Beruflich Dokumente

Kultur Dokumente

Syllabus QC PDF

Hochgeladen von

mathewalex18Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Syllabus QC PDF

Hochgeladen von

mathewalex18Copyright:

Verfügbare Formate

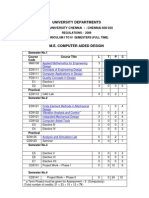

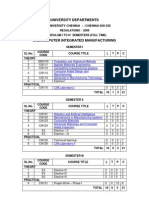

ED5152 QUALITY CONCEPTS IN DESIGN L T P C

3 0 0 3

OBJECTIVE:

To impart knowledge on various concepts in engineering design and principles of

implementing quality in a product or service through tools such as quality houses, control

charts, statistical process control method, failure mode effect analysis and various

strategies of designing experiments, methods to uphold the status of six sigma and

improve the reliability of a product.

UNIT I DESIGN FUNDAMENTALS, METHODS AND MATERIAL SELECTION 9

Morphology of Design – The Design Process – Computer Aided Engineering – Concurrent

Engineering – Competition Bench Marking – Creativity – Theory of Problem solving (TRIZ) – Value

Analysis - Design for Manufacture, Design for Assembly – Design for casting, Forging, Metal

Forming, Machining and Welding

UNIT II DESIGN FOR QUALITY 9

Quality Function Deployment - House of Quality-Objectives and functions-Targets-Stakeholders-

Measures and Matrices-Design of Experiments –design process-Identification of control factors,

noise factors, and performance metrics - developing the experimental plan- experimental design –

testing noise factors- Running the experiments –Conducting the analysis-Selecting and

conforming factor-Set points-reflecting and repeating.

UNIT III FAILURE MODE EFFECTS ANALYSIS AND DESIGN FOR SIX SIGMA 9

Basic methods: Refining geometry and layout, general process of product embodiment -

Embodiment checklist- Advanced methods: systems modeling, mechanical embodiment

principles- MEA method - linking fault states to systems modeling - Basis of SIX SIGMA –Project

selection for SIX SIGMA- SIX SIGMA problem solving- SIX SIGMA in service and small

organizations - SIX SIGMA and lean production –Lean SIX SIGMA and services

UNIT IV DESIGN OF EXPERIMENTS 9

Importance of Experiments, Experimental Strategies, Basic principles of Design, Terminology,

ANOVA, Steps in Experimentation, Sample size, Single Factor experiments - Completely

Randomized design, Randomized Block design, Statistical Analysis, Multifactor experiments - Two

and three factor full Factorial experiments, 2K factorial Experiments, Confounding and Blocking

designs, Fractional factorial design, Taguchi’s approach - Steps in experimentation, Design using

Orthogonal Arrays, Data Analysis, Robust Design- Control and Noise factors, S/N ratios

UNIT V STATISTICAL CONSIDERATION AND RELIABILITY 9

Frequency distributions and Histograms- Run charts –stem and leaf plots- Pareto diagrams-Cause

and Effect diagrams-Box plots- Probability distribution-Statistical Process control–Scatter diagrams

–Multivariable charts –Matrix plots and 3-D plots.-Reliability-Survival and Failure-Series and

parallel systems-Mean time between failure-Weibull distribution

TOTAL: 45 PERIODS

OUTCOME:

It helps the students to get familiarized with various concepts in design, quality and

reliability principles in the design of an engineering product or a service.

REFERENCES:

1. Dieter, George E., “Engineering Design - A Materials and Processing Approach”, McGraw Hill,

International Editions, Singapore, 2000.

2. Fundamentals of Quality control and improvement 2nd edition, Amitava Mitra, Pearson

Education Asia, 2002.

3. Montgomery, D.C., Design and Analysis of experiments, John Wiley and Sons, 2003.

4. Phillip J.Rose, Taguchi techniques for quality engineering, McGraw Hill, 1996.

5. Product Design And Development, Karl t. Ulrich, Steven D. Eppinger,Tata Mcgraw-Hill- 3rd

Edition, 2003.

6. Product Design Techniques in Reverse Engineering and New Product Development, Kevin

Otto & Kristin Wood, Pearson Education (LPE), 2001.

Das könnte Ihnen auch gefallen

- M.E. Mech (Prod Des & Devp)Dokument41 SeitenM.E. Mech (Prod Des & Devp)Peter PushpanathanNoch keine Bewertungen

- Anna University Affiliated Institutions M.E. Engineering Design CurriculumDokument36 SeitenAnna University Affiliated Institutions M.E. Engineering Design CurriculumAnonymous RCbfTbNoch keine Bewertungen

- Anna University ME Product Design and Development CurriculumDokument10 SeitenAnna University ME Product Design and Development Curriculumelango_mm3307Noch keine Bewertungen

- Engineering DesignDokument34 SeitenEngineering DesignEmmanuel NicholasNoch keine Bewertungen

- MTech PLM 2011Dokument15 SeitenMTech PLM 2011Ubaid BahussainNoch keine Bewertungen

- Engineering Design for Manufacture and AssemblyDokument6 SeitenEngineering Design for Manufacture and AssemblyMariappan ArumugamNoch keine Bewertungen

- Terminologies of Unit 1 2 3 06 12 2022Dokument6 SeitenTerminologies of Unit 1 2 3 06 12 2022ajaybalajiranganNoch keine Bewertungen

- Engineering Design SyllabusDokument49 SeitenEngineering Design SyllabusanandandmeenaNoch keine Bewertungen

- Mtech Ie PDFDokument15 SeitenMtech Ie PDFAnonymous 1kUvpdbWGNoch keine Bewertungen

- Sem 3Dokument7 SeitenSem 3Upender DhullNoch keine Bewertungen

- Anna University Curriculum for ME Manufacturing EngineeringDokument34 SeitenAnna University Curriculum for ME Manufacturing EngineeringAnantha NarayananNoch keine Bewertungen

- List & Details of Some of The Subjects Studied in M.tech Industrial Engineering CurriculumDokument2 SeitenList & Details of Some of The Subjects Studied in M.tech Industrial Engineering CurriculumkishorechakravarthyNoch keine Bewertungen

- Advanced Manufacturing SystemsDokument23 SeitenAdvanced Manufacturing SystemsDhanish KumarNoch keine Bewertungen

- Anna University EDDokument48 SeitenAnna University EDSivaji SivaNoch keine Bewertungen

- Industrial Engineering and Management-PrintDokument55 SeitenIndustrial Engineering and Management-PrintekstsalembaNoch keine Bewertungen

- Mechanical Engineering Department Scheme of Examination M. Tech. (Product Design and DevelopmentDokument7 SeitenMechanical Engineering Department Scheme of Examination M. Tech. (Product Design and Developmentharshottam2977Noch keine Bewertungen

- M.Tech - AMS - III - IV - SyllabusDokument5 SeitenM.Tech - AMS - III - IV - Syllabusshaukat779sdNoch keine Bewertungen

- M.Tech SOFTWARE ENGINEERING Curriculum and Elective CoursesDokument50 SeitenM.Tech SOFTWARE ENGINEERING Curriculum and Elective CoursessavitrinaikNoch keine Bewertungen

- Vehicle Design Lecture1Dokument31 SeitenVehicle Design Lecture1noubyluxorNoch keine Bewertungen

- Sem 2Dokument11 SeitenSem 2jtsrinivasdownNoch keine Bewertungen

- Regulations - 2009 M.E. Cad / CamDokument10 SeitenRegulations - 2009 M.E. Cad / CamRajueswarNoch keine Bewertungen

- ME CAD SyllabusDokument50 SeitenME CAD Syllabussubha_aeroNoch keine Bewertungen

- MTech Construction Engineering & Management Course OutlineDokument26 SeitenMTech Construction Engineering & Management Course OutlineRamzad KumbleNoch keine Bewertungen

- BDM Curriculum 1665047518017Dokument2 SeitenBDM Curriculum 1665047518017syedNoch keine Bewertungen

- Pom IeDokument5 SeitenPom IepmagrawalNoch keine Bewertungen

- M.E. Software Engineering Regulations 2009Dokument22 SeitenM.E. Software Engineering Regulations 2009Karthik Sp0% (1)

- M.E. Engineering DesignDokument47 SeitenM.E. Engineering DesignSms RajaNoch keine Bewertungen

- ANNA UNIVERSITY M.E. COMPUTER AIDED DESIGN REGULATIONSDokument50 SeitenANNA UNIVERSITY M.E. COMPUTER AIDED DESIGN REGULATIONSJoswa CaxtonNoch keine Bewertungen

- Mtech Iem 2013Dokument12 SeitenMtech Iem 2013Jaykrishnan GopalakrishnanNoch keine Bewertungen

- Amie SylllDokument28 SeitenAmie SylllORKUTSHOEBNoch keine Bewertungen

- Semester 5 McaDokument8 SeitenSemester 5 McaSreekanth JayanNoch keine Bewertungen

- Syllabus M.tech MechanicalDokument23 SeitenSyllabus M.tech Mechanicalडॉ. कनिष्क शर्माNoch keine Bewertungen

- IP5SEMSYLLABUSDokument6 SeitenIP5SEMSYLLABUSAditya RaoNoch keine Bewertungen

- Master Product Design CurriculumDokument41 SeitenMaster Product Design CurriculumVenkatakrishnan NatchiappanNoch keine Bewertungen

- 1 Cad Cam Intro PDFDokument40 Seiten1 Cad Cam Intro PDFWesleyNoch keine Bewertungen

- Syllabus Prod. MNGTDokument1 SeiteSyllabus Prod. MNGTNalini PuthranNoch keine Bewertungen

- ME LM SyllabusDokument5 SeitenME LM SyllabusSiddharth Narayanan ChidambareswaranNoch keine Bewertungen

- First Sem PDFDokument5 SeitenFirst Sem PDFRajvardhan JaidevaNoch keine Bewertungen

- Course 11.pdfind. EnggDokument5 SeitenCourse 11.pdfind. EnggNavneet VermaNoch keine Bewertungen

- M.e.,cim SyllabusDokument44 SeitenM.e.,cim SyllabusSiva PrakashNoch keine Bewertungen

- Regina Problem DomainDokument62 SeitenRegina Problem DomainRmoodiRNoch keine Bewertungen

- Seminar Proposal For SHSJ ADC Dan Elemia Ver 1.0Dokument57 SeitenSeminar Proposal For SHSJ ADC Dan Elemia Ver 1.0Charlton S.InaoNoch keine Bewertungen

- GTU M.E CAD/CAM Subject Advanced Materials And ProcessesDokument29 SeitenGTU M.E CAD/CAM Subject Advanced Materials And ProcessesDilip SutariaNoch keine Bewertungen

- M.E. Computer Integrated Manufacturing Curriculum RegulationsDokument42 SeitenM.E. Computer Integrated Manufacturing Curriculum RegulationsJeyaram KumarNoch keine Bewertungen

- Puter Integrated Manufacturing SyllabusDokument41 SeitenPuter Integrated Manufacturing SyllabusJoswa CaxtonNoch keine Bewertungen

- M.E. CAD/CAM CURRICULUM AND SYLLABUS AT ANNA UNIVERSITYDokument27 SeitenM.E. CAD/CAM CURRICULUM AND SYLLABUS AT ANNA UNIVERSITYBhuvanesh KumarNoch keine Bewertungen

- Machine Design P1-25Dokument11 SeitenMachine Design P1-25Carl Vincent TaboadaNoch keine Bewertungen

- Creative Engineering Design & Analysis (Theory & Practice) 16MPD31Dokument4 SeitenCreative Engineering Design & Analysis (Theory & Practice) 16MPD31Sai SrinivasNoch keine Bewertungen

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesVon EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesBewertung: 4 von 5 Sternen4/5 (4)

- Artificial intelligence: AI in the technologies synthesis of creative solutionsVon EverandArtificial intelligence: AI in the technologies synthesis of creative solutionsNoch keine Bewertungen

- Implementing the Stakeholder Based Goal-Question-Metric (Gqm) Measurement Model for Software ProjectsVon EverandImplementing the Stakeholder Based Goal-Question-Metric (Gqm) Measurement Model for Software ProjectsNoch keine Bewertungen

- Product Performance Evaluation using CAD/CAE: The Computer Aided Engineering Design SeriesVon EverandProduct Performance Evaluation using CAD/CAE: The Computer Aided Engineering Design SeriesNoch keine Bewertungen

- Integrated Design of Multiscale, Multifunctional Materials and ProductsVon EverandIntegrated Design of Multiscale, Multifunctional Materials and ProductsNoch keine Bewertungen

- Modeling and Problem Solving Techniques for EngineersVon EverandModeling and Problem Solving Techniques for EngineersNoch keine Bewertungen

- The Analytics Lifecycle Toolkit: A Practical Guide for an Effective Analytics CapabilityVon EverandThe Analytics Lifecycle Toolkit: A Practical Guide for an Effective Analytics CapabilityNoch keine Bewertungen

- Knowledge-Based Process Planning for Construction and ManufacturingVon EverandKnowledge-Based Process Planning for Construction and ManufacturingNoch keine Bewertungen

- Steps For PF Amount Transfer (New) ..............Dokument5 SeitenSteps For PF Amount Transfer (New) ..............SasiKumar PetchiappanNoch keine Bewertungen

- Grade 3 MathsDokument3 SeitenGrade 3 MathsSasiKumar PetchiappanNoch keine Bewertungen

- Work Permit (Ra Puram) - 28-Nov - 2013Dokument1 SeiteWork Permit (Ra Puram) - 28-Nov - 2013SasiKumar PetchiappanNoch keine Bewertungen

- Slot Information Report - 07!15!2015!19!28-07Dokument2 SeitenSlot Information Report - 07!15!2015!19!28-07SasiKumar PetchiappanNoch keine Bewertungen

- A R Collage of Engineering and TechnologyDokument1 SeiteA R Collage of Engineering and TechnologySasiKumar PetchiappanNoch keine Bewertungen

- Chapter-4: 4.1 Matrix MaterialsDokument17 SeitenChapter-4: 4.1 Matrix MaterialsSasiKumar PetchiappanNoch keine Bewertungen

- Front Pagels and BonofideDokument2 SeitenFront Pagels and BonofideSasiKumar PetchiappanNoch keine Bewertungen

- User Manual 5 PDFDokument518 SeitenUser Manual 5 PDFSasiKumar PetchiappanNoch keine Bewertungen

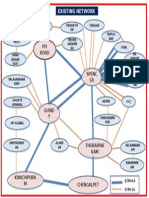

- Existing Network Connecting Key Areas in ChennaiDokument1 SeiteExisting Network Connecting Key Areas in ChennaiSasiKumar PetchiappanNoch keine Bewertungen

- Slot Information Report - 07!15!2015!19!28-07Dokument2 SeitenSlot Information Report - 07!15!2015!19!28-07SasiKumar PetchiappanNoch keine Bewertungen

- SalmanDokument2 SeitenSalmanSasiKumar PetchiappanNoch keine Bewertungen

- Theory of Machines12Dokument1 SeiteTheory of Machines12SasiKumar PetchiappanNoch keine Bewertungen

- Chapter-5: 5.1 Fabrication Techniques of Composite MaterialsDokument6 SeitenChapter-5: 5.1 Fabrication Techniques of Composite MaterialsSasiKumar PetchiappanNoch keine Bewertungen

- Content Materials1Dokument40 SeitenContent Materials1SasiKumar PetchiappanNoch keine Bewertungen

- Institution Paper Presentation Contests: S.No Name of The Program Duration of The Program Resource Person(s)Dokument34 SeitenInstitution Paper Presentation Contests: S.No Name of The Program Duration of The Program Resource Person(s)SasiKumar PetchiappanNoch keine Bewertungen

- Design Fundamentals and Methods for Materials SelectionDokument1 SeiteDesign Fundamentals and Methods for Materials SelectionSasiKumar PetchiappanNoch keine Bewertungen

- 2K Factor PDFDokument6 Seiten2K Factor PDFvmgobinathNoch keine Bewertungen

- Question Bank: Ee 1403 - Design of Electrical ApparatusDokument11 SeitenQuestion Bank: Ee 1403 - Design of Electrical ApparatussuriyasureshNoch keine Bewertungen

- Electrical Based Titles 2009-2010Dokument2 SeitenElectrical Based Titles 2009-2010Siva SankarNoch keine Bewertungen

- Food and OilDokument11 SeitenFood and OilSasiKumar PetchiappanNoch keine Bewertungen

- 405 M.E. Computer Science and EngineeringDokument68 Seiten405 M.E. Computer Science and EngineeringThanuambikaNoch keine Bewertungen

- Ieee Electronics 2013 - 2014Dokument49 SeitenIeee Electronics 2013 - 2014SasiKumar PetchiappanNoch keine Bewertungen

- Iat-2 EgDokument1 SeiteIat-2 EgSasiKumar PetchiappanNoch keine Bewertungen

- Centre For Research Anna University:: Chennai 600025 Enrolment Form/ Registration Renewal FormDokument1 SeiteCentre For Research Anna University:: Chennai 600025 Enrolment Form/ Registration Renewal FormruthshaNoch keine Bewertungen

- Line Chart 3Dokument2 SeitenLine Chart 3SasiKumar PetchiappanNoch keine Bewertungen

- Write The Procedure To Compile and Install Linux Kernel From SourceDokument1 SeiteWrite The Procedure To Compile and Install Linux Kernel From SourceSasiKumar PetchiappanNoch keine Bewertungen

- Muhammad NijasDokument2 SeitenMuhammad NijasSasiKumar PetchiappanNoch keine Bewertungen

- Time Table For EngDokument1 SeiteTime Table For EngSasiKumar PetchiappanNoch keine Bewertungen

- Rainwater Harvesting Basic ComponentsDokument3 SeitenRainwater Harvesting Basic ComponentsSasiKumar PetchiappanNoch keine Bewertungen

- Cqe Q&aDokument51 SeitenCqe Q&aGaren Chen 凯仁100% (1)

- L3 Intro OFATDokument13 SeitenL3 Intro OFATShouharda GhoshNoch keine Bewertungen

- Experimental Research: Factorial DesignDokument9 SeitenExperimental Research: Factorial DesignBuen SaliganNoch keine Bewertungen

- DBB2103 Unit-03Dokument26 SeitenDBB2103 Unit-03Silent KillerNoch keine Bewertungen

- Permutation Tests For Stochastic Ordering and ANOVA Theory and Applications With RDokument220 SeitenPermutation Tests For Stochastic Ordering and ANOVA Theory and Applications With REric RojasNoch keine Bewertungen

- Improve - 5 - Experimental Methods - v12-1Dokument27 SeitenImprove - 5 - Experimental Methods - v12-1okanboragameNoch keine Bewertungen

- 01 Complete ThesisDokument98 Seiten01 Complete ThesisAkhilesh KajarekarNoch keine Bewertungen

- Certified Lean Six Sigma Black Belt Assessment Belt AssessmentDokument51 SeitenCertified Lean Six Sigma Black Belt Assessment Belt AssessmentVinod VargheseNoch keine Bewertungen

- Malhotra MR6e 07Dokument37 SeitenMalhotra MR6e 07Sajjad PirzadaNoch keine Bewertungen

- Makalah ExperimentalDokument13 SeitenMakalah ExperimentalNurjannah AnwarNoch keine Bewertungen

- The Essentials of 2-Level Design of ExperimentsDokument16 SeitenThe Essentials of 2-Level Design of Experimentshyoung65Noch keine Bewertungen

- A Modern Theory of Factorial Design - R. Mukerjee & C. F. Jeff Wu PDFDokument231 SeitenA Modern Theory of Factorial Design - R. Mukerjee & C. F. Jeff Wu PDFFioreNoch keine Bewertungen

- Factorial experiment optimizes lactic acid production from mango peel wasteDokument7 SeitenFactorial experiment optimizes lactic acid production from mango peel wasteVj ReddyNoch keine Bewertungen

- Robustness and Ruggedness in Analytical Method ValidationDokument48 SeitenRobustness and Ruggedness in Analytical Method Validationiabureid7460100% (2)

- 2008-Response Surface Methodology (RSM) As A Tool For Optimization in Analytical Chemistry PDFDokument13 Seiten2008-Response Surface Methodology (RSM) As A Tool For Optimization in Analytical Chemistry PDFElifNoch keine Bewertungen

- DOE Handouts Exercises Solutions WedDokument468 SeitenDOE Handouts Exercises Solutions Wediabureid7460Noch keine Bewertungen

- Documents - MX - Ps Work BooksolutionDokument39 SeitenDocuments - MX - Ps Work BooksolutionHaziq MansorNoch keine Bewertungen

- Understanding The Two-Way ANOVADokument14 SeitenUnderstanding The Two-Way ANOVAMaridil Joy IsidroNoch keine Bewertungen

- DoE in Organic Chem Slides PDFDokument62 SeitenDoE in Organic Chem Slides PDFChris SmithNoch keine Bewertungen

- Design and Analysis of Nickel Electroplating Process Using DOEDokument19 SeitenDesign and Analysis of Nickel Electroplating Process Using DOESaheed A BusuraNoch keine Bewertungen

- Doe CH 25Dokument18 SeitenDoe CH 25RITIK YADAVNoch keine Bewertungen

- Factorial ExperimentsDokument35 SeitenFactorial ExperimentswhmimbsNoch keine Bewertungen

- 1.8.1 Factorial Treatment Structure (Hale) - Supp ReadingDokument23 Seiten1.8.1 Factorial Treatment Structure (Hale) - Supp ReadingTeflon SlimNoch keine Bewertungen

- Improvement of Rubber Roller Processing and Line Balance Efficiency of An Office Automation Department Using Design of Experiments PDFDokument130 SeitenImprovement of Rubber Roller Processing and Line Balance Efficiency of An Office Automation Department Using Design of Experiments PDFAleia ColeenNoch keine Bewertungen

- Experimental Design GuideDokument25 SeitenExperimental Design GuidesrinivasanaNoch keine Bewertungen

- Teaching Design of Experiment and Response Surface Methodology Using Paper Helicopter ExperimentDokument11 SeitenTeaching Design of Experiment and Response Surface Methodology Using Paper Helicopter ExperimentEven OngNoch keine Bewertungen

- Astm E1325Dokument7 SeitenAstm E1325AlbertoNoch keine Bewertungen

- Design of Experiments (DOE): Optimize Process Factors with Statistical TechniquesDokument13 SeitenDesign of Experiments (DOE): Optimize Process Factors with Statistical Techniqueszaib hassanNoch keine Bewertungen

- 18MEO113T - DOE - Unit 4 - AY2023 - 24 ODDDokument65 Seiten18MEO113T - DOE - Unit 4 - AY2023 - 24 ODDRuggedrouge RascalNoch keine Bewertungen