Beruflich Dokumente

Kultur Dokumente

MVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014

Hochgeladen von

BALACHANDAR SOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MVML/TPM/3S Audit Sheet-Shop Floor/f/03: Rev. No.: 01 Rev. Date: 12th Nov'2014

Hochgeladen von

BALACHANDAR SCopyright:

Verfügbare Formate

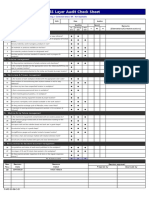

3S - Audit Sheet (Shop floor)

Zone Name : Zone Leader Name :

Audit Level (Pl Tick on Audit Level) 1st □ 2nd □ 3rd □

Audit By Self Team (Cell Leaders) PU Manager HOD / TPM Cell

Audit Frequency Weekly Fortnightly Monthly

Audit Qualifying Score More Than 90 Points More Than 85 Points More Than 80 Points

Score Audit Date

` Check Items Requirements 1 Audit Observations Actions Planned Resp. Target Date

Visible Features at the Shop Entry are properly

1 maintained (Shop Name , Red Area , Assest Area , Scrap 5

,LPG Yard ,stock, Oil Yard,m/c spares, Etc.)

No Unwanted & Unnecessary items lying unattended

around shop peripheral area.( Tea cup , loose papers,

2 Outside Area 5

A

parts, plastic , canteen waste , packaging m/c parts not

lying unattended )

Elements such as structures, buildings & emergency

3 Doors are clean and properly maintained. 5

Shop Layout , All Movable Display boards & Safety

4 Main Entrance Instructions are available & Displayed in the entrance 5

& and maintained in good condition.

B

DWM Area 5s is followed and maintaines at Main Entrance and DWM

5 5

Area

No Material like Parts , Caps , Hardware , Polybags ,

6 Papers , Hand glooves , oil ,coolant , mops ,swart ,cotton 5

found on the floor, No spillage on Conveyor & Line side

All the Line side racks are properly placed, aligned & Part

7 Nos. are displayed on both sides. Parts are placed 5

According to Part Nos. (5S is Respected)

Safety instructions , SOP/ SOS are available/displayed at

the appropriate locations. (Work areas requiring

8 Personal Protective Equipment & MSDS are clearly 5

Labelled / Displayed) Any Documents of that BWT Area

should be available in 4 minute .

Line Condition

C

Tools have a dedicated Storage location that is within

9 reach of the operator. The location is properly labelled, 5

Marked and tools can easily identified if absent ,

Calibration due date can be tracked ,

10 Awareness to Associate and Team Leader. 5

11 Safety is Respected ,(PPE are followed , First Aid Box in 5

maintained etc )

12 5 Donts & 5S Reference standards are Respected on Line 5

Are all Dustbins, tube lights, fans, switches , BWT Board ,

13 Battery Chargers are cleaned and free from dust and 5

dirt , Visual available , Easy to access.

14 5S is Respected in Maintenance crib area & Spare Part 5

area

Switch Board - No Loose Mounting , Caps to All socket,

Maintenance & Earthing points are respected (No Loose & Sticker

15 Utility Area 10

D

Available), No written with marker and Pen on switch

Board , All Swicth Board are Closed.

16 5S audit is adhere & Adequate , Abnormality & Closure 5

Report are shared with Shop Team.

17 Aisles / Gangway are clearly identified and unobstructed 5

from Vehicle / WIP Parts / Trolley etc.

Floors are free from dust dirt, debris, oil, parts,

18 Aisles / Gangway / hardware, empty boxes, packaging material, etc. Drains 5

(if required) are properly located and closed.

E

Washroon

WashRoom & Toilet - No damages , No written & sketch

19 on wall , No Unnecessary items on floor , Clean , Check 5

sheet is adhere & Adequate.

20 Walkways are Respected . 5

21 Tea Table area are identified, Marked & Hygiene is 5

maintained in and around the area & 5S is respected

Tea Table Area

F

22 Involvement of team seen in terms of good displays or 5

and decorations done to improve tea table sitting area?

Rejection area are properly identified& Marked , Red

Rejection Trolley Bins are Respected , Material is Tagged , Daily rejection is

23 Area 5

G

Monitored , Action communication to Line

associate,Awareness to Associate and Team Leader.

All BWT & QCRT are maintained in good condition, No

24 unwanted Material, Boards and Display material is 5

BWT Office & maintained with proper identification, aligned, clean and

looks good , Visual Indication.

H

QCRT

25 Storing racks / Cupboards are maintained as per 5s 5

Norms and not dumped with unnecessary items.

26 Are 5s Audits conducted as per decided frequency by the 5

Audits & team?

Closure

I

27 Is previous month audit closure report submitted to TPM 5

Cell & Improvements are visible?

Respect Audit time , Involve all Member (Maintenance ,

Prod,Logistic Line incharge ), New initiative

28 Team Involvement implemented, Cross Sharing , Drive Audit & Revision of 10

J

Standards .

150

Total

Audit Result Points (Pass - Yes /No)

Auditor Name & Sign.

3S - Audit Sheet (Shop floor)

Zone Name : Zone Leader Name :

Audit Level (Pl Tick on Audit Level) 1st □ 3rd □

Audit By Self Team (Cell Leaders) HOD / TPM Cell

Audit Frequency Weekly Monthly

Audit Qualifying Score More Than 90 Points More Than 80 Points

Score Audit Date

` Check Items Requirements Guideline Actions Planned Resp. Target Date GUIDELINE

Visible Features at the Shop Entry are properly Outside round is Done Once in quarter , All are collected at one place & Sorting is done , Separate location

1 maintained (Shop Name , Red Area , Assest Area , Scrap 5 is made , Identification to each area with Stad displayed ( SOP , Checksheet ) , All Area are clean, tidy & is

,LPG Yard ,stock, Oil Yard,m/c spares, Etc.) maintained always

No Unwanted & Unnecessary items lying unattended

around shop peripheral area.( Tea cup , loose papers, List of unnecessary items are identified near dock & Road side around shop , Closure of identified

2 Outside Area 5

A

parts, plastic , canteen waste , packaging m/c parts not abnormalities , Clean & tidy road and outside area , Standardization of closure , Sustainous of closure .

lying unattended )

3 Elements such as structures, buildings & emergency 5 List of abnormalities are identifiedod structures building Doors , Closure of identified abnormalities ,

Doors are clean and properly maintained. Clean & tidy status , Standardization of action , Sustainous of closure .

Shop Layout , All Movable Display boards & Safety DWM Board & 5S Board location is defined , Shop Layout with ownership is available and Adhere (Layout

4 Main Entrance Instructions are available & Displayed in the entrance 5 & Board) , Clean & Tidy Boards , Standardization (Aligned , lOcation & Updation) of Boards , Sustainious .

& and maintained in good condition.

B

DWM Area 5s is followed and maintaines at Main Entrance and DWM No Unnecessary Items documents , Place for Everything , Clean & Tidy , Standards are Repected ,

5 5

Area Sustainous.

No Material like Parts , Caps , Hardware , Polybags , All SOC are Identified - 1 mark , more than 50 % Countermeasure is taken and implemented -3 , More

6 Papers , Hand glooves , oil ,coolant , mops ,swart ,cotton 5 than 80% countermeasure are closed -4 , No SOC found on Line side - 5 mark

found on the floor, No spillage on Conveyor & Line side

All the Line side racks are properly placed, aligned & Part

7 Nos. are displayed on both sides. Parts are placed 5 1 Mark for Each S of 5S .

According to Part Nos. (5S is Respected)

Safety instructions , SOP/ SOS are available/displayed at

the appropriate locations. (Work areas requiring

8 Personal Protective Equipment & MSDS are clearly 5 No Mix up Documents -1 , Easily accessible & Identification-2 , Documents are Live & Clean-3 , Documents

Labelled / Displayed) Any Documents of that BWT Area are Revised & Not in Hanging and Torn condition-4 , No Abnormaility of documents -5 mark

should be available in 4 minute .

Line Condition Tools have a dedicated Storage location that is within

C

9 reach of the operator. The location is properly labelled, 5 Dedicated Location 1 mark, Insulation & no metal to Metal Contact-2 mark, Easily accessible and Clean

Marked and tools can easily identified if absent , area - 3 , Standardize parking-4 , Sustainious plan and adherence -5 mark

Calibration due date can be tracked ,

10 Awareness to Associate and Team Leader. 5 1 Mark for Each S of 5S .

PPE Not Respected -0 mark. List of Unsafe condition is identified on WS -1 , more than 50 %

11 Safety is Respected ,(PPE are followed , First Aid Box in 5 Countermeasure is taken and implemented -3 , More than 80% countermeasure are closed -4 , No

maintained etc ) Abnormality in First Aid Registrar , First Aid Box , Unsafe condition - 5 mark

12 5 Donts & 5S Reference standards are Respected on Line 5 1 Mark for Each Don’t . If 2 Abnormalities are observed of any Donts , score is Zero for that Donts.

Are all Dustbins, tube lights, fans, switches , BWT Board ,

13 Battery Chargers are cleaned and free from dust and 5 Clean and Tidy 3 , all Visual available with Standard - 4 , All in good Condition - 5 mark.

dirt , Visual available , Easy to access.

14 5S is Respected in Maintenance crib area & Spare Part 5 1 Mark for each S.

area

Switch Board - No Loose Mounting , Caps to All socket,

Maintenance & Earthing points are respected (No Loose & Sticker

15 Utility Area 10 Each Check points carries 2 marks.

D

Available), No written with marker and Pen on switch

Board , All Swicth Board are Closed.

5S audit is adhere & Adequate , Abnormality & Closure

16 Report are shared with Shop Team. 5 1 Mark for each S.

17 Aisles / Gangway are clearly identified and unobstructed 5 No Unnecessary Items - 1 marks , Clean & Tidy area -3 marks, Sustain in Good condition- 5 mark

from Vehicle / WIP Parts / Trolley etc.

Floors are free from dust dirt, debris, oil, parts,

18 Aisles / Gangway / hardware, empty boxes, packaging material, etc. Drains 5 No Unnecessary Items - 1 marks , Clean & Tidy area -3 marks, Sustain in Good condition- 5 mark

(if required) are properly located and closed.

E

Washroon

WashRoom & Toilet - No damages , No written & sketch

19 on wall , No Unnecessary items on floor , Clean , Check 5 Each Check points carries 1 marks.

sheet is adhere & Adequate.

20 Walkways are Respected . 5

Tea Table area are identified, Marked & Hygiene is

21 maintained in and around the area & 5S is respected 5 1 Mark for each S.

Tea Table Area

F

22 Involvement of team seen in terms of good displays or 5 2 marks if Table is Clean & Tidy , Motivation Theme - 3 mark, New motivational Theme -4 Mark ,

and decorations done to improve tea table sitting area? Standards are followed and in Good Condition 5 Mark

Rejection area are properly identified& Marked , Red

Rejection Trolley Bins are Respected , Material is Tagged , Daily rejection is

23 Area 5 1 Mark for Each check point

G

Monitored , Action communication to Line

associate,Awareness to Associate and Team Leader.

All BWT & QCRT are maintained in good condition, No

unwanted Material, Boards and Display material is

24 maintained with proper identification, aligned, clean and 5 1 Mark for Each check point

BWT Office &

looks good , Visual Indication.

H

QCRT

Storing racks / Cupboards are maintained as per 5s

25 Norms and not dumped with unnecessary items. 5 1 Mark for each S.

26 Are 5s Audits conducted as per decided frequency by the 5 Latest Audit sheet is shown - 1 mark , Shop Gaps are identified & All Area Score is monitored - 2 , shop

Audits & team? floor condition matches with Audit Sheet- 3 mark, Shop Round focus in Lagging Area - 4 .

Closure

I

Is previous month audit closure report submitted to TPM Closure Report Submitted 2 mark, Incomplete Closure report - 3 , 85 % closure of points 4 mark , more

27 Cell & Improvements are visible? 5 than 95 % closure - 5 mark

Respect Audit time , Involve all Member (Maintenance ,

28 Team Involvement Prod,Logistic Line incharge ), New initiative 10 Each Point Carries 2 mark.

implemented, Cross Sharing , Drive Audit & Revision of

J

Standards .

150

Total

Audit Result Points (Pass - Yes /No)

Auditor Name & Sign.

Outside Area 10.0 Chart Title

Main Entrance & DWM Area 6.7

Line Condition 26.7

Maintenance & Utility Area 13.3

Aisles / Gangway Washroom 13.3

Tea Table 6.7

Rejection Area 3.3

BWT Office & QCRT 6.7

Audit closure 6.7

Outs i de Area

Team involvement 6.7 Ma i n Entra nce & DWM Area

Li ne Condi tion

Ma i ntena nce & Util i ty Area

Total 100 Ai s l es / Gangway Was hroom

Tea Ta bl e

Rejection Area

BWT Office & QCRT

Audi t cl os ure

Title Chart Title

6.7 6.7 10.0

6.7 6.7

3.3 26.7

6.7

13.3 13.3

Outsi de Area

& DWM Area Ma i n Entra nce & DWM Area

Li ne Condi tion

Util i ty Area Ma i ntenance & Util i ty Area

ay Was hroom Ai s l es / Ga ngway Was hroom

Tea Ta bl e

Rejection Area

RT BWT Office & QCRT

Audit cl os ure

Das könnte Ihnen auch gefallen

- 5 SDokument9 Seiten5 Sarai29733Noch keine Bewertungen

- 5S Audit Check SheetDokument5 Seiten5S Audit Check SheetKalki KalkiNoch keine Bewertungen

- Shriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)Dokument5 SeitenShriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)deepak sharma100% (1)

- 5s Audit Check SheetDokument1 Seite5s Audit Check SheetDevendra Singh100% (1)

- 1S2S3S - Check SheetDokument1 Seite1S2S3S - Check SheetManoj KaushikNoch keine Bewertungen

- Housing Keeping Audit Check List: Area: MonthDokument4 SeitenHousing Keeping Audit Check List: Area: MonthMagesh WaranNoch keine Bewertungen

- 5s - Office ChecklistDokument1 Seite5s - Office ChecklistChokri AouinaNoch keine Bewertungen

- MVML/TPM/3S Audit Sheet-Shop Floor/f/03Dokument1 SeiteMVML/TPM/3S Audit Sheet-Shop Floor/f/03BALACHANDAR SNoch keine Bewertungen

- 5S Audit Checklist FactoryDokument2 Seiten5S Audit Checklist FactoryGaneshNoch keine Bewertungen

- 5S Audit Check SheetDokument1 Seite5S Audit Check SheetSiva Subramanian ( Ebauche )Noch keine Bewertungen

- 3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1Dokument1 Seite3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNoch keine Bewertungen

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Dokument1 SeiteAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SNoch keine Bewertungen

- 05 House KeepingDokument4 Seiten05 House Keepingjosira6121Noch keine Bewertungen

- Process Audit - Sheet New ......Dokument1 SeiteProcess Audit - Sheet New ......MUKESH KUMARNoch keine Bewertungen

- 5s AuditchecklistDokument8 Seiten5s AuditchecklistDINESH SHARMANoch keine Bewertungen

- 1S 2S - Audit Sheet (Shopfloor) : MQS/TPM/3S/1S2S Audit Sheet-Shop Floor/f/03 Rev. No.: 00 Rev. Date: 10th April'2013 1Dokument1 Seite1S 2S - Audit Sheet (Shopfloor) : MQS/TPM/3S/1S2S Audit Sheet-Shop Floor/f/03 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNoch keine Bewertungen

- Batch Production RecordDokument83 SeitenBatch Production Recordsina yadegari100% (1)

- Maintain Training FacilitiesDokument14 SeitenMaintain Training FacilitiesArlynPorrasBonifacioNoch keine Bewertungen

- Daimler-Chrysler Layered Process AuditsDokument27 SeitenDaimler-Chrysler Layered Process AuditsR JNoch keine Bewertungen

- 1 S Checklist ShopfloorDokument2 Seiten1 S Checklist ShopfloorImam MansyurNoch keine Bewertungen

- Housekeeping ChecklistDokument1 SeiteHousekeeping ChecklistSachin Yashwant kumbharNoch keine Bewertungen

- Daimler-Chrysler Layered Process Audits (DCX Lpa) : Alberta RisnerDokument23 SeitenDaimler-Chrysler Layered Process Audits (DCX Lpa) : Alberta Risneralberto100% (1)

- 6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1Dokument5 Seiten6'S Audit Sheet: Step S.No Item Rating (0-5) Comments 5 4 3 2 1stylish eagleNoch keine Bewertungen

- New Microsoft Excel WorksheetDokument9 SeitenNew Microsoft Excel WorksheetVijay Kumar GuptaNoch keine Bewertungen

- NT-SCM-F06 Supplier Audit & Evaluation SheetDokument7 SeitenNT-SCM-F06 Supplier Audit & Evaluation SheetSuraj RawatNoch keine Bewertungen

- BF Area - 5S Check ListDokument30 SeitenBF Area - 5S Check ListVi KraNoch keine Bewertungen

- Information:: YellowDokument6 SeitenInformation:: YellowAllocation ResourceNoch keine Bewertungen

- 5s Audit PlanDokument3 Seiten5s Audit PlansomuanindianNoch keine Bewertungen

- Audit Area: Stores / Goods in Name of Auditor:: Check Item Description Check Item DescriptionDokument1 SeiteAudit Area: Stores / Goods in Name of Auditor:: Check Item Description Check Item DescriptionrjueiNoch keine Bewertungen

- 5S ChecksheetDokument1 Seite5S ChecksheetbasavarajNoch keine Bewertungen

- Auditor Auditee Audit Zone: Audit Date: 5S Audit Check List - Scoring GuidelinesDokument2 SeitenAuditor Auditee Audit Zone: Audit Date: 5S Audit Check List - Scoring GuidelinesRishi Gautam100% (2)

- 5S Guidelines, Checklist, Rules & ResponsibilityDokument14 Seiten5S Guidelines, Checklist, Rules & ResponsibilityNurin Afzani Makrai71% (7)

- 5S - Levels of ExcellenceDokument2 Seiten5S - Levels of ExcellenceRamanagiri BharathanNoch keine Bewertungen

- PP 3) . - Aud's S's OficinasDokument2 SeitenPP 3) . - Aud's S's OficinasJose OrtegaNoch keine Bewertungen

- 5S Check List: Geographical Area Zone Number SL - No Activity Check Lists YES NO Score Sort - 1SDokument2 Seiten5S Check List: Geographical Area Zone Number SL - No Activity Check Lists YES NO Score Sort - 1Sgowtham_venkat_4Noch keine Bewertungen

- Minda Stoneridge Instruments LTD: 5S Audit Check Sheet-Shop FloorDokument5 SeitenMinda Stoneridge Instruments LTD: 5S Audit Check Sheet-Shop FloorMangesh YenkarNoch keine Bewertungen

- S5 - Sustain: 5S Housekeeping Score SheetDokument1 SeiteS5 - Sustain: 5S Housekeeping Score SheetRama PrasetiaNoch keine Bewertungen

- Supplier Audit Check ListDokument6 SeitenSupplier Audit Check ListShalinMishraNoch keine Bewertungen

- 4638 20210429 10 23 18 Sci-Ims-P-10.2 Form 2 Page 1 Rev. 02 Ehs Non-Conformity or Safety Observation Checklist FormDokument10 Seiten4638 20210429 10 23 18 Sci-Ims-P-10.2 Form 2 Page 1 Rev. 02 Ehs Non-Conformity or Safety Observation Checklist Formvelumurgan mNoch keine Bewertungen

- 5s ChecklistDokument8 Seiten5s ChecklistMohini MaratheNoch keine Bewertungen

- Maintain Training FacilitiesDokument10 SeitenMaintain Training FacilitiesCatherine SolNoch keine Bewertungen

- Audit Check List-9001Dokument9 SeitenAudit Check List-9001akash batraNoch keine Bewertungen

- Operational Procedure: Equipment Type Equipment Code Location Operation ProcedureDokument9 SeitenOperational Procedure: Equipment Type Equipment Code Location Operation ProcedureJoel MilanNoch keine Bewertungen

- Form Penilaian 5SDokument1 SeiteForm Penilaian 5Smuhamad nardinubaNoch keine Bewertungen

- Maintain Training FacilitiesDokument10 SeitenMaintain Training Facilitieslei melendrezNoch keine Bewertungen

- Internal Audit Checklist - StoresDokument2 SeitenInternal Audit Checklist - StoresSachin Ramdurg75% (4)

- 5S Safety AuditDokument9 Seiten5S Safety Auditmuthuswamy77Noch keine Bewertungen

- Welcome: Workplace Organization & Housekeeping 101Dokument70 SeitenWelcome: Workplace Organization & Housekeeping 101Pedro SousaNoch keine Bewertungen

- 5S ChecklistDokument2 Seiten5S Checklisteidlberto casedoNoch keine Bewertungen

- 5S - Levels of ExcellenceDokument2 Seiten5S - Levels of ExcellenceHartoyo SwiNoch keine Bewertungen

- 5S - Excellence Assessment PDFDokument2 Seiten5S - Excellence Assessment PDFAshokNoch keine Bewertungen

- PSSR ChecklistDokument5 SeitenPSSR ChecklistzhangjieNoch keine Bewertungen

- Maintain Training FacilitiesDokument15 SeitenMaintain Training FacilitiesrobNoch keine Bewertungen

- Maintain Training FacilitiesDokument10 SeitenMaintain Training FacilitiesSSVTC LRCNoch keine Bewertungen

- Dozer InspectionDokument8 SeitenDozer Inspectionkhaled fathyNoch keine Bewertungen

- 5S Audit FormDokument2 Seiten5S Audit Formmounirs719883Noch keine Bewertungen

- 5S Audit FormDokument2 Seiten5S Audit FormNavnath Tamhane100% (2)

- Plating Process Audit Checksheet 9332E-XDokument3 SeitenPlating Process Audit Checksheet 9332E-Xabhionlyster63% (8)

- 5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityVon Everand5S: A Practical Guide to Visualizing and Organizing Workplaces to Improve ProductivityBewertung: 5 von 5 Sternen5/5 (3)

- 5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsVon Everand5S- The True Mean to Enhance Productivity and Work Value for Customers: Toyota Production System ConceptsBewertung: 5 von 5 Sternen5/5 (1)

- PRICE LISTDokument3 SeitenPRICE LISTBALACHANDAR SNoch keine Bewertungen

- Sustainability Awareness Behavior Based Safety Industrial Fire HandlingDokument1 SeiteSustainability Awareness Behavior Based Safety Industrial Fire HandlingBALACHANDAR SNoch keine Bewertungen

- grdgzsdthgdfkjgkjhDokument8 SeitengrdgzsdthgdfkjgkjhBALACHANDAR SNoch keine Bewertungen

- Step 4: Overall InspectionDokument8 SeitenStep 4: Overall InspectionBALACHANDAR SNoch keine Bewertungen

- OS For Domain B 3mu The Killer Virus!Dokument5 SeitenOS For Domain B 3mu The Killer Virus!BALACHANDAR SNoch keine Bewertungen

- Audit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50Dokument1 SeiteAudit Sheet For 5S Evaluation - Shop Floor: 1S2S3S Score (1S + 2S + 3S) / 50BALACHANDAR SNoch keine Bewertungen

- Name of Applicant: Personal DetailsDokument4 SeitenName of Applicant: Personal DetailsBALACHANDAR SNoch keine Bewertungen

- Level 4 Level 3 Level 2 Level 1 Skill Levels: Concept of Skill-UpDokument1 SeiteLevel 4 Level 3 Level 2 Level 1 Skill Levels: Concept of Skill-UpBALACHANDAR SNoch keine Bewertungen

- AlagDokument31 SeitenAlagBALACHANDAR SNoch keine Bewertungen

- MQS/TPM/3S/1S2S Audit Sheet-Office/F/04 Rev. No.: 00 Rev. Date: 10th April'2013 1Dokument1 SeiteMQS/TPM/3S/1S2S Audit Sheet-Office/F/04 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNoch keine Bewertungen

- Key Benefits Summary (1S 2S 3S) : F - (FY &month) SR - No. Description BenefitsDokument1 SeiteKey Benefits Summary (1S 2S 3S) : F - (FY &month) SR - No. Description BenefitsBALACHANDAR SNoch keine Bewertungen

- MVML/TPM/3S Audit Sheet-Shop Floor/f/03Dokument1 SeiteMVML/TPM/3S Audit Sheet-Shop Floor/f/03BALACHANDAR SNoch keine Bewertungen

- PU / Shop Zone Area Description Zone Leader's Name: 3 'S' Zones Details - PlantDokument1 SeitePU / Shop Zone Area Description Zone Leader's Name: 3 'S' Zones Details - PlantBALACHANDAR SNoch keine Bewertungen

- 3S' Score Board - PU: Total Plant Level ScoreDokument1 Seite3S' Score Board - PU: Total Plant Level ScoreBALACHANDAR SNoch keine Bewertungen

- 3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1Dokument1 Seite3S - Audit Sheet (Shopfloor) : MQS/TPM/3S/3S Audit Sheet-Shop Floor/f/05 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNoch keine Bewertungen

- 3S' Score Board - PlantDokument1 Seite3S' Score Board - PlantBALACHANDAR SNoch keine Bewertungen

- 1S 2S - Audit Sheet (Shopfloor) : MQS/TPM/3S/1S2S Audit Sheet-Shop Floor/f/03 Rev. No.: 00 Rev. Date: 10th April'2013 1Dokument1 Seite1S 2S - Audit Sheet (Shopfloor) : MQS/TPM/3S/1S2S Audit Sheet-Shop Floor/f/03 Rev. No.: 00 Rev. Date: 10th April'2013 1BALACHANDAR SNoch keine Bewertungen

- Improvement Sheet (1S 2S 3S)Dokument1 SeiteImprovement Sheet (1S 2S 3S)BALACHANDAR SNoch keine Bewertungen

- This Moment Is Real and Valuable Give More Than You Take Build Trust by Giving Trust If We Did Good We Will Get GoodDokument1 SeiteThis Moment Is Real and Valuable Give More Than You Take Build Trust by Giving Trust If We Did Good We Will Get GoodBALACHANDAR SNoch keine Bewertungen

- Quality DocumentsDokument221 SeitenQuality DocumentsBALACHANDAR SNoch keine Bewertungen

- RA 8203 - Special Law On Counterfeit DrugsDokument13 SeitenRA 8203 - Special Law On Counterfeit DrugsYuzu SakuraNoch keine Bewertungen

- The Health Care Delivery System in The PhilippinesDokument15 SeitenThe Health Care Delivery System in The PhilippinesXandra Basnillo100% (2)

- 30 BÀI LUẬN MẪU DÀNH CHO HS CẤP 2Dokument7 Seiten30 BÀI LUẬN MẪU DÀNH CHO HS CẤP 2Đào Thị HảiNoch keine Bewertungen

- The Value of Urine Specific Gravity in Detecting Diabetes Insipidus in A Patient With DMDokument2 SeitenThe Value of Urine Specific Gravity in Detecting Diabetes Insipidus in A Patient With DMFaryalBalochNoch keine Bewertungen

- Nursing TheoryDokument13 SeitenNursing TheoryYana VictyNoch keine Bewertungen

- Nurs 3021 Midterm Evaluation - Blessing Nwogu 1Dokument17 SeitenNurs 3021 Midterm Evaluation - Blessing Nwogu 1api-673227957Noch keine Bewertungen

- 2013 Nursing BulletsDokument77 Seiten2013 Nursing BulletsHarley Justiniani Dela CruzNoch keine Bewertungen

- And The Band Played On - Day 3 and 4 AnswersDokument5 SeitenAnd The Band Played On - Day 3 and 4 AnswersAngelica ValmonteNoch keine Bewertungen

- Freiburg Flap ApplicatorDokument3 SeitenFreiburg Flap Applicatorapi-299403846Noch keine Bewertungen

- Clinical Evaluation and Management of Spasticity PDFDokument397 SeitenClinical Evaluation and Management of Spasticity PDFRicardo Pedro100% (1)

- 3.1.1.3 CONTOH Pedoman Manual Mutu OKKKKDokument39 Seiten3.1.1.3 CONTOH Pedoman Manual Mutu OKKKKsapnah SKM100% (1)

- MSN Project Template Su21Dokument47 SeitenMSN Project Template Su21api-577186606Noch keine Bewertungen

- Nursing Care Plan For Coronary Artery DiseaseDokument3 SeitenNursing Care Plan For Coronary Artery DiseaseLorraineAnneSantiagoCandelario91% (22)

- PCO Accreditation Application Form 2017Dokument3 SeitenPCO Accreditation Application Form 2017Miguel Pillas100% (4)

- Who Boys Z Score PDFDokument15 SeitenWho Boys Z Score PDFRizky Indah SorayaNoch keine Bewertungen

- ICH Guideline E2C (R2) - Questions and AnswersDokument26 SeitenICH Guideline E2C (R2) - Questions and Answersaicha MbarekNoch keine Bewertungen

- Regula - Suture Products and Techniques What To Use, Where, and Why - 2015Dokument14 SeitenRegula - Suture Products and Techniques What To Use, Where, and Why - 2015Ana MariaNoch keine Bewertungen

- Persuasive Essay On Weed LegalizationDokument6 SeitenPersuasive Essay On Weed LegalizationAlyssa HilliardNoch keine Bewertungen

- PolicyDokument5 SeitenPolicySriharsha ReddyNoch keine Bewertungen

- AmoebiasisDokument54 SeitenAmoebiasistummalapalli venkateswara rao0% (1)

- Culture Bound Syndromes NotesDokument7 SeitenCulture Bound Syndromes NotesPragnya NidugondaNoch keine Bewertungen

- 839 FullDokument5 Seiten839 Fullwinda athyaNoch keine Bewertungen

- Venta Airwasher User Manual (LW 44, LW 24, LW 14)Dokument16 SeitenVenta Airwasher User Manual (LW 44, LW 24, LW 14)Tom100% (5)

- Professional Exchange Program Krakow, Poland By: Luthfiyya Syafiqa TahanyDokument3 SeitenProfessional Exchange Program Krakow, Poland By: Luthfiyya Syafiqa Tahanyluthfiyya syafiqaNoch keine Bewertungen

- Mad - men.S01E01.720p.bluray.2CH.x264 PSADokument62 SeitenMad - men.S01E01.720p.bluray.2CH.x264 PSARakshan SharmaNoch keine Bewertungen

- A Detailed Lesson Plan in ScienceDokument6 SeitenA Detailed Lesson Plan in ScienceJohny Villanueva78% (72)

- CaffeineDokument11 SeitenCaffeineDuch Guillen SoloveresNoch keine Bewertungen

- Download: Spirit Releasement Therapy: A Technique ManualDokument6 SeitenDownload: Spirit Releasement Therapy: A Technique ManualНиколай КутузовNoch keine Bewertungen

- PRC-BON Resolution No. 17 Series of 2010Dokument2 SeitenPRC-BON Resolution No. 17 Series of 2010PhilippineNursingDirectory.comNoch keine Bewertungen

- Elca/Cspm Final Exam 2007 14 July, 2007Dokument23 SeitenElca/Cspm Final Exam 2007 14 July, 2007Dr Atef Hadedy100% (3)