Beruflich Dokumente

Kultur Dokumente

Dynamic Low Choke High Quality PDF

Hochgeladen von

WCGOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dynamic Low Choke High Quality PDF

Hochgeladen von

WCGCopyright:

Verfügbare Formate

WELL CONTROL

New dynamic low choke method kills wells

at balance point using surface-applied pressure

By Javed Shah, Well Control Group

2400

IN A WELL control situation when Leak-off at 2,234 kPa

the casing pressure reaches the maxi- 2200

mum allowable casing pressure (MACP), 2000

the choke operator reacts by opening the Surface Pressure to Pumps Off

choke to keep casing pressure at MACP, 1800 Reach Leak off (6 min)

thus reducing the bottomhole pressure 1600

(BHP) and inducing a bigger kick. Even

Pressure Applied (kPa)

when the gas is at surface, the casing 1400

pressure is kept at MACP, making the 1200

situation worse.

1000

The low choke method of well control

— used in killing wells where the cas- 800

ing pressure is at MACP — has major 600

shortcomings, such as what shut-in drill

pipe pressure (SIDPP) is being killed by 400

pumping heavier-density mud and what

200

is happening to the hydrostatic pressure

in the wellbore. 0

0 100 200 300 400 500 600 700 800

A new approach to well control has been Volume Pumped (litres)

developed to address the situation when

the casing pressure reaches MACP while If a formation leak off test, shown in graph above, is required in the drilling program, the

circulating a gas kick. It allows opera- wellbore is pressured up to the point of breakdown.

tors to control the well and kill the well

at a balance point — exactly increase total depth of the well and pressure pre- surface around the conductor, and all

the mud density in the well to balance diction of the formations to be drilled. well control would be lost. Therefore, the

the SIDPP after the kick has been circu- The rig selection process ensures that well is never shut in, wellbore fluids are

lated out of the wellbore. This method the rig will be capable of drilling the well diverted away from the rig, and the well

was developed to utilize surface-applied safely and efficiently. The pressure rat- is circulated over to heavier drilling mud

pressure to control bottomhole pressure. ing of the well control equipment, such to control the formation pressure and

as blowout preventers and choke mani- kill the well.

This article describes the sequence of fold, deployed, while drilling the well,

pressures being applied to the wellbore is capable of containing the expected Pumping of the kill mud takes place at

as the drilling continues and after the formation pressures. The well control a high rate of circulation to outrun the

kick is taken. The pressure applied at the equipment installed should be able to unwanted influx entering the well. The

casing shoe and the bottomhole pressure shut in the well and contain the well shallow gas zones are limited in extent

are presented during the kick circula- pressures with or without the drill string and usually deplete soon. Most operators

tion. Details will be provided on the well in the hole. avoid drilling in areas that are prone to

control method as applied to circulate shallow gas-bearing zones.

the kick out and control bottomhole pres- A well-trained drilling crew will recog-

nize the kick warning signs and be able Surface hole drilling continues to the

sure by exceeding the MACP (with gas at

to shut in the well in case an influx of surface casing setting point. At this

surface) without losing control of the well

the formation fluid enters the wellbore. time, surface casing is run into the hole

or compromising wellbore integrity.

and cemented in place. The program-

recommended BOP stack arrangement

DRILLING, PLANNING SHALLOW GAS ZONES, is rigged up and pressure-tested as per

When the drilling of a well is undertaken, DIVERTER PROCEDURES regulatory standards. The stack will usu-

certain guidelines must be established in The surface hole is drilled using a con- ally contain an annular BOP, one or two

order to drill the well without setbacks ductor set and cemented at a depth of 20 sets of pipe ram BOPs (to close in the

that can lead to the total loss of the well. m (±60 ft) to 30 m (±100 ft). There is no well around the drill pipe to be used),

The drilling program specifies the casing well control equipment installed at this and one ram BOP having blind rams (to

setting points, the drilling fluids to use, time. If shallow gas zones are expected, close in on the open hole) when the drill

the types of bits to be used, well head a diverter is installed to divert the string is out of the hole.

equipment and the desired pressure rat- unwanted influx from shallow gas zones

ing of the well control equipment. away from the rig. The well is never shut TESTING

in to avoid gas broaching around the After the surface casing shoe is drilled

The drilling rig and well control equip-

conductor. If the integrity of the conduc- out and 5-10 m (15-30 ft) of new hole is

ment selection is based on expected

tor shoe is lost, the gas would broach to drilled, the drill cuttings are circulated

104 July/August 2007 D R I L L I N G CONTRACTOR

WELL CONTROL

out of the well. Using a high- soon as the drilling continues

pressure, low-volume pump, further, the open hole section

the formation strength exposed below the shoe does

(of the formation exposed not get tested to more than

below the casing shoe) is the annular pressure loss

established by carrying out and the hydrostatic pres-

a formation integrity test sure unless open hole leak

(the pressure being applied off tests are done and MACP

at the casing seat is pre- adjusted accordingly to a

determined, usually in the higher or lower value.

range of 18.1 kPa/m (0.8 psi

/ft), and the pump is stopped Choices for well control

when this pressure gradient methods, under normal con-

is reached). ditions, have been:

If the drilling program calls 1. DRILLER’S

for a formation leak off test,

the wellbore is pressured up METHOD

to the point of breakdown. The driller’s method is sim-

The pressure applied at ple and done in two steps.

the casing shoe at this time First, the gas influx is circu-

is the sum of hydrostatic In Pressure Test #3 on the wellbore, with circulation started, the lated out. Second, the well is

pressure (HP) (at the cas- displaced to kill mud density

pressure applied to the open hole during kick circulation is SIDPP +

ing seat) and the surface- to balance the shut-in drill

HP + APL + overkill. pipe pressure. This method’s

applied pressure.

Hydrostatic Pressure + Shut In Drill big advantage is that the

Leak Off Pressure (LOP at casing shoe) Pipe Pressure. circulation can start as soon as the well

= Surface Applied Pressure (from the shut-in pressures have stabilized.

graph) + HP (at the casing seat). This test is like a reverse leak off test.

Pressure is applied by the formation

These pressure tests are used to estab- instead of a high-pressure pump. If the

2. WAIT AND WEIGHT

lish the MACP by using the following wellbore integrity is lost at this time, the The wait and weight method applies

equation: drill pipe pressure would drop from a when the casing shoe is set deep in the

higher pressure to a lower pressure. well. There is no concern with the casing

MACP = LOP – HP (at the casing seat of

pressure reaching MACP. Usually the for-

the drilling mud in use). The industry, as a general rule, empha- mations exposed below the casing shoe

The MACP information is updated for sizes not exceeding MACP while circulat- have high fracture pressure. If the well is

the drilling crew as the drilling densi- ing the kick out of the well. This leads a high-pressure, high-temperature pros-

ties change with the wellbore depth. A to the problem of not even exceeding pect, the drilling fluid density is quite

new leak off pressure is only established the MACP with the gas at surface, as no close to the maximum fluid densities that

after the intermediate casing string is guidelines are available. can be used in the well. Therefore, there

installed/cemented in the well and the is still a chance that the formation might

Usually a MACP number with gas at

intermediate casing shoe is drilled out. break down. Since the well is deep, there

surface is posted at the drilling rig on

is no chance for the fracture to broach to

When a unwanted influx enters the well, the assumption that all mud from the

surface. Loss of circulation can be treat-

the appropriate BOP is closed to contain annulus has been displaced by gas.

ed with loss-circulation material. As the

the wellbore pressures and to prevent This would be possible if the well were

well is deep, the kick will be circulated

the wellbore fluids from venting at the opened up completely and all the well-

out and the well displaced to kill fluid at

rig floor. The release of the fluids (under bore fluid is blown out of the well. The

the same time.

pressure) is facilitated using the choke new MACP is calculated (with gas at sur-

at the choke manifold, which is located face) by multiplying the leak off gradient

usually about 25m (75 ft) away from the with the shoe depth. In this approach, 3. CONCURRENT METHOD

drilling rig and the well centre. gas density is ignored, with no consid- The concurrent method of well control

eration being given to the amount of gas is designed to circulate the kick out and

in the returning mud, giving a very high partially kill the well in the first circula-

PRESSURE TESTS number for MACP. tion. In subsequent circulations, the well

Pressure test #1: Until the well experi- can be balanced and mud system evened

ences a kick, the only pressure test on In reality, after setting the casing, usu-

out. As the weight material is added to

the well is hydrostatic pressure and the ally a leak off test is not done, and all

the mud being pumped down the drill

annular pressure loss (friction pressure the MACP calculated numbers are based

pipe, the mud properties have to be con-

lost while pumping the drilling mud from on assumed leak off gradient. Usually

ditioned for the drilling to continue.

total depth to surface). the leak off gradient is 18.1 kPa/m (0.8

psi /ft). The formation may or may not Choice of the well control method

Pressure Test #2: After the kick is hold this equivalent leak off gradient. In depends on the surface casing setting

taken, the well is shut in, and the pres- the absence of a leak off test, the casing depth, the surface shut-in pressures,

sures are allowed to stabilize. The pres- cement job integrity is also questionable. migration rate of the gas influx, and bar-

sure test at this time on the well is: Even if a leak off test is conducted, as ite mixing capabilities of the rig.

106 July/August 2007 D R I L L I N G CONTRACTOR

WELL CONTROL

All these methods can be implemented • What happens to the hydrostatic pres- earlier in the circulation. If the wellbore

if there is a big difference between the sure in the well when the crew adds integrity was there earlier, why should it

SICP (shut-in casing pressure) and the ±2 sacks of barite in the mud system not be there a few hours later?

posted MACP. Most often the room to through the hopper?

MACP (difference between SICP and In a situation where the operator is

MACP) is a function of kick volume in • The barite-carrying capabilities of the already at MACP as soon as an attempt

the well and not a function of abnor- mud is not even considered, so it could is made to shut in the well, the same

mal formation pressure. The volume of settle out as soon as the circulation is approach can be taken and casing pres-

kick in the annulus dictates the SICP. stopped. sure can be increased gradually.

Therefore the larger the kick volume in Initially when the addition of barite If the drill pipe pressure keeps increas-

the annulus, the more chances that cas- is started, the differential pressure ing along with a reduction in the

ing pressure will reach MACP during between the drill pipe and annulus pit volume, the wellbore integrity is

the circulation. During the initial start increases, forcing the casing pressure to apparent under dynamic conditions.

of circulation of the kick, the well is sub- increase. The choke operator is trying to If while increasing the casing pres-

jected to Pressure Test #3, in which the keep the casing pressure at MACP, there- sure, no increase in drill pipe pressure

pressure applied to the open hole during fore the choke has to be opened more to is observed, partial loss circulation is

kick circulation is SIDPP + HP + APL + control the pressure. As the choke open- indicated and the casing pressure can

overkill. ing is increased, the bottomhole pres- be backed off to cut down on the partial

Once the initial circulation pressure is sure reduces, increasing the chances losses. Using the pressure approach is

established, with no drop in the drill pipe of letting more influx into the well until better to establish the true SIDPP before

pressure, it can be said that the open the heavy mud turns the corner at the increasing the density. After the kick has

hole is capable of handling this applied bottom of the drill pipe. Whenever the been circulated out, the well can be shut

pressure. low choke method is applied, sooner or in and the overkill bled off to establish a

later both chokes are wide open and true shut in drill pipe pressure.

Established pressure is RSPP + SIDPP the straight thru line in the manifold is

Javed Shah is a professional engineer and

+ APL + Overkill (if any is used). opened. All the mud is circulated to the has 24 years of experience with well control

flare pit, and the mud volume has to be operations and training.

There have been no guidelines for the rebuilt before well control operations

operators to follow when the casing can continue. This article is based on a presentation sched-

pressure is close to MACP or is going uled for the IADC Well Control Conference of

to exceed MACP on initial shutting-in The dynamic low choke method was the Americas, 28-29 August 2007, Galveston,

Texas.

of the well. All established well control developed to give an alternate method

procedures emphasize not exceeding the to apply when the shut-in casing pres-

posted MACP, when the casing pressure sure is close to MACP on initial shut-in

reaches this pressure. This could happen or the shut-in casing pressure is going to

on initial shutting in of the well or during exceed the posted MACP and the gas is

the circulation of the initial kick. While at surface.

circulating the influx out of the wellbore,

if the MACP is reached, the rig crew con- The method utilizes surface applied

trols the casing pressure at the MACP by pressure to control bottomhole pressure,

keeping the casing pressure constant. without barite addition. After the gas has

been circulated out of hole, the mud den-

The only available method of well control sity can be increased exactly to kill the

has been the low choke method of well well at a balance point as it can be based

control. This method calls for increas- on the shut-in drill pipe pressure.

ing the pump speed to drilling rate, hold

casing pressure at the posted MACP and It is common knowledge that the hydro-

start adding barite to increase the den- static pressure at the casing shoe

sity of the mud in the well. reduces drastically once the gas is at

surface. With gas at surface, if the choke

is closed instead of being opened (to

LOW CHOKE METHOD keep the casing pressure at MACP), the

The method calls for opening the choke, casing pressure starts to rise and MACP

holding casing pressure at MACP, start- is exceeded. The bottomhole pressure

ing pump at drilling rate and adding bar- also starts to increase, and the entry of

ite at ±2 sacks of barite per minute. It the second kick starts to slow down and

further calls for the crew to keep pump- eventually stops. As soon as the drill

ing the heavy fluid into the well until the pipe pressure reaches the original estab-

well is killed. lished initial circulating drill pipe pres-

sure (Pressure Test #3), the operator

Draw back to this approach has been: can maintain the circulating drill pipe

• Barite should be available on location. pressure.

• At higher rates of pumping, what is the Although the MACP has been exceeded,

probability to wash out the choke or sur- the well has not seen any extra pres-

face equipment? sure than what was already applied to it

D R I L L I N G CONTRACTOR July/August 2007 107

WELL CONTROL

Dynamic Low Choke Method

Well is shut in and shut-in pressures are established, but the SICP 2. Hold casing pressure at MACP.

is close to MACP (100 kPa or ±30 psi below MACP): No gas at Establish the circulating DP.

surface.

3. As circulation continues, close

1. Open the choke and bring pump to reduced speed (allows better the choke and increase the CP by

control of choke and reduces chance of washing out surface equip- 200 kPa (30 psi or one gauge divi-

ment). sion) each time.

2. Hold casing pressure at MACP. Observe the DP pressure for an

Record the circulating drill pipe identical increase (indication of well-

pressure. bore integrity).

As the kick is circulated to surface, 4. Keep increasing the casing pres-

the drill pipe pressure will drop and sure until the pit gain stabilizes

there will be a continuous feed of (pit gain should stop increasing

formation fluids into the well, mak- at a rapid rate as formation stops

ing it impossible to keep bottom- feeding gas into the well, and pit

hole pressure above the formation gain starts to drop, with drill pipe

pressure. circulating pressure staying stable).

Record the circulating DP pressure.

3. Once the kick is at surface, cal-

culate the drop in circulating drill 5. Now keep the DP pressure con-

pipe pressure. stant till all the kick is circulated out

2 - circulating with and the well can be shut in.

2 - Circulating kick (casing 4. Start closing the choke to

CP at MACP

pressure at MACP) exceed the MACP by the amount of

drop in drill pipe pressure

until the drill pipe pressure

is at the original circulating

drill pipe pressure (recorded

in step 2).

As the gas entry at the bot-

tom of the well is stopped,

the pit volume will start to

reduce. This indicates that

the bottomhole pressure is

now higher than the forma-

4 - Gas at surface tion pressure.

5. Keep the drill pipe pres-

sure constant at this pres-

sure until all the kick is

circulated from the well.

6. Stop pump and shut in

the well. Check pressures.

Shut-in drill pipe pressure

5- MACP exceeded by 1,200 kPa and shut-in casing pressure

should be equal. 4 - Exceeding MACP 5 - Well shut in with CP

below MACP

Kill mud can be now

mixed to the correct

density and step 2

of the driller’s meth-

od used to displace

the well to kill mud.

6 - Gas circulated out and well shut in

Now the kill mud density can be mixed

and well circulated over to kill mud,

using step 2 of the driller’s method.

Unable to shut in the well: Gas at sur-

face.

1. Open the choke and bring pump to

reduced speed.

Dynamic low choke - with gas at surface and

1 - Kick taken, CP at MACP CP at MACP

108 July/August 2007 D R I L L I N G CONTRACTOR

Das könnte Ihnen auch gefallen

- Training Report Down HoleDokument36 SeitenTraining Report Down HolePulkit GururaniNoch keine Bewertungen

- Management of Lost CirculationDokument8 SeitenManagement of Lost CirculationKolawole AdisaNoch keine Bewertungen

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsVon EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNoch keine Bewertungen

- A&p FaqDokument3 SeitenA&p FaqNinerMike MysNoch keine Bewertungen

- Iwcf NotesDokument81 SeitenIwcf NotesShraddhanand More100% (1)

- Liner Hanger JobDokument4 SeitenLiner Hanger JobAjay HotkarNoch keine Bewertungen

- ENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageDokument8 SeitenENM210 Cementing Operations Lecture 2 - Stage Cementing - 1 StageHamid Reza BabaeiNoch keine Bewertungen

- Micropile Design and Construction - FHWA05Dokument454 SeitenMicropile Design and Construction - FHWA05virajNoch keine Bewertungen

- Formation Pressure For Well DesignDokument20 SeitenFormation Pressure For Well DesignadeniyiNoch keine Bewertungen

- CSG Design by AmrDokument19 SeitenCSG Design by AmrSudish BhatNoch keine Bewertungen

- Deep Illustration For Loss of Circulation While DrillingDokument17 SeitenDeep Illustration For Loss of Circulation While DrillingfuatNoch keine Bewertungen

- Drilling Fluids: Islamic Azad University Science and Research Branch Drilling DepartmentDokument26 SeitenDrilling Fluids: Islamic Azad University Science and Research Branch Drilling Departmentali nahiNoch keine Bewertungen

- DC Sept08 DeepwaterCementingDokument6 SeitenDC Sept08 DeepwaterCementinganon_634030219Noch keine Bewertungen

- Development of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PDokument20 SeitenDevelopment of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PSen HuNoch keine Bewertungen

- Formation Testing: Supercharge, Pressure Testing, and Contamination ModelsVon EverandFormation Testing: Supercharge, Pressure Testing, and Contamination ModelsNoch keine Bewertungen

- Agitator Handbook 2005Dokument22 SeitenAgitator Handbook 2005casda73Noch keine Bewertungen

- Jars and Accelerators.Dokument10 SeitenJars and Accelerators.driller22100% (1)

- Vinoth CVDokument5 SeitenVinoth CVNikhatRizaviNoch keine Bewertungen

- Rules of Thumb To Improve High-Angle Hole CleaningDokument29 SeitenRules of Thumb To Improve High-Angle Hole CleaningjalalNoch keine Bewertungen

- Formation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsDokument6 SeitenFormation Pressure While Drilling Technology - Game Changer in Drilling Overpressured ReservoirsJamalNoch keine Bewertungen

- PE-12 Well Stimulation and Clean UpDokument14 SeitenPE-12 Well Stimulation and Clean Upeng20072007Noch keine Bewertungen

- Drilling With Casing Promises Major BenefitsDokument12 SeitenDrilling With Casing Promises Major BenefitsRaul Alberto Miranda LoayzaNoch keine Bewertungen

- Meerkat PT ShakerDokument8 SeitenMeerkat PT ShakerEdgar Angulo ArizaNoch keine Bewertungen

- Off-Bottom Drilling PracticesDokument3 SeitenOff-Bottom Drilling PracticesAdel Ahmed AlkhaligyNoch keine Bewertungen

- Spe 30364 Seebty Ofpotrebum Endnws: Platform Concept OutlineDokument12 SeitenSpe 30364 Seebty Ofpotrebum Endnws: Platform Concept Outlinebr_fdm1604100% (1)

- Air and Gas Drilling NewDokument19 SeitenAir and Gas Drilling Newabdul wahabNoch keine Bewertungen

- Measurement While Drilling: Signal Analysis, Optimization and DesignVon EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNoch keine Bewertungen

- Mud/Gas Separator Sizing and Evaluation: G.R. MacdougallDokument6 SeitenMud/Gas Separator Sizing and Evaluation: G.R. MacdougallDiego AraqueNoch keine Bewertungen

- FG05W1 - Introduction To Process Control PDFDokument28 SeitenFG05W1 - Introduction To Process Control PDFknightfelix12100% (1)

- 3050A ManualDokument31 Seiten3050A Manualilegalll100% (1)

- TUTORIAL 1 Drilling EngineerDokument4 SeitenTUTORIAL 1 Drilling EngineerAnonymous AkV8maWxGNNoch keine Bewertungen

- CSG Type & DesignDokument45 SeitenCSG Type & Designcrown212100% (2)

- Ch.03 Aircraft Specification SASDokument12 SeitenCh.03 Aircraft Specification SASAhmad Faisal Ibrahim100% (1)

- Recommended Practice for Open Hole Sidetrack DrillingDokument5 SeitenRecommended Practice for Open Hole Sidetrack DrillingAdel Ahmed AlkhaligyNoch keine Bewertungen

- RT Bit Specific Energy SPE#00092194Dokument10 SeitenRT Bit Specific Energy SPE#00092194Asahel NuñezNoch keine Bewertungen

- Casing Running and Drilling ToolsDokument33 SeitenCasing Running and Drilling Toolsfffggg777Noch keine Bewertungen

- Well CompletionDokument82 SeitenWell CompletionFlorian Ananias ByarugabaNoch keine Bewertungen

- APD - Positive Test, Negative Test and Displacement ProceduresDokument7 SeitenAPD - Positive Test, Negative Test and Displacement ProceduresAntonio Hdez JmnzNoch keine Bewertungen

- Casing Design PreliminaryDokument29 SeitenCasing Design Preliminaryalizareiforoush100% (2)

- Optimizing ROP with Schlumberger TechniquesDokument14 SeitenOptimizing ROP with Schlumberger TechniquesMaría MarquinaNoch keine Bewertungen

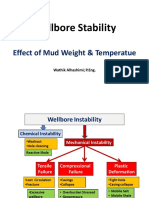

- Wellbore Stability Effect of Mud Weight 1645782860Dokument27 SeitenWellbore Stability Effect of Mud Weight 1645782860Muhammad Husein MahfudzNoch keine Bewertungen

- Determine Hole Cleaning Requirement in Deviated WellsDokument22 SeitenDetermine Hole Cleaning Requirement in Deviated WellsCut Fanni Ayutaya100% (1)

- SILDRIL System Engineering GuidelinesDokument7 SeitenSILDRIL System Engineering GuidelinesAhmer AkhlaqueNoch keine Bewertungen

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- Solids Induced Pack-Off Packing Off - First ActionsDokument4 SeitenSolids Induced Pack-Off Packing Off - First ActionsBhagwal TravelsNoch keine Bewertungen

- Well Control Checklist for Safe Drilling OperationsDokument14 SeitenWell Control Checklist for Safe Drilling OperationsAdam InesNoch keine Bewertungen

- Well Control Principles & Procedures Subsea BOPDokument5 SeitenWell Control Principles & Procedures Subsea BOPKRNoch keine Bewertungen

- Section02 Drilling ApparatusDokument31 SeitenSection02 Drilling ApparatusMohamed ElshoraNoch keine Bewertungen

- Remedial Cementing TechniquesDokument4 SeitenRemedial Cementing TechniquesColor RougeNoch keine Bewertungen

- Running Procedure 5Dokument2 SeitenRunning Procedure 5Pesireron RoberthNoch keine Bewertungen

- GTSC Simulator Profile Offers 10 Training OptionsDokument14 SeitenGTSC Simulator Profile Offers 10 Training OptionsDurga PrasadNoch keine Bewertungen

- Packer Testing Program Design and Management: August 2013Dokument7 SeitenPacker Testing Program Design and Management: August 2013wily784Noch keine Bewertungen

- Mud Training SchoolDokument78 SeitenMud Training School叶芊Noch keine Bewertungen

- PPE I PR 005Dokument11 SeitenPPE I PR 005MahanderOadNoch keine Bewertungen

- Spe 196232 MSDokument18 SeitenSpe 196232 MShijoetigreNoch keine Bewertungen

- 5B. High Pressure RiserDokument10 Seiten5B. High Pressure Riserdriller22Noch keine Bewertungen

- Drilling Deviated Holes GuideDokument28 SeitenDrilling Deviated Holes GuideMohamed ElshoraNoch keine Bewertungen

- Drilling Fluid QuestionsDokument2 SeitenDrilling Fluid QuestionsMunsef AL-juroshyNoch keine Bewertungen

- FOCUSSTUCKPIPEDokument21 SeitenFOCUSSTUCKPIPEVikas kumar singhNoch keine Bewertungen

- 200 Drilling Engineering PDFDokument10 Seiten200 Drilling Engineering PDFJesus De la RosaNoch keine Bewertungen

- Underbalanced DrillingDokument2 SeitenUnderbalanced DrillingWilson WanNoch keine Bewertungen

- CompassDokument4 SeitenCompassEnny RachelNoch keine Bewertungen

- 3 USIT InterpretationDokument18 Seiten3 USIT InterpretationAnkit Sharma100% (1)

- TAMU - Pemex: Offshore DrillingDokument31 SeitenTAMU - Pemex: Offshore DrillingkfranovskyNoch keine Bewertungen

- Audiobahn A2002V User Manual PDFDokument27 SeitenAudiobahn A2002V User Manual PDFCarlos FornesNoch keine Bewertungen

- 11071414113824Dokument68 Seiten11071414113824Ermin MutapcicNoch keine Bewertungen

- G Dyno CatalogueDokument4 SeitenG Dyno CataloguecarlosNoch keine Bewertungen

- Designation: E674 12 StandardDokument12 SeitenDesignation: E674 12 StandardLupita Ramirez100% (2)

- Interface Qos: Security LevelDokument6 SeitenInterface Qos: Security Levelmafasa_2005Noch keine Bewertungen

- Novag Star Diamond Communication ProtocolDokument8 SeitenNovag Star Diamond Communication ProtocolShamattNoch keine Bewertungen

- Manual Reparos Ohaus Linha ArDokument56 SeitenManual Reparos Ohaus Linha ArJoao Victor BNoch keine Bewertungen

- GM I & S PDFDokument178 SeitenGM I & S PDFsanjibkrjanaNoch keine Bewertungen

- S4CPlus-IRB6600 M2000A Electrical Maintenance Training Manual PDFDokument1.020 SeitenS4CPlus-IRB6600 M2000A Electrical Maintenance Training Manual PDFWilber Santiago Toledo0% (1)

- Opamp Based Power AmplifierDokument7 SeitenOpamp Based Power AmplifierBrenda Archer MorenoNoch keine Bewertungen

- Building Scalable Apps With Redis and Node - Js Sample ChapterDokument44 SeitenBuilding Scalable Apps With Redis and Node - Js Sample ChapterPackt PublishingNoch keine Bewertungen

- Proporation & RatioDokument16 SeitenProporation & RatioPranav KunteNoch keine Bewertungen

- Store student data using structures in CDokument20 SeitenStore student data using structures in C13 - Anshu Singh ENC 02Noch keine Bewertungen

- Courseware SampleDokument8 SeitenCourseware SampleScott ConnollyNoch keine Bewertungen

- MAS Practice Standards and Ethical ConsiderationsDokument27 SeitenMAS Practice Standards and Ethical ConsiderationsLorraineMartinNoch keine Bewertungen

- Programming With Curlpp: 1 About This DocumentDokument18 SeitenProgramming With Curlpp: 1 About This DocumentEugen IordacheNoch keine Bewertungen

- Electronic Pressure Switch With Two Switching Outputs: RE 30278/03.06 Replaces: 01.06 RE 30275Dokument6 SeitenElectronic Pressure Switch With Two Switching Outputs: RE 30278/03.06 Replaces: 01.06 RE 30275honghoaso1Noch keine Bewertungen

- Silay Patag PDF Page 1 - 9 PDFDokument10 SeitenSilay Patag PDF Page 1 - 9 PDFRalph Emmanuel MercadoNoch keine Bewertungen

- IDRAC7 1 57 57 A ReleaseNotesDokument33 SeitenIDRAC7 1 57 57 A ReleaseNotesthoan26Noch keine Bewertungen

- 3850 Switch Wired C3PL Configuration For Cisco Identity Services EngineDokument20 Seiten3850 Switch Wired C3PL Configuration For Cisco Identity Services EnginecsystemsNoch keine Bewertungen

- Integrating Snort and OSSIMDokument7 SeitenIntegrating Snort and OSSIMMarcelo LaurentiNoch keine Bewertungen

- Compliance CertificateDokument2 SeitenCompliance CertificateSwat Guratai by javed Javed iqbalNoch keine Bewertungen

- CEN EPB Standards EN/ISO 52000-1Dokument8 SeitenCEN EPB Standards EN/ISO 52000-1nbilicNoch keine Bewertungen