Beruflich Dokumente

Kultur Dokumente

Cable Reeling Drum

Hochgeladen von

fnahas_bh0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

78 Ansichten6 SeitenCable Reeling Drum

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCable Reeling Drum

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

78 Ansichten6 SeitenCable Reeling Drum

Hochgeladen von

fnahas_bhCable Reeling Drum

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

Eg ELECTRO ZAVOD:

Cable Reeling Drum

Cable Reeling Drum

Cable Reeling Drums are used for automatic reeling and

unreeling of flexible trailing cables for current consuming

mobile machines, whose travel is mostly track bound.

There are mainly three modes of drive for the drums :—

a) Cable Reeling Drum with spring drive

b) Cable Reeling Drum with counter weight drive

c) Cable Reeling Drum with stall torque motor drive

a) Cable Reeling Drum with spring

drive

The spring acts as the drive

force. The spring drum is

used for small sizes and

lengths of cable. Due to the

limited torque available from

the spring, the size and length

of cable that can be wound is

limited. The efficiency of the

drive mainly depends upon the

spring life, and the life of the

spring depends upon the

number of operations i.e. the

working cycle.

The application of spring drum

is limited to electro-magnets,

machine tools, etc. Since the

efficiency and reliability of the

drum depends on the quality of

the spring, great care should

be taken in the selection and

manufacture of the spring.

b) Cable Reeling Drum with counter

weight drive

The counter weight acts as the

drive force and is suitable for

cable sizes upto 4 x 95 mm sq.

and travel length upto a

maximum of 100 metres. The

length of cable is limited by the

height the counter weight has

to traverse.

c) Cable Reeling Drum with stall

torque motor drive

The drum is driven by a

specially designed “Stall

Torque Motor”. The motor

provides the necessary torque

for the rotation of the drum and

has proven to be the most

reliable drive for the cable

reeling drum. Motorised cable

reeling drums can handle

almost all sizes and lengths of

cable.

The stall torque motor is a

brake motor capable of

producing a strong torque

while remaining close to or

exactly at zero speed i.e. rotor

in locked condition, without

overheating. While the reel is

unwinding the rotor is moved

against its natural direction of

rotation, without being

electrically reversed. This is

the unique feature of the stall

torque motor which makes it

extremely suitable for reeling motor is available in squirrel

and unreeling application. This cage as well as slipring

motor has a conical rotor and a construction. The two types

built-in-brake. The stall torque used are:

i) Squirrel cage motor — 12 poles operating range

- 500 to + 500 rpm.

4 poles operating range

- 600 to + 1500 rpm.

ii) Slipring motor —

The output torque can be reduced in the slipring motor by increasing the

rotor resistance.

There are three types of

Cable Reeling Drums, namely;

(a) Semi-parallel

(b) Monospiral

(c) Parallel

Semi-parallel

The semi-parallel drum is used for Normally the winding on these

asmall length of cable, say; upto drums is not entirely uniform. In

250 metres, and for voltage upto cases where uniform winding is a

415 V. The winding of the cable is major consideration the width of

not guided by a winding device. the drum may be reduced to

The width of the drum ranges accommodate only 2/3 turns of

between 300 and 500 mm. cable in each layer.

Monospiral

The monospiral drum is used for

all sizes and lengths of cable, and

voltage upto 11 KV. The cable

drum is fully ventilated and the

derating factor is not high. The

number of layers is unlimited but

the overall diameter of the drurn is

limited by the clearance available.

The width of the drum is equal to

cable diameter plus 5 mm.

Parallel

The parallel drum is used for all

sizes and lengths of cable and for

voltage upto 35 KV. The width of a

parallel drum varies between

0.8 Mand 5 M. This drum is also

popularly known as barrel type

drum. The winding of cable is

uniformly guided by a winding

device.

The Cable Reeling Drum

consists of the following main components :

1, Drum body

2. Slipring assembly

3. Drive motor

4, Cable layering mechanism/guide arrangement

5. Cable length limiting switch

6, Over tension/under tension limit switch

7. Cable feeding devices

8. Control and power supply accessories

Drum Body

The drum body accommodates

the required length of the flexible

cable to be wound and unwound.

The size of the drum depends

upon the diameter of cable and

the length of the cable. The |.D. of

the drum is 16 times the O.D. of

cable for L.T., and 25 times the

0.D. of cable for H.T.

Length of cable and number of layers :

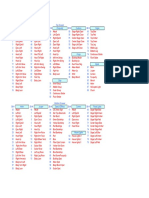

Type of drum No. of layers Length of cable

Semi-parallel 3to5 250M

Monospiral 15 to 60 400M

Parallel 2to3 3000 M

The parallel drum body is provided with a perforated sheet, primarily for

better heat dissipation.

Slipring assembly

The power, control and communi-

cation signal is transmitted by the

slipring assembly to the machine:

The slipring assembly has to be

suitably designed to withstand

the short circuit level of the

system and the current carrying

capacity. The number of sliprings

and the ratings will depend upon

the requirement of the machine.

The brush gear is designed to

carry the required current.

Cable layering mechanism/guide

arrangement

This mechanism is very vital

in the case of a parallel drum. It

provides a proper layering of the

cable side by side, and one over

the other after the completion of

one layer across the width of the

drum. If the chain and the gear

box are not properly selected,there

will be frequent problems of chain

snapping and non uniform

winding. The cable guide assists

in the formation of proper

catenary and deposit of the cable

on the ground at a pre-determined

place. The over tension/under

tension protection switch is also

mounted on the guide

arrangement

Cable length limiting switch

This is a gear cam switch with

associated electrical switches and

is driven by a sprocket and chain

mechanism from the drum. This

cam switch can be set for a

particular length of cable, and if the

set values are exceeded the control

circuit provides for automatic

stoppage of the machine. This is a

very important protection and

should not be ignored. This switch is

also used for regulating tension in

the case of Monospiral drum.

Flexible cable:

Flexible trailing cables are tailor made and specially designed for reeling and

unreeling duty. To select the cable size, the following formula can be used:

AC. D.C.

c ‘ KW x 1000 i: Kw x 1000

tAc ———_ eee

eae 1.73xVxCos @xn x d1xd2 Vxnxdlxd2

V = Voltage in Volts

Cos @ = Power factor KW = 1.36 HP

n= Efficiency H P=0.736 KW

A= Current in Amps

dl = Derating factor for Ambient temperature

d2 = Derating factor for flexible cable wound on drum

dl for Buty! or EP Rubber Cables

Ambient temp. 30 35 40 45 50 55 60 65

Rating factor 1.00 | 0.93 | 0.86 | 0.80 | 0.72 | 063 | 0.54 | 0.44

d2 for Cable wound on drum

Layers 1 2 3 4 Monospiral

Rating factor 0.76 0.58 0.47 0.40 0.85

EZ

ELECTRO ZAVOD (invia) pvt.iro

19/1B, Keyatala Road, Calcutta-700 029

Phone : 464-3831, 464-4920, 464-0156,

Fax : (033) 464-0103

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- September - Earth, Wind and Fire (D) - BassDokument1 SeiteSeptember - Earth, Wind and Fire (D) - BassPierreSottas100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Chapter 1. Pitch Centricity and Composition With Motivic CellsDokument9 SeitenChapter 1. Pitch Centricity and Composition With Motivic CellsZach Todd100% (1)

- RSK200109 Casio Keys 2019 DIGITAL PDFDokument30 SeitenRSK200109 Casio Keys 2019 DIGITAL PDFGearóid Ó Broin100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Lynyrd Skynyrd - Sweet Home AlabamaDokument2 SeitenLynyrd Skynyrd - Sweet Home AlabamaJulie Papin100% (1)

- Niccolo Paganini's Caprice No.1Dokument4 SeitenNiccolo Paganini's Caprice No.1jorcos82Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Mal WaldronDokument5 SeitenMal WaldronburkeNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- J. S. Bach For Solo Guitar: Prelúdio # I em C MaiorDokument4 SeitenJ. S. Bach For Solo Guitar: Prelúdio # I em C MaiorSergey SuloevNoch keine Bewertungen

- Glenn Miller and His Orchestra DiscographyDokument24 SeitenGlenn Miller and His Orchestra DiscographybooksfNoch keine Bewertungen

- Banjo MethodDokument1 SeiteBanjo Methodvidaldoval0% (2)

- Assignment #4 - Film QuestionsDokument4 SeitenAssignment #4 - Film QuestionsAnh Nguyen BuiNoch keine Bewertungen

- Design Charts For Machine FoundationDokument22 SeitenDesign Charts For Machine Foundationroy1zhou100% (2)

- Europe Carrie Piano PDFDokument2 SeitenEurope Carrie Piano PDFSteven25% (4)

- Baroque Guitar TuningDokument3 SeitenBaroque Guitar TuningJonel Boljanac100% (1)

- FOUNDATIONS FOR INDUSTRIAL MACHINES AND EARTHQUAKE EFFECTS - K.G. Bhatia - ISET Journal of Earthquake Technology, Paper No. 495, Vol. 45, No. 1-2, March-June 2008, Pp. 13-29Dokument17 SeitenFOUNDATIONS FOR INDUSTRIAL MACHINES AND EARTHQUAKE EFFECTS - K.G. Bhatia - ISET Journal of Earthquake Technology, Paper No. 495, Vol. 45, No. 1-2, March-June 2008, Pp. 13-29R Mani MuruganNoch keine Bewertungen

- Pump Clinic 43Dokument3 SeitenPump Clinic 43fnahas_bhNoch keine Bewertungen

- Amazing Grace: Frank Ticheli Manhattan Beach Music - Medium (Grade 3) /6 Minutes Broad DescriptionDokument12 SeitenAmazing Grace: Frank Ticheli Manhattan Beach Music - Medium (Grade 3) /6 Minutes Broad Descriptionapi-550015101Noch keine Bewertungen

- 2014 04 01 Classic Catalog 53955 Rev.GDokument40 Seiten2014 04 01 Classic Catalog 53955 Rev.Gfnahas_bhNoch keine Bewertungen

- Pump Clinic 33Dokument8 SeitenPump Clinic 33fnahas_bhNoch keine Bewertungen

- THG Hooks Forged Hooks Catalogue SheetDokument5 SeitenTHG Hooks Forged Hooks Catalogue SheetAnderson SantosNoch keine Bewertungen

- Cantoneira Perfis Abas IguaisDokument20 SeitenCantoneira Perfis Abas IguaisRogerio Salarini JabbourNoch keine Bewertungen

- Poema Dificil Da Língua InglesaDokument2 SeitenPoema Dificil Da Língua Inglesafnahas_bhNoch keine Bewertungen

- 2013 10 12 GrabiQ Catalog 55801 Rev.EDokument32 Seiten2013 10 12 GrabiQ Catalog 55801 Rev.Efnahas_bhNoch keine Bewertungen

- Me2 Learning AnsysDokument67 SeitenMe2 Learning Ansysfnahas_bhNoch keine Bewertungen

- To Tksolver: by Robert L. Norton P. E. All Rights ReservedDokument27 SeitenTo Tksolver: by Robert L. Norton P. E. All Rights Reservedfnahas_bhNoch keine Bewertungen

- Falhas em Componentes de Sustentação - Cabos de Aço, Correntes e GanchosDokument19 SeitenFalhas em Componentes de Sustentação - Cabos de Aço, Correntes e Ganchosfnahas_bhNoch keine Bewertungen

- Strusoft TheoryDokument115 SeitenStrusoft TheorydesignmukeshNoch keine Bewertungen

- Falhas em Componentes de Sustentação - Cabos de Aço, Correntes e GanchosDokument19 SeitenFalhas em Componentes de Sustentação - Cabos de Aço, Correntes e Ganchosfnahas_bhNoch keine Bewertungen

- Mitos de Comportamento MecanicoDokument1 SeiteMitos de Comportamento Mecanicofnahas_bhNoch keine Bewertungen

- Cartuchos FerroviáriosDokument8 SeitenCartuchos Ferroviáriosfnahas_bhNoch keine Bewertungen

- Falhas em Componentes de Sustentação - Cabos de Aço, Correntes e GanchosDokument19 SeitenFalhas em Componentes de Sustentação - Cabos de Aço, Correntes e Ganchosfnahas_bhNoch keine Bewertungen

- Pump Clinic 38Dokument4 SeitenPump Clinic 38fnahas_bhNoch keine Bewertungen

- Tambor Cond ContDokument1 SeiteTambor Cond Contfnahas_bhNoch keine Bewertungen

- Pump Clinic 45Dokument2 SeitenPump Clinic 45fnahas_bhNoch keine Bewertungen

- Pump Clinic 44Dokument7 SeitenPump Clinic 44fnahas_bhNoch keine Bewertungen

- TIMKEN - BearingsDokument476 SeitenTIMKEN - Bearingsbube2Noch keine Bewertungen

- Cartuchos FerroviáriosDokument8 SeitenCartuchos Ferroviáriosfnahas_bhNoch keine Bewertungen

- Pump Clinic 45Dokument2 SeitenPump Clinic 45fnahas_bhNoch keine Bewertungen

- Pump Clinic 36Dokument14 SeitenPump Clinic 36fnahas_bh100% (1)

- TIMKEN - BearingsDokument476 SeitenTIMKEN - Bearingsbube2Noch keine Bewertungen

- Designação SKF Dos Rolamentos de Alta PrecisãoDokument2 SeitenDesignação SKF Dos Rolamentos de Alta Precisãofnahas_bhNoch keine Bewertungen

- Bloco Cad ModelDokument1 SeiteBloco Cad Modelfnahas_bhNoch keine Bewertungen

- Egito - Canal de Suez - Esquadra EUADokument90 SeitenEgito - Canal de Suez - Esquadra EUAfnahas_bhNoch keine Bewertungen

- I Feel It Coming The Weeknd Piano Sheets PDFDokument1 SeiteI Feel It Coming The Weeknd Piano Sheets PDFlib1973Noch keine Bewertungen

- Q1 Grade 7 Music DLL Week 1Dokument7 SeitenQ1 Grade 7 Music DLL Week 1Leonor Mayoya100% (1)

- WorksheetsDokument2 SeitenWorksheetsAna Sofia Moreira MacanjoNoch keine Bewertungen

- Goldberg Variations - BookletDokument7 SeitenGoldberg Variations - BookletEduardo SylvagránNoch keine Bewertungen

- Sentence Structure: Dosen: Iswandi, S. PD, M.S. Bobot: 2 Sks Mata Kuliah: Bahasa Inggris Semester: GanjilDokument3 SeitenSentence Structure: Dosen: Iswandi, S. PD, M.S. Bobot: 2 Sks Mata Kuliah: Bahasa Inggris Semester: GanjilYassir Al-aqibNoch keine Bewertungen

- African Musical Instruments From The Environment: Example of Improvised Musical InstrumentDokument2 SeitenAfrican Musical Instruments From The Environment: Example of Improvised Musical InstrumentDiayanara Rose CachoNoch keine Bewertungen

- 3stg Bit Final ChartDokument1 Seite3stg Bit Final ChartJC AMARONoch keine Bewertungen

- As I Kneel Before YouDokument1 SeiteAs I Kneel Before YouHoàn Tiền CatbackNoch keine Bewertungen

- Parents Day End Credits - Jim Lang (Arranged For Solo Guitar)Dokument3 SeitenParents Day End Credits - Jim Lang (Arranged For Solo Guitar)PNoch keine Bewertungen

- Gcse Composition Briefs 2019/20: Least 1 Minute in Duration and Both Compositions MustDokument15 SeitenGcse Composition Briefs 2019/20: Least 1 Minute in Duration and Both Compositions Mustvcecilia2002Noch keine Bewertungen

- Sweet Dreams AnalysisDokument4 SeitenSweet Dreams AnalysisClara GayedNoch keine Bewertungen

- Music Grade 8 Quarter 4 Wayang KulitDokument4 SeitenMusic Grade 8 Quarter 4 Wayang KulitZaira CabusayNoch keine Bewertungen

- 701 - 702 Mayo 10 Biography JuanesDokument3 Seiten701 - 702 Mayo 10 Biography Juanesmimenteconaltavozen2020Noch keine Bewertungen

- Women Music Culture An Introduction 2nd Edition Ebook PDF VersionDokument62 SeitenWomen Music Culture An Introduction 2nd Edition Ebook PDF Versionnorma.fegley884100% (37)

- Dobry Start Dla III Etapu Edukacyjnego - TESTDokument5 SeitenDobry Start Dla III Etapu Edukacyjnego - TESTmichalczukm41Noch keine Bewertungen

- Flora Audition Document PDFDokument4 SeitenFlora Audition Document PDFDaniel NixonNoch keine Bewertungen

- Idiophones: - These Are Percussion Instrument That Are Either Struck With A Mallet or Against One AnotherDokument24 SeitenIdiophones: - These Are Percussion Instrument That Are Either Struck With A Mallet or Against One AnotherCharlene F MiaNoch keine Bewertungen