Tool

mum of 5 turns. (Mark the casing

clearly prior to recovery). The run-

ning string should be balanced dur-

ing this operation such that the Run-

ning Tool is unloaded.

26. Recover the Running Tool to the

surface visually inspect the seals,

sealing areas and threaded areas.

27. Replace the o-rings. Apply a light

coat of sea water resistant lubri-

cant. 13-3/8" Casing

Hanger

NOTE: Do Not apply Pipe Dope or other

metal based compounds to the Hanger/

Running Tool thread connection.

28. Run the Tapping Tool to clean out

the internal threads in the Hanger, if

the Running Tool Washout port can

not be closed.

29. Rerun the Running Tool on the cas-

ing string torqued to the maximum

allowable torque.

RP000295

30. When the Running Tool is 5 feet

from the Hanger top slow the rate of

descent and stab the Running Tool

into the Hanger. (Watch the casing

mark carefully)

31. Land the Running Tool into the

Hanger and rotate 5 turns to the left

to a positive stop, balancing the

weight as the Running Tool moves

down such that it is unloaded. It will

take 5 turns to make up.

32. Pressure test the casing string

through the cement head to 80% of

casing burst pressure, or as indi-

cated by the company representa-

tive.

WMSW Mudline RP-603

Running Procedure Page 11

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 13-3/8" Casing

Run the Latch Brush/Jetting

Tool 13-3/8" Latch Brush and Jetting Tool

33. Examine the 13-3/8" Latch Brush

and Jetting Tool (Item ST3). Verify 4-1/2" IF

the following:

threads are clean and undam-

aged

jetting ports are clean and un-

obstructed

Jetting Ports

brushes are properly installed

and adequate

latch fingers are properly in- Latch Fingers

stalled and operational

34. Make up a joint of drill pipe to the top

of the Tool.

35. Lower the Tool into the well to the

Retainer Ring

area of the hanger landing profile.

36. Pump wash fluid, per rig procedure,

through the drill pipe and rotate the

Tool.

Brushes

37. Reciprocate the Tool through the

landing profile until the latch fingers

of the Tool identify the profile.

38. Secure the pump and retrieve the

Tool to the rig floor.

NOTE: Ensure the Tool is centered in the RP000296

BOP stack when retrieving so the latch

finger will not be damaged.

39. Clean, grease and store the Tool.

RP-603 WMSW Mudline

Page 12 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 4 9-5/8" Casing

Hang Off the Casing 11.41" Max

9-5/8" WMSW Casing

1. Run the 9-5/8" casing as required.

Hanger Running Tool

2. At a predetermined position in the 9-5/8" Casing

casing string, hang off the casing in Thread

the floor slips.

3. Examine the Casing Hanger Run- 16.44"

O-Rings

ning Tool (Item ST4). Verify the fol-

lowing:

Washport

bore is clean and free of debris

8.82" Min

all seals are clean and undam- 1" Pitch LH

Thread

aged

12.19" Max

all threads are clean and un- 9-5/8" WMSW

damaged Casing Hanger

washports are clean and unob-

structed

4. Orient the Running Tool with the

running threads down. 1" Pitch LH

Thread

5. Make up a joint of casing to the top of

the Tool.

6. Examine the Mudline Hanger (Item

A4). Verify the following: Latching Fingers

33.44"

Ring

bore is clean and free of debris

latch fingers are properly in-

stalled and operational

Shear Ring

8.82" Min

all threads are clean and un- and Shear

Pin

damaged

7. Orient the Hanger with the internal

Retainer Ring

running threads up.

9-5/8" Casing

Thread

RP000297

WMSW Mudline RP-603

Running Procedure Page 13

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 4 9-5/8" Casing

NOTE: The Hanger and Tool will usually be delivered already

made up with casing pup joints made up into each component

and the overall length equivalent to standard casing length. 9-5/8"

Always verify, prior to picking up, that the Hanger/Tool connec- Landing Joint

tion is properly made up by verifying that the mark across the

interface is properly aligned. If the mark across the Hanger/ 9-5/8"

Tool interface is not aligned, disassemble the components Running Tool

and continue with this procedure.

8. Wipe the running threads of both the Tool and Hanger and

the o-rings of the Tool with a light coat of oil or grease.

WARNING: Do not apply pipe dope or other metal based

compounds to the running threads of either the Tool or Hanger.

9. Make up the Running Tool to the Casing Hanger with left

hand rotation five full turns to a positive stop.

9-5/8" Casing

10. Install the Hanger/Tool joint into the casing string as a Hanger

normal joint would be installed.

9-5/8"

Casing

RP000298

RP-603 WMSW Mudline

Page 14 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 4 9-5/8" Casing

11. Lower the hanger and Tool through

the BOP stack. 13-3/8"

Landing Joint

12. Approximately 5 feet from the antici-

pated landing point, slow the rate of

decent. 9-5/8"

Landing Joint

13. Land the Hanger on the landing pro-

13-3/8"

file of the 13-3/8" Hanger.

Running Tool

14. Cement as required. 9-5/8"

15. If reciprocation is required, with the Running Tool

Hanger fully landed, make a hori-

zontal mark on the landing joint, level

with the rig floor.

16. Lift the Hanger approximately 5 feet. 13-3/8" Casing

Hanger

17. Reciprocate the casing as required

during cementing, never allowing

the mark on the landing joint to go

below the rig floor.

18. Once cementing operations are

complete, land the Hanger on the

landing profile of the 13-3/8" Hanger,

following the same procedure as 9-5/8" Casing

Hanger

described earlier.

13-3/8" Casing

9-5/8" Casing

RP000299

WMSW Mudline RP-603

Running Procedure Page 15

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 4 9-5/8" Casing

19. Immediately following cementing

operations, it is necessary to wash- 13-3/8"

Landing Joint

out the annulus.

20. Balancing the string weight, rotate 9-5/8"

the landing joint to the right 3 full Landing Joint

turns. This will expose the washports

of the Running Tool. 9-5/8"

Running Tool

21. Begin pumping wash fluid, per rig

procedure, through the casing, until Washports

Exposed

returns are clean and free of debris.

22. Continue to pump wash fluid until an 13-3/8"

amount 2 times that of the mudline Running Tool

to surface annular volume has been

displaced.

NOTE: During this process, high pump 13-3/8" Casing

rates and a pressure of between 400 and Hanger

500 psi must be maintained.

23. Once a satisfactory washout is com-

pleted, close the washports by rotat-

ing the landing joint to the left 3 full

turns to a positive stop.

24. Pressure test the casing string

9-5/8" Casing

through the cement head to 80% of Hanger

casing burst pressure or as indi-

cated by the Drilling Supervisor. 13-3/8" Casing

9-5/8" Casing

RP000300

RP-603 WMSW Mudline

Page 16 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 4 9-5/8" Casing

Contingency

Unable to Close Washports on 13-3/8"

Landing Joint

9-5/8" Running Tool or Test Fails

25. Rotate the casing string to the right 9-5/8"

until the Running Tool is released Landing Joint

from the Hanger, this will be a maxi-

mum of 5 turns. (Mark the casing

clearly prior to recovery). The run-

9-5/8"

ning string should be balanced dur-

Running Tool

ing this operation such that the Run-

ning Tool is unloaded.

26. Recover the Running Tool to the

surface visually inspect the seals,

sealing areas and threaded areas.

27. Replace the o-rings. Apply a light

coat of sea water resistant lubri- 13-3/8"

cant. Running Tool

NOTE: Do Not apply Pipe Dope or other

metal based compounds to the Hanger/

Running Tool thread connection. 13-3/8" Casing

Hanger

28. Run the Tapping Tool to clean out

the internal threads in the Hanger, if

the Running Tool Washout port can

not be closed.

29. Rerun the Running Tool on the cas-

ing string torqued to the maximum

allowable torque.

9-5/8" Casing

30. When the Running Tool is 5 feet Hanger

from the Hanger top slow the rate of

descent and stab the Running Tool 13-3/8" Casing

into the Hanger. (Watch the casing

mark carefully)

9-5/8" Casing

31. Land the Running Tool into the

Hanger and rotate 5 turns to the left

RP000301

to a positive stop, balancing the

weight as the Running Tool moves

down such that it is unloaded. It will

take 5 turns to make up.

32. Pressure test the casing string

through the cement head to 80% of

casing burst pressure, or as indi-

cated by the company representa-

tive.

WMSW Mudline RP-603

Running Procedure Page 17

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 4 9-5/8" Casing

Run the Latch Brush/Jetting

Tool 9-5/8" Latch Brush and Jetting Tool

33. Examine the 9-5/8" Latch Brush and

Jetting Tool (Item ST5). Verify the 4-1/2" IF

following:

threads are clean and undam-

aged

jetting ports are clean and un-

obstructed

Jetting Ports

brushes are properly installed

and adequate

latch fingers are properly in- Latch Fingers

stalled and operational

34. Make up a joint of drill pipe to the top

of the Tool.

35. Lower the Tool into the well to the

Retainer Ring

area of the hanger landing profile.

36. Pump wash fluid, per rig procedure,

through the drill pipe and rotate the

Tool.

Brushes

37. Reciprocate the Tool through the

landing profile until the latch fingers

of the Tool identify the profile.

38. Secure the pump and retrieve the

Tool to the rig floor.

NOTE: Ensure the Tool is centered in the RP000307

BOP stack when retrieving so the latch

finger will not be damaged.

39. Clean, grease and store the Tool.

RP-603 WMSW Mudline

Page 18 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 5 7" Casing

Hang Off the Casing

1. Run the 7" casing as required.

7" WMSW Casing

Hanger Running Tool 8.22" Max

2. At a predetermined position in the

casing string, hang off the casing in

the floor slips.

3. Examine the Casing Hanger Run- 9-5/8" Casing

ning Tool (Item ST6). Verify the fol- Thread

lowing:

bore is clean and free of debris 16.12" O-Rings

all seals are clean and undam-

aged

Washport

all threads are clean and un- 5.97"

Min.

damaged

1/2" Pitch LH

washports are clean and unob- Thread

structed

4. Orient the Running Tool with the

running threads down. 8.38" Max

7" WMSW

5. Make up a joint of casing to the top of Casing Hanger

the Tool.

6. Examine the Mudline Hanger (Item

A5). Verify the following:

bore is clean and free of debris

1/2" Pitch LH

latch fingers are properly in- Thread

stalled and operational

all threads are clean and un-

damaged Latching Fingers

Ring

7. Orient the Hanger with the internal 30.12"

running threads up.

5.91"

Min. Shear Ring

and Shear

Pin

Retainer Ring

9-5/8" Casing

Thread

RP000302

WMSW Mudline RP-603

Running Procedure Page 19

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 5 7" Casing

NOTE: The Hanger and Tool will usually be delivered already

made up with casing pup joints made up into each component

and the overall length equivalent to standard casing length.

Always verify, prior to picking up, that the Hanger/Tool connec-

7"

tion is properly made up by verifying that the mark across the Landing Joint

interface is properly aligned. If the mark across the Hanger/

Tool interface is not aligned, disassemble the components

and continue with this procedure.

8. Wipe the running threads of both the Tool and Hanger and 7"

the o-rings of the Tool with a light coat of oil or grease.

Running Tool

WARNING: Do not apply pipe dope or other metal based

compounds to the running threads of either the Tool or Hanger.

9. Make up the Running Tool to the Casing Hanger with left

hand rotation 10 full turns to a positive stop.

10. Install the Hanger/Tool joint into the casing string as a

normal joint would be installed.

11. Lower the hanger and Tool through the BOP stack.

12. Approximately 5 feet from the anticipated landing point,

slow the rate of decent.

13. Land the Hanger on the landing profile of the 9-5/8"

Hanger.

14. Cement as required.

15. If reciprocation is required, with the Hanger fully landed, 7" Casing

make a horizontal mark on the landing joint, level with the Hanger

rig floor.

16. Lift the Hanger approximately 5 feet.

17. Reciprocate the casing as required during cementing, 7"

never allowing the mark on the landing joint to go below the Casing

rig floor.

18. Once cementing operations are complete, land the Hanger

RP000303

on the landing profile of the 9-5/8" Hanger, following the

same procedure as described earlier.

RP-603 WMSW Mudline

Page 20 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 5 7" Casing

19. Immediately following cementing

operations, it is necessary to wash- 9-5/8"

out the annulus. Landing Joint

20. Balancing the string weight, rotate 7"

the landing joint to the right 6 full Landing Joint

turns. This will expose the washports

7"

of the Running Tool.

Running Tool

21. Begin pumping wash fluid, per rig

procedure, through the casing, until

returns are clean and free of debris. Washports

Exposed

22. Continue to pump wash fluid until an

amount 2 times that of the mudline

to surface annular volume has been

displaced.

NOTE: During this process, high pump 9-5/8"

rates and a pressure of between 400 and Running Tool

500 psi must be maintained.

23. Once a satisfactory washout is com-

pleted, close the washports by rotat- 9-5/8" Casing

ing the landing joint to the left 6 full Hanger

turns to a positive stop.

24. Pressure test the casing string

through the cement head to 80% of

casing burst pressure or as indi-

cated by the Drilling Supervisor. 7" Casing

Hanger

9-5/8" Casing

7" Casing

RP000305

WMSW Mudline RP-603

Running Procedure Page 21

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 5 7" Casing

Contingency

Unable to Close Washports on 7" 7"

Running Tool or Test Fails Landing Joint

25. Rotate the casing string to the right 9-5/8"

until the Running Tool is released Landing Joint

from the Hanger, this will be a maxi-

mum of 10 turns. (Mark the casing

clearly prior to recovery). The run-

ning string should be balanced dur-

ing this operation such that the Run-

ning Tool is unloaded. 7"

Running Tool

26. Recover the Running Tool to the

surface visually inspect the seals,

sealing areas and threaded areas.

27. Replace the o-rings. Apply a light

coat of sea water resistant lubri-

cant.

9-5/8"

NOTE: Do Not apply Pipe Dope or other Running Tool

metal based compounds to the Hanger/

Running Tool thread connection.

28. Run the Tapping Tool to clean out 9-5/8" Casing

the internal threads in the Hanger, if Hanger

the Running Tool Washout port can

not be closed.

29. Rerun the Running Tool on the cas-

ing string torqued to the maximum

allowable torque.

7" Casing

30. When the Running Tool is 5 feet Hanger

from the Hanger top slow the rate of

descent and stab the Running Tool

into the Hanger. (Watch the casing

mark carefully) 9-5/8" Casing

31. Land the Running Tool into the 7" Casing

Hanger and rotate 10 turns to the RP000306

left to a positive stop, balancing the

weight as the Running Tool moves

down such that it is unloaded. It will

take 10 turns to make up.

32. Pressure test the casing string

through the cement head to 80% of

casing burst pressure, or as indi-

cated by the company representa-

tive.

RP-603 WMSW Mudline

Page 22 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

System Drawing Stage 2 Temporary Abandonment

20" T.A. Cap

13-3/8"

T.A. Cap

9-5/8"

T.A. Cap

7" T.A. Cap

20" Casing

Hanger

13-3/8" Casing

Hanger

9-5/8" Casing

Hanger

7" Casing

Hanger

RP000321

WMSW Mudline RP-603

Running Procedure Page 23

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 1 7" Casing Temporary Abandonment

Install the Temporary Abandonment Cap

T/A Cap

1. While balancing the string weight, retrieve the 7" Running Tool from the Running Tool

well by rotating the 7" casing to the right, manually, 10 full turns and

pulling the Tool to the rig floor with a straight vertical lift. 4-1/2" IF

2. Clean, grease and store the Tool.

3. Examine the Temporary Abandonment (T/A) Cap Running Tool (Item

ST7). Verify the following:

threads are clean and undamaged

Stinger

stinger is properly installed and secure 18.75"

j-slot is clean and free of debris

4. Make up a joint of drill pipe to the top of the Tool.

5. Examine the Temporary Abandonment (T/A) Cap (Item B4). Verify the

following: Funnel

(for Central-

threads are clean and undamaged ization)

o-rings are properly installed and undamaged

back pressure valve is properly installed

8.39" RP991716

7" T/A Cap

Torque Pin

10.56" 2" BPV

22.00"

8.19" O-Rings

Max

1/2" Pitch LH

Running

Threads

RP000322

RP-603 WMSW Mudline

Page 24 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 1 7" Casing Temporary Abandonment

6. Lower the Tool onto the cap, guiding the torque pin of the

Cap into the J-slots of the Tool.

Drill Pipe

7. Rotate the Tool 15 degrees to the right. This fully engages

the Running Tool onto the Cap.

8. Wipe the threads and o-rings of the Cap with a light coat

of oil or grease.

T.A. Cap

Running Tool

WARNING: Do not apply pipe dope or other metal based

compounds to the running threads of the Cap.

9. Lower the Cap/Tool assembly into the well, approximately

5 feet from the anticipated landing point slow the rate of 7" T.A. Cap

decent.

10. Once the mating threads of the Cap and Hanger have

made contact, balance the string weight and rotate the

landing joint to the left 10 full turns to a positive stop.

11. Using left hand rotation, retrieve the Cap to the rig floor with

a straight vertical lift.

12. Remove the cap form the drill pipe, clean, grease and

store.

RP000323

WMSW Mudline RP-603

Running Procedure Page 25

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 2 9-5/8" Casing Temporary Abandonment

Install the Temporary Abandonment Cap

T/A Cap

1. While balancing the string weight, retrieve the 9-5/8" Running Tool from Running Tool

the well by rotating the 9-5/8" casing to the right, manually, 5 full turns

and pulling the Tool to the rig floor with a straight vertical lift. 4-1/2" IF

2. Clean, grease and store the Tool.

3. Examine the Temporary Abandonment (T/A) Cap Running Tool (Item

ST7). Verify the following:

threads are clean and undamaged

Stinger

stinger is properly installed and secure 18.75"

j-slot is clean and free of debris

4. Make up a joint of drill pipe to the top of the Tool.

5. Examine the Temporary Abandonment (T/A) Cap (Item B3). Verify the

following: Funnel

(for Central-

threads are clean and undamaged ization)

o-rings are properly installed and undamaged

back pressure valve is properly installed

8.39" RP991716

9-5/8" T/A Cap

Torque Pin

2" BPV

11.56"

12.00"

MAX.

36.81"

O-Rings

1" Pitch LH

Running

Threads

RP000324

RP-603 WMSW Mudline

Page 26 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 2 9-5/8" Casing Temporary Abandonment

6. Lower the Tool onto the cap, guiding the torque pin of the

Cap into the J-slots of the Tool.

Drill Pipe

7. Rotate the Tool 15 degrees to the right. This fully engages

the Running Tool onto the Cap.

8. Wipe the threads and o-rings of the Cap with a light coat

of oil or grease.

T.A. Cap

WARNING: Do not apply pipe dope or other metal based Running Tool

compounds to the running threads of the Cap.

9. Lower the Cap/Tool assembly into the well, approximately 9-5/8"

5 feet from the anticipated landing point slow the rate of T.A. Cap

decent.

10. Once the mating threads of the Cap and Hanger have

made contact, balance the string weight and rotate the

landing joint to the left 5 full turns to a positive stop.

11. Using left hand rotation, retrieve the Cap to the rig floor with

a straight vertical lift.

12. Remove the cap form the drill pipe, clean, grease and

store.

RP000325

WMSW Mudline RP-603

Running Procedure Page 27

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 13-3/8" Casing Temporary Abandonment

Install the Temporary Abandonment Cap

T/A Cap

1. While balancing the string weight, retrieve the 13-3/8" Running Tool Running Tool

from the well by rotating the 13-3/8" casing to the right, manually, 5 full

turns and pulling the Tool to the rig floor with a straight vertical lift.

2. Clean, grease and store the Tool.

4-1/2" IF

3. Examine the Temporary Abandonment (T/A) Cap Running Tool (Item

ST7). Verify the following:

threads are clean and undamaged

Stinger

stinger is removed 18.75" (Removed)

j-slot is clean and free of debris

4. Make up a joint of drill pipe to the top of the Tool.

5. Examine the Temporary Abandonment (T/A) Cap (Item B2). Verify the

following: Funnel

(for Central-

threads are clean and undamaged ization)

o-rings are properly installed and undamaged

8.39" RP000215

13-3/8" T/A Cap

Non-Sealing

Torque Pin

13.00"

16.03"

MAX.

Vent Port

55.81"

1" Pitch LH

Running

Threads

RP000326

RP-603 WMSW Mudline

Page 28 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 13-3/8" Casing Temporary Abandonment

6. Lower the Tool onto the cap, guiding the torque pin of the

Cap into the J-slots of the Tool.

Drill Pipe

7. Rotate the Tool 15 degrees to the right. This fully engages

the Running Tool onto the Cap.

8. Wipe the threads and o-rings of the Cap with a light coat

of oil or grease.

T.A. Cap

WARNING: Do not apply pipe dope or other metal based Running Tool

compounds to the running threads of the Cap.

9. Lower the Cap/Tool assembly into the well, approximately

5 feet from the anticipated landing point slow the rate of

decent.

10. Once the mating threads of the Cap and Hanger have

13-3/8"

made contact, balance the string weight and rotate the T.A. Cap

landing joint to the left 5 full turns to a positive stop.

11. Using left hand rotation, retrieve the Cap to the rig floor with

a straight vertical lift.

12. Remove the cap form the drill pipe, clean, grease and

store.

RP000327

WMSW Mudline RP-603

Running Procedure Page 29

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 4 20" Casing Temporary Abandonment

Install the Temporary Abandonment Cap

T/A Cap

1. While balancing the string weight, retrieve the 20" Running

Tool from the well by rotating the 20" casing to the right,

Running Tool

manually, 5 full turns and pulling the Tool to the rig floor with

a straight vertical lift.

2. Clean, grease and store the Tool.

3. Examine the Temporary Abandonment (T/A) Cap Run- 4-1/2" IF

ning Tool (Item ST7). Verify the following:

threads are clean and undamaged

stinger is removed

j-slot is clean and free of debris Stinger

18.75" (Removed)

4. Make up a joint of drill pipe to the top of the Tool.

20" T/A Cap

Non-Sealing

Torque Pin

Funnel

13.00"

(for Central-

ization)

Vent Port

8.39" RP000215

5. Examine the Temporary Abandonment (T/A) Cap (Item

B1). Verify the following:

threads are clean and undamaged

o-rings are properly installed and undamaged

75.87"

22.65" MAX.

1" Pitch LH

Running

Threads

RP000328

RP-603 WMSW Mudline

Page 30 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 4 20" Casing Temporary Abandonment

6. Lower the Tool onto the cap, guiding

the torque pin of the Cap into the J-

slots of the Tool. Drill Pipe

7. Rotate the Tool 15 degrees to the

right. This fully engages the Run-

ning Tool onto the Cap.

8. Wipe the threads and o-rings of the

Cap with a light coat of oil or grease. T.A. Cap

Running Tool

WARNING: Do not apply pipe dope or

other metal based compounds to the

running threads of the Cap.

9. Lower the Cap/Tool assembly into

the well, approximately 5 feet from

the anticipated landing point slow

the rate of decent.

10. Once the mating threads of the Cap

and Hanger have made contact,

balance the string weight and rotate

the landing joint to the left 5 full turns

to a positive stop.

11. Using left hand rotation, retrieve the

Cap to the rig floor with a straight

vertical lift. 20" T.A. Cap

12. Remove the cap form the drill pipe,

clean, grease and store.

RP000329

WMSW Mudline RP-603

Running Procedure Page 31

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

System Drawing Stage 3 Tieback

20"

Tieback Tool

13-3/8"

Tieback Tool

9-5/8"

Tieback Tool

7"

Tieback Tool

20" Casing

Hanger

13-3/8" Casing

Hanger

9-5/8" Casing

Hanger

7" Casing

Hanger

RP000330

RP-603 WMSW Mudline

Page 32 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 1 20" Casing Tieback

Cleanout Procedure

24" Cleanout Tool 4-1/2" IF

1. Examine the Cleanout Tool (Item

ST8). Verify the following:

bore is clean and free of debris

all threads are clean and un- Junk Basket

damaged

28.25"

24.00"

96.25"

80.00"

23.00"

RP000331

WMSW Mudline RP-603

Running Procedure Page 33

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 1 20" Casing Tieback

2. Make up a joint of drill pipe to the top of the Cleanout Tool. Wash Out Through

Drill Pipe

3. Lower the Tool until it lands on the top of the 20" Hanger.

4. Lift the Tool approximately 1" to 2" off the top of the 20"

Landing Joint

hanger.

5. Pump wash fluid through the drill pipe per rig procedure

while rotating the Tool.

6. Secure the pump and retrieve the Tool to the rig floor.

24" Cleanout

Tool

7. Check the junk basket for debris.

8. Remove all debris from the junk basket.

9. Rerun the Cleanout Tool and repeat this procedure until

no more debris is retrieved in the basket.

10. Remove the Cleanout Tool from the drill string, clean,

grease and store.

20" T.A. Cap

20" Hanger

RP000332

RP-603 WMSW Mudline

Page 34 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 1 20" Casing Tieback

Remove the Abandonment Cap

11. Examine the T/A Cap Running Tool and remove the inter-

nal stinger. T.A. Cap

Running Tool

12. Make up the T/A Cap running tool to drill pipe.

13. Lower the Tool to approximately 5 feet above the Cap,

slow the rate of decent until the Tool tags the Cap.

14. Once the Tool is landed on the cap, rotate 15 degrees to

the right. This fully engages the running tool onto the

Cap.

15. Keeping the casing string balanced such that the run-

ning thread is unloaded, rotate drill string to right a mini-

mum of 5 turns. This will disengage the Cap from the

Hanger.

16. Upon completion, lift the Running Tool to the rig floor with

a straight pull.

17. Remove the Cap and Tool from the drill string, clean, 20" T.A. Cap

grease and store.

RP000333

WMSW Mudline RP-603

Running Procedure Page 35

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 1 20" Casing Tieback

Tap the Running Threads

20" Tap Tool

NOTE: The need for the Tap Tool is only

in the event that there was a problem in

retrieving the T/A Cap or if the Tieback

Tool will not make up into the Hanger.

18. Examine the 20" Tap Tool (Item ST9). 4-1/2" IF

Verify the following:

bore is clean and free of debris

all threads are clean and un-

damaged

79.19"

22.65" MAX

1" Pitch LH

Thread

RP000334

RP-603 WMSW Mudline

Page 36 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 1 20" Casing Tieback

19. Make up a joint of drill pipe to the top

of the Tool.

20. Lower the Tool slowing the rate of 20" Landing

decent approximately 5 feet from the Joint

top of the 20" Hanger.

21. While balancing the string weight,

rotate the Tool gently to the left, using

a back and forth motion, 5 full turns

while pumping wash fluid through

the drill pipe to remove any debris

trapped in the threads.

22. Once the tool has rotated the 5 turns

to a positive stop, begin to rotate

back to the right, manually, continu-

ing to pump wash fluid to remove any

20" Tapping

debris. Tool

NOTE: Once the Tool clears the Hanger

it will turn freely.

23. Secure the pump and retrieve the

Tool to the rig floor.

24. Remove the Tool from the drill string,

clean, grease and store.

20" Hanger

RP000335

WMSW Mudline RP-603

Running Procedure Page 37

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 1 20" Casing Tieback

Install the Tieback Tool 20" WMSW Tieback Tool

25. Examine the Tieback Tool (Item C1). Verify the following: 21.91" Max

bore is clean and free of debris

20" Casing Thread

all seals are clean and undamaged

all threads are clean and undamaged O-Ring

26. Make up a joint of casing to the top of the Tieback Tool. 17.25"

27. Wipe the seals on the OD of the Tool with a light coat of oil

or grease. 1" Pitch LH

18.87" Max Thread

WARNING: Do not apply pipe dope or other metal based

compounds to the tieback threads of either the Tool or Hanger. RP000336

28. Lower the Tool slowing the rate of decent approximately 5

feet from the top of the 20" Hanger.

29. While balancing the string weight, rotate the Tool gently to

the left 5 full turns to a positive stop.

30. Apply pressure, per rig procedure, to the ID of the 20"

casing to 80% of casing burst maximum.

20" Landing

31. Once a satisfactory test is achieved, install surface equip- Joint

ment as required.

20" Tieback

Tool

RP000337

RP-603 WMSW Mudline

Page 38 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 2 13-3/8" Casing Tieback

Remove the Abandonment

Cap

1. Examine the T/A Cap Running Tool

T.A. Cap

and ensure the internal stinger is Running Tool

removed.

2. Make up the T/A Cap running tool to

drill pipe.

3. Lower the Tool to approximately 5

feet above the Cap, slow the rate of

decent until the Tool tags the

Hanger.

4. Once the Tool is landed on the cap,

rotate 15 degrees to the right. This

fully engages the running tool onto

the Cap.

5. Keeping the casing string balanced

such that the running thread is un-

loaded, rotate drill string to right a 13-3/8"

minimum of 5 turns. This will dis- T.A. Cap

engage the Cap from the Hanger.

6. Upon completion, lift the Running

Tool to the rig floor with a straight

pull.

7. Remove the Cap and Tool from the

drill string, clean, grease and store.

20" Tieback

Tool

RP000338

WMSW Mudline RP-603

Running Procedure Page 39

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 2 13-3/8" Casing Tieback

Tap the Running Threads

13-3/8" Tap Tool

NOTE: The need for the Tap Tool is only in the event that there

was a problem in retrieving the T/A Cap or if the Tieback Tool

will not make up into the Hanger.

8. Examine the 13-3/8" Tap Tool (Item ST10). Verify the 4-1/2" IF

following:

bore is clean and free of debris

all threads are clean and undamaged

9. Make up a joint of drill pipe to the top of the Tool.

62.62"

16.41" MAX

1" Pitch LH

Thread

RP000339

RP-603 WMSW Mudline

Page 40 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 2 13-3/8" Casing Tieback

10. Lower the Tool slowing the rate of decent approximately 5

feet from the top of the 13-3/8" Hanger.

Drill Pipe

11. While balancing the string weight, rotate the Tool using a

back and forth motion, gently to the left 5 full turns while

pumping wash fluid through the drill pipe to remove any

debris trapped in the threads.

12. Once the tool has rotated the 5 turns to a positive stop,

begin to rotate back to the right, manually, continuing to

pump wash fluid to remove any debris.

NOTE: Once the Tool clears the Hanger it will turn freely.

13. Secure the pump and retrieve the Tool to the rig floor.

14. Remove the Tool from the drill string, clean, grease and

store. 13-3/8"

Tap Tool

13-3/8"

Hanger

RP000340

WMSW Mudline RP-603

Running Procedure Page 41

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 2 13-3/8" Casing Tieback

Install the Tieback Tool

13-3/8" WMSW Tieback Tool

15. Examine the Tieback Tool (Item C2). Verify the following:

bore is clean and free of debris 15.15" Max

all seals are clean and undamaged

13-3/8"

all threads are clean and undamaged Casing Thread

16. Make up a joint of casing to the top of the Tieback Tool.

O-Ring

17. Wipe the seals on the OD of the Tool with a light coat of oil

16.50"

or grease.

WARNING: Do not apply pipe dope or other metal based

compounds to the tieback threads of either the Tool or Hanger. 12.74" Min 1" Pitch LH

Threads

18. Lower the Tool slowing the rate of decent approximately 5

feet from the top of the 13-3/8" Hanger. RP000341

19. While balancing the string weight, rotate the Tool gently to

the left 5 full turns to a positive stop.

20. Apply pressure, per rig procedure, to the ID of the 13-3/8"

casing to 80% of casing burst maximum.

21. Once a satisfactory test is achieved, install surface equip-

ment as required.

13-3/8"

Tieback Tool

13-3/8"

Hanger

RP000342

RP-603 WMSW Mudline

Page 42 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 9-5/8" Casing Tieback

Remove the Abandonment

Cap

1. Examine the T/A Cap Running Tool T.A. Cap

and ensure the internal stinger is Running Tool

properly installed.

2. Make up the T/A Cap running tool to

drill pipe.

3. Lower the tool to approximately 5 9-5/8"

feet above the Cap, slow the rate of T.A. Cap

decent until the Tool tags the

Hanger.

4. Once the Tool is landed on the cap,

rotate 15 degrees to the right. This

fully engages the running tool onto

the Cap.

5. Keeping the casing string balanced

such that the running thread is un-

loaded, rotate drill string to right a

minimum of 5 turns. This will dis-

engage the Cap from the Hanger.

6. Upon completion, lift the Running

Tool to the rig floor with a straight

pull.

7. Remove the Cap and Tool from the

drill string, clean, grease and store.

9-5/8"

Hanger

RP000343

WMSW Mudline RP-603

Running Procedure Page 43

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 9-5/8" Casing Tieback

Tap the Running Threads

9-5/8" Tap Tool

NOTE: The need for the Tap Tool is only in the event that there

was a problem in retrieving the T/A Cap or if the Tieback Tool

will not make up into the Hanger.

8. Examine the 9-5/8" Tap Tool (Item ST11). Verify the follow- 4-1/2" IF

ing:

bore is clean and free of debris

all threads are clean and undamaged

9. Make up a joint of drill pipe to the top of the Tool.

56.93"

12.00"

MAX

1" Pitch LH

Thread

RP000344

RP-603 WMSW Mudline

Page 44 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 9-5/8" Casing Tieback

10. Lower the Tool slowing the rate of decent approximately 5

feet from the top of the 9-5/8" Hanger.

11. While balancing the string weight, rotate the Tool using a

back and forth motion, gently to the left 5 full turns while

pumping wash fluid through the drill pipe to remove any

debris trapped in the threads. 9-5/8"

Tap Tool

12. Once the tool has rotated the 5 turns to a positive stop,

begin to rotate back to the right, manually, continuing to

pump wash fluid to remove any debris.

NOTE: Once the Tool clears the Hanger it will turn freely.

13. Secure the pump and retrieve the Tool to the rig floor.

14. Remove the Tool from the drill string, clean, grease and

store.

9-5/8"

Hanger

RP000345

WMSW Mudline RP-603

Running Procedure Page 45

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 9-5/8" Casing Tieback

Install the Tieback Tool 9-5/8" WMSW Tieback Tool

15. Examine the Tieback Tool (Item C3). Verify the following:

11.41" Max

bore is clean and free of debris

all seals are clean and undamaged

9-5/8" Casing

all threads are clean and undamaged Thread

16. Make up a joint of casing to the top of the Tieback Tool.

16.44"

17. Wipe the seals on the OD of the Tool with a light coat of oil O-Rings

or grease.

WARNING: Do not apply pipe dope or other metal based

compounds to the tieback threads of either the Tool or Hanger. 8.82" Min 1" Pitch LH

Thread

18. Lower the Tool slowing the rate of decent approximately 5 RP000346

feet from the top of the 9-5/8" Hanger.

19. While balancing the string weight, rotate the Tool gently to

the left 5 full turns to a positive stop.

20. Apply pressure, per rig procedure, to the ID of the 9-5/8""

casing to 80% of casing burst maximum.

9-5/8"

21. Once a satisfactory test is achieved, install surface equip- Tieback Tool

ment as required.

9-5/8"

Hanger

RP000347

RP-603 WMSW Mudline

Page 46 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 7" Casing Tieback

Remove the Abandonment

Cap

1. Examine the T/A Cap Running Tool T.A. Cap

and ensure the internal stinger is Running Tool

properly installed.

2. Make up the T/A Cap running tool to

drill pipe.

3. Lower the Tool to approximately 5

feet above the Cap, slow the rate of 7" T.A. Cap

decent until the Tool tags the

Hanger.

4. Once the Tool is landed on the cap,

rotate 15 degrees to the right. This

fully engages the running tool onto

the Cap.

5. Keeping the casing string balanced

such that the running thread is un-

loaded, rotate drill string to right a

minimum of 10 turns. This will dis-

engage the Cap from the Hanger.

7" Casing

6. Upon completion, lift the Running Hanger

Tool to the rig floor with a straight

pull.

7. Remove the Cap and Tool from the

drill string, clean, grease and store.

RP000348

WMSW Mudline RP-603

Running Procedure Page 47

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 7" Casing Tieback

Tap the Running Threads

NOTE: The need for the Tap Tool is only in the event that there

7" Tap Tool

was a problem in retrieving the T/A Cap or if the Tieback Tool

will not make up into the Hanger.

8. Examine the 7" Tap Tool (Item ST12). Verify the following:

bore is clean and free of debris 4-1/2" IF

all threads are clean and undamaged

9. Make up a joint of drill pipe to the top of the Tool.

31.18"

8.18"

MAX

1/2" Pitch LH

Thread

RP000349

RP-603 WMSW Mudline

Page 48 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 7" Casing Tieback

10. Lower the Tool slowing the rate of decent approximately 5

feet from the top of the 7" Hanger.

11. While balancing the string weight, rotate the Tool using a

back and forth motion, gently to the left 10 full turns while

7" Tap Tool

pumping wash fluid through the drill pipe to remove any

debris trapped in the threads.

12. Once the tool has rotated the 10 turns to a positive stop,

begin to rotate back to the right, manually, continuing to

pump wash fluid to remove any debris.

NOTE: Once the Tool clears the Hanger it will turn freely.

13. Secure the pump and retrieve the Tool to the rig floor.

14. Remove the Tool from the drill string, clean, grease and

store.

7" Casing

Hanger

RP000350

WMSW Mudline RP-603

Running Procedure Page 49

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Section 3 7" Casing Tieback

Install the Tieback Tool 7" WMSW Tieback Tool

15. Examine the Tieback Tool (Item C4). Verify the following:

8.22" Max

bore is clean and free of debris

all seals are clean and undamaged

all threads are clean and undamaged 7" Casing

Thread

16. Make up a joint of casing to the top of the Tieback Tool.

17. Wipe the seals on the OD of the Tool with a light coat of oil

or grease. 16.12" O-Rings

WARNING: Do not apply pipe dope or other metal based

compounds to the tieback threads of either the Tool or Hanger.

5.97"

18. Lower the Tool slowing the rate of decent approximately 5 Min. 1/2" Pitch LH

feet from the top of the 7" Hanger. Thread

19. While balancing the string weight, rotate the Tool gently to RP000351

the left 10 full turns to a positive stop.

20. Apply pressure, per rig procedure, to the ID of the 7"" casing

to 80% of casing burst maximum.

21. Once a satisfactory test is achieved, install surface equip-

ment as required.

7"

Tieback Tool

7" Casing

Hanger

RP000371

RP-603 WMSW Mudline

Page 50 Running Procedure

30" x 20" x 13-3/8" x 9-5/8" x 7" Casing Program

Das könnte Ihnen auch gefallen

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsVon EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNoch keine Bewertungen

- Vetco Mud Line HangerDokument39 SeitenVetco Mud Line HangerAnh Tuan Nguyen100% (1)

- Bop Test Info PDFDokument18 SeitenBop Test Info PDFjairaso2950Noch keine Bewertungen

- Casing and Liners for Drilling and Completion: Design and ApplicationVon EverandCasing and Liners for Drilling and Completion: Design and ApplicationBewertung: 5 von 5 Sternen5/5 (3)

- 2 JFE BEAR Design FeatureDokument15 Seiten2 JFE BEAR Design FeatureDaniel ChiriacNoch keine Bewertungen

- Shear CapacitiesDokument7 SeitenShear CapacitiesGlen Ashwell100% (2)

- Casing String and SuspensionDokument26 SeitenCasing String and SuspensionJaimin PrajapatiNoch keine Bewertungen

- 01-Conventional - Casing HeadsDokument61 Seiten01-Conventional - Casing HeadsChairul AbdiNoch keine Bewertungen

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersVon EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersNoch keine Bewertungen

- Ratings Packers PDFDokument10 SeitenRatings Packers PDFsabilco13Noch keine Bewertungen

- VersaFlex LinerDokument19 SeitenVersaFlex LinerKHALEDFEKAIR100% (1)

- SPE Rig SelectionDokument8 SeitenSPE Rig SelectionEyoma EtimNoch keine Bewertungen

- Best Practices Drilling 26 inDokument6 SeitenBest Practices Drilling 26 inmanuelperdomotNoch keine Bewertungen

- BH Liner HangerDokument9 SeitenBH Liner HangerzhiqianxuNoch keine Bewertungen

- Final Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Dokument21 SeitenFinal Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Nipple Up-Down BopDokument6 SeitenNipple Up-Down Bopsanjeet giri100% (2)

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Dokument3 SeitenDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNoch keine Bewertungen

- Strength of Casing and Tubing - PetroWiki PDFDokument15 SeitenStrength of Casing and Tubing - PetroWiki PDFLuis David Concha CastilloNoch keine Bewertungen

- W W W W Wood Group Pressure Control Ood Group Pressure Control Ood Group Pressure Control Ood Group Pressure Control Ood Group Pressure ControlDokument17 SeitenW W W W Wood Group Pressure Control Ood Group Pressure Control Ood Group Pressure Control Ood Group Pressure Control Ood Group Pressure ControlilkerkozturkNoch keine Bewertungen

- Gas Well Status Diagram (1) (Version 1)Dokument6 SeitenGas Well Status Diagram (1) (Version 1)Olaoluwa OlatonaNoch keine Bewertungen

- Section 2e - RTTS PackersDokument118 SeitenSection 2e - RTTS Packerswee zoo100% (1)

- Casing DesignDokument8 SeitenCasing DesignJason Bash100% (1)

- Shts & RPSB, HPSRDokument8 SeitenShts & RPSB, HPSRAyman100% (1)

- Vetco MLC Mudline Operating and Service ProcedureDokument40 SeitenVetco MLC Mudline Operating and Service Procedurecrni rokoNoch keine Bewertungen

- 5 Liner HangersDokument26 Seiten5 Liner HangersAjar Waspodo50% (2)

- SC-90 Conventional Surface Wellhead System PDFDokument12 SeitenSC-90 Conventional Surface Wellhead System PDFErcan YilmazNoch keine Bewertungen

- Ttt2b Drillable TlsDokument26 SeitenTtt2b Drillable TlsMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Aluminum Alloy Drill PipeDokument20 SeitenAluminum Alloy Drill PipeMark Garrett100% (1)

- Casing DesignDokument10 SeitenCasing DesignAry Rachman0% (1)

- 0620000008Dokument6 Seiten0620000008mahsaNoch keine Bewertungen

- Lesson 5A - The Drilling RiserDokument30 SeitenLesson 5A - The Drilling RisernaefmubarakNoch keine Bewertungen

- BHA Tally: Customer: Well Name: Job Number: Drillstring IADC Rig BHA# 0100 Run# 100Dokument2 SeitenBHA Tally: Customer: Well Name: Job Number: Drillstring IADC Rig BHA# 0100 Run# 100Animesh ChoudharyNoch keine Bewertungen

- Superior Packer Setting ProceduereDokument10 SeitenSuperior Packer Setting ProcedueretarangtusharNoch keine Bewertungen

- Service Tools Test Tools USA Manual Best Practices PDFDokument45 SeitenService Tools Test Tools USA Manual Best Practices PDFahmedhussien1Noch keine Bewertungen

- Plug Setting Tool and Junk Basket: Purpose of The ServiceDokument15 SeitenPlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806Noch keine Bewertungen

- Casing ThreadsDokument7 SeitenCasing ThreadsNaser KhanNoch keine Bewertungen

- Fishing ToolsDokument10 SeitenFishing Toolsdanarkurniadi123Noch keine Bewertungen

- Logan Oil Tools String-Book PDFDokument123 SeitenLogan Oil Tools String-Book PDFDon Braithwaite100% (1)

- Cameron Drilling Products Overview CatalogDokument587 SeitenCameron Drilling Products Overview CatalogJayro LeninNoch keine Bewertungen

- HeavyWeight 3.5 25.58lbs NC-38Dokument3 SeitenHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNoch keine Bewertungen

- Workover Procedure For HCE-30A (If Fishing Success by CTU) PDFDokument27 SeitenWorkover Procedure For HCE-30A (If Fishing Success by CTU) PDFfitriyanto ahmadNoch keine Bewertungen

- Storm PackerDokument38 SeitenStorm PackerJay T. Yong100% (1)

- Liner Tie-Back StringDokument1 SeiteLiner Tie-Back StringYougchu LuanNoch keine Bewertungen

- Casing ModuleDokument12 SeitenCasing ModuleFarahKhanJamaliNoch keine Bewertungen

- Asi-X Packer: DescriptionDokument5 SeitenAsi-X Packer: DescriptionPARAGNoch keine Bewertungen

- Liner OperationDokument22 SeitenLiner OperationHosam Ali100% (1)

- DOX Generated Default BHADokument1 SeiteDOX Generated Default BHAEl que lo peta CordovaNoch keine Bewertungen

- Casing HangerDokument2 SeitenCasing Hangerandreinicusor1958-1Noch keine Bewertungen

- Camaron Ann BOPDokument24 SeitenCamaron Ann BOPBiswajyoti Bora50% (2)

- BHA StabilizationDokument14 SeitenBHA StabilizationenantioagaNoch keine Bewertungen

- Well Barrier Gas Lifted ProducerDokument2 SeitenWell Barrier Gas Lifted Producerdragan2507Noch keine Bewertungen

- Inline Tech UnitDokument3 SeitenInline Tech UnitMohamed Mahmoud Rezk Dimo100% (1)

- 20 in Surf - 94 PPFDokument12 Seiten20 in Surf - 94 PPFAnonymous XbmoAFtINoch keine Bewertungen

- 2014 TUBING Reference Tables: Listings For Pipe Sizes To 5 - In. OdDokument28 Seiten2014 TUBING Reference Tables: Listings For Pipe Sizes To 5 - In. OdOMSD-01 OPMNoch keine Bewertungen

- F-S Divertor PDFDokument174 SeitenF-S Divertor PDFJohn NorrieNoch keine Bewertungen

- Hassan Abdel-Aziz Galal Abdel-Aal: ContactDokument2 SeitenHassan Abdel-Aziz Galal Abdel-Aal: ContactMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Avg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Dokument1 SeiteAvg Downhole Losses: 4 BBLS/HR.: G.P.C Daily Drilling Report Att. Eastern Desert Rig Heading: 206°Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Drillsim PDFDokument4 SeitenDrillsim PDFMahmoud Ahmed Ali Abdelrazik0% (1)

- 6 - Stability Sign ConventionsDokument2 Seiten6 - Stability Sign ConventionsMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Ades - Admarine III - We019 Issued 26-03-2018 at 0401 LTDokument3 SeitenAdes - Admarine III - We019 Issued 26-03-2018 at 0401 LTMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Daily HSE Summary Report 25-03-2018Dokument1 SeiteDaily HSE Summary Report 25-03-2018Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Daily HSE Summary Report 26-03-2018Dokument1 SeiteDaily HSE Summary Report 26-03-2018Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Daily HSE Summary Report 27-03-2018Dokument1 SeiteDaily HSE Summary Report 27-03-2018Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Ades - Admarine III - We019 Issued 27-03-2018 at 0401 LTDokument3 SeitenAdes - Admarine III - We019 Issued 27-03-2018 at 0401 LTMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Daily HSE Summary Report 28-03-2018Dokument1 SeiteDaily HSE Summary Report 28-03-2018Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Trip Sheet: Following Data Is AvailableDokument2 SeitenTrip Sheet: Following Data Is AvailableMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- HSE Sept 15Dokument2 SeitenHSE Sept 15Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- BHA #2 Length in FT Cum Length in FTDokument1 SeiteBHA #2 Length in FT Cum Length in FTMahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Workover Operations (Ok)Dokument6 SeitenWorkover Operations (Ok)Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Rig Equipment (Ok)Dokument25 SeitenRig Equipment (Ok)Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Daily HSE Summary Report 28-03-2018Dokument1 SeiteDaily HSE Summary Report 28-03-2018Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Cementing Sept 15 (Ok)Dokument2 SeitenCementing Sept 15 (Ok)Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- SR.11.10961 - Sour Well Design GuideDokument52 SeitenSR.11.10961 - Sour Well Design GuideMahmoud Ahmed Ali Abdelrazik100% (1)

- Casing Design Sept 15 (Ok)Dokument5 SeitenCasing Design Sept 15 (Ok)Mahmoud Ahmed Ali AbdelrazikNoch keine Bewertungen

- Incident Classification and ReportingDokument56 SeitenIncident Classification and ReportingMahmoud Ahmed Ali Abdelrazik100% (2)

- TS12 - Standard EPE Wells - Well Abandonment - Mar 2009Dokument18 SeitenTS12 - Standard EPE Wells - Well Abandonment - Mar 2009Mahmoud Ahmed Ali Abdelrazik100% (1)

- Basic Hydraulics and Pneumatics: Module 1: Introduction To HydraulicsDokument42 SeitenBasic Hydraulics and Pneumatics: Module 1: Introduction To HydraulicsKevin ArteagaNoch keine Bewertungen

- Basic Setting Out in ConstructionDokument4 SeitenBasic Setting Out in ConstructionRambabu100% (1)