Beruflich Dokumente

Kultur Dokumente

BUL: 3-Way Unit Valve, PN 16: Features

Hochgeladen von

Diego Felipe Orellana AravenaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BUL: 3-Way Unit Valve, PN 16: Features

Hochgeladen von

Diego Felipe Orellana AravenaCopyright:

Verfügbare Formate

Product data sheet 55.

009

BUL: 3-way unit valve, PN 16

Improving energy efficiency

Linear mixture and no loss through leakage in the control passage for energy-efficient regulation

Features

• Flat-sealing standard version or version with clamping-ring screw fitting for pipe Ø 15 mm with

DN 10

• Valve with male thread as per DIN/EN ISO 228-1, class B

• Special model for fan coil units with cast-on by-pass T-piece

• Control passage A–AB is closed when the spindle is moved in BUL015F310

• Can be used as a control valve and, thanks to its tight-sealing third passage, as a distribution valve

• Nickel-plated valve body of cast brass

• Plug with EPDM soft seal for control passage and mixing passage

• Stainless-steel spindle

• Stuffing box with double O-ring seal

Technical data

Parameters

Nominal pressure PN 16

Valve characteristic, control passage Equal-percentage

Valve characteristic, mixing passage Linear

Valve stroke 3.7 mm BUL010F410

Leakage rate of control passage A- 0.0001% of kvs value

AB

Leakage rate of mixing passage B- Approx. 0.1% of kvs value

AB

Ambient conditions

Admissible operating temperature for 2...120 °C

valve

Admissible operating temperature for 100 °C at the valve

valve in combination with AXT 211,

AXS 215 and AXM 217 (S)

Operating pressure up to 120 °C 16 bar Control valve

Standards and directives

Pressure and temperature data EN 764, EN 1333

Flow parameters VDI/VDE 2173

Pressure Equipment Directive 97/23/EC (fluid group II)

No CE label

article 3.3

Overview of types

Distribution valve

/ The BUL 3-way valve must not be used as a 2-way valve

/ kvs value: The kvs value of the mixing passage (B-AB) is reduced by approx. 30%.

Type Nominal diameter kvs value Connection Weight

BUL010F330 DN 10 0.4 m³/h G½" B 0.30 kg

BUL010F320 DN 10 0.63 m³/h G½" B 0.30 kg

BUL010F310 DN 10 1 m³/h G½" B 0.30 kg

BUL010F300 DN 10 1.6 m³/h G½" B 0.30 kg

BUL015F310 DN 15 2.5 m³/h G¾" B 0.33 kg

BUL015F300 DN 15 4 m³/h G¾" B 0.33 kg

BUL020F300 DN 20 5 m³/h G1" B 0.36 kg

BUL010F430 DN 10 0.4 m³/h G½" B 0.38 kg

BUL010F420 DN 10 0.63 m³/h G½" B 0.38 kg

BUL010F410 DN 10 1 m³/h G½" B 0.38 kg

BUL010F400 DN 10 1.6 m³/h G½" B 0.38 kg

BUL015F410 DN 15 2.5 m³/h G¾" B 0.42 kg

BUL015F400 DN 15 4 m³/h G¾" B 0.42 kg

Right of amendment reserved © 2015 Fr. Sauter AG 7.1 1/8

Product data sheet 55.009

Type Nominal diameter kvs value Connection Weight

BUL020F400 DN 20 5 m³/h G1" B 0.50 kg

BUL010F630 DN 10 0.4 m³/h Clamping ring vers. Ø 0.38 kg

15 mm

BUL010F620 DN 10 0.63 m³/h Clamping ring vers. Ø 0.38 kg

15 mm

BUL010F610 DN 10 1 m³/h Clamping ring vers. Ø 0.38 kg

15 mm

BUL010F600 DN 10 1.6 m³/h Clamping ring 0.38 kg

A BUL0**F4**: Version with bypass T-piece

Accessories

Type Description

0378133010 1 threaded sleeve, R⅜", flat-sealing, DN 10, with cap nut and flat seal

0378133015 1 threaded sleeve, R½", flat-sealing, DN 15, with cap nut and flat seal

0378133020 1 threaded sleeve, R¾", flat-sealing, DN 20, with cap nut and flat seal

0378134010 1 solder nipple, Ø 12, flat-sealing, DN 10, with cap nut and flat seal

0378134015 1 solder nipple, Ø 15, flat-sealing, DN 15, with cap nut and flat seal

0378134020 1 solder nipple, Ø 22, flat-sealing, DN 20, with cap nut and flat seal

0378135010 1 clamping-ring screw fitting for pipe Ø 15 mm, DN 10

0378145015 1 clamping-ring screw fitting for pipe Ø 15 mm, DN 15, flat-sealing, ¾" B

0378145020 1 clamping-ring screw fitting for pipe Ø 22 mm, DN 20, flat-sealing, 1" B

0378126001 Stuffing box for BUL valves

Combination of BUL with electric actuators

/ Warranty: The technical data and pressure differences indicated here are applicable only in com-

bination with SAUTER valve actuators. The warranty does not apply if used with valve actuators

from other manufacturers.

/ Definition of ∆p s: Maximum admissible pressure drop in the event of a malfunction (pipe break

after the valve) at which the actuator reliably closes the valve.

/ Definition of ∆p max: Maximum admissible pressure drop in control mode at which the actuator

reliably opens and closes the valve.

Pressure differences with motorised actuators

Actuator AXM217F200 AXM217F202 AXM217SF402

Voltage 230 V~ 24 V~/= 24 V~/=

0/2...10 V, 0...5 V, 5...10 V,

Control signal 3-point 3-point

0/4...20 mA

Running time 48 s 48 s 48 s

∆p [bar]

As control valve ∆pmax ∆pmax ∆pmax

BUL010F330

BUL010F320

BUL010F310

BUL010F300

BUL010F430

BUL010F420

1.7 1.7 1.7

BUL010F410

BUL010F400

BUL010F630

BUL010F620

BUL010F610

BUL010F600

BUL015F310

1.4 1.4 1.4

BUL015F410

BUL015F300

1.2 1.2 1.2

BUL015F400

BUL020F300

1.0 1.0 1.0

BUL020F400

2/8 7.1 Right of amendment reserved © 2015 Fr. Sauter AG

Product data sheet 55.009

Actuator AXM217F200 AXM217F202 AXM217SF402

As distribution valve

BUL010F330

BUL010F320

BUL010F310

BUL010F300

BUL010F430

BUL010F420

1.9 1.9 1.9

BUL010F410

BUL010F400

BUL010F630

BUL010F620

BUL010F610

BUL010F600

BUL015F310

BUL015F300

BUL020F300

1.2 1.2 1.2

BUL015F410

BUL015F400

BUL020F400

Pressure differences with thermal actuators

Actuator AXT211F210 AXT211F212 AXT211F110 AXT211F112

AXT211HF210 AXT211HF212 AXT211F110B AXT211F112B

AXT211F110M AXT211F112M

AXT211F190 AXT211F192

AXT211HF110 AXT211HF112

Voltage 230 V~ 24 V~/= 230 V~ 24 V~/=

Control signal 2-point 2-point 2-point 2-point

Running time 122 s 148 s 122 s 148 s

∆p [bar]

As control valve ∆pmax ∆pmax ∆pmax ∆ps ∆pmax ∆ps

BUL010F330

BUL010F320

BUL010F310

BUL010F300

BUL010F430

BUL010F420

1.7 1.7 1.7 1.8 1.7 1.8

BUL010F410

BUL010F400

BUL010F630

BUL010F620

BUL010F610

BUL010F600

BUL015F310

1.4 1.4 1.4 1.5 1.4 1.5

BUL015F410

BUL015F300

1.2 1.2 1.2 1.3 1.2 1.3

BUL015F400

BUL020F300

1.0 1.0 1.0 1.1 1.0 1.1

BUL020F400

As distribution valve

BUL010F330

BUL010F320

BUL010F310

BUL010F300

BUL010F430

BUL010F420

1.9 1.9 1.9 4.0 1.9 4.0

BUL010F410

BUL010F400

BUL010F630

BUL010F620

BUL010F610

BUL010F600

BUL015F310

1.6 1.6 1.6 2.1 1.6 2.1

BUL015F410

Right of amendment reserved © 2015 Fr. Sauter AG 7.1 3/8

Product data sheet 55.009

Actuator AXT211F210 AXT211F212 AXT211F110 AXT211F112

AXT211HF210 AXT211HF212 AXT211F110B AXT211F112B

AXT211F110M AXT211F112M

AXT211F190 AXT211F192

AXT211HF110 AXT211HF112

BUL015F300

1.4 1.4 1.4 2.1 1.4 2.1

BUL015F400

BUL020F300

1.2 1.2 1.2 2.0 1.2 2.0

BUL020F400

Actuator AXS215SF222 AXS215SF122

AXS215SF222B AXS215SF122B

Voltage 24 V~ 24 V~

Control signal 0...10 V 0...10 V

Running time 111 s 111 s

∆p [bar]

As control valve ∆pmax ∆pmax ∆ps

BUL010F330

BUL010F320

BUL010F310

BUL010F300

BUL010F430

BUL010F420

1.7 1.7 1.8

BUL010F410

BUL010F400

BUL010F630

BUL010F620

BUL010F610

BUL010F600

BUL015F310

1.4 1.4 1.5

BUL015F410

BUL015F300

1.2 1.2 1.3

BUL015F400

BUL020F300

1.0 1.0 1.1

BUL020F400

As distribution valve

BUL010F330

BUL010F320

BUL010F310

BUL010F300

BUL010F430

BUL010F420

1.9 1.9 4.0

BUL010F410

BUL010F400

BUL010F630

BUL010F620

BUL010F610

BUL010F600

BUL015F310

1.6 1.6 2.1

BUL015F410

BUL015F300

1.4 1.4 2.1

BUL015F400

BUL020F300

1.2 1.2 2.0

BUL020F400

Additional technical data

kvs value in m3/h

Valve Control passage Mixing passage

BUL010F*30 0.40 0.30

BUL010F*20 0.63 0.47

BUL010F*10 1.0 0.75

BUL010F*00 1.6 1.2

BUL015F*10 2.5 1.9

4/8 7.1 Right of amendment reserved © 2015 Fr. Sauter AG

Product data sheet 55.009

Valve Control passage Mixing passage

BUL015F*00 4.0 3.0

BUL020F*00 5.0 3.8

Technical information

SAUTER slide rule for valve sizing 7090011001

Manual on slide rule 7000129001

Software tool for valve and drive sizing 7000675001

Valvedim.exe

Technical manual: “Control units” 7000477001

Description of operation

The spindle is pressed in to close the control passage (passage A-AB) and open the mixing passage

B-AB. It is returned by the spring force from the spring in the valve. The valve can be controlled to the

OPEN or CLOSED positions with the thermal actuator for unit valves AXT 211. Used in combination

with the “normally closed” version of the actuator, the control passage of the valve closes in the event

of a power failure.

Used as a control valve Used as a distribution valve

The valve can be controlled to any desired position with the continuous actuator for unit valves

AXS 215S. Depending on the position of the DIP switches, the valve is adjusted continuously with a

control voltage of 0...10 V / 10...0 V or 2...10 V / 10...2 V. The control signal is then assigned linearly

to the valve stroke and produces the equal-percentage characteristic in the valve. The positioner inte-

grated into the actuator controls the actuator according to the setting of the DIP switches and posi-

tioning signal y. The continuous actuator positions the valve and, as soon as the position is reached, it

stops.

The valve can be controlled to any desired position with the motorised actuator for unit valves

AXM 217. With type AXM 217S (with positioner) the valve is continuously adjusted using a 0...10 V or

4-20 mA control signal, according to the position of the DIP switches. The kvs values in the by-pass

are reduced by approx. 30% compared to the kvs values of the control passage. This takes into ac-

count the flow rate resistance of the consumer, so that the total flow rate remains as constant as pos-

sible in every stroke position. The practically equal-percentage characteristic in the control passage

allows optimal control together with a continuous 0...10 V actuator.

Intended use

This product is only suitable for the purpose intended by the manufacturer, as described in the “De-

scription of operation” section.

All related product documents must also be adhered to. Changing or converting the product is not ad-

missible.

Engineering and fitting notes

The control unit can be fitted in any desired position, but not in a suspended fitting position. Conden-

sate, dripping water, etc. must be prevented from entering the actuator.

To prevent any flow noise from being audible in very quiet rooms, the pressure difference over the

valve must not exceed the following values:

BUL010F*30 = 0.5 bar, F*20 = 0.6 bar / F*10 and F*00 = 0.8 bar

BUL015F*10 = 0.6 bar, F*00 = 0.8 bar

BUL020F*00 = 0.5 bar

So that impurities are retained in the water (welding beads, rust particles, etc.) and the spindle seal is

not damaged, we recommend installing collecting filters, for example one for each floor or pipe run.

Requirements for water quality as per VDI 2035. Medium with coolant such as glycol, min. 16%, max.

40%.

To prevent damage resulting from non-usage, the valves should be activated for a short time at regu-

lar intervals. We recommend performing a stroke movement of at least 10% every month.

Right of amendment reserved © 2015 Fr. Sauter AG 7.1 5/8

Product data sheet 55.009

To increase the functional reliability of the valves, the system should conform to DIN/EN 14336 (heat-

ing systems in buildings). DIN EN 14336 states, amongst other things, that the system has to be

flushed through before being put into service.

When insulating the unit valve, it may only be insulated up to the cap nut or the bayonet ring of the

actuator.

Further information

Fitting instructions MV 505864

Assembly of AXT 211/AXS 215S MV P100002547

With auxiliary contact:

Assembly of AXM 217/217S MV P100011418

Assembly of AXM217F200 MV P100000986

Declaration on materials and the environment MD 55.009

Additional version information

Valve body and T-piece of permanent mould casting nickel-plated, and male thread as per ISO 228/1,

class B, flat seal on body. Stuffing box with O-ring made of ethylene propylene, plug made of brass

with EPDM sealing ring, spindle made of stainless steel, protective cap (or manual adjustment knob)

made of plastic.

Material numbers as per DIN

DIN material no. DIN designation

Valve body CC 754S-GM Cu Zn 39 Pb 1 AI-C according to EN1982

Valve seat CC 754S-GM Cu Zn 39 Pb 1 AI-C according to EN1982

Spindle 1.4305 X 8 Cr Ni S 18-9 according to EN188-1

Plug CW617N Cu Zn 40 Pb 2 according to EN12164

Stuffing box CW617N Cu Zn 40 Pb 2 according to EN12164

Disposal

When disposing of the product, observe the currently applicable local laws.

More information on materials can be found in the Declaration on materials and the environment for

this product.

Dimension drawing

M 30x1,5 M 30x1,5

Ø4 Ø4

s19 s19

11,5

11,5

c

c

G

G

A

F6 . .

G

G

L

Type A c G L 0378135010

BUL 010 F3.. 30 27 G1/2B 60 Type A c G L d

BUL 015 F3.. 30 27 G3/4B 60 BUL 010 F4 . . 40 27 G1/2B 60 -

BUL 020 F3.. 30 27 G1B 60 BUL 015 F4 . . 40 27 G3/4B 60 -

BUL 020 F4 . . 50 27 G1B 60 -

BUL 010 F6 . . 40 27 G1/2B 60 15

6/8 7.1 Right of amendment reserved © 2015 Fr. Sauter AG

Product data sheet 55.009

Accessories

Threaded fitting Solder-joint screw fitting

378133 378134

DN A B L DN A B C L

A

B

10 G1/2 R3/8 24 10 G1/2 12 8,6 14

15 G3/4 R1/2 27,5 15 G3/4 15 10,6 15,5

20 G1 R3/4 32,5 20 G1 22 15.4 20

L C

L

Clamping ring screw fitting

0378145

DN A L Ød h

15 G3/4 39 15,2 12,5

Ød

A

20 G1 41,5 22,2 16

h

L

Assembly

Combinations with thermal actuator AXT and motorised actuator AXM

AXT 211/AXS 215S AXM 217/217S

61

Ø 44

AXM 217(S)

AXM 217S F...

h (max)

h (min)

73

c

c

H (min) H (max)

NC 59 66

NO 59 64

Manual 66.5 73.5

Right of amendment reserved © 2015 Fr. Sauter AG 7.1 7/8

Product data sheet 55.009

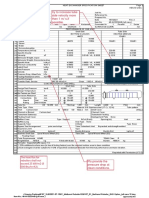

Table of pressure losses for VUL and BUL valves

?Pmax [bar]

0.01

0.02

0.04

0.06

0.1

0.2

0.4

0.6

1.0

4

6

40 11.1

30 Recommended range 8.33

Working range

20 5.55

10 2.77

8 2.22

6 1.67

Kvs-Wert

4

[m3/h] 1.11

5.0

3 0.83

4.0

2 0.55

2.5

V [m3/h]

V [l/s]

1.6

1.0 0.27

0.8 0.22

1.0

0.6 0.17

3

0.6

0.4 0.11

0.3 0.083

0.4

0.2 0.055

6

0.1

0.1 0.027

0.08 0.022

0.06 0.017

0.04 0.011

0.03 ?Pmax [kPa] 0.008

0.025

1

3

4

6

8

10

20

30

40

60

80

100

200

300

400

600

Fr. Sauter AG

Im Surinam 55

CH-4016 Basel

Tel. +41 61 - 695 55 55

www.sauter-controls.com

8/8 7.1 Right of amendment reserved © 2015 Fr. Sauter AG

Das könnte Ihnen auch gefallen

- Sauter Vug032f304Dokument10 SeitenSauter Vug032f304NORODDINENoch keine Bewertungen

- Pressure Drop and Vent Sizing Calculations for 2500 Litre Diesel TankDokument5 SeitenPressure Drop and Vent Sizing Calculations for 2500 Litre Diesel TankDinesh VaghelaNoch keine Bewertungen

- Pressure regulating valve technical manualDokument8 SeitenPressure regulating valve technical manualDavid VilchesNoch keine Bewertungen

- Operating Data - WTP-M A B KSB PumpDokument5 SeitenOperating Data - WTP-M A B KSB Pumphafid CJSPNoch keine Bewertungen

- SelectRT Coils 2023-02-07Dokument2 SeitenSelectRT Coils 2023-02-07Yutt WattNoch keine Bewertungen

- Gas Chiller DatasheetDokument2 SeitenGas Chiller DatasheetidilfitriNoch keine Bewertungen

- Gas Chiller Datasheet PDFDokument2 SeitenGas Chiller Datasheet PDFidilfitriNoch keine Bewertungen

- HM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionDokument2 SeitenHM34 Series Carbon Steel Inverted Bucket Steam Traps: DescriptionsabaNoch keine Bewertungen

- Deep Well Pump 22,8 m3h @141mDokument3 SeitenDeep Well Pump 22,8 m3h @141mAndreas B KresnawanNoch keine Bewertungen

- 3 Way Sauter ValveDokument8 Seiten3 Way Sauter ValverkssNoch keine Bewertungen

- 1615.00209 - BCPDokument4 Seiten1615.00209 - BCPRufus D SNoch keine Bewertungen

- Technical Data Sheet for PumpDokument3 SeitenTechnical Data Sheet for PumpDerkung BenowatNoch keine Bewertungen

- CH 10 Additional ProductsDokument47 SeitenCH 10 Additional Productssaddam khanNoch keine Bewertungen

- Fisher Y690aDokument12 SeitenFisher Y690ayg89Noch keine Bewertungen

- Thruster Room CFW PumpsDokument5 SeitenThruster Room CFW PumpsKiko RijekaNoch keine Bewertungen

- SV10-20 Poppet, 2-Way, Normally Closed: Solenoid ValvesDokument2 SeitenSV10-20 Poppet, 2-Way, Normally Closed: Solenoid ValvesMartin Andrew TugadeNoch keine Bewertungen

- Optimize water flow measurement with a Corona P 423/424 multi-jet meterDokument5 SeitenOptimize water flow measurement with a Corona P 423/424 multi-jet meterDhanushka RathnasooriyaNoch keine Bewertungen

- CORONA P 423/424: Multi-Jet Meter - Wet RunnerDokument5 SeitenCORONA P 423/424: Multi-Jet Meter - Wet RunnerDhanushka RathnasooriyaNoch keine Bewertungen

- Wireline Core Barrel P-p3 LW Cam Latch - 34904 - 595x842Dokument10 SeitenWireline Core Barrel P-p3 LW Cam Latch - 34904 - 595x842Abiot Tarekegn DagnewNoch keine Bewertungen

- Tipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For Diverter ValvesDokument5 SeitenTipiel Sa Tipiel Sa Tipiel Sa Tipiel Sa: Specification Sheets For Diverter ValvesMichell TurbayNoch keine Bewertungen

- TWE 10 - 15 - 18 ENG EU WebsiteDokument2 SeitenTWE 10 - 15 - 18 ENG EU Websitemurtada gubaNoch keine Bewertungen

- Kelvion Select RT Air Cooler DatasheetDokument2 SeitenKelvion Select RT Air Cooler DatasheetRuslan SlusarNoch keine Bewertungen

- Pressure DropDokument36 SeitenPressure DropdesignselvaNoch keine Bewertungen

- MAXIDokument1 SeiteMAXIWilson Romario Pillco LaymeNoch keine Bewertungen

- SCHROEDAHL Automatic Recirculation ValveDokument12 SeitenSCHROEDAHL Automatic Recirculation ValveJaebeom YiNoch keine Bewertungen

- vb7 219-EnDokument4 Seitenvb7 219-EnReynard HaryantoNoch keine Bewertungen

- Overrunning ClutchDokument6 SeitenOverrunning ClutchThang LeNoch keine Bewertungen

- SelectRT Coils 2023-03-30Dokument2 SeitenSelectRT Coils 2023-03-30Aheron HizmoNoch keine Bewertungen

- 2-Way Pressure Reducing Valve: Spool Type, Direct-Acting Metric Cartridge - 450 BarDokument4 Seiten2-Way Pressure Reducing Valve: Spool Type, Direct-Acting Metric Cartridge - 450 BarFelipe Pisklevits LaubeNoch keine Bewertungen

- CM901K Spareparts EN Rev.04Dokument8 SeitenCM901K Spareparts EN Rev.04Elton Luiz Trinchette de SantanaNoch keine Bewertungen

- Re25860 2011-11Dokument12 SeitenRe25860 2011-11melih topcakilNoch keine Bewertungen

- Technical specifications and operating data for hydraulic pumpDokument3 SeitenTechnical specifications and operating data for hydraulic pumpDerkung BenowatNoch keine Bewertungen

- NTBNG0704ENDokument3 SeitenNTBNG0704ENgvp9000Noch keine Bewertungen

- Pump Calc PranayDokument24 SeitenPump Calc PranayNitin KurupNoch keine Bewertungen

- 9.... Evmsg 1023F5 Hq1bege-11Dokument7 Seiten9.... Evmsg 1023F5 Hq1bege-11tinhNoch keine Bewertungen

- ProMinent Beta Solenoid Diaphragm Metering PumpsDokument6 SeitenProMinent Beta Solenoid Diaphragm Metering PumpsRoga29Noch keine Bewertungen

- Fisatehnica533251 7908 41 1706926566Dokument6 SeitenFisatehnica533251 7908 41 1706926566Gina VNoch keine Bewertungen

- 521B0841 DKCFNPD040A902 VRH3060120PressureReliefValve GBDokument5 Seiten521B0841 DKCFNPD040A902 VRH3060120PressureReliefValve GBlayetajNoch keine Bewertungen

- IBAU-Flow Control GateDokument8 SeitenIBAU-Flow Control Gateturbomiha100% (3)

- ECON 3-Piece Firesafe Ball ValveDokument6 SeitenECON 3-Piece Firesafe Ball ValveKunming WangNoch keine Bewertungen

- Modelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11ADokument2 SeitenModelo Pilot-Operated, Reductor de Presión Válvula: Series 1 / Capacidad: 40 L/Min. / Cavidad: T-11AVictor CMNoch keine Bewertungen

- 01-Duct Pressure Drop Calculator FCU-01Dokument9 Seiten01-Duct Pressure Drop Calculator FCU-01Hamdy AdelNoch keine Bewertungen

- Bolt Torque Calculation - Apr19Dokument69 SeitenBolt Torque Calculation - Apr19Raj SNoch keine Bewertungen

- Multifunctional Pilot-Operated Regulator: Technical ManualDokument8 SeitenMultifunctional Pilot-Operated Regulator: Technical ManualJuan JuanNoch keine Bewertungen

- Z612 12-4OS technical data sheetDokument3 SeitenZ612 12-4OS technical data sheetAndreas B KresnawanNoch keine Bewertungen

- Work Shop Manual DV 29Dokument180 SeitenWork Shop Manual DV 29Saeid SharifiNoch keine Bewertungen

- 2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01Dokument2 Seiten2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01controlorNoch keine Bewertungen

- PRDC Sun ValveDokument3 SeitenPRDC Sun ValvekhairulanuarjunNoch keine Bewertungen

- Sec 6 Parts List 8830 Control ConsoleDokument8 SeitenSec 6 Parts List 8830 Control ConsoleRenan Fardim BoronowskyNoch keine Bewertungen

- D070Q Agr CatDokument4 SeitenD070Q Agr CatRuben ManuelNoch keine Bewertungen

- 5 - Counter Balance Valve TSCA 70-10 - CBCHDokument4 Seiten5 - Counter Balance Valve TSCA 70-10 - CBCHIvan MaltsevNoch keine Bewertungen

- Tube Side Velocity CalculationDokument20 SeitenTube Side Velocity CalculationNitin KurupNoch keine Bewertungen

- SQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdDokument4 SeitenSQ8167 - 01 - Methanol Reboiler - BKU Option - (Alt Case 10 Deg Approach) .HTRI 6th Aug 21-CmtdSRINoch keine Bewertungen

- BS-HWC4_Butterfly valveDokument10 SeitenBS-HWC4_Butterfly valvesidparikh254Noch keine Bewertungen

- CBT - Leaflets - 1400G - Van cân bằng nhiệt tự động - MDokument4 SeitenCBT - Leaflets - 1400G - Van cân bằng nhiệt tự động - MNguyễn Xuân HùngNoch keine Bewertungen

- Drawings of BoilerDokument10 SeitenDrawings of Boilerramnath008100% (1)

- En5919 1 0 09 20 - WK08X 01RDokument4 SeitenEn5919 1 0 09 20 - WK08X 01RAyman AlhalfawyNoch keine Bewertungen

- Flow Switches For Insertion Installation: Threaded Adapter With Trimmable PaddleDokument6 SeitenFlow Switches For Insertion Installation: Threaded Adapter With Trimmable Paddleeaglego00Noch keine Bewertungen

- Performance Characteristics of Sensors and Actuators PDFDokument40 SeitenPerformance Characteristics of Sensors and Actuators PDFKuppan Chetty RamanathanNoch keine Bewertungen

- Positioners: Sizing & SelectionDokument4 SeitenPositioners: Sizing & SelectionsnamprogNoch keine Bewertungen

- Finals IEEEDokument7 SeitenFinals IEEEVhinzy AlineaNoch keine Bewertungen

- Intro to Pneumatics: Understanding the Basics of Pneumatic SystemsDokument21 SeitenIntro to Pneumatics: Understanding the Basics of Pneumatic SystemsaddiNoch keine Bewertungen

- Product Portfolio: Ask About Our Expanding Selection of FNW ProductsDokument8 SeitenProduct Portfolio: Ask About Our Expanding Selection of FNW ProductsJvlValenzuelaNoch keine Bewertungen

- Technical Service Bulletin: 6MMT DTC P0900 Clutch Actuator Circuit MalfunctionDokument4 SeitenTechnical Service Bulletin: 6MMT DTC P0900 Clutch Actuator Circuit MalfunctionNv TháiNoch keine Bewertungen

- Fluid Power and Control Lab ManualDokument69 SeitenFluid Power and Control Lab Manualakshay DandadeNoch keine Bewertungen

- ROTORK IQTF Pub002-065-00 0318Dokument34 SeitenROTORK IQTF Pub002-065-00 0318Arturo Treviño MedinaNoch keine Bewertungen

- Hydraulic Pump CalculationsDokument23 SeitenHydraulic Pump CalculationsChinmay Jodder100% (1)

- ACTAIR 1,5 To 1600Dokument20 SeitenACTAIR 1,5 To 1600Muhamad Ekbar SeninNoch keine Bewertungen

- 26300V1 - NEW Woodward Master Index Non-RestrictedDokument70 Seiten26300V1 - NEW Woodward Master Index Non-RestrictedDuong Phan0% (1)

- Bladder Tank O&m, Testing Procedure-UnlockedDokument83 SeitenBladder Tank O&m, Testing Procedure-UnlockedRichard RajkumarNoch keine Bewertungen

- TechnipFMC Long Distance Subsea ControlDokument27 SeitenTechnipFMC Long Distance Subsea ControlNugroho100% (1)

- Valve Control Tops Easymind 2 0 f783 Suedmo Operating Manual enDokument39 SeitenValve Control Tops Easymind 2 0 f783 Suedmo Operating Manual enJosueGonzalezDePalaciosNoch keine Bewertungen

- Iii MicropumpstypesDokument14 SeitenIii Micropumpstypesrajaram huptaNoch keine Bewertungen

- Water Mist Systems FM 5560Dokument314 SeitenWater Mist Systems FM 5560Amir100% (1)

- 1 - CONTROL SYSTEM CONCEPTS Rev2Dokument38 Seiten1 - CONTROL SYSTEM CONCEPTS Rev2Mohamed Bin IerousNoch keine Bewertungen

- (FCENBR00002 02 (E) ControlValve - LR1 PDFDokument36 Seiten(FCENBR00002 02 (E) ControlValve - LR1 PDFMéliani SalahNoch keine Bewertungen

- DOXE B5i - ENG PDFDokument7 SeitenDOXE B5i - ENG PDFRiswanda HimawanNoch keine Bewertungen

- Actuator DRD DREDokument35 SeitenActuator DRD DRESandi AslanNoch keine Bewertungen

- Orbitroles Catalogo GeneralDokument60 SeitenOrbitroles Catalogo GeneralbenjaminNoch keine Bewertungen

- A PDFDokument122 SeitenA PDFmarlonNoch keine Bewertungen

- Steering StabilisationDokument24 SeitenSteering StabilisationRooftop Gardener100% (1)

- CAT 769c Valvula de Control de Transmision 1Dokument28 SeitenCAT 769c Valvula de Control de Transmision 1Taller Pahr100% (1)

- ARW FuzzyDokument62 SeitenARW FuzzyAnubhav PandeyNoch keine Bewertungen

- W01 358 7737Dokument29 SeitenW01 358 7737MROstop.comNoch keine Bewertungen

- CSB Final Report of Fatal Release at Lyondellbasell Plant 1685102063Dokument38 SeitenCSB Final Report of Fatal Release at Lyondellbasell Plant 1685102063mono000Noch keine Bewertungen

- Hydrocom: Experience Real Capacity Control and Energy SavingsDokument8 SeitenHydrocom: Experience Real Capacity Control and Energy SavingsVignesh Dheenakumar100% (1)

- Electromagnetic DamperDokument6 SeitenElectromagnetic DamperamitNoch keine Bewertungen

- 349, Cat02-04 Eng GRP Rev05b Xp-Intelli-s.pdf0Dokument36 Seiten349, Cat02-04 Eng GRP Rev05b Xp-Intelli-s.pdf0sithulibraNoch keine Bewertungen