Beruflich Dokumente

Kultur Dokumente

Business Plan Pencil Plant

Hochgeladen von

ebubecCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Business Plan Pencil Plant

Hochgeladen von

ebubecCopyright:

Verfügbare Formate

FEASIBILITY REPORT

ON THE PRODUCTION OF

POLYMER WRITING PENCILS

PREPARED BY:

STEMGART VENTURES NIGERIA LIMITED

11 OKUNFOLAMI STREET,

OFF ADEBAYO MAKOLU

ANTHONY VILLAGE,

LAGOS STATE.

PHONE: +234-805-641-6008

Email: ebubec@stemgartventuresandconsult.com

Feasibility report on the production of wooden Writing Pencils

IMPORTANT NOTICE

This Feasibility Report has been compiled by Stemgart Ventures Limited on behalf of Z-

Industries Limited. The Feasibility Report is prepared for the exclusive use of directors

and lenders and investors in Z- Industries Limited.

The information contained in this Feasibility Report is subject to updating, expansion,

revision and amendment. It does not purport to contain all the information that the

recipient may require.

It must be emphasised that no business is free of major risk and few business

plans/feasibility reports are free of errors of omission and/or commission. Therefore no

representation or warranty, express or implied, is or will be given by Stemgart Ventures

Limited, or their respective partners, employees, or consultants or any other person as to

the accuracy and the achievement or reasonableness of any projections, targets, estimates

or forecasts included in this report.

Potential investors are therefore advised to be aware of the inherent risks associated with

this business, which must be fully appreciated, evaluated and discussed with their

professional advisers as a preclude to making investment decisions.

Accordingly, neither Stemgart Ventures Limited, nor their respective partners,

employees, or consultants nor any other person shall be liable for any direct, indirect, or

consequential loss or damage suffered by any person as a result of relying on any

statement in or omission from this report and any such liability is expressly disclaimed.

This report is confidential and meant for use only by the person to whom it is issued and

who have signed the required confidentiality agreement. This report may not be copied

or distributed by the recipient to third parties (other than in confidence to the Recipient’s

professional advisers). In the event that the recipient does not continue with his interest

in the company, this business plan must be returned to Stemgart Ventures Limited.

11 B Okunfolami Street,

Anthony Village,

Lagos

+234 805 641 6008

© Z INDUSTRIES NIGERIA LIMITED

Page 37 of 48

Feasibility report on the production of wooden Writing Pencils

TABLE OF CONTENTS

CHAPTER ONE ......................................................................................................5

1.1 THE ASSIGNMENT .................................................................................................5

1.2 EXECUTIVE SUMMARY ........................................................................................6

CHAPTER TWO .................................................................................................... 10

2.1 THE NIGERIAN ECONOMIC AND INVESTMENT REVIEW ....................... 10

2.2 PENCIL MANUFACTURING INDUSTRY IN NIGERIA'S ECONOMY ....... 12

CHAPTER THREE ............................................................................................... 14

3.1 COMPANY FORMATION .......................................................................................... 14

3.2 OWNERSHIP STRUCTURE AND BOARD REPRESENTATION................... 14

3.3 SHAREHOLDERS ......................................................................................................... 14

3.4 MANAGEMENT ............................................................................................................ 14

CHAPTER FOUR .................................................................................................. 16

4.1 PROJECT DESCRIPTION ........................................................................................... 16

4.2 PRODUCTION PROCESS........................................................................................... 16

4.3 RAW MATERIALS ......................................................................................................... 17

4.4 PACKAGING METHODS .......................................................................................... 18

4.5 MANPOWER DEVELOPMENT AND TRAINING ............................................. 18

4.6 TECHNICAL MANAGEMENT ................................................................................. 18

4.7 ENVIRONMENTAL FACTORS ................................................................................ 19

CHAPTER FIVE .................................................................................................... 20

5.1 PROJECT COST ............................................................................................................. 20

5.2 FINANCING PLAN ...................................................................................................... 21

5.3 DETAILS OF INVESTMENT COST......................................................................... 21

5.3.1 Land Acquisition and Development .............................................................................. 21

5.3.2 Buildings ....................................................................................................................... 21

5.3.3 Plant and Machinery ..................................................................................................... 21

5.4 ESSENTIAL SERVICES/UTILITIES........................................................................ 22

5.5 VEHICLES ....................................................................................................................... 23

5.6 OFFICE FURNITURE, FITTINGS AND EQUIPMENT ..................................... 23

5.7 PRELIMINARY AND PRE-OPERATIVE EXPENSES: ....................................... 23

5.8 INTEREST DURING CONSTRUCTION ................................................................ 23

5.9 WORKING CAPITAL ................................................................................................... 24

5.10 CONTINGENCIES ..................................................................................................... 24

CHAPTER SIX ....................................................................................................... 25

6.1 INTRODUCTION ......................................................................................................... 25

6.2 PRODUCT IDENTIFICATION ................................................................................. 25

6.3 LOCATIONAL ADVANTAGE .................................................................................. 26

6.4 SUPPLY ANALYSIS....................................................................................................... 26

6.4.1 Writing Pencils ............................................................................................................. 26

6.5 PROJECTED SUPPLY .................................................................................................. 27

6.5.1 Demand Analysis ......................................................................................................... 28

6.6 SUPPLY GAP ANALYSIS ............................................................................................ 30

6.7 MARKET PROSPECTS ................................................................................................ 30

© Z INDUSTRIES NIGERIA LIMITED

Page 3 of 65

Feasibility report on the production of wooden Writing Pencils

6.8 MARKET NEEDS/TRENDS ...................................................................................... 35

6.9 PRICING AND DISTRIBUTION STRATEGIES .................................................. 35

6.10 MARKETING MIX ...................................................................................................... 36

CHAPTER SEVEN................................................................................................ 41

7.1 PROFITABILITY AND FINANCIAL ANALYSIS ................................................. 41

7.2 UTILITIES ....................................................................................................................... 41

7.3 MAINTENANCE ........................................................................................................... 41

7.4 ADVERTISEMENT AND SELLING EXPENSES ................................................ 41

7.5 DEPRECIATION ........................................................................................................... 42

7.6 AMORTIZATION.......................................................................................................... 42

7.7 FINANCE CHARGES ................................................................................................... 42

7.8 TAX PROVISION .......................................................................................................... 42

7.9 PROFITABILITY ANALYSIS ..................................................................................... 42

7.10 CASH FLOW ANALYSIS ........................................................................................... 43

7.11 BALANCE SHEET ANALYSIS ................................................................................ 44

7.12 SENSITIVITY ANALYSIS ......................................................................................... 44

7.13 INTERNAL RATE OF RETURN ............................................................................. 44

7.14 BREAK EVEN POINT ............................................................................................... 45

CHAPTER EIGHT ................................................................................................ 46

8.1 EMPLOYMENT ............................................................................................................. 46

8.2 GROSS VALUE ADDED ............................................................................................. 46

8.3 LOCAL INPUT/FOREIGN INPUT RATIO ........................................................... 46

8.4 FOREIGN EXCHANGE SAVINGS .......................................................................... 46

8.5 ECONOMIC RATE OF RETURN (ERR) ................................................................. 46

8.6 SOCIAL BENEFITS....................................................................................................... 46

CHAPTER NINE .................................................................................................. 48

9.1 RISK ANALYSIS:............................................................................................................ 48

9.2 FUNDING ....................................................................................................................... 48

9.3 RAW MATERIALS SUPPLY ........................................................................................ 48

9.4 COMPETENT TECHNICAL EXPERTISE ............................................................. 48

9.5 UNSTABLE ENERGY SECTOR ................................................................................ 48

9.6 SWOT ANALYSIS .......................................................................................................... 49

9.7 SUGGESTIONS.............................................................................................................. 49

9.8 RECOMMENDATIONS .............................................................................................. 50

Project Cost – Appendix 1 ..................................................................................................... 51

Profit and loss Account – Appendix 2.................................................................................... 55

Balance Sheet – Appendix 3 .................................................................................................. 56

Cash Flow – Appendix 4 ...................................................................................................... 58

Financial Ratios – Appendix 5.............................................................................................. 59

Cost of Management and Labour – Appendix 6 (N) ............................................................. 61

Assumptions and Milestones – Appendix 7 ........................................................................... 63

Capital Funding – Appendix 8 ............................................................................................. 65

© Z INDUSTRIES NIGERIA LIMITED

Page 4 of 65

Feasibility report on the production of wooden Writing Pencils

CHAPTER ONE

PREAMBLE

1.1 THE ASSIGNMENT

Following initial consultation with the Directors of Z- Industries Nigeria Limited, the

company commissioned our firm to carry out a feasibility study of their proposed writing

pencil plant with the following terms of reference:

a} To determine the investment cost of setting up a modern manufacturing outfit for the

production of polymer writing pencils in Ikorodu, Lagos state, covering both the fixed

and floating assets, as well as the working capital requirement.

b} To propose a suitable financing structure for the project.

c} To investigate the demand and supply structure of the products and justify the

establishment of this project on the basis of the market analysis.

d} To investigate the raw material requirements, their sources and cost implications as

well as the strategies for an uninterrupted supply to guarantee optimal capacity

utilization.

e} To analyse and advise on the required plant and machinery, and to ensure complete

configuration, reliable operation and high quality products.

f} To prepare detailed financial projections and demonstrate the ability of the company

to service its debt obligations and make reasonable returns to shareholders.

g} To recommend an appropriate Organizational and Management structure, and to

ensure effective management of the company.

h} To prepare Draft and Final Reports on the result of the various investigations,

advising on the feasibility or otherwise of the project.

The study was done based on information collected from the sponsors as well as from

primary and secondary sources.

The information gathered from various sources were analyzed and an in-depth feasibility

report was put in place.

The summary of the report is given hereunder.

© Z INDUSTRIES NIGERIA LIMITED

Page 5 of 65

Feasibility report on the production of wooden Writing Pencils

1.2 EXECUTIVE SUMMARY

a) Company: Z- Industries Nigeria Limited

b) Factory Site: Kilometre KM 321, Ikorodu Road, Ikorodu, Lagos State.

c) Ownership structure: 100% Nigerian.

d) Products:

i. Writing Pencil.

ii. Cosmetic Eye Pencils.

e) Proposed Machinery Suppliers:

i. AMASCO ENTERPRISES LTD.

1303 China Aerospace Centre,

143 Hoi Bun Road Kwun Tong,

Kowloon Hong Kong,

Tel:+852 2889 3812 Fax:+852 2898 7727.

Email: info@amasco-hk.com

OR

ii. QINGDAO EVERSHINING IMPORT & EXPORT

CO.,LTD.

120 Ningxia Road, Qingdao,P.R. China

© Z INDUSTRIES NIGERIA LIMITED

Page 6 of 65

Feasibility report on the production of wooden Writing Pencils

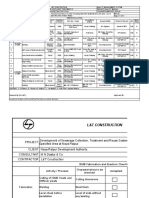

f) Project cost.

COST ITEM COST COST TO BE TOTAL N

ALREADY INCURRED ‘000

INCURRED N ‘000

31/12/2007

N ‘000

LAND & LAND DEVELOPMENT 0 3000 3,000

BUILDINGS 0 9000 9,000

PLANT AND MACHINERY 0 47,207 47,207

ESSENTIAL SERVICES/UTILITIES 0 3,500 3,500

PRICE CONTINGENCY 0 6,271 6270.745321

TOTAL FIXED ASSETS 0 68,978 68,978

MOVEABLE ASSETS 0 5,800 5,800

PRELIM. & PRE-OP. EXP. 3,000 6,000 9,000

WORKING CAPITAL 0 63,521 63,521

TOTAL CAPITAL COST 3,000 144,299 147,299

INTEREST AND LOAN REPAYMENTS 0 41,712 41,712

CAPITALISED

OTHER CONTINGENCIES 0 7,215 7,215

TOTAL PROJECT COST 3,000 193,226 196,226

g) FINANCING ARRANGEMENT:

FINANCING MODE EXISTING ADDITIONAL TOTAL N %

31/12/2007 N N ‘000 ‘000

‘000

Promoters Equity 3,000 35,332 38,332 20%

Long Term Loan 0 81,000 81,000 41%

Mezannine Debt 0 54,000 54,000 28%

Over Draft 0 22,894 22,894 12%

Total 3,000 193,226 196,226 100%

© Z INDUSTRIES NIGERIA LIMITED

Page 7 of 65

Feasibility report on the production of wooden Writing Pencils

h) Manpower:

Direct – 69

Indirect – 20

Total 89

i) Long Term Loan

Amount: N81.0 million (US $0.623 million)

Payment period: 6 years

Frequency: Quarterly

Moratorium: 1 year

Interest Rates: 15% per annum for Mezannine and 21% per annum for term

loan.

j) Capacity utilization

Year 1 2 3 4 5

(%) 70 75 80 90 90

k) Break – even point (1st year): 68.8 % of installed capacity

l) Internal Rate of Return (IRR): 95.3 %

m) Return on Capital Employed (ROCE): 50%

n) Gross Value Added: N1,089 million in the fifth year of operation.

o) Market prospect:

i. Assured Local Market.

ii. Proposed selling price policy is realistic and reasonable

iii. Good quality products assured

iv. Export market potential exists, especially to neighbouring West

African countries.

© Z INDUSTRIES NIGERIA LIMITED

Page 8 of 65

Feasibility report on the production of wooden Writing Pencils

p) Economic Justification

i. Employment generation

ii. High potential for foreign exchange savings/earnings.

iii. Gross Value added is very high.

iv. High Economic Rate of Return (ERR)

v. Revenue generation to Government through Tax

© Z INDUSTRIES NIGERIA LIMITED

Page 9 of 65

Feasibility report on the production of wooden Writing Pencils

CHAPTER TWO

INTRODUCTION

2.1 THE NIGERIAN ECONOMIC AND INVESTMENT REVIEW

Industrialisation has been acknowledged as the engine of growth for almost all countries

of the world. Over the years, Nigeria has exported all its primary products to European

and other western countries where they are processed into finished goods. These finished

goods are later imported back into the country at exorbitant amounts of money. The

Governments over the years have made concerted efforts to change Nigeria’s agrarian

nature to an industrialized one. To accomplish this, the Governments embarked on

series of plans and visions that were designed to encourage industrialization.

The various National Development Plans, the Rolling Stock Perspective Plan and the

Vision 2010 embodied the goals, strategies and public investment programmes and

socio-economic policies of the various Governments designed with a view to accelerate

the country's development process.

The prime objective of the various programmes embarked upon between 1990 and 2000

were to consolidate the gains of SAP (Structural Adjustment Programme) in order to

break fetters that have shackled the economy in low-key equilibrium or in a state of

fundamental disequilibrium.

The democratisation of the polity and the free market economy of the present

government appear to be a good terrain for the growth of the economy in the spirit of

the Vision 2010. It is expected that inflow of foreign exchange will be enhanced, as the

various sanctions are being lifted. Internally, the Government is expected to regulate the

economy, constantly fine-tuning the monetary and fiscal policies by introducing measures

to pacify the turbulent environment in which investors find themselves. Funds are

expected to be made available to private investors in the form of soft loans for

establishing projects which will utilize available local resources, and promote input-

output linkages within the country's manufacturing and other sectors. Companies that

are foreign exchange earners are considered priority.

The country has the indices, (large population, varied natural resources, and expertise)

for rapid economic growth. This explains why the current Government policies are

skewed in favour of the manufacturing sector.

After years of economic mismanagement and deep corruption, there is now a dynamic

reform team comprising the Economic Management Team, which is supporting the

President in driving forward an ambitious reform agenda. The government has launched

its poverty reduction strategy - the National Economic Empowerment and

Development Strategy (NEEDS), and alongside this, it has restored macroeconomic

stability, and effectively managed oil revenues. DFID and the World Bank are supporting

the NEEDS programme through a joint Country Partnership Strategy.

The NEEDS focuses on four key strategies:

Reforming government institutions and to restructure and strengthen

government

© Z INDUSTRIES NIGERIA LIMITED

Page 10 of 65

Feasibility report on the production of wooden Writing Pencils

Growing the private sector by reducing the influence of government in the

economy and accelerating the privatisation, deregulation and liberalisation

programme

Beginning to implement a social charter to improve people’s access to health,

education, welfare, employment, security and participation

Value re-orientation including anti-corruption, freedom of information and

enhancing the role of civil society.

The administration is taking decisive action against corruption. Nigeria is leading the

world on its implementation of the Extractive Industries Transparency Initiative (EITI)

and has established a dynamic Economic and Financial Crimes Commission (in 2003) to

fight corruption. At State level, the challenges are greater, but here too there has been

progress. Most States have implemented State Economic Empowerment and

Development Strategies (SEEDS). Their performance in economic governance - the

policy, institutional, and legal environment within which an economy functions, and

transparency, is being measured. Reforms are being introduced to improve the

accountability of local government. Donors and the Federal government are helping

States to reform.

2.1.1 Nigeria and the Millennium Development Goals (MDGs)

DFID has been working hard with the Nigerian authorities to ensure that all the savings

from the debt cancellation are effectively targeted on reducing poverty. The debt deal will

mean an additional $1 billion a year is available for the government of Nigeria to spend

on poverty reduction, employ an extra 120,000 teachers and put 3.5 million children into

school.

A Universal Basic Education (UBE) bill, to get girls as well as boys into school, was

recently approved at the federal level, and most states are in the process of applying this

ruling at the local level. Net primary enrolment is around 60% and rising slowly, but

greater effort is required if Nigeria is to reach the universal primary education MDG by

2015. Pencils are one of the products that will receive a boost due to these policies. Z –

Industries Limited intends to contribute to satisfaction of this need.

With a start-up production capacity of 103 million units representing less than 10% of

the 2005 figures, meeting our sales target should not be a problem considering the

envisaged quality of Z –Pencil’s' products and our unique and innovative sales strategy.

Presently, due to the massive demand of pencils attributable to the ever-increasing

population growth and the aggressive educational drive by the Federal and State

governments, the importers have capitalised on the availability of this collossal market to

bring in very low quality pencils since Nigerians have no other choice. It is this anomaly

that Z-Pencils Limited hopes to address.

To advise on the technical input of the company is Qingdao Evershine of China - a

company with over a hundred years in the pencils manufacturing industry. Apart from

the manufacturing of pencils, Qingdao are the leading manufacturers of pencil-making

machines on the Asian continent and their products compete favourably with that of the

EU countries and are relatively cheaper. This company shall supply the needed

© Z INDUSTRIES NIGERIA LIMITED

Page 11 of 65

Feasibility report on the production of wooden Writing Pencils

machinery and the locally unavailable raw materials of Z - Pencils, the most important

being the graphite lead input.

2.2 PENCIL MANUFACTURING INDUSTRY IN NIGERIA'S ECONOMY

According to Forbes.com, the pencil rank as the fourth most important tool of all time,

in terms of its impact on human civilization after the knife, the abacus and the

compass. The origins of the pencil date to the ancient Romans, who used to write with a

device known as a stylus - a metal stick, usually lead, which was used to scratch words

onto papyrus. In 1564, a huge cache of graphite was discovered in Borrowdale, England.

Local residents used it to mark sheep, and soon discovered that they could cut it into

sticks and carry it with them. Scientists of the day thought graphite was a form of lead –

that’s why we still call the stuff in pencils "lead" even though it is graphite. Graphite is

generally soft and crumbly, so soon after, Italian craftsmen came up with the idea of

hollowing out a stick of juniper wood and filling it with graphite. Later versions would

sandwich the lead between two pencil halves and glue them together.

In 1662, the first mass-produced pencils were made in Nuremburg, Germany, and in

1795, a French Chemist named Nicholas Conte invented a technique to make pencils

lead out of powdered graphite and clay. In 1770, Edward Naime, an English engineer,

created and began selling the first rubber erasers. The practice of painting pencils yellow

began in the 1890s. Pencil manufacturers wanted to advertise that they were using high-

quality Chinese graphite, so they painted them a color associated with Chinese royalty.

Today, 75% of the pencils sold are still painted yellow though with some other color

inputs. Pencils are however not manufactured in Nigeria, and the local demand is

supplied by imports mainly from Asia. (Source: statistics from the Central Bank of

Nigeria (CBN) and the Nigerian Customs Service)

All the pencils currently being used in Nigeria and indeed, the West and East African

sub-regions are imported mainly from Asia. Nigeria alone imported over 1.4 billion units

in 2005 at over $50 million and it is expected that this shall exceed 2 billion units in 2008

when Z-Pencils Limited shall commence operations.

Z-Pencils Limited is a limited liability company set up to function as an integrated wood

processing and manufacturing Company with specialization in the production of various

pencil types as initial product focus. The company will be located on a 2 acre property in

Ikorodu, Lagos State of Nigeria. The property has been identified and Design/Pre-

construction plan for the Factory shed, Warehouse, Bay, Admin and Residential

Blocks/Buildings are in the final stages. Total project cost for start-up is

$1.41(NGN182.9) million. We are seeking $1,038,000 (NGN135 million) for the

purpose of start-up operations and to cover operating expenses for a three month

period. Promoters will invest $295,000 (NGN38.4 million) as its equity in the company.

The $1,038,000 in loan funds will enable the company acquire the needed machinery and

other capital assets to commence operations with a projection of over 150 million pencils

annually running on a three shift basis. As pioneer manufacturers of pencils in Nigeria,

with immense marketing opportunities in Nigeria and the West African sub-region, it is

projected that the company will reach its break-even point in the first year of operations

and achieve a minimum turnover in excess of $3.5 million in the first and second years of

operations after which production capacity shall be increased to 90% to about 200

© Z INDUSTRIES NIGERIA LIMITED

Page 12 of 65

Feasibility report on the production of wooden Writing Pencils

million units annually. It is projected that turnover shall reach $6.3 million in the third

year of operation and production capacity shall be increased by adding a new line every

two years for the next eight years which shall bring the capacity to about one billion

annually with 10 production lines. This is to enable Z-Pencils meet a minimum of 40%

demand of Nigerian pencil users in 10 years.

© Z INDUSTRIES NIGERIA LIMITED

Page 13 of 65

Feasibility report on the production of wooden Writing Pencils

CHAPTER THREE

THE COMPANY

3.1 COMPANY FORMATION

Z- INDUSTRIES Nigeria Limited (ZIL) is a private limited liability company

incorporated on the 26th of July, 2007 with an authorized share capital of N1,000,000

divided into 1,000,000 ordinary shares of N1.00 each. To provide the company with

adequate capital base for the implementation of the proposed project, arrangement will

be made to increase the authorised share capital to N60.0 million by the creation of

additional 59,000,000 ordinary shares of N1.00 each, ranking pari-passu in all respects

with the existing shares. The Memorandum of Association of the company permits it to

go into the production of pencils. Both the Certificate of Incorporation and the

Memorandum and Articles of Association are available for inspection. Its registered

Office is at Anthony in Lagos. However, the Company’s certificate of Incorporation

No.RC.386431 and the Memorandum and Article of Association will be updated to

reflect the new additions.

The amended certified true copies of the above documents must be submitted to the

funding institution for scrutiny and they should be found satisfactory prior to

disbursement of the loan.

3.2 OWNERSHIP STRUCTURE AND BOARD REPRESENTATION

It is planned that the board of Z- Industries Limited will consist of five members. The

board representation can be changed, amended and altered after due process has been

followed.

The present shareholders of the company have considerable business experience. They

are on the board of other successful companies.

3.3 SHAREHOLDERS

The three main shareholders of Z- Industries Limited are Nigerians who have the means

of increasing their share capital in the company whenever the need arises. Profile of

Directors are included in Appendix xxx

3.4 MANAGEMENT

The Z- Industries management team will be made up of the following: The Chairman, a

General Manager, a Production Manager, an Accountant, a Marketing/Sales Manager

and a Quality Control Manager.

While the General Manager reports to the Chairman the weekly activities of the

company, the Chairman in turn will report the monthly performance of the company to

the Board of Directors.

The functions of other members of the management team are highlighted below:

© Z INDUSTRIES NIGERIA LIMITED

Page 14 of 65

Feasibility report on the production of wooden Writing Pencils

General Manager: In addition to assisting the Chief Executive in the day to day running

of the company’s affairs, he or she shall directly be in charge of Production and

Maintenance as well as the Quality Control Departments. He or she will develop

production plans and control to ensure efficient operations of the production plants. He

will liaise with the Accounts Department for the timely supply of required raw materials

to ensure uninterrupted production. He or she will develop standards for the company’s

products in co-operation with the Marketing/Sales Department.

He or she will vet and recommend for approval all maintenance schedules as may be

prepared by the Departmental Heads. He is to see to the general safety of both men and

material through constant review of safety procedures and training. He will ensure the

efficient operation and maintenance of the company’s facilities.

A seasoned Engineer or Technologist with cognate experience in similar ventures will

occupy this position.

Production Manager: He or she will head the Production Division. He or she shall be

responsible for all production activities of the company.

The incumbent shall be an Engineer with not less than 5 years cognate experience with at

least two in a pencil processing plant. His or her field of specialisation could be

Mechanical, Production or Industrial Engineering and the qualification must be

registered with Council for the Regulation of Engineering in Nigeria (COREN).

Accounts Manager: He or she will ensure the optimal utilisation of the company’s

resources - human, materials and finance. He or she will enforce discipline and good

labour relations. He or she will keep record of all company assets and ensure maximum

returns on the utilisation of the assets.

A qualified Accountant with ICAN or ACCA qualification or B.Sc. Accounting will hold

this position. He or she must have not less than two years cognate experience in a

manufacturing outfit.

Marketing/Sales Manager: He or she will be responsible for the supervision of the

Marketing and Purchasing Departments, which form the Commercial Division. He or

she must ensure that the right quality of goods are purchased and sold. He or she will

conduct periodic research on market situations as well as on the availability of good raw

materials for management decisions. He or she will advise management on the current

market prices and product distribution dynamics.

The incumbent must be a graduate of Economics or any of the Social Sciences and must

have undergone practical training/experience in Marketing/Purchasing. He or she must

have not less than 5 years relevant experience.

Manager (Quality, Research & Development): He or she shall be responsible for the

control of the quality of the company’s products. He or she shall also be responsible for

the development of new products that will ensure the competitiveness of the company’s

products in the market. The incumbent must have at least an HND certificate in wood

Technology with not less than four years experience.

© Z INDUSTRIES NIGERIA LIMITED

Page 15 of 65

Feasibility report on the production of wooden Writing Pencils

CHAPTER FOUR

THE PROJECT

4.1 PROJECT DESCRIPTION

Z- Industries Nigeria Limited is proposing to writing pencils. The company’s second

product which it will commence production in the third year, will be cosmetic pencils.

The plants to be used have the following annual installed capacities based on three shift

of eight hours per day and working 300 days in a year.

(a) Writing Pencils –100 million units per annum

(b) Cosmetic Pencils – 90 million units per year

4.2 PRODUCTION PROCESS

Pencils are made of wood and lead graphite. Most pencils are made of cedar wood and

Gmelina as these do not warp easily. The most important ingredient in a pencil is the

graphite, which most people continue to call lead. Pencils were initially made with pure

graphite but the graphite mines of Borrowdale in the UK were soon depleted and

graphite was less plentiful. Presently, graphite powder is combined with clay, water, wax

and other chemicals then baked. A harder or softer writing core could be produced by

varying the proportion of clay to graphite – the more graphite, the blacker and softer the

pencil.

Now that most commercially used graphite is made in factories rather than mined,

manufacturers are able to easily control its density. The graphite is mixed with clay

according to the type of pencil being made – the more graphite used, the softer the

pencil, and the darker its line. For colored pencils, pigments are added to the clay, and

virtually no graphite is used.

Two methods are used to form the graphite into its finished state. The first is an

extrusion method in which the graphite and wax mixture is forced through a mold to

create a spaghetti-like string, which is then cut to precise measurements and dried in

ovens. In the second method, the graphite and clay mixture is poured into a machine

called a billet press. A plug is placed over the top of the press, and a metal ram ascends

from the bottom to squash the mixture into a hard, solid cylinder called a billet. The

billet is then removed from the top of the machine and placed into an extrusion press

that forces it through a mold, slicing off strips the size of the pencil core.

To make the wood casings for the pencils, square slats are formed, and then grooves are

cut into the slats. Next, graphite sticks are inserted into the grooves on one slat, and then

a second slat with empty grooves is glued on top of the graphite-filled slot. Correctly

sized pencils are cut out of the sandwich, and the eraser and metal ferrule attached.

The wood usually arrives at the factory already dried, stained, and waxed, to prevent

warping. Logs are then sawed into narrow strips called slats; these are about 7.25 inches

(18.4centimeters) long; .25 inch ( .635 centimetres ) thick, and 2.75 inches ( 6.98

© Z INDUSTRIES NIGERIA LIMITED

Page 16 of 65

Feasibility report on the production of wooden Writing Pencils

centimetres ) wide. The slats are placed into a feeder and dropped, one by one, onto a

conveyor belt which moves them along at a constant rate.

The slats are then planed to give them a flat surface. Next, they pass under a cutter head

that makes parallel semi-circular grooves – one half as deep as the graphite is thick –

along the length of one side of each slat. Continuing along the conveyor belt, half of the

slats are coated with a layer of glue, and the cut graphite is laid in the grooves of these

slats.

The slats without glue – and without graphite in the grooves – are placed on another belt

that carries them to a machine that picks them up and turns them over, so they are laying

on the belt with the grooves facing down. The two conveyor belts then meet, and each

unglued slat is placed over a slat with glue and graphite, forming a sandwich. After the

sandwiches have been removed from the conveyor belt, they are placed into a metal

clamp and squeezed by a hydraulic press and left clamped together until the glue is dried.

When the pencils are dried, the ends are trimmed to remove excess glue.

The next step is shaping, when the sandwiches actually become pencils. The sandwiches

are placed on a conveyor belt and moved through two sets of cutters, one above and one

below the belt. The cutters above the sandwiches cut around the top half, while the

lower set cuts around the bottom half and separates the finished pencils. The majority of

pencils are hexagonal, so designed to keep the pencils from rolling off surfaces. A single

sandwich yields six to nine hexagonal pencils.

After the pencils have been cut, their surfaces are smoothed by sanders, and varnish is

applied and dried. This is done with varnishing machines, in which the pencils are

immersed in a vat of varnish and then passed through a felt disk, which removes the

excess varnish. After drying, the pencils are put through the process again and again until

the desired color is achieved. Finally, the pencils receive a finishing coat.

The pencils once again are sent on a conveyor belt through shaping machines, which

remove the excess varnish that has accumulated on the ends of the pencils. This step also

ensures that all of the pencils are of same length.

Erasers are then attached, held to the pencil by a round, metal case called a ferrule. The

ferrule first attaches to the pencil either with glue or with small metal prongs, and then

the eraser is inserted and the ferrule clamped around it. As a final step, a heated steel die

presses the company logo onto each pencil.

Colored pencils are produced in much the same way as black-writing pencils, except that

their cores contain coloring materials such as dyes and pigments instead of graphite.

First, clay and gum are added to pigment as bonding agents, and then the mixture is

soaked in wax to give the pencils smoothness. When the pencils have been formed, the

outsides are painted according to the color of the center mixture.

4.3 RAW MATERIALS

The main raw materials are wood, graphite, paints, ink, aluminium clips, white glue,

erazer, and heat transfer aluminium. The company will source its wood raw materials

from the open wood market in Ondo State.

© Z INDUSTRIES NIGERIA LIMITED

Page 17 of 65

Feasibility report on the production of wooden Writing Pencils

The finished lead, paints & ink, aluminium clips, white glue, heat transfer film aluminium

shall be supplied by Quingdao Evershine of China. The plant/ machineries shall also be

sourced from same company however, there are other resourceful suppliers in Hong

Kong, China, Germany and Taiwan who have indicated their willingness to supply Z-

Pencils with the needed raw materials in case of any eventuality or delay by our main

suppliers.

Wood represents 50% volume of our raw materials; Lead 40% in volume; Ink, Paints and

other inputs, 10%.

4.4 PACKAGING METHODS

Pencils are universally measured and sold in "Gross". A gross is 144 units. There are

carton options the least being 12 grosses in one. Other sizes of cartons include 20, 24,

36, 50, and 100 gross content. The gross method of measurement is mainly applicable to

the open market through distributors and wholesalers. Each gross will be packed in clear

plastic with minimal markings but the encasing carton will be attractively designed for

aesthetics and with enough information as statutorily required.

The intended packaging for schools, colleges, corporate bodies, politicians and NGO's

shall come in clear plastic packages containing three, six and twelve units. The pencils

shall be clearly branded as required by the requesting organisation, school or individual.

4.5 MANPOWER DEVELOPMENT AND TRAINING

(a) Staffing:

The estimated manpower to operate and maintain the plant facilities at the initial stage,

including the technical and general administration of the factory is about 89. This

estimate covers the top management; middle and junior level executives and other

supporting staff.

The breakdown of the manpower requirement for the factory is as follows:

S/N Category Direct Indirect Total

1. Top Management 4 4

2. Other Managers 2 2

3. Senior Staff 4 4

4. Other Staff 59 20 79

Total 69 24 89

4.6 TECHNICAL MANAGEMENT

Although proposals for the supply of plant and machinery for this project are being

obtained from some suppliers, it is advisable to ensure the reliability of the suppliers

through the preparation of Plant and Machinery Supply Agreement, incorporating

guarantees and Spare parts back up. In view of the need for good quality product and

the potential to develop new ones, an experienced General Manager would be appointed,

and training will be arranged with the assistance of the Machinery Suppliers.

© Z INDUSTRIES NIGERIA LIMITED

Page 18 of 65

Feasibility report on the production of wooden Writing Pencils

4.7 ENVIRONMENTAL FACTORS

Waste water is the main by-product in the manufacture of pencils. Other waste products

are torn paper, damaged cartons and pieces of cellophane sheets.

The waste water will be drained into soak-away pits. This way, the waste water is

absorbed back into the ground naturally. The waste water is not harmful to life or the

environment because it contains no harmful chemicals. .

Damaged cartons as well as pieces of cellophane sheets will be sold to companies that

recycle them. This will help to preserve natural resources, as the whole world is looking

for ways to reduce the depletion of natural resources.

The proposed methods of waste disposal are considered reasonable as they do not

offend any known existing environmental sanitation law. Generally, the production

process is environmental friendly.

© Z INDUSTRIES NIGERIA LIMITED

Page 19 of 65

Feasibility report on the production of wooden Writing Pencils

CHAPTER FIVE

THE PROJECT COST

5.1 PROJECT COST

The total project cost including financing costs is estimated at N196.3million, including a

working capital provision of N63.5 million. The project base cost is estimated at N

141.03 million.

The breakdown of the project cost is summarized below:

COST ITEM INCURRED TOTAL

31/12/2004 N’000

N’000 COST TO BE INCURRED

FOREIGN LOCAL

N’000 N’000

LAND & LAND 0 0 3000 3,000

DEVELOPMENT

BUILDINGS 0 0 9000 9,000

PLANT & MACHINERY 0 42,487 4,721 47,207

ESSENTIAL 0 0 3,500 3,500

SERVICES/UTILITIES

TOTAL FIXED ASSETS 0 42,487 20,221 62,707

MOVEABLE ASSETS 0 0 5,800 5,800

PLELIM. & PRE-OP. EXP. 3,000 3900 2,100 9,000

WORKING CAPITAL 0 19,056 44,465 63,521

TOTAL PROJECT BASE COST 3,000 22,956 52,365 78,321

INTEREST AND LOAN 0 0 41,712 41,712

REPAYMENT CAPITALISED

CONTINGENCIES & 0 0 13,486 13,486

PROVISIONS

TOTAL PROJECT COST 3,000 65,443 127,783 196,226

© Z INDUSTRIES NIGERIA LIMITED

Page 20 of 65

Feasibility report on the production of wooden Writing Pencils

5.2 FINANCING PLAN

The estimated total project cost of N196.2 million is proposed to be financed as follows

EXISTING

ADDITIONAL

COST TOTAL

FINANCING MODE COST %

31/12/2007 N’000

N’000

N’000

SHARE CAPITAL 3,000 35,332 38,332 19.53%

LONG TERM LOAN 0 81,000 81,000 41.28%

OTHER FINANCING 0 76,894 76,894 39.19%

TOTAL 3,000 193,226 196,226

This financing arrangement gives a Debt/Equity Ratio of 4:1 and a Fixed Assets

Coverage of 3:2 over the long-term loan. The ratios are considered satisfactory. The

foreign portion of the term loan will be used to import the required items of plant and

machinery while the local portion will be used for the payment of customs duty, and

such related charges.

5.3 DETAILS OF INVESTMENT COST

5.3.1 Land Acquisition and Development

The Chief Promoter of the project has negotiated to acquire about 1 acre of land at

Ikorodu, Lagos state. An assessment of the space shows that it is more than enough for

the proposal. The land is estimated to cost about N3.0 million.

5.3.2 Buildings

The factory complex will be developed with three distinct and functional structures

linearly arranged in about three adjacent rows. Construction material will be clad steel

structures (Clad with aluminium Long span sheets) suitable for the purpose of

manufacturing.. The production factory will cover 1500 m². Other buildings will include

the security office (16.82m²), Administrative block (119.0 m²), Main store (700 m²),

Generator house (54.80m²), Toilet/washrooms (4.2 m²) Canteen (39.53 m²), General hall

(55.0m²), Perimeter fence built with solid concrete blocks (8,975.63 m²). It is estimated

that about N9.0 million will be expended on the buildings.

5.3.3 Plant and Machinery

The complete plant and machinery could be supplied by any of the three machinery

suppliers listed below:

(a) AMASCO ENTERPRISES LTD.

(b) QINGDAO EVERSHINING IMPORT & EXPORT CO.,LTD

The long–term loan of N81.0 million will be used towards procuring the machines as

well as cover other expenses.

© Z INDUSTRIES NIGERIA LIMITED

Page 21 of 65

Feasibility report on the production of wooden Writing Pencils

5.4 ESSENTIAL SERVICES/UTILITIES

Water: Water is needed for the preparation of the wooden slates, general cleaning of the

production plants as well as for general use on the factory complex. The company will

sink one borehole at a cost of N700,000..

Electricity: Given the epileptic supply of electricity in the country, provision has been

made for one (1) standby Generator of 120 KVA rating, to ensure an uninterrupted

electricity supply. This is planned to be acquired at a cost of about N3.5 million,

including the switchgear and cables. The company will also need to purchase a 3-phase

Transformer and connect directly to the National High Tension (33,000 V) line that is

about 0.2 kilometres away.

Others: Other utility requirements are, fire-fighting equipment, Fuel storage tanks for

Diesel and Fuel Oils. This can be procured locally.

© Z INDUSTRIES NIGERIA LIMITED

Page 22 of 65

Feasibility report on the production of wooden Writing Pencils

5.5 VEHICLES

The following provisions are made: (These costs are for Lease arrangement)

Type No. Use Cost (N'000)

Salon Cars 2 Management 2,000.0

Pick-up truck 1 Workshop 800.0

Salon Car 1 Admin/Finance 400.0

10 Ton Trucks 1 Sales/Raw Materials 1,200.0

Total 4,400.0

5.6 OFFICE FURNITURE, FITTINGS AND EQUIPMENT

A provision of N1.4 million has been made to cover the cost of buying computers,

photo copiers, Air conditioners, Tables, Chairs, Filling Cabinets, electrical fittings,

carpets, etc.. The amount is to be apportioned as follows:

Equipment Type N'000

Office Equipment 900.0

Office Furniture 400.0

Fittings 100.0

Total 1,400.0

5.7 PRELIMINARY AND PRE-OPERATIVE EXPENSES:

These Preliminary expenses would be on; Company Formation, Feasibility Study,

Travelling/ Hotel Expenses, Administrative Expenses, Consultancy Expenses and

Miscellaneous activities. About N7.8 million would be spent as follows:

Item Incurred N’000 To be Incurred Total N’000

N’000

Company Incorporation Expenses 1,000.00 250 1,250.00

Travelling Expenses 1,000.00 500 2,500.00

Admin Expenses 1,000.00 1,500.00 2,500.00

Feasibility Study 800 - 800

Miscellaneous 250.00 500.00 750.00

TOTAL 4,050.00 2,750.00 7,800.00

5.8 INTEREST DURING CONSTRUCTION

The total financial charges payable before the commercial operation of the plant is

capitalized as Interest during Construction. The estimated sum of N12.5 million is based

on the planned disbursement of 30% of the machinery cost at ordering, 60% at shipment

and the balance of 10% after successful commissioning. This estimate covers both the

commitment fee as well as the interest charges on the disbursement of the overdraft

towards the procurement of Raw Materials before commercial operations begin.

© Z INDUSTRIES NIGERIA LIMITED

Page 23 of 65

Feasibility report on the production of wooden Writing Pencils

5.9 WORKING CAPITAL

A working capital requirement of N63.5 million is estimated for the first year of

operation. This is broken down as follows:

Item Stock level (days) N'000

Cash at Hand 30 5,483

Stock of Raw Materials (Foreign) 60 5,821

Stock of Raw Materials (Local) 30 6,791

Work-In-Progress 1 1,617

Stock of Finished Goods 14 9,504

Accounts Receivable 30 44,488

Accounts Payable 15 -10,183

TOTAL 63,521

5.10 CONTINGENCIES

Three types of contingencies are provided for in our estimates. These are:

Physical - This is to make provisions for the cost of items that may have been

inadvertently omitted in the course of estimating the machines.

Price - This is to provide for possible cost escalation arising from increased price

of goods due to inflationary pressure.

Currency Fluctuations - It is assumed that the exchange rate of the Naira to

other foreign currencies may increase to N140 for US Dollars and N174 for the

Euro used in the conversions respectively.

© Z INDUSTRIES NIGERIA LIMITED

Page 24 of 65

Feasibility report on the production of wooden Writing Pencils

CHAPTER SIX

MARKET ANALYSIS

6.1 INTRODUCTION

Z- Industries Nigeria Limited is proposing to set up facilities for the production of

writing pencils. It also intends to produce cosmetic pencils. Both products will be

produced in conformity with the international Standard Organization and the Standards

Organisation of Nigeria (SON)

6.2 PRODUCT IDENTIFICATION

A pencil is a handheld instrument used to write and draw, usually on paper. The writing

is done with graphite (except for colored pencils), which is typically covered by a wooden

sheath. Pencils may also have an eraser or "rubber" attached to one end. The pencil

differs from most pens (other than erasable pens) in that erasing is possible.

Made of graphite, a crystalline form of carbon, mixed with clay. There are varying

degrees of hardness for pencils, the softest varieties contain little or no clay. Pencils are

rated and labelled by degrees of hardness. 6B is very soft, producing a darker line. HB

and F are the middle degree of hardness. 2H up to 8H (hardest) and produce very light

graphite deposits respectively

Z-Pencils will manufacture all pencil degrees from school pencils to professional pencils

for artists, artisans, engineers and architects. These include: 9H, 8H, 7H, 6H, 5H, 4H,

3H, 2H, H, HB, B, 2B, 3B, 4B, 5B and 6B and colored pencils. These will come in exotic

colors and attractive shapes which will include ergonomic triangular, round, oval flat and

rectangular. The B series are softer than the H series. But Z-Pencils shall commence

operations with the market-dominant degrees which are the common writing pencils

(H, HB and 2B) for all categories of students from the nursery schools through to the

universities.

We aim to produce about seven different brands of these pencil degrees with the

following brand names:

Unzu

Asante

Zulu

Kusu

Bogolo

Massai

Asabi

Each brand shall have its own distinct shape and color and shall be managed as a distinct

brand even though they shall be coming from one stable. Some will come complete with

erasers and some will not. It is expected that the brand manager shall strategize towards

making his/her brand the most dominant and most visible thus engendering a healthy

competition.

© Z INDUSTRIES NIGERIA LIMITED

Page 25 of 65

Feasibility report on the production of wooden Writing Pencils

The reason for this unique marketing strategy is not farfetched as there are a plethora of

pencils in the market but no leading brand although Faber Castel and Staedler are well-

known by professionals. It is almost impossible for anyone to mention or remember a

pencil brand despite the fact that pencils are purchased daily. We aim to position our

brands of pencils as the most unique by embarking on massive advertising and marketing

strategies that will ensure our pencils become household names.

6.3 LOCATIONAL ADVANTAGE

The factory shall be located on a 2 acre plot of land in Ikorodu, Lagos State and shall be

fitted with state-of-the-art pencil production facilities that can compare and compete

effectively with what is obtainable in Europe and Asia. The choice of location is based

on the proximity of Ikorodu to Ore in Ondo state from where the bulk of the wood

input for the pencils shall be obtained and the vast pencils market of south western

Nigeria. South western Nigeria has the largest number of schools and students in the

country and the West African sub-region. And the nearness of Ikorodu to the Lagos

Ports makes for easy delivery of lead to the factory once in every three months.

Also, Ikorodu has all the infrastructural facilities which Z-Pencils shall benefit from.

There are modern means of transporting both raw materials and finished goods to and

from the factory site. Electricity is available and there is an abundance of potential

technical labour. Apart from the factory building and machinery, other facilities shall

include comfortable staff quarters complete with amenities for all categories of staff;

delivery trucks, official vehicles, safety equipments, fire fighting equipment, generators,

forklifts, boilers, warehouses, boreholes, office equipments, communications gadgets,

staff canteens, staff clinic and security posts.

6.4 SUPPLY ANALYSIS

6.4.1 Writing Pencils

Nigeria, according to statistics from the Central Bank of Nigeria, imported 1.4 billion

units of pencils in 2005 (approximately 10 million Gross) at $50 million. It is expected

that this figures will be surpassed in 2006 and shall be in excess of 2 Billion units by the

time we commence operations in 2008.

There are different types of pencils with degrees ranging from 9H to 6B with 8H, 7H,

6H, 5H, 4H, 3H, 2H, H, HB, 2B, 3B, 4B, and 5B in between. These pencils are classified

according to professional usages viz:

Writing Pencils (H, HB, B, and 2B)

Drawing and shading Pencils (2B, 3B, 4B, 5B, and 6B)

Masonry Pencils

Steno Pencils

Copying Pencils

Carpenter's Pencils

The dominant degree range of pencils are the writing pencils which are predominantly

utilized by all categories of students irrespective of whether they are in the nursery,

primary, secondary or tertiary institution. For the nursery and primary schools, the

© Z INDUSTRIES NIGERIA LIMITED

Page 26 of 65

Feasibility report on the production of wooden Writing Pencils

dominant pencils are the H, HB, and 2B which accounts for about 90% of the total

volume of pencils imported. These students shall be our primary target market. The

remaining 10% is shared amongst the other degrees of pencils and colored pencils. The

professional pencils are exclusively used by professionals i.e graphic artists, architects and

engineers. These shall form our secondary target market. Pencils are also used in every

office nationwide and these categories of users are mostly executives.

As earlier stated, pencil importation is primarily dominated by Asians, especially the

Chinese; but the distributors, wholesalers and merchants are predominantly, Nigerians.

Amongst the major importers are:

TABLE 6.1 MAJOR IMPORTERS OF PENCILS IN NIGERIA

MARKET VOLUME

S/N COMPANY ADDRESS

SHARE (million)

5th Floor, Great Nigeria

Quing Xiang Long

1 House, 47/57 Marina, 40% 650 million Units

Commodity Co.

Lagos

China Town, Lekki,

2 Lee Yang Commodities 25% 450 million Units

Lagos

China Town, Lekki,

3. Schneider Investments 15% 200 million Units

Lagos

28, Ojuelegba Road,

4 Artworld Limited 10% 150 million Units

Suru-lere,Lagos

5 Others 10% 150 million Units

Total 1,600

Sources: (1) Central Bank of Nigeria,

6.5 PROJECTED SUPPLY

WRITING PENCILS

There are strong indications that the yearly increase in supply of writing Pencils will

persist into the future for several reasons.

With the democratically elected government in place and more conducive economic

environment, investors are prepared to invest. This is because the financial sector is

better placed to solve the problem of sourcing working capital funds; the energy sector is

expected to improve significantly to minimize the logistic problems; while capital inflow

may encourage new entrants or existing producers to modernize their machinery. These

would enhance capacity utilization of the existing installed capacity and increase the

national installed capacity thereafter.

In projecting the supply of writing Pencils, the following assumptions were made;

(1) That the present known and unknown importers supply 1.6 billion units per annum

(2) This is thereafter projected at 3%, which is the estimated growth rate of the supply.

The resultant projection is shown in Table 6.2 below.

© Z INDUSTRIES NIGERIA LIMITED

Page 27 of 65

Feasibility report on the production of wooden Writing Pencils

TABLE 6.2 PROJECTED SUPPLY OF WRITING PENCILS (MILLION PENCILS)

YEAR PROJECTED

SUPPLY

2006 1,600

2007 1,648

2008 1,697

2009 1,748

2010 1,801

Sources: From assumptions

6.5.1 Demand Analysis

6.5.1.1 Demand for Writing Pencils

Nigeria, with a population of over 130 million according to UN statistics, has over 80

million students with primary and nursery school students making up 70% of this figure.

This category of students must necessarily utilize pencils between the ages of two and

eight before being introduced to other writing materials like ball-point pens. However,

since pencils are indispensable in homes, schools and offices, it simply means that all

literate adults and every single student is a potential user or actual user of pencils. The

usage of pencils continues through primary school to the university, and even beyond,

though, to different degrees. Also, according to CBN statistics, the usage of pencils in

Nigeria is not uniform as some regions have more students than others.

Table 6.3 below shows the population of pencil users in Nigeria in 2005 :

TABLE: 6.3 POPULATION OF PENCIL USERS IN 2005

Estimated

Pencil Users in Population Volume Average Per Sales Value in US $

Nigeria (Million) (Million) Person (Million)

Nurser/Primary

School Students 44 1300 30 23

Secondary school

students 28 308 11 16

Tertiary Students 11 90 8.1 8

Professionals 3 28 8.3 2.3

Total 86 1726 49.3

© Z INDUSTRIES NIGERIA LIMITED

Page 28 of 65

Feasibility report on the production of wooden Writing Pencils

TABLE 6.4 REGIONAL ANALYSIS

Nos of Students Volume Sales Value in

Regions (million) (million) US $ (million)

Northern 20 350 11

Western 35 600 23

Sothern 30 450 16

The national population is expected to exceed 140 million in 2008 with a projected 10%

increase in the number of primary school students according to UN statistics. The same

trend is applicable to other West African countries that shall form the bulk of our

offshore market.

TABLE 6.5 MARKET ANALYSIS

Market Analysis

2008 2009 2010 2011 2012

Potential Units Units Units Units Units

Customers

Primary/Nursery 1,573,000,000 1,730,300,000 1,903,330,000 2,093,663,000 2,303,029,300

school students

Secondary School 370,260,000 407,286,000 448,014,600 492,816,060 542,097,666

students

Tertiary Students 109,147,500 120,062,250 132,068,475 145,275,323 159,802,855

Professionals 32,675,720 35,943,292 39,537,621 43,491,383 47,840,522

Others 11,444,400 12,588,840 13,847,724 15,232,496 16,755,746

Totals 2,096,527,620 2,306,180,382 2,536,798,420 2,790,478,262 3,069,526,088

The above potential market size is based on UN statistics

Market Analysis (Pie Chart)

© Z INDUSTRIES NIGERIA LIMITED

Page 29 of 65

Feasibility report on the production of wooden Writing Pencils

6.6 SUPPLY GAP ANALYSIS

Table 6.7 below compares the projected supply with the projected demand for writing

Pencils to determine the supply gap

TABLE 6.6-PROJECTED SUPPLY GAP (IN MILLION UNITS)

PROJECTED PROJECTED SUPPLY GAP

SUPPLY DEMAND

WRITING PENCILS WRITING PENCILS WRITING PENCILS

YEAR

2006 1,600 1,792 192

2007 1,648 1,886 238

2008 1,697 2,096 399

2009 1,748 2,159 411

2010 1,801 2,224 423

Average Supply Gap 332

Source: Calculated from Tables 6.2 and 6.5

6.7 MARKET PROSPECTS

According to available statistics from the CBN, the total number of pencils imported

into the country in 2005 was in excess of 1.4 billion units or about 10 million gross. A

gross is 144 units. This is 9% higher than the previous year's figure of 1.23 billion. This

indicates that the growth rate is in tandem with that of the overall population as each

new-born baby automatically becomes a potential user of pencils. It is estimated that the

demand will further grow by 10% in 2006, 12% in 2007 and 14% in 2008.

Simply put, since the Nigerian population rate is growing at about 9% annually according

to the United Nations statistics, the market growth rate for pencils follows the same

trend.

Also, there has been a massive educational drive by world bodies like UNESCO, the

federal and state governments and this has considerably increased the number of

children being registered in primary schools annually. Statistics from the Federal Ministry

of Education indicate that the number of children registered in primary schools across

the country has consistently increased by 11% annually since the advent of democracy in

1999.

The crave for educational and professional attainment by Nigerians has increased the

number of tertiary institutions with a resultant turnout of pencil users. In other words,

the pencils market will keep growing at about 10% annually if the population growth

remains the same

© Z INDUSTRIES NIGERIA LIMITED

Page 30 of 65

Feasibility report on the production of wooden Writing Pencils

From our analysis as shown in Table 6.6, the supply gap for writing Pencils averaged 332

million units per annum.

6.7.1 INDUSTRY ANALYSIS

The Nigerian pencils industry is dominated by a few very large Asian companies, such as

Quing Xiang Long Commodity Company and Lee Yang Investments Limited. Of these

major competitors, Quing Yang Long is the largest, with approximately 40% market

share. Last year, the company reported sales of approximately $27 million.

As earlier stated pencils are not manufactured in Nigeria but imported. The industry is

primarily dominated by Asians who import from their home countries in China, Taiwan,

Hong Kong and Malaysia and distributed to Nigerian wholesalers and distributors.

The quality of the lead or graphite input is rather low compared with what is available in

the EU countries and this is due to the fact that nothing that can be done about it since

Nigerians do not have any options. The graphite inputs are rather brittle and of the

lowest grade. The offshoot of this is incessant and frequent breakages. However, this has

not debarred Nigerians from purchasing these inferior pencils as there are no options to

choose from. On the average, about 800,000 gross of pencils are imported on a monthly

basis with a market price of over $4.3million.

The introduction of a locally manufactured pencil of a better quality is bound to be

appreciated by end-users especially if the market price is relatively lower than what is

presently obtainable. Also, there is no dominating or leading brands of pencils as the

importers believe solely in the availability of a ready market. There is no conscious effort

at promotional or positioning strategy since the market is always growing. It is this vital

weakness that Z-Pencils shall capitalize upon by embarking on massive promotional

efforts aimed at positioning Z-Pencils’ range of pencils as a household name

6.7.2 GLOBAL ANALYSIS

Data available from the Writing Instrument Manufacturers Association, WIMA, (a global

association) indicates that in 2005 a total of 77 billion units of wooden-cased pencils

were produced and that the global market will continue to grow at 25% for the next five

years. This table shows the volume per continent. Australia and Africa are insignificant

players as most of the pencil factories located here are subsidiaries of the giants in

Europe and America:

Continent Volume in 2005 Percentage

Asia 37.5 billion units 45%

European Union 25 billion units 30%

North America 14.5 billion units 23%

Others 800 million units 2%

Major Global Pencil Players include:

(a) Faber-Castell of Germany

(b) Dixon Ticonderoga Company of the USA

(c) Qingdao Evershine of China

© Z INDUSTRIES NIGERIA LIMITED

Page 31 of 65

Feasibility report on the production of wooden Writing Pencils

(d) General Pencil Company

(e) Rose Moon Inc

(f) Camel Pencil Mfg Co of Japan

(g) mitsubishi Pencil Co of Japan

(h) Sanford Pencil Co of the UK

(i) Shelbyville Pencil Company, Inc

(j) Staedler Mars GnbH & Co

(k) Bic Deuschland GmbH & Co

(l) Acco Cumberland Pencil Co, UK

(m) Shachiata (UK) Limited

(n) Cleo Veryrieb GmbH & Co

6.7.3 TARGET MARKET SEGMENT STRATEGY

Based on the above analysis of the market demographics, size and unit potential, our

core target markets are:

1. Students - primary, secondary and tertiary

2. Professionals - Engineers, Architects, Graphic Artists and Visual Artists

3. Office Workers

Surveys indicate that in the students category the nursery and primary students constitute

over 70% of the entire student population of 80 million hence the plan to manufacture

more of writing pencils. These utilised over a billion units in 2005. Z-Pencils

Limited shall focus on this unique target market, through regional distribution and

direct selling via its various relationship and referral networks. In addition, a significant

amount of investment will be made in advertising to promote product awareness. Direct

selling is far more effective in closing sales as well as in terms of sales and marketing

costs. Direct marketing shall be directed at schools who would have their

names engraved on the pencils.

In reaching the student population, Z-Pencils intends to adopt a direct marketing strategy

of sales to the following institutions :

The Federal Government - Ministry of Education

National, State and Local Governments Primary & Secondary Education Boards

National Petroleum Development Trust Fund

Universal Basic Education (UBE)

Educational Trust Fund (ETF)

The various multilateral education agencies – USAID, EDC, DFID, UNESCO &

UNDP - focusing on their various Literacy Enhancement Assistance Programs.

With a production capacity of 100 million pencils for the first year and a projected

growth rate of 100% biennially, it is estimated that Z-Pencils can meet 50% of the

national pencil requirements in about eight years. It is also safe to say that the demand in

the market and the specific marketing & sales strategy to be adopted will ensure that all

of Z-Pencils brands are successfully sold without much fuss in Nigeria. Empowering

minds and strengthening literacy and education in Nigeria and indeed the West African

sub-region.

© Z INDUSTRIES NIGERIA LIMITED

Page 32 of 65

Feasibility report on the production of wooden Writing Pencils

6.7.4 REVIEW OF THE FUNDING OF PRIMARY EDUCATION IN

NIGERIA - A view into potential funding sources for our direct

marketing of pencils to Governmental organizations

Under the Nigerian Constitution, federal and state governments have concurrent

responsibility for primary education. The federal government determines national policy,

sets standards, and monitors performance. State governments are responsible for

designing, developing, and delivering the service. Examples include designing the

curriculum and preparing legislation.

In addition, local governments have a formal responsibility, dating from the Local

Government Decree of 1976, for providing and maintaining primary education, subject

to necessary assistance from the states (Federal Ministry of Education, Education Sector

Status

Report, Abuja, Nigeria, 2003). All three tiers of government—federal, state, and local—

fund primary education.

6.7.4.1 Federal and state governments:

Capital expenditures (buildings, books, and furniture) come from the federal and state

governments’ share of the Federation Account. The Federation Account holds all

federally collected revenues. The funds are divided among the three tiers of government

according to a formula determined by the National Assembly. Some of the funds in this

account accrue from government-owned mineral resources, a set percentage (13%) of

which is returned to the states, apportioned on the basis of the states’ original

contributions. Thereafter, 15% of VAT revenues is distributed to the federal

government, 50% to state governments, and 35% to local governments. Of the funds

remaining within the Federation Account, 54.7% goes to the federal government, 24.7%

to state governments, and 20.6% to local governments.

State governments also pay the recurrent costs for managing State Primary Education

Boards (SPEBs), Local Government Education Authorities (LGEAs), and primary

schools.

6.7.4.2 Local governments:

The local governments’ 20.6% share of the Federation Account results in two types of

local funding for education. First, at the state level, a percentage of the local share (a

“first charge”) is set aside for primary school teachers’ salaries and allowances. Local

governments may then use a part of what remains for direct assistance to primary

schools. They also contribute own-source revenues to primary education.

6.7.4.3 Funding towards education

i. Federal government:

Of the federal government’s total budget of N893.3 billion in 2005, only about 11%,

or N93.8 billion, was budgeted for the education sector. This 11% allocation

compares negatively to 21% in Botswana; 26% in Ghana; and 22% in Namibia.

Nigeria allocates almost 60% of its education budget to tertiary education and less

than 40% to primary and secondary education combined.

© Z INDUSTRIES NIGERIA LIMITED

Page 33 of 65

Feasibility report on the production of wooden Writing Pencils

Most of the federal government education budget for 2005 (N72.2 billion) went in

for recurrent expenditures. The remaining N21.6 billion funded capital expenditures.

Another national source of revenue is the Universal Basic Education (UBE)

programme, which also provides money for capital expenditures in primary schools.

The national Education Tax Fund (ETF) transfers funds directly to benefiting

institutions for specific capital projects. Allocations are made according to pre-agreed

percentages for primary (20%), secondary (30%), and tertiary (50%) Disbursements

for primary education are made on the basis of “equality.” Every local government in

the country receives an equal amount, irrespective of the number of primary schools

it has or its primary school enrollment. The money is transferred directly to the

SPEB in each state.

Despite the criterion that 20% of total ETF revenues be allocated to the primary

level, ETF allocations to SPEBs that are dedicated to primary education— as

opposed to secondary or tertiary— have declined over time. Further, the total

percentage of Naira actually distributed to SPEBs has been continuously lower than

100% and has declined as well. This results in negative consequences for school

environments, in areas such as overcrowded classrooms and inadequate furniture.

ii. State governments:

State governments allocate minimal proportions of their recurrent and capital

budgets to primary education. The accompanying graphs illustrate, for a sample of

two states, that 2003 contributions for recurrent costs for primary education were

around 2.7% and 2.2%, and for capital costs around 1% and 0.6%.

iii. Local governments:

Local governments shoulder the brunt (86%) of the costs for primary education from

their share of the Federation Account. Although state governments are expected to

provide around 10–12%, the previous graphs show that they provide much less. The

federal government provides even smaller amounts. The horizontal formula