Beruflich Dokumente

Kultur Dokumente

General Description: Technical Reference

Hochgeladen von

shadiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

General Description: Technical Reference

Hochgeladen von

shadiCopyright:

Verfügbare Formate

Technical Reference

General Description

Servo Motor Compensation Features Command Language

Galil motor controllers provide a compensation filter, which includes a Galil‘s Command Language is comprised of intuitive, two-letter,

PID (Proportional-Integral-Derivative) filter followed by a notch filter English-like ASCII commands that make programming quick and easy.

and a low-pass filter.The compensation also includes velocity and accel- For example, the “BG” command begins motion while the “SP 2000,

eration feedforward. All filter parameters are adjustable, allowing servo 4000” command sets the speed of the X-axis as “2000” and the

system tuning for best performance. Dual loop control is provided for Y-axis to “4000”. Commands are included for system set-up, tuning,

reducing the effect of backlash. prescribing motion, error handling and application programming.

The dual-loop (DV) feature enables the controller to compensate for Custom commands can be created upon request.

mechanical backlash.Typically, dual-loop systems use a rotary encoder One of the more powerful features of all Galil controllers is their

on the motor and a linear encoder on the load (most Galil controllers ability to store and execute complex application programs designed by

accept inputs from two encoders per axis as a standard feature). Dual- the user. Application programs can be downloaded directly to the con-

loop control changes the standard PID control and closes the position troller and executed without host intervention.The main benefit is that

loop with the load encoder (“PI”) and derives the damping terms (“D”) this frees the PC for system-level tasks. In fact, Galil controllers permit

from the motor encoder.This method provides smooth and accurate multitasking, which allows up to eight programs to execute simultane-

control along the motion path regardless of backlash. ously. Also, special commands are available for application programming

Most Galil motion controllers also include a sinusoidal commutation including event triggers, IF/THEN/ELSE statements, conditional jumps,

feature that allows designers to use lower-cost servo drives.This feature subroutines, symbolic variables and arrays.

assures smooth motion and reduces torque ripple when using brushless A list of typical DMC commands is shown at the end of this section.

motors. Each axis of sinusoidal commutated motion requires two DAC

outputs that are phase shifted by 120°.The servo amplifier generates

the third commutation signal.The commutation can be initialized with

or without hall sensors.Two controller axes are required for each brush-

less motor. For example, a two-axis controller is required to drive one

brushless motor with sinusoidal commutation.

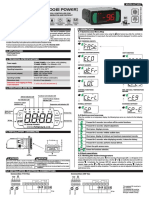

PID Block Diagram Dual-loop Block Diagram

S FA R

+

∑ PI

+

∑ AMP/MOTOR

- -

FV Σ D BACKLASH

LOAD

OF

S Kp MOTOR

ENCODER

Σ Σ Σ Σ

R + LOW OUT

Kd • s NOTCH

PASS

NF LOAD ENCODER

–

PL TL

Ki

s

IL

TECHNICAL REF

www.galilmc.com / Galil Motion Control, Inc. 1

Technical Reference

Modes of Motion

I/O acceleration (AC) and deceleration (DC) to be specified independently for

Error Handling each axis.Upon begin (BG),the controller generates a trapezoidal velocity

Dedicated I/O is provided for the following safety controls:forward profile where the speed and acceleration can be changed anytime during

and reverse limit inputs for each axis,home input for each axis,amplifier motion.For applications that require smooth motion without abrupt

enable output for each axis,configurable abort inputs for each axis,mas- velocity transitions,a motion smoothing function (IT) is provided.The

ter abort input,and error output. Most Galil drives have an electronic position (TP) and position error (TE) may be interrogated at any time.

lockout input (ELO). Also,the controller provides the following safety Position Tracking

functions in software:upper and lower software travel limits,position The Position Tracking mode allows an axis to precisely follow a

error limits,and automatic shut-off on excess position error.Program dynamic position target.In this mode, a new absolute position may be

interrupts are provided for error and limit conditions and run-time specified even if the axis is in motion.The controlled axis is commanded

program errors.The program interrupts cause the program sequencer

to move to the new position following a trapezoidal velocity profile.

to automatically branch to an error handling subroutine. In order to pro-

The (PT) command places the controller in the Position Tracking

vide flexibility and system protection,the error handling subroutine can

be customized by the user. mode,which allows the host to issue absolute position commands on the

fly.The axis moves to the new position and waits until a new position

User I/O target is specified and given by the (PA) command.The (ST) Stop com-

In addition to dedicated inputs for home and limits, Galil controllers mand is used to exit the Position Tracking mode.

provide user I/O for synchronizing motion with external events such

as switches and relays.The DMC-18x6 controller, for example, includes Example 2—Change Speed on Input, Position Tracking

8 analog inputs, 8 digital inputs and 8 digital outputs for 1 to 4-axis

models; and 8 analog inputs, 24 digital inputs and 16 digital outputs Move the x-axis forward a distance of 20,000 counts at an initial speed

for 5–8 axis models. All Galil controllers include many commands for of 50,000 counts/sec and with an acceleration and deceleration of

handling I/O such as input interrupts, I/O triggers and timers.The com- 1,000,000 counts/sec 2. Once the sensor connected to input 1 triggers,

bination of user I/O and application programming often eliminates reduce the speed to 25,000 counts/sec. Upon motion complete, begin

position tracking mode and follow the target as updated by a host PC.

the need for a PLC.When extra I/O is needed, Galil provides daughter

Activation of input 2 will end motion. Note: multiple commands can be

boards and remote I/O units such as the RIO Pocket PLC to expand a issued on the same line to conserve program space and give command

controller’s I/O capability. priority while multitasking.

As part of the user I/O,Galil controllers provide a high-speed position

PROGRAM INTERPRETATION

capture and position compare feature for each axis.The high-speed

#A Label

position capture latches the exact position within 0.1 microseconds

PR20000;SP50000 Relative Move, Speed

(40 µsec with optoisolation) of the occurrence of an input.Position AC1000000;DC1000000 Accel and Decel

capture is crucial for applications requiring precise synchronization of BGX Begin motion

position to external events such as coordinate measurement machines. AI1 Trip point: Wait for sensor input

The high-speed position compare feature produces an output pulse SP25000 Reduce speed

at a precise position.The starting position for the initial pulse and incre- AMX Wait for original distance to profile

mental distance for subsequent pulses are programmable. PT1 Turn on position tracking mode

target=_RPX Set target to current commanded position

Modes of Motion #LOOP Label

Point-to-Point Motion PAX=target Track target updated by host

Any combination of axes can be operated in the Point-to-Point JP#LOOP,@IN[2]=1 Repeat unless input two is tripped

Motion mode to allow the target position (PA or PR),slew speed (SP), STX;AMX;EN End position tracking mode and program

Example 1—Point-to-Point Motion

PROGRAM INTERPRETATION

AC 1000000;DC 1000000 Specify acceleration and deceleration

TECHNICAL REF

SP20000 Specify slew speed

PR40000 Specify distance

BG Begin motion

2 www.galilmc.com / Galil Motion Control, Inc.

Technical Reference

Modes of Motion

Jogging cutting tools. Helical motion is also possible by commanding the third

In the jog mode, each axis is given a jog speed and direction (JG), axis to follow the coordinated path at the same rate.

acceleration (AC), and deceleration (DC). Upon begin (BG), the con- Example 4—Vector motion with tangential following

troller ramps up to the jog speed at the prescribed acceleration follow- and curve slowdown

ing a trapezoidal profile. A smoothing function (IT) is provided to

smooth abrupt velocity transitions.The stop command (ST) stops the

motion at the prescribed deceleration rate.The jog speed and direc- Perform a move along the trajectory shown in figure 1 starting at the point

A and move counter clockwise toward B. Due to accuracy requirements,the

tion, acceleration and deceleration may be changed at any time during

vector speed must be limited to 5,000 counts/sec on the circular segments

motion.The average speed can be interrogated at any time using the

BC and DE.On the linear segments,the motor speed is limited to 25,000

Tell Velocity (TV) command. counts/sec.This operation is simplified given the controller’s ability to asso-

Example 3—Joystick with Coarse/Fine Speed Control ciate two speeds with each segment—upper and lower limits.These limits

are designated by the < and > symbols.The resulting vector speed is

shown as a function of the path in figure 2 below. A saw is attached to

To control the motor velocity by a potentiometer, connect it to

Axes Z and is lowered externally by setting bit 2 and turned on by setting

analog input #1 and read its voltage. Set the motor speed in pro-

bit 1.The blade will stay tangent to the vector path through the tangential

portion to the analog input with a maximum speed of 100,000

following mode.

counts/sec for a 10 Volt input. Also, limit the acceleration and

deceleration to 500,000 counts/sec2. The speed scale is selectable PROGRAM INTERPRETATION

by input 1 for fine or coarse velocity. #PATH Label

PROGRAM INTERPRETATION CAS Set coordinate system

#AUTO #AUTO label executed on powerup VMXYZ Define XY plane, Z is tangent

JG0 Initial Speed TN100,0 Setup Tangential following

AC500000;DC500000 Accel and Decel VA500000;VD500000 Vector mode accel and decel

BGX Begin Jog mode VP4000,0<25000>5000 Segment AB, slows for curve

#LOOP Label CR500,-90,180 Arc segment BC

scale=(9*@IN[1])+1 Set scaling, 1 (fine) or 10 (coarse) VP-1000,1000<25000>5000 Segment CD

JG@AN[1]*1000*scale Read pot and update speed CR500,90,180 Arc segment DE

JP#LOOP Repeat VP0,0<25000 Segment EA

EN End Program VE Indicate end of path

PAZ=_TN;BGZ;AMZ Orient saw blade to tangent

BGS Start motion sequence

2D Linear and Circular Interpolation AV4000 Wait 4000 vector distance (B)

(for controllers with two or more axes) SB1;WT100;SB2 Turn on and lower saw

The Vector Mode (VM) is an extremely powerful mode where any AV6571 Wait 6571 vector distance ( D)

two-dimensional path consisting of straight-line (VP) and arc segments CB2;WT500;CB1 Raise and turn off saw

(CR) can be prescribed. Up to 511 segments can be given prior to the EN End program

start of motion and additional segments can be sent during motion

allowing unlimited motion paths to be followed without stopping.The D (-1000,1000) C (4000,1000) 1

vector speed (VS), vector acceleration (VA), vector deceleration (VD), SAW BLADE

and motion smoothing (VT/IT) are also prescribed.The vector speed can STAYS TANGENT

TO VECTOR

be changed at any time during motion, permitting feedrate override, E (-1000,0) A (0,0) B (4000,0)

SAW OFF

slow down around corners and assignment of different speeds to specif- SAW ON

VECTOR SPEED

ic segments. Setting the vector speed ratio (VR) to zero and increasing

the vector ratio to resume can easily accomplish a pause during motion. 2

The vector mode can be operated on two sets of coordinated axes

at the same time using the (CA) command, which specifies the plane of

motion as S and T. By having dual sets of coordinated motion, users can

TECHNICAL REF

accomplish completely separate coordinated motion tasks with a single 5000

controller. It can even handle more complex motion control functions

A B C D E A

such as collision avoidance. VECTOR DISTANCE

Another feature of the vector mode is tangential following that

allows a third axis to remain tangent to the trajectory, which is ideal for

www.galilmc.com / Galil Motion Control, Inc. 3

Technical Reference

Modes of Motion

Electronic Gearing Contouring

The electronic gearing mode makes it easy for Galil controllers to The contouring mode (CM) is extremely flexible as it allows any

simulate the motion of mechanical gears electronically. Any slave axis arbitrary profile on any set of axes to be prescribed. Here, the user

or set of slave axes can be geared to a master at a prescribed gear ratio bypasses the controller profiler and directly inputs the position versus

defined by the (GR) command.The gear ratio can be changed on-the-fly time trajectory.The trajectory is described as the position increment

and the controller permits multiple masters as defined by the (GA) (CD) over a defined time period (DT). Additionally, the controller per-

command. A powerful feature of electronic gearing is that an axis can forms linear interpolation between prescribed points.The contour

be geared and simultaneously be commanded to perform an independ- mode is useful for following complex, computer-generated paths or for

ent or vector move.This is useful for the position correction required in “teaching” position paths. An automatic data-recording feature allows

packaging applications or when shapes must be cut on a moving con- the controller to “learn” a path and then follow it in the contour mode.

veyer belt.The electronic gearing mode is also useful for gantry applica-

tions where a special gantry mode (GM) command tightly couples two Example 6—Contour circle with buffer monitoring

axes by ensuring that gearing cannot be disabled.

Fill arrays with contour data inscribing a circle with radius of 50000

The gearing mode allows for a gradual ramp-to-gearing which

counts. Contour the data at a time interval of 4 samples. The

results in smoother transitions when the gear ratio is changed. (GD) sets

Accelera series incorporates a buffer of 512 contour segments to

the distance of the master axis over which the slave will be engaged or allow caching of contour data. The program will monitor this buffer

changed to a new gear setting.The parameter (_GP) corrects for any to avoid overruns and fill it with more data when possible.

accumulated errors in gearing during the ramp-to-gearing phase.

PROGRAM INTERPRETATION

Example 5—Electronic Gearing with Correction #CONTOUR Label

radius=50000 Set radius variable

Gear Axis X and Z to Y with gear ratios of 2 and -4 respectively. Output the DMcdx[720];DMcdy[720] Dimension arrays for data

absolute single turn position for X at regular intervals. Assume the resolution i=0;d=0 Index and degrees variables

of the X axis is 4000 counts per revolution. Upon input 1, automatically issue a #CALC Label

correction movement superimposed upon the concurrent gearing. cdx[i]=radius*@COS[d]-radius Calculate shifted Cosine data

PROGRAM INTERPRETATION cdy[i]=radius*@SIN[d] Calculate sin data

#GEAR Label d=d+0.5 Increment degrees

GAY,,Y Specify Y axis as master for X and Z i=i+1 Increment index

GR2,,-4 Specify gear ratios for X and Z JP#CALC,i<720 Repeat until arrays are full

PRY=50000;SPY=10000 Specify relative move and speed of Y i=0 Reset index

ACY=1000000;DCY=1000000 Specify Accel and Decel of Y CMXY Start Contour mode

II1 Setup Input Interrupt on input 1 DT2 Setup time slice, 22

BGY Begin motion on Y axis. X & Z gear curx=0;cury=0 Set incremental reference

#POS Label #PLAY Label

abposx=_TPX%4000 Current position modulo encoder resolution CD (cdx[i]-curx),(cdy[i]-cury) Contour with incremental

% available on Accelera Class calculation

MGabposx Message current single turn position curx=cdx[i];cury=cdy[i] Update incremental reference

WT500 Wait 500 ms i=i+1 Increment index

JP#POS repeat JP#PLAY,(_CM>0)&(i<720) Repeat while buffer not full

EN End of program & more data remains

#CORRECT Label for #CORRECT JP#END,i=720 Jump to end if data done

IP-1000,,-1000 X and Y move back 1000 counts, #WAIT;JP#WAIT,_CM<100 Wait until buffer has plenty

gearing is still engaged. of space

EN End of correction program JP#PLAY Jump back to continue playback

#ININT Automatically run on input 1 #END Label for exit

XQ#CORRECT,1 Run #CORRECT in separate thread CD0,0=0 Stop contour mode

TECHNICAL REF

AI1 Wait for input 1 to clear EN End of program

RI Return from Interrupt

4 www.galilmc.com / Galil Motion Control, Inc.

Technical Reference

Modes of Motion

PVT Electronic Cam

The PVT mode of motion allows arbitrary motion profiles to be Any slave axis or set of slave axes can be linked to a master axis to

defined by position, velocity and time individually on all 8 axes.This simulate the motion of a mechanical cam. Here, the master axis can be

motion is designed for systems where the load must traverse a series of a motor-driven axis or a master encoder.The Cam functions are speci-

coordinates with no discontinuities in velocity. By specifying the target fied by a table that allows complex profiles with varying position ratios

position, velocity and time to achieve those parameters the user has to be prescribed. Any follower axis may be engaged or disengaged inde-

control over the velocity profile.Taking advantage of the built in buffer- pendently at specific points along a Cam cycle.This allows the user to

ing the user can create virtually any profile including those with infinite select engagement and disengagement points where the speed change

path lengths. of the follower is minimal.The electronic Cam is an ideal mode for peri-

PVT segments must be entered one axis at a time using the PVn odic operation, especially those requiring a varying position ratio along

command.The PV command includes the target distance to be moved the motion cycle. Applications include flying shears, rotating knives, and

and target velocity to be obtained over the specified timeframe.Positions packaging systems. Galil’s Cam-generating software can assist the user

are entered as relative moves, similar to the standard PR command, in

in defining the Cam table.

units of encoder counts and velocity is entered in counts/second.The

controller will interpolate the motion profile between subsequent PV

commands using a 3rd order polynomial equation.

Example 7—PVT

PROGRAM INTERPRETATION

PVA=1000,500,1024 Horizontal axis segment AB. Ending velocity 500

PVA=800,100,1024 Horizontal axis segment BC. Ending velocity 100

PVA=100,1000,1024 Horizontal axis segment CD. Ending velocity 1000

PVA=1000,0,1024 Horizontal axis segment DE. Ending velocity 0

PVA=0,0,0 Exit PVT mode on the A axis

PVB=1000,500,1024 Vertical axis segment AB. Ending velocity 500

PVB=500,1000,1024 Vertical axis segment BC. Ending velocity 1000

PVB=1000,100,1024, Vertical axis segment CD. Ending velocity 100

PVB=-1000,0,1024 Vertical axis segment DE. Ending velocity 0

PVB=0,0,0 Exit PVT mode on the B axis

BT Begin PVT motion on both axes

EN End program

3000

D (1900, 2500)

Y POSITION

2000

C E

(1800, 1500) (2900, 1500)

1000 B

(1000, 1000)

A

(0, 0)

0 1000 2000 3000 4000

X POSITION

TECHNICAL REF

www.galilmc.com / Galil Motion Control, Inc. 5

Technical Reference

Modes of Motion

Linear Interpolation

(for controllers with two or more axes)

The linear interpolation mode (LM) allows any arbitrary path of up

to 8 axes to be defined as a set of linear segments (LI).The vector speed

(VS), vector acceleration (VA), vector deceleration (VD), and vector

smoothing (VT) are also defined. Up to 511 LI segments can be given

prior to the start of motion and additional segments can be sent during

motion to allow paths of unlimited length to be followed.

Example 8— Linear Interpolation with High Speed Latch

Move a 3D Cartesian robot through the following points with the coordinates indicated

in inches.Assume that the resolutions of all the axes are 1,000 counts/inch,and set the

required speed to 1.2 inches/sec (1,200 counts/sec) and the acceleration and deceleration

to 100 in/sec2 (100,000 counts/sec2). Note that the LM mode requires defining the seg-

ments in incremental form. A sensor will trigger a high speed latch on each axis to indi-

cate a desired or reference position. The latch will store the current position within 40µsec

of the sensor trip and the robot will return to this “set”position after the initial move.

Point Coordinates Coordinates Incremental length

(inches) (counts) (LI argument)

P0 (0,0,0) (0,0,0) 0,0,0

P1 (4,2,1) (4000,2000,1000) 4000,2000,1000

P2 (6,6,2) (6000,6000,2000) 2000,4000,1000

P3 (8,8,0) (8000,8000,0) 2000,2000,-2000

PROGRAM INTERPRETATION

#ROBOT Label

CAS Set coordinate system

LMXYZ Define XYZ space

VS1200;VA100000;VD100000 Vector speed, Accel, Decel

LI4000,2000,1000 Segment P0-P1

LI2000,4000,1000 Segment P1-P2

LI2000,2000,-2000 Segment P2-P3

LE End of sequence

ALXYZ Arm latches for axes XYZ

BGS Begin motion

AMS Wait for motion to profile

IF _ALX I _ALY I _ALZ Ensure axes have latched

MG"Not all axes have latched" Message to operator

ELSE If not all axes tripped sensor

MG"Tracking back to latch positions" Message to operator

LMXYZ Define XYZ space

LI(_RLX-_RPX),(_RLY-_RPY),(_RLZ-_RPZ) Incremental distance back to latch

LE End of sequence

BGS Begin move back to latches

AMS Wait for motion to profile

TECHNICAL REF

MG"Robot in position" Message to operator

ENDIF End of IF

EN End of program

Note: There are many homing and positioning algorithms available.

6 www.galilmc.com / Galil Motion Control, Inc.

Technical Reference

Galil Instruction Set*

Ethernet System Configuration Interrogation (cont.) Independent Motion

DH DHCP Configuration BN Burn parameters TD Tell dual encoder AB Abort motion

HS Handle switch BP Burn program TE Tell error AC Acceleration

IA Set IP address BR Brush motor enable TH Tell handle BG Begin motion

IH Open IP handle BV Burn variables and arrays TI Tell input DC Deceleration

IK Ethernet port blocking BW Brake Wait TP Tell position FE Find edge

MB Modbus CC Configure communications port TR Trace program FI Find index

MW Modbus wait CE Configure encoder type TS Tell switches HM Home

SA Send command CF Configure unsolicited messages handle TT Tell torque HV Home speed

SM Subnet mask CI Configure communication interrupt TV Tell velocity IP Increment position

Servo Motor CN Configure switches TZ Tell I/O configuration IT Smoothing time constant

AF Analog feedback CW Data adjustment bit WH Which handle JG Jog mode

DE Define dual encoder position PA Position absolute

AG Set amplifier gain

DP Define position

Programming PR Position relative

AU Set current loop gain BK Breakpoint

AW Report AMP-43040 bandwidth DR Data record update rate PT Position tracking

DA Deallocate variables/arrays

DV Dual loop operation EI Event interrupts SD Switch deceleration

DL Download program

FA Acceleration feedforward EO Echo SP Speed

DM Dimension arrays

FV Velocity feedforward IT Independent smoothing ST Stop

ED Edit program

IL Integrator limit LB LCD Bias contrast ELSE Conditional statement Contour Mode

KD Derivative constant ˆLˆK Program protect (Lock)

ENDIF End of cond.statement CD Contour data

KI Integrator constant LU LCD Update EN End program CM Contour mode

KP Proportional constant LZ Leading zeros format

HX Halt execution DT Contour time interval

NB Notch bandwidth MO Motor off

IF If statement

NF Notch frequency MT Motor type

IN Input variable

PVT Mode

NZ Notch zero PF Position format PV Position, velocity, time

JP Jump

OF Offset PW Password BT Coordinate start

JS Jump to subroutine

PL Pole QD Download array ECAM/Gearing

NO No-operation—for comments

SH Servo here RS Reset EA ECAM master

RA Record array

TK Peak torque ˆRˆS Master reset

RC Record interval EB Enable ECAM

TL Torque limit UI User interrupt EC ECAM table index

RD Record data

TM Sample time VF Variable format EG ECAM go

RE Return from error routine

Stepper Motor Math Functions REM Remark program EM ECAM modulus

KS Stepper motor smoothing @ABS[x] Absolute value of x RI Return from interrupt routine EP ECAM interval

LC Low current @ACOS[x] Arc cosine of x SL Single step EQ Disengage ECAM

QS Error magnitude @ASIN[x] Arc sine of x UL Upload program ET ECAM table entry

YA Step drive resolution @ATAN[x] Arc tangent of x XQ Execute program EW ECAM widen

YB Step motor resolution @COM[x] 1’s complement of x ZA Data record variables EY ECAM cycle counter

YC Encoder resolution @COS[x] Cosine of x ZS Zero stack GA Master axis for gearing

YR Error correction @FRAC[x] Fraction portion of x ‘ Comment GD Engagement distance for gearing

YS Stepper position maintenance @INT[x] Integer portion of x GM Gantry mode

Error Control _GP Correction for gearing

@RND[x] Round of x

Internal Sine Commutation @SIN[x] Sine of x

BL Backward software limit

GR Gear ratio for gearing

BA Brushless axis ER Error limit

@SQR[x] Square root of x FL Forward software limit Vector/Linear Interpolation

BB Brushless phase

BC Brushless calibration @TAN[x] Tangent LD Limit disable CA Define vector plane

BD Brushless degrees % Modulus operator OA Encoder failure CR Circular interpolation move

BI Brushless inputs Interrogation OE Off-on-error function CS Clear motion sequence

BM Brushless modulo ID AMP ID OT Encoder failure period ES Elliptical scaling

BO Brushless offset LA List arrays OV Encoder failure voltage IT Smoothing time constant

BS Brushless setup LL List labels TW Timeout for in-position LE Linear interpolation end

BZ Brushless zero LS List program LI Linear interpolation segment

Trippoint LM Linear interpolation mode

I/O LV List variables AD After distance

MG Message command ST Stop motion

AL Arm latch AI After input

QH Query hall state TN Tangent

AQ Analog configuration AM After motion profiler

QR Data record VA Vector acceleration

CB Clear bit AP After absolute position

QU Upload array VD Vector deceleration

CO Configure I/O points AR After relative distance

QZ Return data record information VE Vector sequence end

II Input interrupt AS At speed

RL Report latch VM Coordinated motion mode

OB Define output bit AT After time

VP Vector position

TECHNICAL REF

OC Output compare function RP Report command position AV After vector distance

ˆRˆV Firmware revision information VR Vector speed ratio

OP Output port MC Motion complete

SC Stop code VS Vector speed

SB Set bit MF After motion—forward

TA Tell amplifier status VV Vector Velocity

@AN[x] Value of analog input x MR After motion—reverse

@IN[x] State of digital input x TB Tell status WT Wait for time

@OUT[x] State of digital output x TC Tell error code

*Typical Instructions. This list is for DMC-40x0 Accelera. Other controllers have a slightly different Instruction Set.

www.galilmc.com / Galil Motion Control, Inc. 7

Das könnte Ihnen auch gefallen

- !!!destiny MatrixDokument107 Seiten!!!destiny Matrixjuancorraliza0% (2)

- Python Programming ExamplesDokument9 SeitenPython Programming ExamplesAshraf JamalNoch keine Bewertungen

- Combinaciones y PermutacionesDokument19 SeitenCombinaciones y PermutacionesConservación EnergyNoch keine Bewertungen

- Classical and Quantum Mechanics Via Lie AlgebrasDokument503 SeitenClassical and Quantum Mechanics Via Lie AlgebrasSol Ipsis100% (3)

- Database DeadlocksDokument5 SeitenDatabase DeadlocksshadiNoch keine Bewertungen

- Pda Mechatro - Handbook 070226Dokument40 SeitenPda Mechatro - Handbook 070226Paul Galvez100% (6)

- HW4 SolutionsDokument11 SeitenHW4 Solutionsglttcgamer100% (2)

- Notes-Full-Set-Slides Stock Market PDFDokument185 SeitenNotes-Full-Set-Slides Stock Market PDFbijayrNoch keine Bewertungen

- MTAP Math ChallengeDokument5 SeitenMTAP Math ChallengeHaron Abedin100% (1)

- Cnc-200A User Manual Ver. H8681/3Dokument14 SeitenCnc-200A User Manual Ver. H8681/3Cristiano Martinez100% (1)

- Buck/Boost Switch-Mode Regulator: FeaturesDokument30 SeitenBuck/Boost Switch-Mode Regulator: FeaturesErasmo Franco SNoch keine Bewertungen

- Automotive, Programmable Stepper Driver: Features and Benefits DescriptionDokument45 SeitenAutomotive, Programmable Stepper Driver: Features and Benefits DescriptionCHADDOU100% (1)

- Vfds CG Drive SKDokument6 SeitenVfds CG Drive SKmanchem sreeram sanjay67% (3)

- Advanced Motion Controls DPRNLIR-030A800Dokument11 SeitenAdvanced Motion Controls DPRNLIR-030A800Servo2GoNoch keine Bewertungen

- Advanced Motion Controls DZCANTE-012L080Dokument8 SeitenAdvanced Motion Controls DZCANTE-012L080Servo2GoNoch keine Bewertungen

- Advanced Motion Controls DPRAHIR-030A800Dokument11 SeitenAdvanced Motion Controls DPRAHIR-030A800Servo2GoNoch keine Bewertungen

- Advanced Motion Controls DZCANTE-040L080Dokument8 SeitenAdvanced Motion Controls DZCANTE-040L080Servo2GoNoch keine Bewertungen

- EZZ023535Dokument35 SeitenEZZ023535fr946ntyjgNoch keine Bewertungen

- Advanced Motion Controls DZRALTE-012L080Dokument8 SeitenAdvanced Motion Controls DZRALTE-012L080Servo2GoNoch keine Bewertungen

- Manual de Produto 115 2Dokument5 SeitenManual de Produto 115 2Reinel Damian Orrego QuinteroNoch keine Bewertungen

- Tip23 e PDFDokument4 SeitenTip23 e PDFThanh BaronNoch keine Bewertungen

- Separately Excited Electronic Motor Speed Controller: Model 1268 SepexDokument5 SeitenSeparately Excited Electronic Motor Speed Controller: Model 1268 Sepexpavli999Noch keine Bewertungen

- Torque Follower Setup Rev 1Dokument7 SeitenTorque Follower Setup Rev 1NelsonNoch keine Bewertungen

- Features: TPIC74100-Q1 Buck/Boost Switch-Mode RegulatorDokument30 SeitenFeatures: TPIC74100-Q1 Buck/Boost Switch-Mode RegulatorSyah NormanNoch keine Bewertungen

- TB9080FG Web Datasheet en 20111213Dokument5 SeitenTB9080FG Web Datasheet en 20111213vllsNoch keine Bewertungen

- TM G5SW 046Dokument15 SeitenTM G5SW 046phungthNoch keine Bewertungen

- Isolation Product Solution For Motor DriveDokument2 SeitenIsolation Product Solution For Motor DriveIvana PrezimeNoch keine Bewertungen

- Amis 30532 D PDFDokument29 SeitenAmis 30532 D PDFjorge luis guevara martinezNoch keine Bewertungen

- TM Ga800sw 064Dokument28 SeitenTM Ga800sw 064physicudoNoch keine Bewertungen

- A4955 DatasheetDokument11 SeitenA4955 DatasheetShah ZaibNoch keine Bewertungen

- Sideos SC: SIDEOS SC Is A Speed Monitoring System That Secures Lifting Operations Controlled by A JoystickDokument2 SeitenSideos SC: SIDEOS SC Is A Speed Monitoring System That Secures Lifting Operations Controlled by A JoystickVINCENT GOGNAUDNoch keine Bewertungen

- 02 02 TRansmissionDokument51 Seiten02 02 TRansmissionKhaerul Ade WiyatnoNoch keine Bewertungen

- An 1397Dokument10 SeitenAn 1397TSNoch keine Bewertungen

- AS5311 DataheetDokument32 SeitenAS5311 DataheetBruno TondinNoch keine Bewertungen

- Motor Control and Diagnostic For Automotive Adaptive Front Lighting SystemDokument6 SeitenMotor Control and Diagnostic For Automotive Adaptive Front Lighting SystemchlisonmailNoch keine Bewertungen

- Sc900a PDFDokument23 SeitenSc900a PDFgoguNoch keine Bewertungen

- Advanced Motion Controls DPRAHIE-060A400Dokument11 SeitenAdvanced Motion Controls DPRAHIE-060A400Servo2GoNoch keine Bewertungen

- DS SG1846 Rev-1.2Dokument17 SeitenDS SG1846 Rev-1.2Yuni MamaNoch keine Bewertungen

- High Voltage Bootstrap High Side Driver Features: FN9087.2 Data Sheet July 25, 2005Dokument6 SeitenHigh Voltage Bootstrap High Side Driver Features: FN9087.2 Data Sheet July 25, 2005Elves MattosNoch keine Bewertungen

- Si-8001ffe Ds enDokument9 SeitenSi-8001ffe Ds enalexNoch keine Bewertungen

- AS5145H/AS5145A/AS5145B: 1 General DescriptionDokument37 SeitenAS5145H/AS5145A/AS5145B: 1 General DescriptionsekoNoch keine Bewertungen

- ATV12 Communication ParametersDokument15 SeitenATV12 Communication ParametersBima Dwi Priya SNoch keine Bewertungen

- Advanced Motion Controls DPRAHIS-060A400Dokument11 SeitenAdvanced Motion Controls DPRAHIS-060A400Servo2GoNoch keine Bewertungen

- High Performance, Triple-Output, Auto-Tracking Combo ControllerDokument15 SeitenHigh Performance, Triple-Output, Auto-Tracking Combo ControllerrolandseNoch keine Bewertungen

- An 11483Dokument31 SeitenAn 11483cahpmasterNoch keine Bewertungen

- 4-Wheel Drive System Outline: 4Wd Warning Light Differential Oil Temperature SensorDokument3 Seiten4-Wheel Drive System Outline: 4Wd Warning Light Differential Oil Temperature SensorAhmad setiadiNoch keine Bewertungen

- MC33977 783737Dokument38 SeitenMC33977 783737renimoNoch keine Bewertungen

- High Voltage Bootstrap High Side Driver Features: FN9087.1 Data Sheet October 2002Dokument7 SeitenHigh Voltage Bootstrap High Side Driver Features: FN9087.1 Data Sheet October 2002Joil AlvesNoch keine Bewertungen

- data/ftp/PLC/FBs Manual/Manual 2/chapter 11 PDFDokument60 Seitendata/ftp/PLC/FBs Manual/Manual 2/chapter 11 PDFwijanarkoNoch keine Bewertungen

- Logix 3000MD Series: Technical BulletinDokument16 SeitenLogix 3000MD Series: Technical BulletinSathishkumar VeluNoch keine Bewertungen

- NDC96 NDC 96 24-75VDC 1.9-6.0a Stepping Motor Drive Boxed Rta Pavia ManualDokument9 SeitenNDC96 NDC 96 24-75VDC 1.9-6.0a Stepping Motor Drive Boxed Rta Pavia Manualrenato vitaliNoch keine Bewertungen

- Abs-Sls Slabs Diagnostic Functions (Discoveryii)Dokument4 SeitenAbs-Sls Slabs Diagnostic Functions (Discoveryii)Richard Andrianjaka LuckyNoch keine Bewertungen

- FDA-Series Manual (영문)Dokument30 SeitenFDA-Series Manual (영문)Inbanesan Ak100% (1)

- Mazda 6 FL Mps Wiring DiagramDokument20 SeitenMazda 6 FL Mps Wiring Diagramfredrick100% (55)

- AC Servo Drive: Operation ManualDokument116 SeitenAC Servo Drive: Operation ManualjassemNoch keine Bewertungen

- ComandosDokument503 SeitenComandosAlexander DíazNoch keine Bewertungen

- Basic Setup Start-Up Process: Quick-Start Guide Check Drive ConnectionsDokument4 SeitenBasic Setup Start-Up Process: Quick-Start Guide Check Drive ConnectionskinenNoch keine Bewertungen

- PFC Boost Calculation TI PDFDokument15 SeitenPFC Boost Calculation TI PDFshawn liNoch keine Bewertungen

- Stepper Motor InterfacingDokument5 SeitenStepper Motor InterfacingShobanraj Letchumanan100% (1)

- Advanced Motion Controls DPCANIR-100A400Dokument11 SeitenAdvanced Motion Controls DPCANIR-100A400Servo2GoNoch keine Bewertungen

- TC-900 Power: 6. Operations 1. DescriptionDokument5 SeitenTC-900 Power: 6. Operations 1. DescriptionReinel Damian Orrego Quintero100% (1)

- 28f102 Flashable Replacement For 27C1024 or 27C210 PDFDokument14 Seiten28f102 Flashable Replacement For 27C1024 or 27C210 PDFfedeNoch keine Bewertungen

- Páginas Desde Programacion-2Dokument26 SeitenPáginas Desde Programacion-2Franz Gómez VásquezNoch keine Bewertungen

- SMC™ Dialog Plus Specifications: Additional ResourcesDokument14 SeitenSMC™ Dialog Plus Specifications: Additional ResourcessimbamikeNoch keine Bewertungen

- Sensored Hall Effect Sensor Based Field Oriented Control of Three Phase BLDC Motor Using dsPIC33CK DS00004064Dokument24 SeitenSensored Hall Effect Sensor Based Field Oriented Control of Three Phase BLDC Motor Using dsPIC33CK DS000040641 Mech Tejas JapeNoch keine Bewertungen

- Anais Do Workshop De Micro-ondasVon EverandAnais Do Workshop De Micro-ondasNoch keine Bewertungen

- SQL Server OperationsDokument5 SeitenSQL Server OperationsshadiNoch keine Bewertungen

- Petabytes Terabytes (9) : Discontinued EditionsDokument5 SeitenPetabytes Terabytes (9) : Discontinued EditionsshadiNoch keine Bewertungen

- Machine Learning ServicesDokument7 SeitenMachine Learning ServicesshadiNoch keine Bewertungen

- Petabytes Terabytes (9) : Discontinued EditionsDokument5 SeitenPetabytes Terabytes (9) : Discontinued EditionsshadiNoch keine Bewertungen

- Petabytes Terabytes (9) : Discontinued EditionsDokument5 SeitenPetabytes Terabytes (9) : Discontinued EditionsshadiNoch keine Bewertungen

- Architecture: Discontinued EditionsDokument5 SeitenArchitecture: Discontinued EditionsshadiNoch keine Bewertungen

- Mainstream Editions: Petabytes TerabytesDokument5 SeitenMainstream Editions: Petabytes TerabytesshadiNoch keine Bewertungen

- Database BasisDokument5 SeitenDatabase BasisshadiNoch keine Bewertungen

- Petabytes Terabytes (9) : Discontinued EditionsDokument5 SeitenPetabytes Terabytes (9) : Discontinued EditionsshadiNoch keine Bewertungen

- Discontinued Editions: Microsoft SQL ServerDokument5 SeitenDiscontinued Editions: Microsoft SQL ServershadiNoch keine Bewertungen

- Locks Can Be AppliedDokument5 SeitenLocks Can Be AppliedshadiNoch keine Bewertungen

- HistoryDokument1 SeiteHistoryshadiNoch keine Bewertungen

- Concurrency and Locking: Pessimistic Concurrency Optimistic ConcurrencyDokument6 SeitenConcurrency and Locking: Pessimistic Concurrency Optimistic ConcurrencyshadiNoch keine Bewertungen

- Pessimistic Concurrency Optimistic Concurrency: Microsoft SQL ServerDokument6 SeitenPessimistic Concurrency Optimistic Concurrency: Microsoft SQL ServershadiNoch keine Bewertungen

- Analytics Platform SystemDokument5 SeitenAnalytics Platform SystemshadiNoch keine Bewertungen

- Fast Track ArchitectureDokument6 SeitenFast Track ArchitectureshadiNoch keine Bewertungen

- Con CurrencyDokument6 SeitenCon CurrencyshadiNoch keine Bewertungen

- Discontinued Editions: Multiversion Concurrency ControlDokument6 SeitenDiscontinued Editions: Multiversion Concurrency ControlshadiNoch keine Bewertungen

- Concurrency and LockingDokument6 SeitenConcurrency and LockingshadiNoch keine Bewertungen

- Buffer ManagementDokument5 SeitenBuffer ManagementshadiNoch keine Bewertungen

- Microsoft SQL ServerDokument5 SeitenMicrosoft SQL ServershadiNoch keine Bewertungen

- Architecture: Discontinued EditionsDokument4 SeitenArchitecture: Discontinued EditionsshadiNoch keine Bewertungen

- How To Connect Python Programs To MariaDBDokument6 SeitenHow To Connect Python Programs To MariaDBshadiNoch keine Bewertungen

- New Tools PDFDokument1 SeiteNew Tools PDFshadiNoch keine Bewertungen

- New Polaris Office DOCX DocumentDokument1 SeiteNew Polaris Office DOCX DocumentshadiNoch keine Bewertungen

- Automation of Database AdministrationDokument1 SeiteAutomation of Database AdministrationshadiNoch keine Bewertungen

- Using Big Data For Analytics and Decision Support: Ais Electronic Library (Aisel)Dokument5 SeitenUsing Big Data For Analytics and Decision Support: Ais Electronic Library (Aisel)shadiNoch keine Bewertungen

- Fluke - Motor Drive Troubleshooting: Once You Upload An Approved Document, You Will Be Able To Download The DocumentDokument1 SeiteFluke - Motor Drive Troubleshooting: Once You Upload An Approved Document, You Will Be Able To Download The DocumentshadiNoch keine Bewertungen

- Criteria For Land LevelingDokument12 SeitenCriteria For Land LevelingtizazuNoch keine Bewertungen

- ADA Lab Manual - AnujJain ITM Universe VadodaraDokument74 SeitenADA Lab Manual - AnujJain ITM Universe VadodaraanujgitNoch keine Bewertungen

- Electric Field Mapping: Experiment 1Dokument5 SeitenElectric Field Mapping: Experiment 1Pi PoliNoch keine Bewertungen

- Sampling Theorem: - Presented By., - S.ShanmatheeDokument16 SeitenSampling Theorem: - Presented By., - S.ShanmatheeSarah Kadhim MohsenNoch keine Bewertungen

- Sample Project Report StructureDokument5 SeitenSample Project Report StructureRodrigo FarruguiaNoch keine Bewertungen

- 1.4: Quadratic Equations: Section OutlineDokument4 Seiten1.4: Quadratic Equations: Section OutlineAHMED ALSHAMMARINoch keine Bewertungen

- MA202 Probability Distributions, Transforms and Numerical MethodsDokument3 SeitenMA202 Probability Distributions, Transforms and Numerical MethodsSáçhìñDêvNoch keine Bewertungen

- DIFTDokument3 SeitenDIFTUnknown LiteNoch keine Bewertungen

- ANSYS Turbomachinery CFD System - 14.5 UpdateDokument39 SeitenANSYS Turbomachinery CFD System - 14.5 UpdatePrabhuMurugesanNoch keine Bewertungen

- ASCCDokument2 SeitenASCCBorja JessaNoch keine Bewertungen

- Find The Positive Root of The Equation Correct To Five Decimal PlacesDokument5 SeitenFind The Positive Root of The Equation Correct To Five Decimal PlacesPramod GowdaNoch keine Bewertungen

- All in One Prof EdDokument65 SeitenAll in One Prof EdJhanina Apdua100% (1)

- Choosing A SolverDokument12 SeitenChoosing A SolversnthejNoch keine Bewertungen

- Spe 184865 MSDokument30 SeitenSpe 184865 MSSSNoch keine Bewertungen

- SimulatedTrain Energy Consumption STECDokument20 SeitenSimulatedTrain Energy Consumption STECCarlos Redondo BenitezNoch keine Bewertungen

- HTML Symbols PDFDokument3 SeitenHTML Symbols PDFSaisri KNoch keine Bewertungen

- Pairsof Angles LinesDokument16 SeitenPairsof Angles LinesSero ArtsNoch keine Bewertungen

- Mixing-A Detailed Look at The Factors That Influence Mix UniformityDokument19 SeitenMixing-A Detailed Look at The Factors That Influence Mix UniformityreyesdavidNoch keine Bewertungen

- Low Power Logic StyleDokument12 SeitenLow Power Logic Stylergangadhar049236Noch keine Bewertungen

- P P Multiplied by 7 P Divided by 7 M: 7 Added ToDokument8 SeitenP P Multiplied by 7 P Divided by 7 M: 7 Added Tonagaraja h iNoch keine Bewertungen

- Audit Sampling (ACP323)Dokument16 SeitenAudit Sampling (ACP323)Aeyjay ManangaranNoch keine Bewertungen

- The Mapping of Space - Perspective, Radar, and 3-D Computer Graphics Lev Manovich PDFDokument14 SeitenThe Mapping of Space - Perspective, Radar, and 3-D Computer Graphics Lev Manovich PDFDudley DeuxWriteNoch keine Bewertungen

- Surveying II O18 R15 3012Dokument3 SeitenSurveying II O18 R15 3012Sufaira ShahadiyaNoch keine Bewertungen