Beruflich Dokumente

Kultur Dokumente

Therm Is Tor Pic Pulser Kit Instructions

Hochgeladen von

artleaderOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Therm Is Tor Pic Pulser Kit Instructions

Hochgeladen von

artleaderCopyright:

Verfügbare Formate

THERMISTOR PIC PULSER KIT INSTRUCTIONS

Parts List

R1, R10 680R (BlGyBr)

R2, R5 1k (BrBR)

R3, R6 3k9 (OWR)

R4, R7 2k (RBBBrBr)

R8, R11, R12 1k8 (BrGyR)

R9 39k (OWO)

R13 4k7 (YPO)

VR1 1k trimmer

TR1 47k thermistor

C1, C2, C6, C7 0.01 or 0.1uF (not critical)

C3, C5 100uF

C4 2200uF or greater

L1 220uH (marked 221L)

L2 1000uH (marked 102L)

IC1 PIC12F683 + 8-pin DIL socket

Q1 IRF9640

Q2, Q3 2N3904

Q4 2N3906

D1 6V2 zener (marked 6V2 or 1N5234B)

D2 5V1 zener (marked 5V1 or 1N5231B)

D3 BYW29-200/ BYV29-500 or similar

D4 BYV29F-200 or equivalent (plastic coated to help prevent shorting)

D5 15V zener

LED1 Green LED

LED2 Red LED

Heatsink 1 off (for fitting to D3)

Fuseholder 1 off

Fuse 2A 20 x 5mm QB fuse 2 off

3mm bolt 1 off

3mm nut 1 off

4mm bolt 2 off

4mm nut 4 off

4mm washer 4 off

PCB 1 off

12V Thermistor PIC Pulser Page 1 of 5 www.courtiestown.co.uk

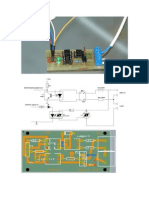

Schematic

12V Thermistor PIC Pulser Page 2 of 5 www.courtiestown.co.uk

Assembly Instructions

1. Check all component parts as listed above are present. I’m assuming you have a

reasonable level of electronic competence in having purchased this kit, please make sure

you correctly identify each part.

2. Carefully remove the PIC from the 8-pin DIL socket it was shipped in and put it

somewhere safe.

3. You will need to drill out the two 3.3mm holes marked +ve and –ve to 4mm and insert

one of the 4mm brass bolts into each and secure tightly with a single nut.

You then need to solder the brass head to the PCB – this will take a fair amount of heat

but the solder will flow eventually. Allow the board to cool down on completion!! The

solder ensures a good solid electrical connection.

4. Then attach the two washers and remaining nut to each of the bolts – makes sure you

don’t lose them.

5. Components can then be inserted in size order as is common with most electronic kits,

however leave L2 out for now and do not insert the PIC yet either.

6. Insert two wire links across J1 and J3.

7. D3 should be loosely attached to its heatsink and then soldered to the board. The bolts

should ideally be shortened but this is not strictly necessary. The bolt can be tightened

once the components are soldered to the board. It would be prudent to use some

heatsink paste to aid heat transmission.

8. My personal preference as regards fitting the thermistor is to have it stuck up in the air

rather than close mounted to the PCB, this allows it to better absorb the ambient heat. It

may be prudent to sleeve the legs in this case.

9. Use the thickest multi-strand wire you can to connect the fuseholder (this connected

across J2) and keep the wire length as short as practicable (I’m assuming you are going

to be mounting this device in a case!!). The PCB holes are 2.1mm diameter to aid this.

10. The trimmer potentiometer should be adjusted to the maximum clockwise position for

start-up.

11. Thoroughly check the underside of the board prior to connecting up to carry out any

testing.

12. I do not know what level of equipment you will have, I’m assuming a minimum of a DMM

and an oscilloscope would be a bonus.

12V Thermistor PIC Pulser Page 3 of 5 www.courtiestown.co.uk

13. With L2 not soldered to the PCB and the PIC out connect the device to a 12V battery.

For testing purposes any old bit of wire will do but I would recommend using at least 12

or 10AWG multi-strand cable with soldered ring terminal connections for the device when

functioning with batteries.

You should see the red LED light up and then slowly go dim, this is C4 charging up and

is nothing to worry about.

13. Check you have circa 5.1V across D2 and 6.2V across D1. Then check you have 5.1V at

pin 1 of the IC socket and 0V at pin 8. This shows voltage is flowing where it should in

the circuit.

14. Assuming this bit is OK then if you have an oscilloscope connect the probe to the gate

(and the earth to the negative supply) of Q1 (or use the end of R9 nearest Q1 as it is

easier to access) and with a jumper wire carefully make a connection from pin 1 of the IC

socket to pin 2 of the IC socket and you should see the MOSFET go on. You will also

see this with a DMM if you don’t have a scope. You should see the battery voltage drop

to around 0.7V as the MOSFET switches.

This bit shows the MOSFET drive circuitry is OK.

15. Time to get brave now. Solder L2 in to the PCB and then insert the PIC and ensure the

trimmer potentiometer is turned fully clockwise.

16. Re-connect the power. After about 2 seconds the green LED should illuminate and then

after a further 3 seconds the red should also illuminate.

So far so good – don’t be alarmed that you can’t hear anything at this point.

If equipped with an oscilloscope you could of course keep the probe attached to the gate

of Q1/ end of R9 and this will give a clear indication of what is going on.

Very carefully turn the trimmer anti-clockwise and the device should ‘burst into life’ very

audibly.

There is no best fixed position for the trimmer, you will need to adjust it then leave it

running for 15-20 minutes for the heat to even out in all components.

The Mk1 finger tip is a very good indication of heat, obviously you don’t want to be

cooking any one component but some heat indicates work is being done.

17. To test the thermistor overheat you’ll need a heat shrink gun (or a hair drier), either, used

carefully, will cause the device to cut-out and the red LED to flash. Once the thermistor

has cooled again the device will just resume pulsing.

12V Thermistor PIC Pulser Page 4 of 5 www.courtiestown.co.uk

SIMPLE PIC PULSER / DESULFATOR INSTRUCTIONS

DO NOT CONNECT THE PULSER DIRECTLY TO THE BATTERY CHARGER – CONNECT IT TO THE

BATTERY & THEN CONNECT THE CHARGER TO THE BATTERY. MAKE SURE THE BATTERY CHARGER

IS UNPLUGGED FROM THE MAINS SUPPLY BEFORE CONNECTING/ DISCONNECTING. DO NOT CHARGE

BATTERIES ABOVE 15V AS THE PULSER IS NOT DESIGNED FOR VOLTAGES ABOVE THS.

1. The start-up sequence for the PIC desulphator is that initially no LED’s will light then after a short period

the GREEN LED will illuminate and then after a further 3-4seconds the RED LED will illuminate and the

unit will emit a circa 1KHz buzzing tone.

2. Please ensure that any battery charging activities are carried out in a reasonably well ventilated

environment. This is particularly relevant here as you will both hear and see sparks generated as you

connect this device. This is perfectly normal, but possibly ‘alarming’ to the first time user.

3. Also ensure that as a minimum you wear suitable eye protection when working with and around charging

batteries

4. The battery to be recovered must, ideally, measure at least 10.5V ‘open circuit’. Any less than this and the

cause of the battery’s deterioration may well be more than sulphation and this device is unlikely to function

as intended i.e. recover a sulphated battery.

5. Ensure that the electrolyte levels are adequate prior to starting, these should be checked regularly whilst

the device is in use. It may seem obvious but don’t do this with the pulser connected, they don’t like water.

Maintaining the electrolyte levels is critical when using a desulphator, the units generate sparks and if the

battery plates become exposed these sparks will ignite the hydrogen gas present and potentially, cause the

battery to explode.

6. The device should be used in conjunction with a simple trickle battery charger.

7. The device can be left connected whilst the trickle charger is connected/disconnected from the battery. I

re-iterate, do not leave the desulfator connected solely to the battery charger.

8. Having said this, the device can be used on its own, i.e. without a charger until the battery voltage drops to

12.0V (10.5V if a deep cycle type), i.e. trickle charge the battery in conjunction with the pulser until a peak

is reached and then disconnect the charger and let the pulser ‘pull’ the battery voltage down. Depending

on the state of the battery this could be several days.

9. If you have a voltmeter, the simplest indication of the battery improving will be the maximum voltage

achieved after charging each time. This should rise noticeably during the first week and then reduce over

time.

The next best reliable indicator is putting a load on it, i.e. put it in a vehicle and try starting it – probably the

simplest ‘load test’ around.

10. I cannot emphasise enough the importance of ensuring the voltage level doesn’t drop below 12.0V (10.5V

for s deep cycle) at any time. It is almost certain irreversible battery damage will result.

11. Ready built desulphators have been bench tested prior to despatch.

12. These devices are supplied with integral reverse polarity and thermal overheat protection.

If you connect the device to the battery the wrong way around the externally mounted fuse will blow (a 5 x 20mm

2A quick-blow type). I would suggest you get a stock of these in as we have all made the mistake of connecting

these devices the wrong way round; the advantage now is that you only blow the fuse and not the whole device!!

The thermal overheat operates automatically when the case internal temperature reaches 60oC. The device will

cut-out automatically and the GREEN LED will flash indicating the cause of the ‘failure’ to be overheating.

o

Once the unit has cooled below 60 C it will resume operation automatically.

If your unit does this frequently please let me know.

12V Thermistor PIC Pulser Page 5 of 5 www.courtiestown.co.uk

Das könnte Ihnen auch gefallen

- bypass relay01Dokument4 Seitenbypass relay01ba3jarNoch keine Bewertungen

- IRMC Transistor CheckDokument7 SeitenIRMC Transistor ChecksebifuenteNoch keine Bewertungen

- Temporizator Start StopDokument12 SeitenTemporizator Start StopeliboyzzNoch keine Bewertungen

- DIY Geiger Counter Radiation Detector Kit Ver.2 PDFDokument16 SeitenDIY Geiger Counter Radiation Detector Kit Ver.2 PDFLeonardo VelezNoch keine Bewertungen

- Kit Manual IN14Dokument19 SeitenKit Manual IN14Caio VilarNoch keine Bewertungen

- 12 To 18vdcDokument4 Seiten12 To 18vdcSergio Ricardo LuizNoch keine Bewertungen

- Proyectos de Electronica.Dokument27 SeitenProyectos de Electronica.saiworNoch keine Bewertungen

- Dds 2016vmanualDokument11 SeitenDds 2016vmanualalirisad aliNoch keine Bewertungen

- Automatic Over Temperature Detection and AlertDokument5 SeitenAutomatic Over Temperature Detection and Alertsmartxdigital marketNoch keine Bewertungen

- High Frequency Plasma Circuit (Electronic Ion Pump)Dokument3 SeitenHigh Frequency Plasma Circuit (Electronic Ion Pump)Peter Benedikt Weber100% (2)

- MooTronDokument10 SeitenMooTronStani-Slav JanáčNoch keine Bewertungen

- Build your own 15Hz zapper in 9 daysDokument5 SeitenBuild your own 15Hz zapper in 9 daysgoransamardziski7225Noch keine Bewertungen

- Mutant Enhancer Glitch GuideDokument7 SeitenMutant Enhancer Glitch GuideWalterAugustoNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument9 SeitenNew Microsoft Office Word DocumentAkhilr NairNoch keine Bewertungen

- DIY Manual - v1.5Dokument8 SeitenDIY Manual - v1.5Indraz NilNoch keine Bewertungen

- Car Battery 6V or 12V ChargerDokument14 SeitenCar Battery 6V or 12V ChargerryandisinfixtifNoch keine Bewertungen

- Automatic Temperature Control Exhaust FanDokument6 SeitenAutomatic Temperature Control Exhaust Fansmartxdigital marketNoch keine Bewertungen

- FET Tester V7 User Guide V2Dokument8 SeitenFET Tester V7 User Guide V2bscurNoch keine Bewertungen

- DIY Geiger Counter Radiation Detector Kit Ver.2Dokument16 SeitenDIY Geiger Counter Radiation Detector Kit Ver.2Adrian PaleacuNoch keine Bewertungen

- Parts List and Assembly Instructions for DIY Infrared Traffic Light TriggerDokument5 SeitenParts List and Assembly Instructions for DIY Infrared Traffic Light TriggerKomishinNoch keine Bewertungen

- Gold PicDokument6 SeitenGold PicBalbalaManiukNoch keine Bewertungen

- Homemade Stun GunDokument61 SeitenHomemade Stun Gun盾謙Noch keine Bewertungen

- General Information: WarningDokument23 SeitenGeneral Information: WarningKristian FonNoch keine Bewertungen

- Build A Nixie Power SupplyDokument3 SeitenBuild A Nixie Power SupplysoretenegroNoch keine Bewertungen

- 4 Channel Running Light: Creating Disco Ligh T Effects, Light Speed Ad Justable. Suited Fo R Inductiv e LoadsDokument12 Seiten4 Channel Running Light: Creating Disco Ligh T Effects, Light Speed Ad Justable. Suited Fo R Inductiv e LoadsNikola TesanovicNoch keine Bewertungen

- Akai LCT37Z6TA CMO (11-27-06) LCDDokument135 SeitenAkai LCT37Z6TA CMO (11-27-06) LCDRicardo PicassoNoch keine Bewertungen

- Ampli 200w Clase D Parte 2 888Dokument5 SeitenAmpli 200w Clase D Parte 2 888loquillo00sNoch keine Bewertungen

- Dimming AC lamps with Arduino using TRIAC phase angle controlDokument21 SeitenDimming AC lamps with Arduino using TRIAC phase angle controlrodolfos_8Noch keine Bewertungen

- Basic Setup of 0.8KW SPINDLE & VFD 220V (Australian Voltage Example)Dokument10 SeitenBasic Setup of 0.8KW SPINDLE & VFD 220V (Australian Voltage Example)Erick GarciaNoch keine Bewertungen

- Amplificator Chitara 60WDokument5 SeitenAmplificator Chitara 60WMărian IoanNoch keine Bewertungen

- DimmerDokument39 SeitenDimmerWahyumithali HamelianiNoch keine Bewertungen

- 12v To 18v ConverterDokument7 Seiten12v To 18v ConverterLuis Paulo100% (1)

- Thermistor Temperature Sensor Project, 70-0315Dokument2 SeitenThermistor Temperature Sensor Project, 70-0315baruaeeeNoch keine Bewertungen

- K 130Dokument3 SeitenK 130Venu KailashNoch keine Bewertungen

- Corrosion Free Water Level Indicator: DescriptionDokument8 SeitenCorrosion Free Water Level Indicator: DescriptionChetan ByalihalNoch keine Bewertungen

- HDD PCB RepairingDokument17 SeitenHDD PCB RepairingLoida PiñaNoch keine Bewertungen

- Biestable IR Con 4013Dokument2 SeitenBiestable IR Con 4013JUANNoch keine Bewertungen

- This Is An Electrical Circuit Protection Device Sound DisappearedDokument9 SeitenThis Is An Electrical Circuit Protection Device Sound DisappearedRaushan Kumar SinghNoch keine Bewertungen

- 3-30v 3A Power Supply Circuit ManualDokument12 Seiten3-30v 3A Power Supply Circuit ManualRavindra ParabNoch keine Bewertungen

- DTMF Telephone Relay Switcher Control GuideDokument8 SeitenDTMF Telephone Relay Switcher Control GuideNiamat KhanNoch keine Bewertungen

- AC PWM Dimmer For ArduinoDokument15 SeitenAC PWM Dimmer For ArduinoJavier PeresNoch keine Bewertungen

- N2CX Accuprobe Plus Assembly InstructionsDokument12 SeitenN2CX Accuprobe Plus Assembly InstructionsRafael SuarezNoch keine Bewertungen

- Capacitor Discharge Ignition Extends Points and Plug LifeDokument0 SeitenCapacitor Discharge Ignition Extends Points and Plug LifeJose De Jesus MoralesNoch keine Bewertungen

- Automatic Emergency TourchDokument2 SeitenAutomatic Emergency TourchchakralabsNoch keine Bewertungen

- Logic Probe MK IIBDokument8 SeitenLogic Probe MK IIBJose GarciaNoch keine Bewertungen

- IC 555 ProjectsDokument14 SeitenIC 555 ProjectsParth Lad100% (1)

- Free Forming The 44-Pin PLCC SocketDokument4 SeitenFree Forming The 44-Pin PLCC SocketvishalbauNoch keine Bewertungen

- Kit 137. Touch Switch: Assembly. Solder The Lowest Height Components FirstDokument2 SeitenKit 137. Touch Switch: Assembly. Solder The Lowest Height Components FirstcastleNoch keine Bewertungen

- CK1620 - Door Minder: ConstructionDokument3 SeitenCK1620 - Door Minder: ConstructionIon GrigorashNoch keine Bewertungen

- Heat Sensor Using NTCDokument5 SeitenHeat Sensor Using NTCsmartxdigital marketNoch keine Bewertungen

- Drone Build Diagramsv4 PDFDokument60 SeitenDrone Build Diagramsv4 PDFDimitri Kabore100% (2)

- ILO Service Manual LCD TV Repair GuideDokument127 SeitenILO Service Manual LCD TV Repair GuidejpineteNoch keine Bewertungen

- EmperorDokument12 SeitenEmperorRafik HergéNoch keine Bewertungen

- Automatic Water Dispenser Using IR PairDokument6 SeitenAutomatic Water Dispenser Using IR Pairsmartxdigital marketNoch keine Bewertungen

- K241 AwebnotesDokument3 SeitenK241 Awebnotespetre_blackNoch keine Bewertungen

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsVon EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsBewertung: 3 von 5 Sternen3/5 (2)

- Troubleshooting Electronic Components With The PET BloodhoundVon EverandTroubleshooting Electronic Components With The PET BloodhoundNoch keine Bewertungen

- Digital LED Thermometer with Microcontroller AVR ATtiny13Von EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Bewertung: 5 von 5 Sternen5/5 (1)

- IR Three-Phase Gate Driver ICDokument2 SeitenIR Three-Phase Gate Driver ICartleaderNoch keine Bewertungen

- HTTP WWW - Junkyardjet.com PrimitiveDokument21 SeitenHTTP WWW - Junkyardjet.com PrimitiveartleaderNoch keine Bewertungen

- Lessons in Electric Circuits - Volume IIDokument16 SeitenLessons in Electric Circuits - Volume IIartleaderNoch keine Bewertungen

- Proven 6 Grid Connect v3.0Dokument74 SeitenProven 6 Grid Connect v3.0artleaderNoch keine Bewertungen

- Repulsion CoilDokument6 SeitenRepulsion CoilJim100% (1)

- Welding Inverter 100ADokument16 SeitenWelding Inverter 100Aartleader50% (2)

- Lockridge DeviceDokument20 SeitenLockridge Deviceartleader0% (1)

- DC-AC Inverter 10KWDokument125 SeitenDC-AC Inverter 10KWnishan80% (5)

- ThesisteslaDokument96 SeitenThesisteslangelectronic5226Noch keine Bewertungen

- TransformerDokument50 SeitenTransformerبنیاد پرست100% (8)

- Laser ListeningDokument2 SeitenLaser Listeningartleader100% (2)

- Transmit Receive CellsDokument2 SeitenTransmit Receive CellsartleaderNoch keine Bewertungen

- Searl Effect GeneratorDokument6 SeitenSearl Effect Generatorartleader100% (7)

- Toroidal TransformersDokument1 SeiteToroidal Transformersartleader100% (1)

- Battery DesulfatorDokument1 SeiteBattery Desulfatorartleader100% (3)

- WB Smith New ScienceDokument34 SeitenWB Smith New ScienceartleaderNoch keine Bewertungen

- Daniel PomerleauDokument19 SeitenDaniel PomerleauartleaderNoch keine Bewertungen

- (Ebook) - Free Energy - Capacitors That Recharge ThemselvesDokument10 Seiten(Ebook) - Free Energy - Capacitors That Recharge ThemselvesHaroon93% (14)

- A G PatentsDokument12 SeitenA G PatentsartleaderNoch keine Bewertungen

- Ion Ocr AftDokument25 SeitenIon Ocr AftartleaderNoch keine Bewertungen

- Residual-Current Device - Wikipedia, The Free EncyclopediaDokument10 SeitenResidual-Current Device - Wikipedia, The Free EncyclopediaCharitha WickramarathneNoch keine Bewertungen

- 13.intelligent Motorized Wall Painting CraneDokument35 Seiten13.intelligent Motorized Wall Painting CraneWORLD360Noch keine Bewertungen

- 6788 BulkheadLightFittings EK00 III en PDFDokument3 Seiten6788 BulkheadLightFittings EK00 III en PDFarturoncNoch keine Bewertungen

- Question Paper Winter 2022Dokument4 SeitenQuestion Paper Winter 2022Gajanan JagtapNoch keine Bewertungen

- Electric Vehicle Conductive Charging System: Indian StandardDokument54 SeitenElectric Vehicle Conductive Charging System: Indian Standardamit singhNoch keine Bewertungen

- Three-Phase Short Circuit Analysis of Synchronous MachinesDokument15 SeitenThree-Phase Short Circuit Analysis of Synchronous MachinesJavierNoch keine Bewertungen

- Si-Tech Semiconductor Co.,Ltd: S10H16R/SDokument8 SeitenSi-Tech Semiconductor Co.,Ltd: S10H16R/SKuntaweeNoch keine Bewertungen

- Aprilaire Dehumidifier Troubleshooting Manual Models 1710A 1750A 1770ADokument17 SeitenAprilaire Dehumidifier Troubleshooting Manual Models 1710A 1750A 1770AReynaldo FloresNoch keine Bewertungen

- Clean Agent (Fm-200) Fire Suppression System Checklist: Project Location System: DateDokument7 SeitenClean Agent (Fm-200) Fire Suppression System Checklist: Project Location System: DateCenon Cyrus JustaleroNoch keine Bewertungen

- LeonicsDokument2 SeitenLeonicsBobi Sukma HanggaraNoch keine Bewertungen

- Directional Over CurrentDokument14 SeitenDirectional Over CurrentAisah El ArinalNoch keine Bewertungen

- Module 1Dokument69 SeitenModule 1Nicholas AntonioNoch keine Bewertungen

- 304 01389 0 M49SP 2KDokument2 Seiten304 01389 0 M49SP 2KBadshah SalamatNoch keine Bewertungen

- NJM2845 NJM2846 e PDFDokument16 SeitenNJM2845 NJM2846 e PDFDJALMA MOREIRANoch keine Bewertungen

- Contents:: Introduction Construction Working Principle Comparison of Rotor ReferencesDokument10 SeitenContents:: Introduction Construction Working Principle Comparison of Rotor Referenceskarthikeyan249100% (1)

- Liquid Level Control Device: SSR 02 SSR 03 SSR 04Dokument2 SeitenLiquid Level Control Device: SSR 02 SSR 03 SSR 04ahmedNoch keine Bewertungen

- Motor ProtectionDokument50 SeitenMotor ProtectionYajidNoch keine Bewertungen

- I29 Ver1Dokument7 SeitenI29 Ver1Yashwant FadnisNoch keine Bewertungen

- Datasheet 3PH 3.3K 12K V3 enDokument1 SeiteDatasheet 3PH 3.3K 12K V3 encatalin.nerajeanu2Noch keine Bewertungen

- Sliding Door Control Board SL1600 User Maunal A7Dokument2 SeitenSliding Door Control Board SL1600 User Maunal A7joya100% (1)

- DB GB NC56Dokument4 SeitenDB GB NC56ciocioi iancuNoch keine Bewertungen

- Thyristors: Bidirectional Trigger Diode (DIAC)Dokument16 SeitenThyristors: Bidirectional Trigger Diode (DIAC)anthonyrobertxNoch keine Bewertungen

- Reemplazo de Transistores MosfetDokument36 SeitenReemplazo de Transistores Mosfetramon navaNoch keine Bewertungen

- A1n1 MM en PDFDokument12 SeitenA1n1 MM en PDFluis tocoraNoch keine Bewertungen

- 2 SK 2882Dokument6 Seiten2 SK 2882Eddy RosarioNoch keine Bewertungen

- Indoor Circuit Breaker Retrofit SolutionDokument2 SeitenIndoor Circuit Breaker Retrofit Solutiondip461Noch keine Bewertungen

- Microelectronic Circuits Chapter 3: Diodes Characteristics Models CircuitsDokument65 SeitenMicroelectronic Circuits Chapter 3: Diodes Characteristics Models CircuitsRAIHAN AZWAR IBRAHIM PULUNGANNoch keine Bewertungen

- Monitoring Technique: Level Sensing Relay MK 9151.11/KSB VarimeterDokument2 SeitenMonitoring Technique: Level Sensing Relay MK 9151.11/KSB VarimeterAbdelrhman AlaaNoch keine Bewertungen

- Sa Ami 460 Fcon 100702 - 1 1Dokument1 SeiteSa Ami 460 Fcon 100702 - 1 1tanyadeasis8Noch keine Bewertungen

- Elotrain Course "Semiconductor Components"Dokument198 SeitenElotrain Course "Semiconductor Components"A aaa AaaNoch keine Bewertungen