Beruflich Dokumente

Kultur Dokumente

Iqwq Ce1092 Mpitp 00 0001 - 0 Tank Plates and Accessories Prefabricate Itp罐板及附件预制itp

Hochgeladen von

Ali MajeedOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Iqwq Ce1092 Mpitp 00 0001 - 0 Tank Plates and Accessories Prefabricate Itp罐板及附件预制itp

Hochgeladen von

Ali MajeedCopyright:

Verfügbare Formate

IQWQ-CE1092-MPITP-00-0001 TANK PLATES AND ACCESSORIES PREFABRICATE-ITP 14-Apr-2017

TANK PLATES AND ACCESSORIES PREFABRICATE-ITP

DISCIPLINE: Equipment Tag

DESCRIPTION OF WORK :TANK PLATES AND ACCESSORIES PREFABRICATE

MECHANICAL number:

Date : Approved By :

Prepared By: CPECC QC DEPARTMENT

EMIL

TYPE Revision Title Remarks

Name

IQWQ-FT-MSPDS-00-090401 Rev .0 Atmospheric storage tanks

SPEC IQWQ-FT-MSPDS-00-410210 Rev .0 Skim Tank and Vessels for Primary Water Treating

IQWQ-FT-MSPDS-00-090701 Rev .0 Accessories for Atmospheric Tanks

CODE API STD 650 LAT.ED Welded Tanks for Oil Storage

IQWQ-FT-QPQAC-00-0001 Rev .0 Construction Site Quality Manual

IQWQ-CE1092-QPQAC-00-0004 Rev .0 Quality Control Procedure for Field Fabricated Tanks

PROCEDURE

IQWQ-CE1092-MPERE-00-0001 Rev .0 Static Equipment Installation Plan (Tank)

IQWQ-CE1092-KPWLD-00-0001 Rev .0 Welding and Cutting Procedure

CPECC Page 1 of 5 Category II, Rev. 0

IQWQ-CE1092-MPITP-00-0001 TANK PLATES AND ACCESSORIES PREFABRICATE-ITP 14-Apr-2017

Tank Plates and Accessories Prefabricate - ITP

Description :Tank Plates and Project Name :

Accessories Prefabricate Project Location: Basra, Iraq Project Number: M109

WQI produced water treatment

Company :ExxonMobil Contractor :CPECC Contract Number:AWQ0109 Issue Date:

DEFINITION OF INSPECTION AND TEST PLAN SYMBOLS APPLICABLE TO ALL SIGNATORIES

SUB-CONSTRUCTOR=CPECC Rumaila Fabrication Shop

CPECC = China Petroleum Engineering Construction Corporation

COMPANY=ExxonMobil and its authorized representative

“H” - HOLD: This indicates an inspection or test which is considered vital to the quality, integrity and safe functioning of the material

and services and which can only be achieved at this point. It is an Inspection/Test. Activity on the ITP that requires the presence of

the Designated Company Representative. The Production/Erection process cannot proceed beyond this point until it has been

cleared by the Designated Company Representative.

Activity: “W” - WITNESS: This indicates an Inspection/Test Activity on the ITP that requires the presence of the Inspection Organization

and/or Representative. The production/erection process can proceed beyond this point if the Representative has not attended,

DEFINITION providing due notice of the activity has been given to the Representative in terms of the relevant contract.

“R” - REVIEW: This indicates a document review by the Inspection Organization and/or Representative which may or may not be

also a Hold Point (H).

"S"- SURVEILLANCE: This indicates an activity subject to surveillance monitoring by Company Notification that the activity is to

begin is required.

INSPECTION / TEST ACTIVITY : A1 - 100% ACTUAL A2 - RANDOM ACTUAL

Remarks: H -Hold W -Witness Point S -Surveillance R -Review C -Certification A1-100%Actual A2-Random

CPECC Page 2 of 5 Category II, Rev. 0

IQWQ-CE1092-MPITP-00-0001 TANK PLATES AND ACCESSORIES PREFABRICATE-ITP 14-Apr-2017

Tank Plates and Accessories Prefabricate - ITP

Description: Tank Plates and Project Name:

Accessories Prefabricate Project Location: Basra, Iraq Project Number: M109

WQI produced water treatment

Company :ExxonMobil Contractor :CPECC Contract Number:AWQ0109 Issue Date:

RESPONSIBILITY

Verifying

Activity No. Inspection/Test Stage Requirement and Acceptance Criteria CPECC COMPANY/

Document SUBCONTRA

QC DEP. OWNER

CTOR

1.0 Documents & Resource availability:

All applicable QC Procedures (ITP, QCP, WPS/PQR,

1.1

WQT, NDE) are approved and available.

IQWQ-FT-QPQAC-00-0001

Personnel to carry-out welding, NDE and special

1.2 IQWQ-CE1092-QPQAC-00-0004 Form F02201Q A1 H R

process are qualified and available at site

Latest versions of Issued for Construction drawings are

1.3

available at site.

2.0 Material Control

Plate Material dimensions, thickness, grade were

2.1

verified and accepted.

Welding consumable brand, size, MTC, storage and IQWQ-FT-QPQAC-00-0001

2.2 Form F02201Q A1 R/S R

control verified and accepted IQWQ-CE1092-QPQAC-00-0004

Welding and cutting machines, inspection tools

2.3 &equipment are inspected/calibrated and records

available

3.0 Tank Bottom Plates Prefabricate

API STD 650

3.1 Check the cutting lines mark before cutting IQWQ-FT-QPQAC-00-0001 Form F02201Q A1 R/S R

IQWQ-CE1092-QPQAC-00-0004

CPECC Page 3 of 5 Category II, Rev. 0

IQWQ-CE1092-MPITP-00-0001 TANK PLATES AND ACCESSORIES PREFABRICATE-ITP 14-Apr-2017

Tank Plates and Accessories Prefabricate - ITP

Description :Tank Plates and Project Name :

Accessories Prefabricate Project Location: Basra, Iraq Project Number: M109

WQI produced water treatment

Company :ExxonMobil Contractor :CPECC Contract Number:AWQ0109 Issue Date:

RESPONSIBILITY

Verifying

Activity No. Inspection/Test Stage Requirement and Acceptance Criteria SUBCONTRA CPECC COMPANY/

Document

CTOR QC DEP. OWNER

API 650

Check the plates dimensions and quality after Form F74103Q

3.2 IQWQ-FT-QPQAC-00-0001 A1 R/S R

cutting and grinding. &F02201Q

IQWQ-CE1092-QPQAC-00-0004

4.0 Tank Shell Plates Prefabricate

API STD 650

4.1 Check the cutting lines mark before cutting IQWQ-FT-QPQAC-00-0001 Form F02201Q A1 R/S R

IQWQ-CE1092-QPQAC-00-0004

API STD 650

Check the plates dimensions and quality after Form F74103Q

4.2 IQWQ-FT-QPQAC-00-0001 A1 R/S R

cutting and grinding. &F02201Q

IQWQ-CE1092-QPQAC-00-0004

API STD 650

Form F74103Q

4.3 Check the radian of the shell plates after rolling. IQWQ-FT-QPQAC-00-0001 A1 R/S R

&F02201Q

IQWQ-CE1092-QPQAC-00-0004

5.0 Tank Roof Plates Prefabricate

API STD 650

5.1 Check the cutting lines mark before cutting. IQWQ-FT-QPQAC-00-0001 Form F02201Q A1 R/S R

IQWQ-CE1092-QPQAC-00-0004

API STD 650

Check the plates dimensions and quality after Form F74103Q

5.2 IQWQ-FT-QPQAC-00-0001 A1 R/S R

cutting and grinding. &F02201Q

IQWQ-CE1092-QPQAC-00-0004

API STD 650

Form F74103Q

5.3 Check the radian of the shell plates after rolling. IQWQ-FT-QPQAC-00-0001 A1 R/S R

&F02201Q

IQWQ-CE1092-QPQAC-00-0004

CPECC Page 4 of 5 Category II, Rev. 0

IQWQ-CE1092-MPITP-00-0001 TANK PLATES AND ACCESSORIES PREFABRICATE-ITP 14-Apr-2017

Tank Plates and Accessories Prefabricate - ITP

Description :Tank Plates and Project Name :

Accessories Prefabricate Project Location: Basra, Iraq Project Number: M109

WQI produced water treatment

COMPANY:ExxonMobil Contractor :CPECC Contract Number:AWQ0109 Issue Date:

RESPONSIBILITY

Verifying

Activity No. Inspection/Test Stage Requirement and Acceptance Criteria SUBCONTRA CPECC COMPANY/

Document

CTOR QC DEP. OWNER

Check the quality of reinforce elements of the roof IQWQ-FT-QPQAC-00-0001

5.4 Form F02201Q A1 R/S R

installation and welding IQWQ-CE1092-QPQAC-00-0004

6.0 Clean Out Hatch Prefabricate

API STD 650

6.1 Check the cutting lines mark before cutting. IQWQ-FT-QPQAC-00-0001 Form F02201Q A1 R/S R

IQWQ-FT-MSPDS-00-090701

Ensure welding is controlled during the API-650

Form F02201Q

6.2 components weld. Joint design and welding shall IQWQ-FT-QPQAC-00-0001 A1 W W/S/R

Form F79001Q

be dimensional checked according to API 650. IQWQ-FT-MSPDS-00-090701

Ensure NDE inspections carried-out as per the API 650 TP NDE Report

6.3 A1 R R

code requirement components fittings. IQWQ-FT-MSPDS-00-90701 Form F74106Q

Ensure furnace thermal stress relief carried-out as API 650

6.4 Form F02201Q A1 R/S R

per the code requirement components fittings. IQWQ-FT-MSPDS-00-90701

7.0 Other Accessories Prefabricate

API STD 650

7.1 Check the cutting lines mark before cutting. IQWQ-FT-QPQAC-00-0001 Form F02201Q A1 R/S R

IQWQ-FT-MSPDS-00-090701

Ensure welding is controlled during the API-650

Form F02201Q

7.2 components weld. Joint design and welding shall IQWQ-FT-QPQAC-00-0001 A1 W W/S/R

Form F79001Q

be dimensional checked according to API 650. IQWQ-FT-MSPDS-00-090701

Ensure NDE inspections carried-out as per the API 650 TP NDE Report

7.3 A1 R R

code requirement components fittings. IQWQ-FT-MSPDS-00-90701 Form F74106Q

CPECC Page 5 of 5 Category II, Rev. 0

West Qurna I 000 509 F74103Q

Contract: Serial No.

Project Location: Basra, Iraq Rev. No.

QUALITY CHECKSHEET CHECK DIMENSIONS OF TANK PLATE PREFABRICATE

Tag Description Tag No.

Contract No. System No.

Contractor Sub-System No.

Drawing Reference Location

AB(mm) CD(mm) AC(mm) BD(mm) EF(mm) |AD-BC|

No. Item AD(mm) BC(mm) GH

±1.5mm ±1.5mm ±1.5mm ±1.5mm ±1.5mm ≤3mm

Remarks:

Contractor West Qurna I Quality Representative

Name: Name:

Signature: Signature:

Date: Date:

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Aisc Asd Gusset Plate Aisc341 16Dokument12 SeitenAisc Asd Gusset Plate Aisc341 16Zarna Modi100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Construction Contract - RaymundDokument9 SeitenConstruction Contract - RaymundRaysunArellanoNoch keine Bewertungen

- IQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFDokument15 SeitenIQWQ-CE1092-QPQAC-00-0004 - 0 -QUALITY CONTROL PROCEDURE FOR FIELD FEBRICATED TANKS罐安装质量控制程序 PDFAli MajeedNoch keine Bewertungen

- IQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFDokument11 SeitenIQWQ-CE1092-QPQAC-00-0008 - 0 -QUALITY CONTROL PROCEDURE FOR STEEL STRUCTURE钢结构安装质量控制程序 PDFAli MajeedNoch keine Bewertungen

- Iqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Dokument17 SeitenIqwq-ce1092-Mpere-00-0001 - 1 Static Equipement Installation Plan (Tank)Ali MajeedNoch keine Bewertungen

- Friendship CenterDokument22 SeitenFriendship CenterJazz100% (2)

- Hollow SectionsDokument199 SeitenHollow SectionsmandregomesNoch keine Bewertungen

- Principles and Practices of Stud Welding: State-Of-The-Art PaperDokument0 SeitenPrinciples and Practices of Stud Welding: State-Of-The-Art PaperTenkre TenNoch keine Bewertungen

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Dokument37 SeitenIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedNoch keine Bewertungen

- SA04C2-MS-MET-AAG-0009 Method Statement of Pneumatic Test For SS and GRE PipesDokument11 SeitenSA04C2-MS-MET-AAG-0009 Method Statement of Pneumatic Test For SS and GRE PipesABAID ULLAHNoch keine Bewertungen

- Natural Ventilation Strategies in Tropical ClimateDokument50 SeitenNatural Ventilation Strategies in Tropical ClimateFirrdhaus Sahabuddin100% (3)

- Twi Radiographic Interpretation Part3 151020171959 Lva1 App6891Dokument55 SeitenTwi Radiographic Interpretation Part3 151020171959 Lva1 App6891Ali Majeed100% (2)

- Conceptual Structural Design Methods of Reinforced Concrete Buildings Rev 2Dokument16 SeitenConceptual Structural Design Methods of Reinforced Concrete Buildings Rev 2Dawit SolomonNoch keine Bewertungen

- West Qurna-2 Well Pads and Oil Gathering System Project: Specification For Warning TapesDokument9 SeitenWest Qurna-2 Well Pads and Oil Gathering System Project: Specification For Warning TapesAli MajeedNoch keine Bewertungen

- Iqwq Ce1092 Mpere 00 0005 - 0 Equipment Lifting Plan (Pump) 设备(泵)吊装计划Dokument23 SeitenIqwq Ce1092 Mpere 00 0005 - 0 Equipment Lifting Plan (Pump) 设备(泵)吊装计划Ali MajeedNoch keine Bewertungen

- Iqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Dokument54 SeitenIqwq Ce1092 Qpqac 00 0002 - 0 Quality Control Procedure for Piping管道质量控制程序Ali Majeed100% (1)

- Walrus hq800 Water Pressure PumpDokument2 SeitenWalrus hq800 Water Pressure PumpDenata Machmud SugandhiNoch keine Bewertungen

- G M CryocoolerDokument22 SeitenG M CryocoolerJaydeep PonkiyaNoch keine Bewertungen

- Simplified Concrete Modeling With Mat - Concrete - Damage - Rel3: Leonard E SchwerDokument14 SeitenSimplified Concrete Modeling With Mat - Concrete - Damage - Rel3: Leonard E Schwersvk_ntNoch keine Bewertungen

- Rodajes Miniatura NSKDokument41 SeitenRodajes Miniatura NSKenicolas2Noch keine Bewertungen

- Compressed Air: Stäubli Invents Active SafetyDokument12 SeitenCompressed Air: Stäubli Invents Active SafetyAlper SakalsizNoch keine Bewertungen

- MAHARASHTRA HPC-Model PDFDokument1 SeiteMAHARASHTRA HPC-Model PDFAbhijeet SahuNoch keine Bewertungen

- Metiche AnalDesign FRP Poles PDFDokument26 SeitenMetiche AnalDesign FRP Poles PDFMojtaba Mohammad PourNoch keine Bewertungen

- Dco MaterialDokument35 SeitenDco MaterialAlakesh PhukanNoch keine Bewertungen

- Mortar Analysis Part 3 - L SchnabelDokument4 SeitenMortar Analysis Part 3 - L SchnabelSugarPOP666Noch keine Bewertungen

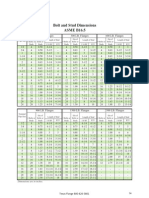

- Bolt and Stud DimentionDokument1 SeiteBolt and Stud DimentionwhngomjNoch keine Bewertungen

- Chapter 3Dokument27 SeitenChapter 3Harshit Raj GuptaNoch keine Bewertungen

- ElevatorDokument2 SeitenElevatorneoNoch keine Bewertungen

- Abe DIY BookletDokument89 SeitenAbe DIY BookletPula ConsultantsNoch keine Bewertungen

- Cib2010 - Design-Bid-Build Versus Design-Build - The Client's ChoiceDokument14 SeitenCib2010 - Design-Bid-Build Versus Design-Build - The Client's ChoiceVan khuongNoch keine Bewertungen

- Material Labor and Equipt PricesDokument5 SeitenMaterial Labor and Equipt PricesABCD EFGNoch keine Bewertungen

- Business Profile: B&J Civil WorksDokument11 SeitenBusiness Profile: B&J Civil WorksJosephine TappNoch keine Bewertungen

- Dairy Building PlanningDokument4 SeitenDairy Building PlanningMonty KushwahaNoch keine Bewertungen

- Data Center Construction MarketDokument13 SeitenData Center Construction MarketHarsh mishraNoch keine Bewertungen

- Al Alloys Chemicals MechanicalsDokument1 SeiteAl Alloys Chemicals MechanicalsFactory FactoryNoch keine Bewertungen

- Mechanics of StructureDokument288 SeitenMechanics of StructureCL ARCHITECTSNoch keine Bewertungen

- Armor-X 600v (4) SouthwireDokument3 SeitenArmor-X 600v (4) SouthwireLuis RamirezNoch keine Bewertungen

- Esdu 68045Dokument6 SeitenEsdu 68045rinoceronte09Noch keine Bewertungen