Beruflich Dokumente

Kultur Dokumente

Get A Lean Certification

Hochgeladen von

Ramón G. PachecoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Get A Lean Certification

Hochgeladen von

Ramón G. PachecoCopyright:

Verfügbare Formate

CAREER

CORNER

Get a Lean Certification

by Greg Hutchins

H

ere is possibly the most impor- with more than 1,100 industry respon- Whats in It for You?

tant career tip you will hear this dents. The survey results are stun- The job numbers are stunning. I

year: Get leancertification, ning:2 think as many as 40% of us will be

that is. A likelihood of pursuing lean cer- itinerant professionals within a few

First, read up on lean in the June tification was indicated by 77%. years, moving from job to job. Our

2005 Quality Progress, which offered Lean certification was critical, personal differentiator and added

great introductory articles on lean very important or important value in the consulting marketplace

along with a glossary of basic lean according to 83%. will be the knowledge we have and

terms. Then consider the new lean cer- Key lean leaders at their supplier the abilities we offer an employer.

tification being developed by three companies should earn lean cer- So, what is in it for you to get lean

organizations. tification, according to 60%. certified? It comes down to personal

So, what is lean? Lean manufactur- marketability and personal brand

ing is a set of simple, doable and equity. The certification should be

proven tools. Process/project lean is a your bottom-line career management

continuous improvement mind-set. Three organizations tool. Lean should be covered in every

Lean enterprise is a way of doing busi- professional workshop, certification

ness. As lean has morphed from a tool are collaborating on a and career development offering you

set into an enterprise solution, so has consider.

its real and perceived value. new industry standard.

In addition to enhancing your

knowledge, skills, marketability, per-

Whats Different Now?

sonal brand equity and added value,

Lean has been around for 40 years, the lean certification will most certain-

but only in the last year has it reached The Society of Manufacturing ly add to your earnings potential.

its tipping point, gaining critical mass Engineers, Assn. for Manufacturing

and exploding. Excellence and Shingo Prize for REFERENCES

Organizations see what works, then Excellence in Manufacturing decided 1. Jack Welch with Suzy Welch, Winning,

follow the herd. Todays mega, global to collaborate on a new industry stan- HarperCollins Publishers, 2005.

2. SME, AME and the Shingo Prize Launch

success story is Toyota. The compa- dard for lean certification, scheduled New Standard for Lean Certification, news

nys management was prescient, for launch in the fourth quarter of release, April 28, 2005, www.sme.org/cgi-bin/

anticipating markets such as com- 2005.3 smenews.pl?/memb/smenews/sn0605index.

htm&200506&snews&.

pacts and hybrids. Toyota has the Think lean White, Yellow, Green, 3. Ibid.

most efficient manufacturing opera- Black and Master Black Beltsthe 4. Ibid.

tions in the world. It has strong brand same as Six Sigma. With hundreds of

equity. Toyotas top line, bottom line Six Sigma training programs and certi- GREG HUTCHINS is an engineering principal

and cash reserves are the envy of fications offered, the challenge for with Quality Plus Engineering and Lean SCM

alland it did all this largely through everyone has been to determine which in Portland, OR. He is a member of ASQ.

lean. offered real value. A credible certifica-

Every movement also needs an tion should be much more than simply

experta visionary to sing its praises getting a ticket punched through tak-

to the world. Jack Welch, former ing a test. To be credible, a certification

General Electric CEO, has been on the needs to be robust and provable.

speaking circuit talking up his recent The new lean certification will have

book, Winning. 1 The leaning of three critical elements that will enhance

American companies is his prescrip- its credibility and acceptance:4 Please

tion for improvement. Remember how 1. An examination that assesses comment

he extolled Six Sigma 10 years ago, and knowledge of lean principles. If you would like to comment on

it exploded. 2. Mentoring of certification candi-

this article, please post your remarks

dates.

Certification on the Quality Progress Discussion

3. A portfolio that illustrates how

The definitive need to create a cre- lean principles were applied Board at www.asq.org, or e-mail

dentialing process for lean manufac- within an organization and doc- them to editor@asq.org.

turing certification was based on a uments the results achieved and

survey conducted a few months ago, lessons learned.

90 I SEPTEMBER 2005 I www.asq.org

Das könnte Ihnen auch gefallen

- CIPS Global Standard UK 4.0 May 2021Dokument96 SeitenCIPS Global Standard UK 4.0 May 2021Kennedy MuneneNoch keine Bewertungen

- Business and Consulting Toolkits - SampleDokument114 SeitenBusiness and Consulting Toolkits - Samplepablors86% (7)

- Using Cost of Quality To Improve Business ResultsDokument4 SeitenUsing Cost of Quality To Improve Business ResultsMiguel BradshawNoch keine Bewertungen

- Bruxism Hypnosis Script No. 2Dokument12 SeitenBruxism Hypnosis Script No. 2Eva Jacinto100% (2)

- MGEC06 Topics in Macroeconomic Theory (Intermediate Macroeconomics II) Summer 2020Dokument6 SeitenMGEC06 Topics in Macroeconomic Theory (Intermediate Macroeconomics II) Summer 2020Mick MendozaNoch keine Bewertungen

- AN6001-G16 Optical Line Terminal Equipment Product Overview Version ADokument74 SeitenAN6001-G16 Optical Line Terminal Equipment Product Overview Version AAdriano CostaNoch keine Bewertungen

- Arc Studio ReviewerDokument62 SeitenArc Studio ReviewerKristine100% (1)

- 413 14 Speakout Upper Intermediate 2nd Tests With Key and ScriptDokument158 Seiten413 14 Speakout Upper Intermediate 2nd Tests With Key and ScriptHal100% (2)

- World Class Service Delivery: Kanthi Basnayake Management ConsultantDokument39 SeitenWorld Class Service Delivery: Kanthi Basnayake Management ConsultantChandani Kanthi BasnayakeNoch keine Bewertungen

- DI - Digital Transformation 7Dokument16 SeitenDI - Digital Transformation 7t_maskNoch keine Bewertungen

- Kinduz Lean Six Sigma Green Belt PDFDokument14 SeitenKinduz Lean Six Sigma Green Belt PDFNirmal mehtaNoch keine Bewertungen

- Six Sigma Guide: Using Quality To Define Process and ProductionDokument13 SeitenSix Sigma Guide: Using Quality To Define Process and ProductionReda KhanfarNoch keine Bewertungen

- Shell Graduate Programe and Assessed InternshipDokument20 SeitenShell Graduate Programe and Assessed InternshipBor Bor GamingNoch keine Bewertungen

- Risk Management by Protiviti X MentorKartDokument14 SeitenRisk Management by Protiviti X MentorKartShubam VermaNoch keine Bewertungen

- Henkel: Building A Wining CultureDokument17 SeitenHenkel: Building A Wining Cultureswagatika100% (1)

- Risk ManagementDokument15 SeitenRisk ManagementVikasNoch keine Bewertungen

- State0fScrum 2016 FINALDokument31 SeitenState0fScrum 2016 FINALabirami.narayanan857Noch keine Bewertungen

- New Product Development Research PaperDokument6 SeitenNew Product Development Research Papert1s1gebes1d3100% (1)

- Post Graduate Program in Product ManagementDokument16 SeitenPost Graduate Program in Product ManagementSushil KumarNoch keine Bewertungen

- Material For Student BMCPC™ (V102021A) ENDokument89 SeitenMaterial For Student BMCPC™ (V102021A) ENApril OxoxNoch keine Bewertungen

- Coaching For Excellence Course 1 - 11062014Dokument17 SeitenCoaching For Excellence Course 1 - 11062014Johanna Andrea DE CASTRO SALASNoch keine Bewertungen

- Research Paper On Iso 9000Dokument5 SeitenResearch Paper On Iso 9000uzmlivznd100% (1)

- Thesis Iso 9001Dokument6 SeitenThesis Iso 9001b0sus1hyjaf2100% (2)

- World Class Service Delivery NewDokument39 SeitenWorld Class Service Delivery NewChandani Kanthi BasnayakeNoch keine Bewertungen

- Company Overview:: Human Capital Solutions Business ServicesDokument6 SeitenCompany Overview:: Human Capital Solutions Business ServicesDipanshu Dey I H21O77Noch keine Bewertungen

- Establishing A Brand ScorecardDokument8 SeitenEstablishing A Brand ScorecardDemand MetricNoch keine Bewertungen

- Audit Risk Oct 2023 1712415584Dokument63 SeitenAudit Risk Oct 2023 1712415584aliNoch keine Bewertungen

- Acca BSC Thesis TopicsDokument8 SeitenAcca BSC Thesis TopicsCheapestPaperWritingServiceCanada100% (1)

- MBQNADokument68 SeitenMBQNAstraf238Noch keine Bewertungen

- LD Best Practices White Paper FinalDokument11 SeitenLD Best Practices White Paper FinalVeronicaNoch keine Bewertungen

- Executive Summary - The Core CompetenciesDokument15 SeitenExecutive Summary - The Core CompetenciesBima Bramantiya PutraNoch keine Bewertungen

- MindTickle Viewpoint Case Study 2018 FinalDokument2 SeitenMindTickle Viewpoint Case Study 2018 Finalppkppk789Noch keine Bewertungen

- NikeDokument10 SeitenNikeRashmi KumariNoch keine Bewertungen

- 5 Simple Actions For Product Managers To Move Towards Product MasteryDokument12 Seiten5 Simple Actions For Product Managers To Move Towards Product MasteryGaurav KatholeNoch keine Bewertungen

- 10 Chapter 4Dokument24 Seiten10 Chapter 4StuartNoch keine Bewertungen

- Individual Project On OSDB: Analyzing The Organization,: Colgate Palmolive (I) LTDDokument8 SeitenIndividual Project On OSDB: Analyzing The Organization,: Colgate Palmolive (I) LTDKaushik SarkarNoch keine Bewertungen

- COTY Student Guidelines 2023Dokument5 SeitenCOTY Student Guidelines 202364xs9hs9thNoch keine Bewertungen

- KM Competencies - Is Certification The Way To Go (Patrick Lambe)Dokument4 SeitenKM Competencies - Is Certification The Way To Go (Patrick Lambe)Preeti SaikumarNoch keine Bewertungen

- Operational ExcellenceDokument24 SeitenOperational ExcellencemaheshNoch keine Bewertungen

- Material Kanban KEPC enDokument121 SeitenMaterial Kanban KEPC enCharlineNoch keine Bewertungen

- Individual Assigntment (Anis Eliani Binti Abdul Rahman) 1Dokument42 SeitenIndividual Assigntment (Anis Eliani Binti Abdul Rahman) 1Eliani RahmanNoch keine Bewertungen

- Lean Fundamentals Training: Gain A World Recognised AccreditationDokument4 SeitenLean Fundamentals Training: Gain A World Recognised AccreditationAhmed ElhajNoch keine Bewertungen

- A Cios Guide Five Steps To Business Agility PDFDokument13 SeitenA Cios Guide Five Steps To Business Agility PDFKarthik SundarNoch keine Bewertungen

- July 21 2a, 3a, 5a.v, 6a, (6b IMP)Dokument43 SeitenJuly 21 2a, 3a, 5a.v, 6a, (6b IMP)Shwetazz NaikNoch keine Bewertungen

- Suggested Ans 2021Dokument90 SeitenSuggested Ans 2021YASHPREETNoch keine Bewertungen

- Executive MBA Sample BCDokument12 SeitenExecutive MBA Sample BCAbreas VazalarisNoch keine Bewertungen

- White Paper - BioPharma Trends 2020Dokument12 SeitenWhite Paper - BioPharma Trends 2020Mohamed MahmoudNoch keine Bewertungen

- IIA CIA Certification Candidate HandbookDokument29 SeitenIIA CIA Certification Candidate HandbookAnimaNoch keine Bewertungen

- Loyalty Summit Brochure 2016 PDFDokument12 SeitenLoyalty Summit Brochure 2016 PDFNilesh GokhaleNoch keine Bewertungen

- Ielts Writing MaterialDokument160 SeitenIelts Writing MaterialGabyNoch keine Bewertungen

- Bringing Effective Quality Assurance Into A Small Business: A common Sense Guide to Getting Quality to Work for the Bottom Line in Your BusinessVon EverandBringing Effective Quality Assurance Into A Small Business: A common Sense Guide to Getting Quality to Work for the Bottom Line in Your BusinessNoch keine Bewertungen

- GE's Two-Decade TransformationDokument10 SeitenGE's Two-Decade TransformationHimanshiNoch keine Bewertungen

- ISO 90012015 Vs Six Sigma A Comparison enDokument13 SeitenISO 90012015 Vs Six Sigma A Comparison enNdi Mvogo100% (1)

- Align Sales Marketing With Lead NurturingDokument6 SeitenAlign Sales Marketing With Lead NurturingDemand MetricNoch keine Bewertungen

- Iso 9001 ThesisDokument7 SeitenIso 9001 ThesisPaperWritersOnlineCanada100% (2)

- Repositioning The Profession Ebook 2016 - Final (RDokument90 SeitenRepositioning The Profession Ebook 2016 - Final (RKhalid MahmoodNoch keine Bewertungen

- KEI APICS CSCP Information Booklet 2009.01Dokument26 SeitenKEI APICS CSCP Information Booklet 2009.01s-nathanNoch keine Bewertungen

- 6 Sigma StandardizationDokument1 Seite6 Sigma Standardizationamanohar188Noch keine Bewertungen

- OKRs and KPIs: What They Are and How They Work Together - ReflektiveDokument1 SeiteOKRs and KPIs: What They Are and How They Work Together - ReflektiveBelishaNoch keine Bewertungen

- Baldrige Award Benifits and CriteriaDokument9 SeitenBaldrige Award Benifits and CriteriaSivakumar NadarajaNoch keine Bewertungen

- Ebook SCD Development PlanDokument23 SeitenEbook SCD Development Planhamet100% (1)

- Sixsigma Green Belt Training Part 1Dokument9 SeitenSixsigma Green Belt Training Part 1Mayur DesaiNoch keine Bewertungen

- Digital Marketing Plan: Created - by - Juan - Jose - DelgadoDokument57 SeitenDigital Marketing Plan: Created - by - Juan - Jose - DelgadoFiorellamc250Noch keine Bewertungen

- Winning in Business Lite Case Study - Read As PreworkDokument3 SeitenWinning in Business Lite Case Study - Read As PreworkAgustinNoch keine Bewertungen

- Cisco Systems Leadership ReferenceDokument4 SeitenCisco Systems Leadership ReferenceSweetEG3377Noch keine Bewertungen

- Presentation ON Six Sigma: (New Opportunities For HR, New Career Growth For Employees)Dokument9 SeitenPresentation ON Six Sigma: (New Opportunities For HR, New Career Growth For Employees)Abhijit HazarikaNoch keine Bewertungen

- A Second Look at 5S PDFDokument5 SeitenA Second Look at 5S PDFRamón G. PachecoNoch keine Bewertungen

- Linking The Supply Chain To TQMDokument7 SeitenLinking The Supply Chain To TQMRamón G. PachecoNoch keine Bewertungen

- Investiga Los ProblemasDokument7 SeitenInvestiga Los ProblemasRamón G. PachecoNoch keine Bewertungen

- Managing Supplier RelationshipsDokument7 SeitenManaging Supplier RelationshipsRamón G. PachecoNoch keine Bewertungen

- Transforming Today S Factory Into A Lean EnterpriseDokument3 SeitenTransforming Today S Factory Into A Lean EnterpriseRamón G. PachecoNoch keine Bewertungen

- The Tao of AuditingDokument4 SeitenThe Tao of AuditingRamón G. PachecoNoch keine Bewertungen

- Improve Your Audit InterviewsDokument5 SeitenImprove Your Audit InterviewsRamón G. PachecoNoch keine Bewertungen

- Data AnalysisDokument41 SeitenData AnalysisRamón G. PachecoNoch keine Bewertungen

- New Standard Guides Internal and Supplier AuditsDokument6 SeitenNew Standard Guides Internal and Supplier AuditsRamón G. PachecoNoch keine Bewertungen

- New Standard Guides Internal and Supplier AuditsDokument6 SeitenNew Standard Guides Internal and Supplier AuditsRamón G. PachecoNoch keine Bewertungen

- Administracion de Las Quejas para Mejora de La Lealtad PDFDokument7 SeitenAdministracion de Las Quejas para Mejora de La Lealtad PDFRamón G. PachecoNoch keine Bewertungen

- Auditor Thinking SkillsDokument2 SeitenAuditor Thinking SkillsRamón G. PachecoNoch keine Bewertungen

- The Tao of AuditingDokument4 SeitenThe Tao of AuditingRamón G. PachecoNoch keine Bewertungen

- Control Financiero y CalidadDokument6 SeitenControl Financiero y CalidadRamón G. PachecoNoch keine Bewertungen

- Tips For Automotive AuditorsDokument4 SeitenTips For Automotive AuditorsRamón G. PachecoNoch keine Bewertungen

- Tips For Automotive AuditorsDokument4 SeitenTips For Automotive AuditorsRamón G. PachecoNoch keine Bewertungen

- GM Recognition LetterDokument3 SeitenGM Recognition LetterRamón G. PachecoNoch keine Bewertungen

- Audit E Procesos AutomotrizDokument1 SeiteAudit E Procesos Automotrizjuande69Noch keine Bewertungen

- Uso de Retroa. de Los Clientes para Proyectos 6 SigmaDokument5 SeitenUso de Retroa. de Los Clientes para Proyectos 6 SigmaRamón G. PachecoNoch keine Bewertungen

- Understand Customer Behavior and ComplaintsDokument5 SeitenUnderstand Customer Behavior and ComplaintsSalman KhaannNoch keine Bewertungen

- Enfoque de Procesos Al Sistema de Quejas InternasDokument8 SeitenEnfoque de Procesos Al Sistema de Quejas InternasRamón G. PachecoNoch keine Bewertungen

- Top 10 Tips For Shop Floor Audit ReadinessDokument6 SeitenTop 10 Tips For Shop Floor Audit ReadinessRamón G. PachecoNoch keine Bewertungen

- Administracion de Las Quejas para Mejora de La Lealtad PDFDokument7 SeitenAdministracion de Las Quejas para Mejora de La Lealtad PDFRamón G. PachecoNoch keine Bewertungen

- Enfoque de Procesos Al Sistema de Quejas InternasDokument8 SeitenEnfoque de Procesos Al Sistema de Quejas InternasRamón G. PachecoNoch keine Bewertungen

- Tus Clientes Estan HablandoDokument6 SeitenTus Clientes Estan HablandoRamón G. PachecoNoch keine Bewertungen

- Audit E Procesos AutomotrizDokument1 SeiteAudit E Procesos Automotrizjuande69Noch keine Bewertungen

- Administracion de Las Quejas para Mejora de La Lealtad PDFDokument7 SeitenAdministracion de Las Quejas para Mejora de La Lealtad PDFRamón G. PachecoNoch keine Bewertungen

- Uso de Retroa. de Los Clientes para Proyectos 6 SigmaDokument5 SeitenUso de Retroa. de Los Clientes para Proyectos 6 SigmaRamón G. PachecoNoch keine Bewertungen

- SAi Sankata Nivarana StotraDokument3 SeitenSAi Sankata Nivarana Stotrageetai897Noch keine Bewertungen

- Marina AbramovićDokument2 SeitenMarina AbramovićTatiana AlbuNoch keine Bewertungen

- Solaris Hardening Guide v1Dokument56 SeitenSolaris Hardening Guide v1GusGualdNoch keine Bewertungen

- UNIT 1 Previewing and PredictingDokument8 SeitenUNIT 1 Previewing and PredictingRisa nurlailiNoch keine Bewertungen

- Klarna: Klarna A Company Valued To Be 5.5 Billion and 8 Most Valued Fintech Company in The WorldDokument1 SeiteKlarna: Klarna A Company Valued To Be 5.5 Billion and 8 Most Valued Fintech Company in The WorldChetan NarasannavarNoch keine Bewertungen

- Atividade de InglêsDokument8 SeitenAtividade de InglêsGabriel FreitasNoch keine Bewertungen

- Floating PonttonDokument9 SeitenFloating PonttonToniNoch keine Bewertungen

- Methods in Enzymology - Recombinant DNADokument565 SeitenMethods in Enzymology - Recombinant DNALathifa Aisyah AnisNoch keine Bewertungen

- Inph 13Dokument52 SeitenInph 13kicaNoch keine Bewertungen

- Chapter 13 Creating and Managing TeamsDokument40 SeitenChapter 13 Creating and Managing TeamsH.Noch keine Bewertungen

- Ogl 350 Paper 2Dokument5 SeitenOgl 350 Paper 2api-672448292Noch keine Bewertungen

- Pentagram Business PlanDokument13 SeitenPentagram Business PlantroubledsoulNoch keine Bewertungen

- What's More: Quarter 2 - Module 7: Deferred AnnuityDokument4 SeitenWhat's More: Quarter 2 - Module 7: Deferred AnnuityChelsea NicoleNoch keine Bewertungen

- Legend of September 2019 MagazineDokument40 SeitenLegend of September 2019 MagazineAswathi ThatchinamoorthiNoch keine Bewertungen

- 3RD Last RPHDokument5 Seiten3RD Last RPHAdil Mohamad KadriNoch keine Bewertungen

- Article On Financial PlanningDokument16 SeitenArticle On Financial PlanningShyam KumarNoch keine Bewertungen

- Nota 4to Parcial ADokument8 SeitenNota 4to Parcial AJenni Andrino VeNoch keine Bewertungen

- OatDokument46 SeitenOatHari BabuNoch keine Bewertungen

- Profix SS: Product InformationDokument4 SeitenProfix SS: Product InformationRiyanNoch keine Bewertungen

- TAX Report WireframeDokument13 SeitenTAX Report WireframeHare KrishnaNoch keine Bewertungen

- Diffusion Osmosis Enzymes Maths and Write Up Exam QuestionsDokument9 SeitenDiffusion Osmosis Enzymes Maths and Write Up Exam QuestionsArooj AbidNoch keine Bewertungen

- Due Books List ECEDokument3 SeitenDue Books List ECEMadhumithaNoch keine Bewertungen

- Summer Anniversary: by Chas AdlardDokument3 SeitenSummer Anniversary: by Chas AdlardAntonette LavisoresNoch keine Bewertungen

- Planning and Design of A Cricket StadiumDokument14 SeitenPlanning and Design of A Cricket StadiumTenu Sara Thomas50% (6)

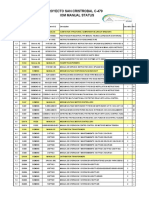

- Proyecto San Cristrobal C-479 Iom Manual StatusDokument18 SeitenProyecto San Cristrobal C-479 Iom Manual StatusAllen Marcelo Ballesteros LópezNoch keine Bewertungen