Beruflich Dokumente

Kultur Dokumente

Measuring Internal Stress Using Polarised Light

Hochgeladen von

Selvaraj BalasundramCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Measuring Internal Stress Using Polarised Light

Hochgeladen von

Selvaraj BalasundramCopyright:

Verfügbare Formate

Stress: Diagnose It Before It Ruins Your Parts

161

Residual stress is an inherent result of plastics manufacturing

processes and occurs when molten polymer is cooled and shaped.

Article: 12/1/2005

JOEL M. FEINGOLD

1.

Fig. 1—Polarized light reveals residual stresses due to non-uniform

annealing, a common cause of field failures in medical, pharmaceutical,

and cosmetic blister packaging.

PreviousNext

Related Suppliers

Strainoptics, Inc.

Residual stress is an inherent result of plastics manufacturing processes

and occurs when molten polymer is cooled and shaped. Sometimes,

these stresses are intentionally produced to impart desirable

characteristics, such as in oriented PET films and bottles. But in most

cases, residual stress is an invisible and insidious problem that can

cause field failures and leave a manufacturer exposed to product-liability

claims. It can reduce product quality and erode a company’s bottom line

due to increased scrap and rejects. High levels of stress also lower a

product’s impact strength and can contribute to environmental stress

cracking and diminished performance at high or cycling temperatures.

Some common causes of harmful residual stress in molded,

thermoformed, and extruded products are differential cooling rates, non-

uniform temperature or flow rate, material contaminants, mechanical

loading, thermal cycling during transport and storage, inadequate or

non-uniform annealing, and sharp corners or protrusions that cause

localized stress concentrations.

When the stress profile within a plastic part is known, adjustments in the

process, material, or part design may be made to eliminate these

stresses or reduce them to an acceptable level.

Effects of residual stress

Problems caused by residual stress in polymers generally fall into one of

the following categories:

Distortion: If you are experiencing field failures of blister packs or

similar products, the problem may be due to stress-relaxation

induced distortion. This occurs when parts with excessive residual

stress go through post-manufacturing thermal cycles, such as

sterilization or heat sealing. It can also happen when products are

exposed to varying ambient temperatures in transportation and

warehousing. The part warps or shrinks, causing packaging

failures, loss of product, or packages that are visually unattractive.

Cracking and crazing: Cracking under normal load conditions is

usually evidence of excessive residual stress. Crazing is the

appearance of many fine microcracks. Exposure to chemicals can

exacerbate these conditions, which may not be apparent during

production and QC inspection. Polystyrene parts dipped in

kerosene, for example, will craze quickly in stressed areas.

Deterioration of optical properties: Residual stress changes a

material’s refractive index, thus introducing optical distortion. This

can adversely affect the appearance of products such as bottles

and windows and the performance of products such as plastic

lenses and compact discs.

Creep and other changes in mechanical properties: Creep occurs

when residual stresses cause initial load deformation to become

permanent. Drawing, forming, and cooling procedures introduce

directional stresses in oriented polymers that can lead to

undesirable changes. An extruded tube or sheet, for example, may

show decreased performance in the unstretched direction.

Likewise, if processed at too low a temperature, the part can shrink

in the machine direction and expand in the cross-machine

direction.

Measuring residual stress

Photoelastic evaluation of stress and orientation, either during

production or in quality control, can help processors identify potential

field failures before parts leave the factory. Even in well-designed parts,

examination of a transparent product under polarized light will typically

reveal stress gradients and orientation changes due to manufacturing or

finishing processes.

When viewed with polarized light, stressed areas of polymers are visible

to the eye as a series of multicolored bands or fringes. This fringe

pattern, sometimes referred to as birefringence, can be interpreted as

varying levels of stress at a specific point and in a particular direction

through the material.

The instrument most commonly used to evaluate stresses is a simple

polariscope, or “strain viewer,” consisting of a white light source and

suitable polarizing elements. The thermoformed medical blister packs

shown in Fig. 1 were evaluated using the instrument shown in Fig. 2.

This type of qualitative evaluation can be used to compare stresses in

two identical parts and/or to survey stress distribution in a part.

When polarized light passes through transparent or translucent plastic,

the components of the light wave that are parallel and perpendicular to

the direction of the stress propagate through the plastic at different

speeds. This effect is known as “retardation” and is proportional to the

degree of stress in the material at that point. When light that has

experienced retardation is viewed with a polariscope, the two

components of the original light beam interfere with one another,

resulting in a visible display of varying colors and intensities (fringes)

wherever stress is present in the material.

In simple cases, the color fringes can be used to evaluate residual

stress, since each color band correlates to the degree of stress in the

inspected sample. A retardation vs. color chart can be used to interpret

the observed pattern (see table). In practice, however, the procedure

requires a trained eye and can never be more than an empirical

technique, best reserved for pass/fail inspection.

Materials that exhibit very low stresses, very high stresses, or complex

geometries and high stress gradients require quantitative measurement

using visual or PC-based instruments known as polarimeters.

A basic method for measuring (rather than just observing) stress is

described in ASTM D4093. This standard test method uses a

polariscope in conjunction with an accessory called a “compensator” or

“measuring wedge” (Fig. 4). This precision device optically converts the

mysterious and often complex stress color pattern into an easy-to-

discern black line that can be used to arrive at a reliable and

reproducible measurement. A calibrated scale on the compensator

supplies a quantitative reading of retardation, which can then be used as

a gauge of the stress value or can be converted into units of

birefringence or stress (MPa or psi) by means of a simple equation.

In addition to visual methods of measuring stress, PC-based

instruments, which replace the human observer with computer vision,

are now available in both on-line and off-line configurations (Figs. 5 and

6). These automated systems take the guesswork out of birefringence

measurement and are used where fast, accurate results are required.

One leading polymer film manufacturer, for example, has five of these

systems installed at plant locations in the U.S., Europe, and Asia.

COLOR SEQUENCEa OBSERVED VS.

RETARDATION VALUE

Color Retardation Retardation,

(δ), nm N fringesc

Black: Zero 0 0

order fringe

Gray 160 0.28

White-Yellow 260 0.45

Yellow 350 0.60

Orange (Dark 460 0.79

Yellow)

Red 520 0.90

Indigo-Violet: 577 1.00

Tint of

passage #1b

(1st order

fringe)

Blue 620 1.06

Blue-Green 700 1.20

Green-Yellow 800 1.38

Orange 940 1.62

Red 1050 1.81

Indigo-Violet: 1150 2.00

tint of

passage #2

(2nd order

fringe)

Green 1300 2.25

Green-Yellow 1400 2.46

Pink 1500 2.60

Violet: tint of 1700 3.00

passage #3

(3rd order

fringe)

Green 1750 3.03

aColors are affected by the type of light source,

characteristics of the polarizing filter, and color of the

sample. bUsing monochromatic light (as transmitted

by a monochromatic filter with 570 nm peak

transmittance), the “fringes” appear as black lines. In

white light, the fringes are located at the red-blue

transition on the first order, red-green on the second

order, and red-pink on the third order. These dividing

zones are referred to as “tints of passage.” cRelative

retardation may be expressed in either wavelength

(nanometers) or fringe order (N) for calculating stress

levels.

Das könnte Ihnen auch gefallen

- Advance Injection Mould Split DesignDokument175 SeitenAdvance Injection Mould Split DesignAkash SinghNoch keine Bewertungen

- Statistical Tolerance AnalysisDokument2 SeitenStatistical Tolerance AnalysisSelvaraj BalasundramNoch keine Bewertungen

- Iso 2768 1Dokument7 SeitenIso 2768 1Gary Ren100% (2)

- Iso 2768-1: 1989Dokument7 SeitenIso 2768-1: 1989jferreiraNoch keine Bewertungen

- CZ - Common ZoneDokument1 SeiteCZ - Common ZoneSelvaraj BalasundramNoch keine Bewertungen

- Measuring Internal Stress Using Polarised LightDokument5 SeitenMeasuring Internal Stress Using Polarised LightSelvaraj BalasundramNoch keine Bewertungen

- INTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Dokument162 SeitenINTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Selvaraj BalasundramNoch keine Bewertungen

- Color in Plastic Parts Part 3Dokument3 SeitenColor in Plastic Parts Part 3Nitin PatilNoch keine Bewertungen

- INTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Dokument162 SeitenINTRODUCTION TO THE TRIZ INVENTIVE PROBLEM SOLVING PROCESS - Excellent 1Selvaraj BalasundramNoch keine Bewertungen

- How To Get Better MFI ResultsDokument5 SeitenHow To Get Better MFI ResultsSelvaraj BalasundramNoch keine Bewertungen

- High Gate - Hot RunnerDokument2 SeitenHigh Gate - Hot RunnerSelvaraj BalasundramNoch keine Bewertungen

- GD&T Guide Symbols TermsDokument6 SeitenGD&T Guide Symbols TermsvasantNoch keine Bewertungen

- Troubleshooting: Injection Molding Seven Steps Toward Scientific TroubleshootingDokument5 SeitenTroubleshooting: Injection Molding Seven Steps Toward Scientific TroubleshootingSelvaraj BalasundramNoch keine Bewertungen

- PC materials guide for injection moldingDokument1 SeitePC materials guide for injection moldingSelvaraj BalasundramNoch keine Bewertungen

- IQ, OQ, PQ in Pharma Industry Validate Equipment PerformanceDokument2 SeitenIQ, OQ, PQ in Pharma Industry Validate Equipment PerformanceSelvaraj BalasundramNoch keine Bewertungen

- Tool Steel SelectionDokument11 SeitenTool Steel SelectionSelvaraj BalasundramNoch keine Bewertungen

- Six Steps To Condition Based Maintenance - GoodDokument3 SeitenSix Steps To Condition Based Maintenance - GoodSelvaraj BalasundramNoch keine Bewertungen

- GD&T Guide Symbols TermsDokument6 SeitenGD&T Guide Symbols TermsvasantNoch keine Bewertungen

- 4 Obstacles to Effective Predictive Maintenance ProgramsDokument3 Seiten4 Obstacles to Effective Predictive Maintenance ProgramsSelvaraj BalasundramNoch keine Bewertungen

- 8 Steps To Ensure PDM Success - Excellent - Not Taken Yet !!!Dokument5 Seiten8 Steps To Ensure PDM Success - Excellent - Not Taken Yet !!!Selvaraj BalasundramNoch keine Bewertungen

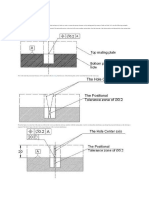

- What Is Projected Tolerance ZoneDokument2 SeitenWhat Is Projected Tolerance ZoneSelvaraj BalasundramNoch keine Bewertungen

- Implement TPM Successfully for Increased ProductivityDokument6 SeitenImplement TPM Successfully for Increased ProductivitySelvaraj BalasundramNoch keine Bewertungen

- A Letter On Good and Bad Kaizen Practices - TakenDokument5 SeitenA Letter On Good and Bad Kaizen Practices - TakenSelvaraj BalasundramNoch keine Bewertungen

- How Nestle Fought Back - Business News Aug 2016Dokument9 SeitenHow Nestle Fought Back - Business News Aug 2016Selvaraj BalasundramNoch keine Bewertungen

- Productivity A Better Way From Stratex HubDokument17 SeitenProductivity A Better Way From Stratex HubSelvaraj BalasundramNoch keine Bewertungen

- How To PERSUADE Your BossDokument8 SeitenHow To PERSUADE Your BossSelvaraj BalasundramNoch keine Bewertungen

- Conference Call TipsDokument7 SeitenConference Call TipsSelvaraj BalasundramNoch keine Bewertungen

- 5 Steps To GDT ApplicationDokument4 Seiten5 Steps To GDT ApplicationSelvaraj BalasundramNoch keine Bewertungen

- Tutorials - 1st Angle Vs 3rd AngleDokument6 SeitenTutorials - 1st Angle Vs 3rd AngleSelvaraj BalasundramNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Vonovia 9M2021 Presentation 20211118Dokument76 SeitenVonovia 9M2021 Presentation 20211118LorenzoNoch keine Bewertungen

- Lazo v. Judge TiongDokument9 SeitenLazo v. Judge TiongKing BadongNoch keine Bewertungen

- Reading in Philippine History (Chapter 3)Dokument14 SeitenReading in Philippine History (Chapter 3)AKIO HIROKINoch keine Bewertungen

- Oreilly Design For Voice InterfacesDokument37 SeitenOreilly Design For Voice InterfacesHarmony JordenNoch keine Bewertungen

- Product Manual 82434 (Revision C) : Generator Loading ControlDokument26 SeitenProduct Manual 82434 (Revision C) : Generator Loading ControlAUGUSTA WIBI ARDIKTANoch keine Bewertungen

- ManuscriptDokument2 SeitenManuscriptVanya QuistoNoch keine Bewertungen

- Falling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsDokument18 SeitenFalling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsEdisson Eduardo Valencia Gomez100% (1)

- Health Information SystemDokument11 SeitenHealth Information SystemVineeta Jose100% (1)

- Simulated Robot Football Team Uses Neural Networks to LearnDokument8 SeitenSimulated Robot Football Team Uses Neural Networks to LearnKishore MuthukulathuNoch keine Bewertungen

- 2.7.3 Lab Use Steganography To Hide Data Answer KeyDokument3 Seiten2.7.3 Lab Use Steganography To Hide Data Answer KeyVivek GaonkarNoch keine Bewertungen

- Surface water drainage infiltration testingDokument8 SeitenSurface water drainage infiltration testingRay CooperNoch keine Bewertungen

- EINC ChecklistDokument3 SeitenEINC ChecklistMARK JEFTE BRIONESNoch keine Bewertungen

- Judges - God's War Against HumanismDokument347 SeitenJudges - God's War Against HumanismgypsylanternNoch keine Bewertungen

- MF-QA-001 PDIR ReportDokument2 SeitenMF-QA-001 PDIR ReportBHUSHAN BAGULNoch keine Bewertungen

- TEI - of - Microsoft - Business Central - FINALDokument23 SeitenTEI - of - Microsoft - Business Central - FINALMarketing ComesaNoch keine Bewertungen

- Explanation of Four Ahadeeth From Imaam Al-Bukhaaree's Al-Adab-Ul-MufradDokument4 SeitenExplanation of Four Ahadeeth From Imaam Al-Bukhaaree's Al-Adab-Ul-MufradMountainofknowledgeNoch keine Bewertungen

- OTGNNDokument13 SeitenOTGNNAnh Vuong TuanNoch keine Bewertungen

- Cefoxitin and Ketorolac Edited!!Dokument3 SeitenCefoxitin and Ketorolac Edited!!Bryan Cruz VisarraNoch keine Bewertungen

- Canopen-Lift Shaft Installation: W+W W+WDokument20 SeitenCanopen-Lift Shaft Installation: W+W W+WFERNSNoch keine Bewertungen

- Telegra Manual - DatasheetDokument79 SeitenTelegra Manual - DatasheetNilanjan Chakravortty100% (1)

- Degree and Order of ODEDokument7 SeitenDegree and Order of ODEadiba adibNoch keine Bewertungen

- Toki PonaDokument2 SeitenToki PonaNicholas FletcherNoch keine Bewertungen

- Chams 1Dokument78 SeitenChams 1Das RavindraNoch keine Bewertungen

- OS9000 AOS 6.1.5 R01 Network Configuration GuideDokument846 SeitenOS9000 AOS 6.1.5 R01 Network Configuration GuideclaupasinaNoch keine Bewertungen

- Economics and The Theory of Games - Vega-Redondo PDFDokument526 SeitenEconomics and The Theory of Games - Vega-Redondo PDFJaime Andrés67% (3)

- Pmls 1 Final Exam Reviewer: Clinical Chemistry ContDokument14 SeitenPmls 1 Final Exam Reviewer: Clinical Chemistry ContPlant in a PotNoch keine Bewertungen

- Sight Reduction Tables For Marine Navigation: B, R - D, D. SDokument12 SeitenSight Reduction Tables For Marine Navigation: B, R - D, D. SGeani MihaiNoch keine Bewertungen

- 02 - Order Quantities When Demand Is Approximately LevelDokument2 Seiten02 - Order Quantities When Demand Is Approximately Levelrahma.samyNoch keine Bewertungen

- Grade 4 DLL Quarter 2 Week 2 Sir Bien CruzDokument47 SeitenGrade 4 DLL Quarter 2 Week 2 Sir Bien CruzRonel Fillomena0% (1)

- APM200 Outdoor Power Supply System User Manual-20060628-B-1.0Dokument52 SeitenAPM200 Outdoor Power Supply System User Manual-20060628-B-1.0Andrés MarroquínNoch keine Bewertungen