Beruflich Dokumente

Kultur Dokumente

ZingOrbit Cut Settings

Hochgeladen von

burgleteensCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ZingOrbit Cut Settings

Hochgeladen von

burgleteensCopyright:

Verfügbare Formate

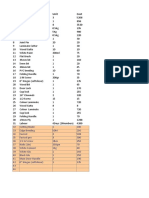

Suggested Cut Settings for Various Materials on KNK Zing Orbit

IMPORTANT: These settings should be used for the initial test cut. Adjustments may be necessary based on the condition of the blade,

variations in the material, humidity, condition of the cutting mat, blade tip height, etc.

ALSO IMPORTANT: Do not use a Blade Tip Height greater than 10 with a blue capped blade. It is very fragile!

Multi- Blade

Material Type Material Brand/Source Blade Pressure Speed Other Comments

Cut Height

Acetate 5 mil (0.13mm) R 1 45 15 15

Apollo Inkjet Transparency

Acetate R 1 60 15 15 Alt: 2 passes at Pressure = 40

Film (0.13mm)

Candle Wax Rayher: 0.025" (0.6 mm) B 1 20 10 10 Alt: Paper side up, Pressure 30

Candle Wax Stockmar: 0.05" (1.2 mm) B 1 25 10 10

AC Textured 216gsm, 80lb

Cardstock R 1 60 15 15 Alt: 2 passes at Pressure = 50

cover

Cardstock Bazzill Linen R 1 55 15 15

Carolina C2S Digital 144lb

Cardstock R 1 75 15 15

(234gsm)

Darice Core'dinations

Cardstock R 1 45 15 15

Premium (65lb)

Georgia Pacific, 110lb index

Cardstock R 1 55 15 15 Alt: 2 passes at Pressure = 45

(199gsm)

Cardstock Graphic 45 (0.22mm) R 1 50 15 15 6x6 Cardstock Pad

Cardstock Neenah Astrobrights 176gsm R 1 50 15 15

Neenah Pastel 176gsm

Cardstock R 1 50 15 15 Alt: 2 passes at Pressure = 40

(65lb)

Cardstock Recollections 176gsm (65lb) R 1 50 15 15

Recollections 176gsm (65lb)

Cardstock R 1 55 15 15

Kraft

Cardstock Wassau 176gsm (65 lb) R 1 50 15 15 Alt: 2 passes at Pressure = 40

Cardstock Worldwin Colormats (65 lb) R 1 50 15 15 Alt: 2 passes at Pressure = 40

Cardstock Worldwin Cutmates R 1 50 15 15 Alt: 2 passes at Pressure = 40

Cardstock Worldwin Smooth & Silky R 1 70 15 15 Alt: 2 passes at Pressure = 60

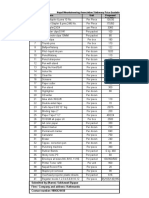

Multi- Blade

Material Type Material Brand/Source Blade Pressure Speed Other Comments

Cut Height

Chipboard 0.022" (0.5 mm) R 2 100 10 15 Brayer well and tape edges

Chipboard Cereal box 0.018" (0.4 mm) R 2 100 10 15 Brayer well and tape edges

Chipboard KNKUSA 0.03" (0.76mm) B 2 120 10 10 Brayer well and tape edges

Chipboard Silhouette .015" (.38mm) R 1 80 10 10

Construction Paper Creatology - pink R 1 30 13 15

Construction Paper Pacon Tru-Ray - black R 1 35 13 15 Alt: 2 passes at Pressure = 30

0.02" PET-G with blue

Craft Plastic B 2 130 8 10 Paper layer peeled off. Corners taped to mat

protection sheets

Craft Plastic Dick Blick; 0.015" (0.38mm) B 2 110 8 10 Paper layer peeled off. Corners taped to mat

Double Sided Adhesive Sookwang R 1 60 15 15

Fabric - Cork embroiderygarden.com Y 2 50 10 10 Used an extra sticky mat

Steam-a-Seam2 fused to wrong side, paper

Fabric - Cotton Batik with Lite Steam-A-Seam 2 Y 1 65 10 15

removed and sticky side pressed down to mat

Steam-a-Seam2 fused to wrong side, paper

Fabric - Cotton Flannel with Lite Steam-A-Seam 2 Y 2 75 10 15

removed and sticky side pressed down to mat

Fabric - Denim with Heat n Bond applied Y 3 115 13 15 Left paper layer on.

Fabric - Quilting Cotton with Heat n Bond applied Y 2 65 13 15

Alt: 2 Passes at Pressure = 70; Steam-a-

Fabric - Quilting Cotton with Lite Steam-A-Seam 2 Y 1 80 10 15 Seam2 fused to wrong side, paper removed

and sticky side pressed down to mat

Foam (Fun Foam) Michael's 0.07" (1.8mm) B 2 20 12 10

HTV refer to Vinyl - Heat Transfer

Label Sheets: water

Creative Label Concepts R 1 35 15 15 The pressure is for kiss cutting the labels.

resistent

Leather 0.02" Bookbinding quality R 2 75 13 15

Leather ~ 0.06" B 2 100 9 10

Tape magnet to a sticky mat; may need

Magnet 0.035" (0.9mm) B 2 120 10 10

slower speed for accurate shapes

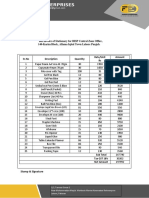

Multi- Blade

Material Type Material Brand/Source Blade Pressure Speed Other Comments

Cut Height

Cricut Printable Magnet

Magnet R 1 50 15 15

Sheets (.25mm)

KNK USA - Printable Magnet

Magnet R 1 70 15 15 Alt: 2 passes at Pressure = 50

Sheets-15 mil (0.4mm)

Mylar 5 mil (0.12mm) R 1 50 15 15

Mylar KNK USA - 10 mil (0.25mm) R 2 100 10 15 Extra sticky mat; tape corners

Mylar KNK USA - 7 mil (0.18mm) R 1 65 15 15

Paper - Copy Paper HP Everyday 20lb (75gsm) R 1 35 15 15

Canson 140lb (300g) Cold

Paper - Watercolor R 1 100 15 15

Press

Photo Paper HP Glossy R 1 80 15 15 Alt: 2 passes at Pressure = 65

Royal Brites Matte White -

Photo Paper R 1 70 15 15 Alt: 2 passes at Pressure = 55

200 gsm

Grocery store 0.013"

Poster Board R 1 70 12 15 Alt: 2 passes at Pressure = 60

(0.33mm)

Backing peeled and sticky side pressed to

Rhinestone Flock KNK USA (Rock-It) R 2 55 15 15

mat

Backing peeled and sticky side pressed to

Rhinestone Flock Sticky Flock R 2 45 15 15

mat

Backing peeled and sticky side pressed to

Rhinestone Rubber KNK USA (green Hartco) R 2 60 15 15

mat

Shrink Film Grafix clear R 2 80 12 15

Shrink Film Grafix Ink Jet white R 2 120 12 15

Shrinky Dink Bright White R 1 125 12 15

Shrinky Dink Frosted Ruff N' Ready R 1 125 12 15

Shrinky Dink Printable Ink Jet white R 1 125 12 15

Stencil Blanks (also Show-Offs 15 mil from Hobby Place side with protection sheet down; tape

R 3 120 10 15

see Mylar) Lobby corners

Styrene ASI .02" (.47mm) R 2 120 15 15

Styrene Evergreen .02" (.47mm) R 3 155 10 15

Styrene Plastruct .01" (.25mm) R 1 90 15 15 Alt: 2 passes at Pressure = 65

Multi- Blade

Material Type Material Brand/Source Blade Pressure Speed Other Comments

Cut Height

Vinyl - Heat Transfer Cricut Glitter Iron On - White R 1 30 15 15 Cut on mat

Vinyl - Heat Transfer Easy Weed - white, navy R 1 40 12 15 Cut on mat

Vinyl - Heat Transfer GlitterFlex Ultra - Black R 1 50 15 15 Cut on mat

Expressions Vinyl 51 Series -

Vinyl - Permanent R 1 20 15 15 Cut on mat

Black

Vinyl - Wall (no mat) Vinyl - Oracal 631 - yellow R 1 20 15 15 Not using a mat: note lower Blade Height

Vinyl - Wall (no mat) Vinyl - Oracal 631 - yellow R 1 25 15 15 Not using a mat

Vinyl - Wall (on mat) Vinyl - Oracal 631 - yellow R 1 20 15 15 Cut with vinyl on the mat

0.015" (0.4mm) from

Wood Veneer B 2 100 10 10 Taped to mat; tested both oak and walnut

cardsofwood.com

Das könnte Ihnen auch gefallen

- Consumption: 02 July 2008 Buyer:: Patenga Footwear (PVT.) LTDDokument4 SeitenConsumption: 02 July 2008 Buyer:: Patenga Footwear (PVT.) LTDapi-26143731Noch keine Bewertungen

- V-2 (Sports)Dokument1 SeiteV-2 (Sports)api-26143731Noch keine Bewertungen

- Consuption (03/NOV/07) Last: Stg-20 Pump: Patenga Footwear (PVT.) Ltd. BuyerDokument14 SeitenConsuption (03/NOV/07) Last: Stg-20 Pump: Patenga Footwear (PVT.) Ltd. Buyerapi-26143731Noch keine Bewertungen

- Information About ApparelDokument32 SeitenInformation About ApparelMd. SajibNoch keine Bewertungen

- Price List - XLS: Patenga Footwear (PVT.) LTDDokument2 SeitenPrice List - XLS: Patenga Footwear (PVT.) LTDapi-26143731Noch keine Bewertungen

- Tic-49 PumpDokument4 SeitenTic-49 Pumpapi-26143731Noch keine Bewertungen

- Ark-18 Boot (Daikobe)Dokument5 SeitenArk-18 Boot (Daikobe)api-26143731Noch keine Bewertungen

- Tic - 49 & STG-5 (Daikobe)Dokument6 SeitenTic - 49 & STG-5 (Daikobe)api-26143731Noch keine Bewertungen

- Liste Des Matériaux (Maker) Français AnglaisDokument9 SeitenListe Des Matériaux (Maker) Français AnglaisSylvain LeblancNoch keine Bewertungen

- Patenga Footwear (PVT.) LTDDokument10 SeitenPatenga Footwear (PVT.) LTDapi-26143731Noch keine Bewertungen

- ARK-18 Long BootDokument2 SeitenARK-18 Long Bootapi-26143731Noch keine Bewertungen

- Belt Specifications - R19-Fabcon - 2rc - 5 - tr24 - 00-00 - Fa-Kc2tr2401Dokument2 SeitenBelt Specifications - R19-Fabcon - 2rc - 5 - tr24 - 00-00 - Fa-Kc2tr2401eng.mark.iskanderNoch keine Bewertungen

- Description: Price ListDokument1 SeiteDescription: Price Listapi-26143731Noch keine Bewertungen

- Price List - XLS: Consumption: 12 July 2008 BuyerDokument5 SeitenPrice List - XLS: Consumption: 12 July 2008 Buyerapi-26143731Noch keine Bewertungen

- Limcon SupplierDokument3 SeitenLimcon SupplierJohn Carlo AmodiaNoch keine Bewertungen

- Item & Specifications Monthly Quantity Requirement: Unit of MeasureDokument11 SeitenItem & Specifications Monthly Quantity Requirement: Unit of MeasureMark Baquilod RamasNoch keine Bewertungen

- MAP Design & Print Inventory ReportDokument3 SeitenMAP Design & Print Inventory ReportmojiamaraNoch keine Bewertungen

- Quotation: Sr. No. Particulars Price / KGDokument1 SeiteQuotation: Sr. No. Particulars Price / KGASIF KHANNoch keine Bewertungen

- STG 16Dokument1 SeiteSTG 16api-26143731Noch keine Bewertungen

- Progress Kebutuhan Material: Dept: Wrap 3/15/2021Dokument3 SeitenProgress Kebutuhan Material: Dept: Wrap 3/15/2021intanNoch keine Bewertungen

- NCC Leather: Patenga Footwear (PVT.) Ltd. Consuption (25-Apr/08) REVISED Buyer:Daikobe Last: Tic - 49Dokument23 SeitenNCC Leather: Patenga Footwear (PVT.) Ltd. Consuption (25-Apr/08) REVISED Buyer:Daikobe Last: Tic - 49api-26143731Noch keine Bewertungen

- RN AccesoriesDokument6 SeitenRN Accesoriesbonnachor017Noch keine Bewertungen

- Buyer: AKIRA (Revised) : Consumption: 14-FEB/2008Dokument9 SeitenBuyer: AKIRA (Revised) : Consumption: 14-FEB/2008api-26143731Noch keine Bewertungen

- Regal Heaven BT - Danube - REV 1Dokument2 SeitenRegal Heaven BT - Danube - REV 1Yogesh SharmaNoch keine Bewertungen

- V-2 Sport SandalDokument6 SeitenV-2 Sport Sandalapi-26143731Noch keine Bewertungen

- Product Images and Specifications Are Subject To Change Without NoticeDokument20 SeitenProduct Images and Specifications Are Subject To Change Without NoticeokiNoch keine Bewertungen

- STG-35 SportDokument1 SeiteSTG-35 Sportapi-26143731Noch keine Bewertungen

- Artwork Confirmation Gamuda LandDokument1 SeiteArtwork Confirmation Gamuda LandmyizzahzarinaNoch keine Bewertungen

- Acrylic Foam Tape: RT8000 SeriesDokument5 SeitenAcrylic Foam Tape: RT8000 SeriesHerman SujarwantoNoch keine Bewertungen

- Luxuria Bonnell Spring Mattress With Convoluted Foam - Danube REV 1Dokument2 SeitenLuxuria Bonnell Spring Mattress With Convoluted Foam - Danube REV 1Yogesh SharmaNoch keine Bewertungen

- Last: STG-12 SANDAL: Material ConsumptionDokument7 SeitenLast: STG-12 SANDAL: Material Consumptionapi-26143731Noch keine Bewertungen

- Artwork Confirmation Movie Hour KPJ SABAHDokument1 SeiteArtwork Confirmation Movie Hour KPJ SABAHmyizzahzarinaNoch keine Bewertungen

- RajaDokument1 SeiteRajaSri SasidharNoch keine Bewertungen

- Digital Printing GuideDokument3 SeitenDigital Printing GuideKervinNoch keine Bewertungen

- Tiêu Chuẩn Stone Paper 3Dokument3 SeitenTiêu Chuẩn Stone Paper 3Huy NguyenNoch keine Bewertungen

- Artwork Confirmation - Universal 4U Automart SDN BHDDokument1 SeiteArtwork Confirmation - Universal 4U Automart SDN BHDmyizzahzarinaNoch keine Bewertungen

- Wash Wash Leather: Buyer: SEIWADokument8 SeitenWash Wash Leather: Buyer: SEIWAapi-26143731Noch keine Bewertungen

- 2020 Ammended APPDokument117 Seiten2020 Ammended APPMark Kaiser TanNoch keine Bewertungen

- Artwork Confirmation WanaDokument1 SeiteArtwork Confirmation WanamyizzahzarinaNoch keine Bewertungen

- New Bulk Month WiseDokument3 SeitenNew Bulk Month WiseHanif AminNoch keine Bewertungen

- Price List - As at 21 Jul 2020Dokument40 SeitenPrice List - As at 21 Jul 2020MarkNoch keine Bewertungen

- Artwork Confirmation Banner FunfairDokument1 SeiteArtwork Confirmation Banner FunfairmyizzahzarinaNoch keine Bewertungen

- CV 37Dokument3 SeitenCV 37api-26143731Noch keine Bewertungen

- Patenga Footwear (PVT.) LTD.: Price ListDokument5 SeitenPatenga Footwear (PVT.) LTD.: Price Listapi-26143731Noch keine Bewertungen

- TACO PVC Sheet E-CatalogueDokument9 SeitenTACO PVC Sheet E-CataloguedickiNoch keine Bewertungen

- Estimated Monthly ConsumptionDokument33 SeitenEstimated Monthly Consumptiontracy zvenhamoNoch keine Bewertungen

- Artwork Confirmation Handmade LemonDokument1 SeiteArtwork Confirmation Handmade LemonmyizzahzarinaNoch keine Bewertungen

- Artwork Confirmation StanleyDokument1 SeiteArtwork Confirmation StanleymyizzahzarinaNoch keine Bewertungen

- Gyproc 1 Gyproc 2 MergedDokument2 SeitenGyproc 1 Gyproc 2 Mergedkaval chhabraNoch keine Bewertungen

- Delivery Note For BOQ E-847 Material Required For E&I Equipments Cleaning For Upcoming Visit (Phase-1) 19-01-2024Dokument3 SeitenDelivery Note For BOQ E-847 Material Required For E&I Equipments Cleaning For Upcoming Visit (Phase-1) 19-01-2024Engineer Atif Rasul ChoudhryNoch keine Bewertungen

- Add Bliss To Your Life.: List Price (LP) W.E.F. 16 Dec. 2020Dokument12 SeitenAdd Bliss To Your Life.: List Price (LP) W.E.F. 16 Dec. 2020Subham Arya, 11100% (1)

- Mountering StationaryDokument2 SeitenMountering StationaryGyanendra Ratna BajracharyaNoch keine Bewertungen

- Canvasting Tagum Davao Del NorteDokument12 SeitenCanvasting Tagum Davao Del NorteJohn Carlo AmodiaNoch keine Bewertungen

- AnalyzationDokument11 SeitenAnalyzationfahad pervaizNoch keine Bewertungen

- Cutter Blade Reference GuideDokument12 SeitenCutter Blade Reference GuideThePrintManNoch keine Bewertungen

- Stationary Invoice BISP 01 PDFDokument1 SeiteStationary Invoice BISP 01 PDFMohsinNoch keine Bewertungen

- Plate Heat Exchanger Gaskets WEBSITEDokument2 SeitenPlate Heat Exchanger Gaskets WEBSITESHAKEEL ISMAIL LAMBAYNoch keine Bewertungen

- Artwork Confirmation POSHAREDokument1 SeiteArtwork Confirmation POSHAREmyizzahzarinaNoch keine Bewertungen

- Sty Demand Jan 22 - Mar 22 (Copy)Dokument9 SeitenSty Demand Jan 22 - Mar 22 (Copy)Ketan PatilNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- Pop UpShopDeetsDokument2 SeitenPop UpShopDeetsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- OttoDIY Programming Mblock Scratch Arduino v01Dokument21 SeitenOttoDIY Programming Mblock Scratch Arduino v01burgleteensNoch keine Bewertungen

- ZingOrbit With SCAL UMDokument305 SeitenZingOrbit With SCAL UMburgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- OttoDIY Programming Mblock Scratch Arduino v01Dokument21 SeitenOttoDIY Programming Mblock Scratch Arduino v01burgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument17 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- Lesson2 PDFDokument6 SeitenLesson2 PDFJessica Nov-nov DodsNoch keine Bewertungen

- Spiral Coil Template PDFDokument1 SeiteSpiral Coil Template PDFburgleteensNoch keine Bewertungen

- Otto DIY Activity+Workshop Build Your Own Otto!: Workshop Sheet V01 Date: 12th February/2018Dokument4 SeitenOtto DIY Activity+Workshop Build Your Own Otto!: Workshop Sheet V01 Date: 12th February/2018burgleteensNoch keine Bewertungen

- Terrain Programs - Window Dressing - Pop Up Shop: INVENTORY SHEET (Page - of - )Dokument2 SeitenTerrain Programs - Window Dressing - Pop Up Shop: INVENTORY SHEET (Page - of - )burgleteensNoch keine Bewertungen

- ZingOrbit Cut SettingsDokument4 SeitenZingOrbit Cut SettingsburgleteensNoch keine Bewertungen

- ZingOrbit With SCAL UMDokument305 SeitenZingOrbit With SCAL UMburgleteensNoch keine Bewertungen

- OttoDIY InstructionManual V06 Arduino PDFDokument28 SeitenOttoDIY InstructionManual V06 Arduino PDFburgleteensNoch keine Bewertungen

- When Zombies Attack: Mathematical Modelling of An Outbreak of Zombie InfectionDokument18 SeitenWhen Zombies Attack: Mathematical Modelling of An Outbreak of Zombie InfectionemmaafiNoch keine Bewertungen

- JLPT N2 Vocab - 04Dokument345 SeitenJLPT N2 Vocab - 04raj_kumartNoch keine Bewertungen

- How To Format Your Business ProposalDokument2 SeitenHow To Format Your Business Proposalwilly sergeNoch keine Bewertungen

- Case Study GingerDokument2 SeitenCase Study Gingersohagdas0% (1)

- Due Books List ECEDokument3 SeitenDue Books List ECEMadhumithaNoch keine Bewertungen

- FCI - GST - Manual On Returns and PaymentsDokument30 SeitenFCI - GST - Manual On Returns and PaymentsAmber ChaturvediNoch keine Bewertungen

- E-Math Sec 4 Sa2 2018 Bukit Panjang - Short AnsDokument36 SeitenE-Math Sec 4 Sa2 2018 Bukit Panjang - Short AnsWilson AngNoch keine Bewertungen

- In Practice Blood Transfusion in Dogs and Cats1Dokument7 SeitenIn Practice Blood Transfusion in Dogs and Cats1何元Noch keine Bewertungen

- TAX Report WireframeDokument13 SeitenTAX Report WireframeHare KrishnaNoch keine Bewertungen

- Deutz Common RailDokument20 SeitenDeutz Common RailAminadav100% (3)

- Phoenix Wright Ace Attorney - Episode 2-2Dokument39 SeitenPhoenix Wright Ace Attorney - Episode 2-2TheKayOneNoch keine Bewertungen

- United States Court of Appeals Fifth CircuitDokument4 SeitenUnited States Court of Appeals Fifth CircuitScribd Government DocsNoch keine Bewertungen

- State Public Defender's Office InvestigationDokument349 SeitenState Public Defender's Office InvestigationwhohdNoch keine Bewertungen

- Nielsen Esports Playbook For Brands 2019Dokument28 SeitenNielsen Esports Playbook For Brands 2019Jean-Louis ManzonNoch keine Bewertungen

- Chronology of Events:: Account: North Davao Mining Corp (NDMC)Dokument2 SeitenChronology of Events:: Account: North Davao Mining Corp (NDMC)John Robert BautistaNoch keine Bewertungen

- 11 PJBUMI Digital Data Specialist DR NOOR AZLIZADokument7 Seiten11 PJBUMI Digital Data Specialist DR NOOR AZLIZAApexs GroupNoch keine Bewertungen

- DentinogenesisDokument32 SeitenDentinogenesisNajeeb UllahNoch keine Bewertungen

- Ogl 350 Paper 2Dokument5 SeitenOgl 350 Paper 2api-672448292Noch keine Bewertungen

- Rock Type Identification Flow Chart: Sedimentary SedimentaryDokument8 SeitenRock Type Identification Flow Chart: Sedimentary Sedimentarymeletiou stamatiosNoch keine Bewertungen

- How A Type 4 Multiverse WorksDokument4 SeitenHow A Type 4 Multiverse WorksIdkNoch keine Bewertungen

- Pentagram Business PlanDokument13 SeitenPentagram Business PlantroubledsoulNoch keine Bewertungen

- Mudbound: Virgil Williams and Dee ReesDokument125 SeitenMudbound: Virgil Williams and Dee Reesmohan kumarNoch keine Bewertungen

- Chapter 3 - StudentDokument38 SeitenChapter 3 - StudentANIS NATASHA BT ABDULNoch keine Bewertungen

- Schopenhauer and KantDokument8 SeitenSchopenhauer and KantshawnNoch keine Bewertungen

- Machiavelli's Political Philosophy and Jamaican PoliticsDokument2 SeitenMachiavelli's Political Philosophy and Jamaican PoliticsAndre RobinsonNoch keine Bewertungen

- Conformity Observation Paper 1Dokument5 SeitenConformity Observation Paper 1api-524267960Noch keine Bewertungen

- Presbuteroi (Elders) and Episkopoi (Overseers) and Are Described in 1 Tim 3 and TitusDokument15 SeitenPresbuteroi (Elders) and Episkopoi (Overseers) and Are Described in 1 Tim 3 and TitusNimaro Brenda100% (1)

- 130004-1991-Maceda v. Energy Regulatory BoardDokument14 Seiten130004-1991-Maceda v. Energy Regulatory BoardChristian VillarNoch keine Bewertungen

- 4h Thank You ProofDokument1 Seite4h Thank You Proofapi-362276606Noch keine Bewertungen

- Lae 3333 2 Week Lesson PlanDokument37 SeitenLae 3333 2 Week Lesson Planapi-242598382Noch keine Bewertungen

- Social Studies 5th Grade Georgia StandardsDokument6 SeitenSocial Studies 5th Grade Georgia Standardsapi-366462849Noch keine Bewertungen