Beruflich Dokumente

Kultur Dokumente

Energy Analytics in A Smart Factory Using Machinesense Power Analyzer

Hochgeladen von

MachineSenseOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Energy Analytics in A Smart Factory Using Machinesense Power Analyzer

Hochgeladen von

MachineSenseCopyright:

Verfügbare Formate

Energy Analytics in

a Smart Factory

using MachineSense

Power Analyzer

by Biplab Pal, PhD

Co-Founder & CTO

MachineSense

Improve Energy and

Productivity Efficiency using

MachineSense Power Analyzer

The lack of understanding of energy consumption

behavior, “who”, “where”, “when”, and “how”, is the

essential reason for the difficulty in evaluating and

improving factory energy efficiency. For example,

imagine an extrusion manufacturer is experiencing

a rising electricity bill without any increase in

productivity. How will management know which

extrusion line is at fault? Even with the help of an

energy meter where a particular energy leaking line

is sorted out, the next question is: Which element is

causing the energy waste? Is it the 240 kW heater

bank or the 600 hp motor? It is not practical to

replace a complete operational extrusion line.

Factory management needs to know why this is

happening and which element is adding to the

greatly increased energy bill.

2

Two vital To achieve energy efficiency in a factory, a manufacturer needs to have

two vital pieces of information:

pieces of

1. A clear picture of energy consumption of each machine, and its

information subassemblies, in real and historical time.

2. The ability to map them into the process and capture the energy

consumption variation from the process variation.

First, it is important to identify the machines that waste energy. Second,

it is vital to diagnose the root cause of that wasted energy, which will

lead to a solution. For example, maybe a 600-horsepower motor is ON

for four hours even when there is no material feed. Energy analytics

should be good enough to understand energy usage under material

feed load vs. no load. Only then is it possible to identify that the energy

wastage is coming from the process. Or, maybe a particular motor has

a high bearing current due to a faulty bearing which can cause the

motor to draw much higher energy under the material load.

MachineSense Power Analyzer is ideal for such energy optimization.

They can be configured to track energy, faults and process of four

machines at a time using 4-port versions, provided all machines are

powered from the same electrical panel.

Define sustainable strategies and

Fig. 1.0: Identification of an practices in production management

energy optimization objective to improve energy efficiency.

in a factory is the first goal.

Integrate energy data into factory’s tools

for improving energy efficiency.

Monitor and analyze energy consumption

in real time using IoT technology.

(i.e., smart metering and sensors)

Understand production processes and

evaluate current energy management

practices.

221 Thomas Ave. Baltimore, MD 21225 | www.MachineSense.com | +1-443-457-1165

© 2017 MachineSense. All rights reserved.

3

Why Choose

Power Analyzer

and Not a

Common Smart

Energy Meter for

Energy Analytic?

The ability to extract such comparative analytics is the first step towards

understanding whether an old machine is consuming more energy than

a new machine for the same level of production. Even if two machines

are relatively the same model and their energy cost is vastly different,

such difference must be understood by understanding the difference in

the process to which the machines are connected.

Fig. 2.1: Energy consumption for

a machine for a period of one

week.

Fig: 2.2 Comparison of energy

consumption for a machine

over two different time periods.

221 Thomas Ave. Baltimore, MD 21225 | www.MachineSense.com | +1-443-457-1165

© 2017 MachineSense. All rights reserved.

4

This is highly

desirable when

a large number

of machines

need to be

monitored for

their energy

efficiency.

Fig. 3.1: A graphical

display of maintenance

advice and their respective

number of occurrences

over a period of time – up

to 2 years.

Fig. 3.2 The list shows

preventative maintenance

advice over a period of one

month.

221 Thomas Ave. Baltimore, MD 21225 | www.MachineSense.com | +1-443-457-1165

© 2017 MachineSense. All rights reserved.

5

Provides energy The MachineSense Power Analyzer also provides a full cost analytic.

The rate chart (Fig. 4.1) from any utility company can be highly complex

cost analytics. as it depends on energy consumption level, seasons, weekdays vs.

weekend, day vs. night, holidays, etc.

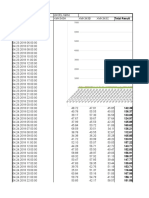

Fig. 4.1: A complex rate chart

from utility company canbe

ingested as a csv file type for

an accurate estimation of

machine operating cost.

With MachineSense Power Analyzer a user can easily see the

rate card in a template and the system will provide an accurate

running energy bill. (Fig. 4.2)

Fig. 4.2: Represents a

graphical display of a cost

analytic for a given

machine during the

period of one week.

221 Thomas Ave. Baltimore, MD 21225 | www.MachineSense.com | +1-443-457-1165

© 2017 MachineSense. All rights reserved.

6

Provides

utilization and

productivity data

Fig. 5 : Usage analytics

from MachineSense

Power Analyzer energy

analytic. Usage analytics

help you understand if

your energy is being

properly used.

221 Thomas Ave. Baltimore, MD 21225 | www.MachineSense.com | +1-443-457-1165

© 2017 MachineSense. All rights reserved.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Be CSC PDFDokument8 SeitenBe CSC PDFRichard DennisNoch keine Bewertungen

- Event Details: 5th Chief Justice Andres Narvasa Lecture SeriesDokument3 SeitenEvent Details: 5th Chief Justice Andres Narvasa Lecture SeriesElijah PunzalanNoch keine Bewertungen

- Understand OMSY TCodeDokument2 SeitenUnderstand OMSY TCodechanduNoch keine Bewertungen

- Delmia IgripDokument6 SeitenDelmia Igrip6toNoch keine Bewertungen

- VisiLogic Software Manual-Getting StartedDokument220 SeitenVisiLogic Software Manual-Getting StartedtomearsovskiNoch keine Bewertungen

- PLSQL APEX Student Guide v1Dokument11 SeitenPLSQL APEX Student Guide v1ssmile100% (1)

- Pattern Recognition and Image Processing in C++-Vieweg+Teubner Verlag (1995)Dokument369 SeitenPattern Recognition and Image Processing in C++-Vieweg+Teubner Verlag (1995)hazim_74Noch keine Bewertungen

- Memory Faults: PCBA Debug GuideDokument8 SeitenMemory Faults: PCBA Debug Guideluiz carlos de souzaNoch keine Bewertungen

- Nested Classes 235-245: Durgasoft MR - RatanDokument4 SeitenNested Classes 235-245: Durgasoft MR - RatanRituraj TripathyNoch keine Bewertungen

- ر ي ي ر رDokument13 Seitenر ي ي ر رRyan SmithNoch keine Bewertungen

- SQLiteDokument9 SeitenSQLitekesarla venkyNoch keine Bewertungen

- Matrix MultiplicationDokument81 SeitenMatrix MultiplicationD Anuradha100% (2)

- FB Audience InsightsDokument1 SeiteFB Audience InsightsJJ VIINoch keine Bewertungen

- Project Progress ReportDokument3 SeitenProject Progress ReportCharan yNoch keine Bewertungen

- Semantic NetworksDokument2 SeitenSemantic NetworksRyan DavisNoch keine Bewertungen

- QR Codes..SeminarDokument25 SeitenQR Codes..SeminarSumit GargNoch keine Bewertungen

- Muhammad Ali ResumeDokument4 SeitenMuhammad Ali ResumeMahboob AliNoch keine Bewertungen

- Manual para Servo Driver Mitsubishi MRZJWDokument30 SeitenManual para Servo Driver Mitsubishi MRZJWNestor Mauricio Barragan NegroNoch keine Bewertungen

- AMOS 12.00 Administration GuideDokument52 SeitenAMOS 12.00 Administration Guidealexander.titaevNoch keine Bewertungen

- IBM SPSS Statistics 23 Part 1 - Descriptive StatisticsDokument18 SeitenIBM SPSS Statistics 23 Part 1 - Descriptive StatisticsRitesh SrivastavaNoch keine Bewertungen

- Nortel Command LineDokument286 SeitenNortel Command Lineamitfromkolkata100% (1)

- OTL R12.x Student GuideDokument196 SeitenOTL R12.x Student GuideSaqib Rahat100% (2)

- Swpm10 SP18 Processes RMOSDokument6 SeitenSwpm10 SP18 Processes RMOSSantiago MonrobéNoch keine Bewertungen

- The Semantics of ClocksDokument16 SeitenThe Semantics of ClocksBrian Cantwell SmithNoch keine Bewertungen

- RSLTE020 MIMO and OFDM RSLTEDokument114 SeitenRSLTE020 MIMO and OFDM RSLTEAnonymous DUua3A5Noch keine Bewertungen

- Cloudera ODBC Driver For Apache Hive Install GuideDokument72 SeitenCloudera ODBC Driver For Apache Hive Install GuideSagarNoch keine Bewertungen

- Nissan Digital - JD For Freshers 2019Dokument3 SeitenNissan Digital - JD For Freshers 2019Aditya Gautam MishraNoch keine Bewertungen

- Chapter 5Dokument46 SeitenChapter 5زهديابوانسNoch keine Bewertungen

- View Itob View Field Field Data Element Data Type LengthDokument14 SeitenView Itob View Field Field Data Element Data Type Lengthkalyani100% (1)

- EIM QuestionDokument4 SeitenEIM QuestionhuntgiriNoch keine Bewertungen