Beruflich Dokumente

Kultur Dokumente

SAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 Version

Hochgeladen von

danishOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SAES-H-201 General Specification For Over-The-Ditch External & Internal ... 2017 Version

Hochgeladen von

danishCopyright:

Verfügbare Formate

Engineering Standard

SAES-H-201 7 February 2017

General Specifications for External and Internal

FBE Coatings of Pipeline Field Girth Welds

Document Responsibility: Paints and Coatings Standards Committee

Contents

1 Scope ................................................................ 2

2 Conflicts and Deviations .................................... 2

3 References ........................................................ 2

4 Definition............................................................ 3

5 Health, Safety, and Environment ....................... 5

6 Material Storage and Handling .......................... 5

7 Design ............................................................... 6

8 Application and Installation ................................ 6

9 Inspection Methods and Acceptance Criteria .. 10

Revision Summary................................................. 13

Previous Issue: 16 November 2011 Next Planned Update: 7 February 2020

Page 1 of 13

Contact: Mansour, Mana H. (mansmh0c) on phone +966-13-8809557

©Saudi Aramco 2017. All rights reserved.

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

1 Scope

This Standard covers minimum mandatory requirements governing the application and

installation of pipelines field girth welds external and internal fusion bonded epoxy

(FBE) coating. For internal girth coating, this document covers pipes with diameters

from 8" to 63". Responsibility of the involved contractors in this service are addressed.

2 Conflicts and Deviations

2.1 Any conflicts between this standard and other applicable Saudi Aramco

Engineering Standards (SAESs), Materials System Specifications (SAMSSs),

Standard Drawings (SASDs), or industry standards, codes, and forms shall be

resolved in writing by the Company or Buyer Representative through the

Manager, Consulting Services Department of Saudi Aramco, Dhahran.

2.2 Direct all requests to deviate from this standard in writing to the Company or

Buyer Representative, who shall follow internal company procedure SAEP-302

and forward such requests to the Manager, Consulting Services Department of

Saudi Aramco, Dhahran.

3 References

All referenced Specifications, Standards, Codes, Forms, Drawings, and similar material

shall be of the latest issue (including all revisions, addenda and supplements) unless

stated otherwise.

3.1 Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-302 Instructions for Obtaining a Waiver of a Mandatory

Saudi Aramco Engineering Requirements

Saudi Aramco Engineering Standards

SAES-H-001 Coating Selection and Application Requirements for

Industrial Plants and Equipment

SAES-H-002 Internal and External Coatings for Steel Pipelines

and Piping

Saudi Aramco Materials System Specifications

09-SAMSS-089 Shop-Applied External Fusion Bonded Epoxy

Coating for Steel Line Pipes

Saudi Aramco: Company General Use

Page 2 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

09-SAMSS-091 Qualification Requirements for Shop-Applied

Internal FBE Coatings

3.2 Industry Codes and Standards

The Society for Protective Coatings

SSPC-PA2 Procedure for Determining Conformance to Dry

Coating Thickness Requirements

SSPC-SP1 Solvent Cleaning

International Organization of Standardization

ISO 8501-1 Pictorial Surface Preparation Standard for Painting

Steel Surface

ISO 8501-3 Preparation Grades of Welds, Edges, and other

Areas with Surface Imperfections

ISO 8502-3 Assessment of Dust on Steel Surface Prepared for

Painting

ISO 8502-6 Extraction of Soluble Contaminants for Analysis -

The Bresle Method

ISO 8502-9 Field Method for the Conductometric Determination

of Water-soluble Salts

ISO 21809-3 Field Joint Coating

American Society for Testing and Materials

ASTM D4417 Field Measurement of Surface Profile of Blasted

Cleaned Steel

ASTM D6677 Evaluating Adhesion by Knife

National Association of Corrosion Engineers

NACE SP 0490 Holiday Detection of Fusion Bonded Epoxy

External Pipeline Coatings of 250~760 μm

Canadian Standard Association

CSA Z245.20 Plant Applied External Coating for Steel Pipe

4 Definition

Approved Procedure: Procedure referred to in this specification that has been

approved in writing by the RUS. Approved procedures do not require re-qualification

in new purchase orders.

Saudi Aramco: Company General Use

Page 3 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

Approved Product: A coating material that has been approved by the RUS as meeting

the requirements of the applicable APCS or SAMSS. Only approved products are

allowed for use in Saudi Aramco jobs. These requirements apply to all coatings

referred to in all the SAES-H-series standards.

Batch: Quantity of material produced in a continuous manufacturing operation using

raw materials of the same source and grade.

Buyer's Representative: The person or persons designated by the Purchasing

Department to monitor / enforce the contract. Normally, this is the on-site inspector.

Cutback: Length of pipe left uncoated at each end for joining purpose.

Contractor: Welding contractor

DFT: Dry film thickness

FBE: Fusion bond epoxy coating

Field Joint Area: Weld zone uncoated area that results when two pipe sections or a

pipe section and a fitting with coating cutbacks are assembled, by welding, in the field.

Holiday: Coating discontinuity that exhibits electrical conductivity when exposed to a

specific voltage.

Manufacturer: Company which manufactures FBE powder coatings and corresponding

repair materials.

Overlap: Length of the field joint coating over the shop-applied coating including the

coating bevel.

Pre-Production Trial (PPT): Conducting a field trial prior to start of the actual

production for the surface preparation, coating application and inspection to confirm

meeting the requirement of the approved coating application procedure.

PWHT: A method for reducing and redistributing the residual stresses in the material

that have been introduced by welding.

Responsible Unit Supervisor (RUS): The Engineering Consultant of Nonmetallic,

CP & Coatings Group who is designated by the Manager, Consulting Services

Department.

Vendor: Girth weld coating applicator

Saudi Aramco: Company General Use

Page 4 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

5 Health, Safety, and Environment

Applicable safety requirements addressed in Section 5 of SAES-H-001 and safety data

sheet of the coating product and equipment shall be followed.

6 Material Storage and Handling

6.1 Coating material shall be stored and handled in accordance with the

Manufacturer's recommendations.

6.2 Powder shall be transported and stored in a sealed container that prevents the

ingress of moisture or water.

6.3 Powder shall be kept dry at all times and not exposed to direct sunlight or used

within 15 m of any source of ignition.

6.4 Transportation and storage climate shall be controlled to meet the

manufacturer’s requirements and conformance shall be demonstrated by

temperature-indication tags or other logging devices.

6.5 Vendor shall load only enough materials to be used in the same day.

Opened, unused powder shall not be used.

6.6 Expired coating materials shall not be used.

6.7 Abrasive blasting materials shall be stored in a dry and controlled environment.

6.8 Health and safety requirements shall be in accordance with Saudi Aramco

requirements and Manufacturer's instructions.

6.9 The Vendor shall use only Saudi Aramco approved products.

6.10 Powder coating materials supplied to the Vendor shall be certified by

Manufacturer with the following information, which must meet initially

approved material:

a) The Manufacturer's name

b) Product description

c) Mass of material

d) The material identification number

e) The batch number

f) Date of manufacture

g) Location of manufacturing

h) Temperature required for transportation and storage

Saudi Aramco: Company General Use

Page 5 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

i) The shelf life (or expiration date)

j) Material identification fingerprints

6.11 Each batch of FBE coating must be tested and certified by the Manufacturer in

accordance with the requirement of Table 1. Vendor shall conduct the same

tests to verify compliance with the requirements.

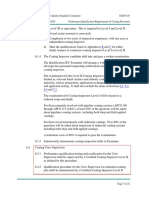

Table 1 - Epoxy Powder Properties

Property Acceptance Criteria Test Method

CSA Z245.20

Density Meets Manufacturer specification

Clause 12.6

3.0% maximum retained on 150 μm mesh and CSA Z245.20

Particle Size

0.2% maximum retained on 250 μm mesh. Clause 12.5

CSA Z245.20

Gel Time Meets Manufacturer specification

Clause 12.2

CSA Z245.20

Cure Time Meets Manufacturer specification

Clause 12.1

CSA Z245.20

Moisture Content 0.5% maximum

Clause 12.3

Thermal Meets Manufacturer specification for Tg1 (°C), CSA Z245.20

Characteristics Tg2 (°C), ΔH (J/g) Clause 12.7

7 Design

7.1 External FBE powder shall meet the requirements of 09-SAMSS-089 and

SAES-H-002, APCS-104A/B/C.

7.2 Internal FBE powder shall meet the requirements of 09-SAMSS-091 and

SAES-H-002, APCS-102A/B/C.

7.3 Semi-automated application process shall be used for the application of external

coating.

7.4 Robotic system shall be used for the inspection, surface preparation and coating

application of internal girth weld.

8 Application and Installation

8.1 General

8.1.1 Application of FBE coating shall be strictly in accordance with the

Vendor’s application procedure approved by the RUS. FBE materials

and method of application and equipment to be used shall be specified in

this procedure.

Saudi Aramco: Company General Use

Page 6 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

8.1.2 For welds that require post weld heat treatment (PWHT), FBE coating on

both Internal and External welds shall be done after PWHT and welds

accepted by responsible Inspector. Demonstration shall be conducted

prior to actual work to determine the required internal and external

cutback after the completion of PWHT. If the cutback is exceeding

280 mm, approved liquid coating can be used for the internal girth weld.

8.1.3 Before welding, the cut back of internal pipe shall be blast cleaned and

the overlap area on shop-applied FBE pipe coating must be feathered.

After blasting, no further mechanical work is allowed, which could affect

the quality of the prepared surface.

8.1.4 The maximum length of the FBE field application is limited by the total

length of the cutback, 50-75 millimeters (2-3 inches), plus a reasonable

overlap, 1-2 inches, to tie in with the initial FBE coating. The maximum

total length of the coating on the girth weld shall be 10 inch (250 mm).

Consult with the RUS, if the length is extended.

8.1.5 Internal cleaning and FBE coating application of line pipes with diameter

of 8" and above shall be commenced by the fully remote controlled

crawling machine fitted with 2 cameras to monitor the work.

8.1.6 A PPT must be conducted at the start of each shift to verify the correct

functioning of the used equipment. The PPT should be conducted on a

spool similar to the pipes to be coated. The following tests in tables 2

and 3 shall be conducted by the Vendor and the result shall be shared

with Saudi Aramco inspector.

Table 2 - PPT On-Site Required Tests

Acceptance

Test Test Method Frequency

Criteria

DFT Para 9.4 SSPC-PA2 All

Holiday Detection No holiday Para. 9.3 All

Cure Test (MEK) No softening Para. 9.2.3 All

Adhesion Test Pass ASTM D6677 All

Table 3 - PPT Required Lab Tests

Acceptance

Test Test Method Frequency

Criteria

Hot-water soak

NACE SP0394-2013, Once out of

Hot-water adhesion: Rating of 1

(Appendix J) twenty PPT

(48 hours) 75 ± 3°C

Saudi Aramco: Company General Use

Page 7 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

Acceptance

Test Test Method Frequency

Criteria

Cathodic Disbondment

CSA Z245.20, Once out of

24 hours 10 mm

Clause 12.8 twenty PPT

@ 65°C, -3.5V

CSA Z245.20, Once out of

Cross-section Porosity Rating of 1

Clause 12.10.3 twenty PPT

ΔTg = -2, +3°C, CSA Z245.20, Once out of

Thermal Characteristics

95% conversion Clause 12.7.3.2.2 twenty PPT

8.2 Surface Preparation

8.2.1 Prior to blast cleaning, all hydrocarbon contaminants within a 500 mm

wide band centered over the weld shall be removed from the pipe by

solvent cleaning per SSPC SP-1. Kerosene, diesel, or similar degreasers

that leave an oily film shall not be used. For internal girth weld, it

should be done by the Contractor, unless otherwise specified in the scope

of work. The responsibilities of Contractor and Vendor for internal girth

weld coating are summarized in Table 4.

8.2.2 All weld joints including adjacent areas to be FBE coated either Internal

or External shall be ground smooth and free from burrs, weld spatter,

sharp edges. Weld toes shall be merged smoothly and rounded with no

sharp undercuts. The weld cap or internal root protrusion shall not be

more than 1.5 mm. Increasing coating thickness shall not be used to

overcome such defects.

8.2.3 The bare metal joint shall be abrasive blasted to near white metal

cleanliness, Sa 2½ , for external and to white metal cleanliness, Sa 3, for

internal. The surface profile shall be 50 to 100 micrometers. For internal

girth weld, it should be done by the Contractor, unless otherwise specified

in the scope of work. Pipe bung shall be used to protected shop- applied

pipe coating.

8.2.4 The gloss shall be feathered out from the shop-applied FBE pipe coating

that will be overlapped by the field coating by light abrasive (sweep)

blasting or sanding. Wire brushes shall not be used for this purpose.

Pre-clean the pipe internal coating cutback prior to welding using an

internal pipe bung.

8.2.5 Blasting abrasives shall comply with paragraphs 6.3 and 8.2 requirements

of SAES-H-001 and shall contain less than 50 ppm chlorides and sulfates.

They shall be stored in a dry condition and maintained dry during use.

Sand shall not be used as an abrasive. The Vendor shall furnish chemical

Saudi Aramco: Company General Use

Page 8 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

analyses for all batches of abrasives used to demonstrate compliance with

these requirements.

8.2.6 The first blasted girth weld in each shift shall be tested for chlorides.

Residual chloride on the surface shall not exceed 20 mg/m² in accordance

with ISO 8502-6. Test one out of each successive 20 girth weld areas.

8.2.7 In the event of a failure, re-test the piece. If it fails, test all pieces that

were blast cleaned both before and after the contaminated girth welds

until five in a row pass the test. All girth welds coated after the last good

test must be re-blasted, re-tested, and re-coated.

8.3 Coating Application Procedures

8.3.1 Coating application shall be performed after completion of welding and

NDT of field welding, to prevent formation of adherent rust, which may

require to cut the joint and reblast.

8.3.2 As soon as surface preparation is completed, the area to be coated shall

be cleaned of any deleterious matter by blowing with clean, dry, oil-free

compressed air.

8.3.3 Preheating shall be accomplished by using induction heating coils only.

8.3.4 The area to be coated shall then be immediately heated to a temperature

in accordance with the Powder Manufacturer's recommendation using

induction heating coil.

Commentary Note:

Temperatures in excess of the Manufacturer's recommended maximum

can damage the adjacent internal and external coating.

8.3.5 Preheating temperatures shall be measured with contact pyrometers.

Temperature crayons shall not be used.

8.3.6 As soon as the correct metal temperature has been reached, the induction

coil shall be removed from the welded joint area and the powder

application equipment placed in position. Powder application shall start

immediately. Coating shall be applied before the surface temperature

drops below the specified application temperature in the manufacturer

datasheet.

8.3.6.1 The machine shall apply powder to a uniform rate, to a correct

width centered on the girth weld, to the coating thickness

specified Table 5, in the least number of passes possible.

Saudi Aramco: Company General Use

Page 9 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

8.3.6.2 Care shall be taken to prevent the spray head, braces or hoses,

etc., from dragging on the ground during application operations.

Dirt or deleterious materials shall not contaminate the powder

coated area during the application and curing stages.

8.3.7 During periods of bad weather (rain, high winds, etc.) cleaning and

coating operations will only proceed if protective canopies are used to

the satisfaction of the Saudi Aramco Inspector.

Table 4 - Responsibilities of Contractor and Vendor

for Internal Coating Application Process

Party Responsibility and Activity

Remove hydrocarbon and other contaminants

Surface preparation to achieve require anchor profile and

Contractor cleanliness level

inspect welds and make sure it meets coating requirements

Repair weld defects, if any

Surface preparation and inspection, after welding

Vendor Coating application and inspection

Repair coating defects

Table 5 - DFT Requirement of Girth Weld (Internal and External)

Internal DFT Range (μm) External DFT Range (μm)

APCS-102A 375-625 APCS-104A 350-525

APCS-102B 500-750 APCS-104B 575-750

APCS-102C 500-750 APCS-104C As per CMR(1)

(1)

CMR (Coating Manufacturer’s Recommendation)

9 Inspection Methods and Acceptance Criteria

9.1 General

This section gives the mandatory inspection methods and acceptance criteria that

shall be met before the FBE-coated welds can be put into service. The inspection

requirements are summarized in Table 6.

9.2 Visual Inspection

9.2.1 The Inspector shall verify that the surface preparation requirements of

paragraph 8.2 are met prior to the commencement of preheating.

Saudi Aramco: Company General Use

Page 10 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

9.2.2 Thickness checks shall be made on each coated weld joint using an

approved, correctly calibrated dry film thickness gauge (e.g., Microtest,

Elcometer or equivalent). The instrument shall be calibrated in

accordance with SSPC-PA2.

A minimum number of 8 readings shall be taken on each field joint

coating, 4 readings in each side, to verify compliance with the thickness

requirement in Table 5.

9.2.3 For external and accessible internal girth weld coating, the quality of

cure shall be checked on the first 5 joints of the job and every 20 joints

thereafter, by maintaining a MEK soaked pad in contact with the coating

surface for one minute and then rubbing vigorously for 15 seconds.

There shall be no softening of the coating or substantial color removal

from the coating. For un-accessible internal girth weld coating, conduct

the cure test as specified in paragraph 8.1.6.

9.2.4 The finished coating shall have a uniform, glossy appearance and be free

of defects such as holidays, fish eyes, lumps, dry spray, sags and runs.

Coating overlap shall be within the thickness specified in 09-SAMSS-089

for external and 09-SAMSS-091 for internal.

9.2.5 Cameras fitted on the crawling machine shall be used during the

inspection of internally coated pipeline with diameters from 8" and above.

9.3 Holiday Detection

9.3.1 100% of the coated girth weld surface area shall be holiday detected,

inspected, and repaired in accordance with the procedures and equipment

specified in 09-SAMSS-089 for external and 09-SAMSS-091 for

internal. Holiday detection shall not be conducted if the surface

temperature of the coated girth weld area exceeds 80°C.

9.3.2 All holidays, imperfections, and damaged areas shall be carefully

identified with a waterproof marker. All markings shall be sufficiently

distant from the area to be repaired to allow surface preparation and

coating application without being a detriment to the adhesion of the

repair coating. This procedure is applicable for external coating and/or

accessible internal coating.

9.4 Destructive Testing

9.4.1 Using a sharp knife with a narrow width blade, make two, approximately

13-mm long incisions through to the metal substrate to form an X in

accordance with ASTM D6677.

Saudi Aramco: Company General Use

Page 11 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

9.4.2 Starting at the intersection of the X, attempt to force the coating from the

steel substrate with the knife point. Refusal of the coating to peel

constitutes a pass. Partial or complete adhesion failure between the

coating and the metal substrate constitutes a failure. Cohesive failure

caused by voids in the coating leaving a honeycomb structure on the

specimen surface also constitutes failure.

9.4.3 This shall be performed once every hour. When three consecutive tests

are successful, the frequency shall be reduced to once every two hours.

9.4.4 If coating fails to meet the acceptance criteria in paragraph 9.4.2, the

adjacent field girth weld areas shall also be tested until acceptable

coatings are found on both sides of the defective coating. The defective

coatings shall all be completely removed and the areas recoated. At least

one of the repaired areas shall be re-inspected, and the subsequent

inspection frequency shall be as given in paragraph 9.4.3.

Table 6 - Test Items for Internal/External Girth Weld (FBE) Coating

Stage Item Acceptance Criteria Frequency

Surface No contamination

All

Contamination (including hydro carbon)

First girth weld each

Before Residual Salt Less than 20 mg/m² joint, then one of each

Welding successive 40 girth weld

Sa 3 (for internal)

Cleanliness Level All

Sa 2.5 (for external)

Anchor Profile 50-100 μm All

After Welding Condition No defect(1) All

Welding Cleaning No contamination All

Visual Inspection No defect All

DFT See Table 5 All

After

Coating Holiday No holiday All

Application

Adhesion Para. 9.4.2 Para. 9.4.3

Curing No softening Para. 9.2.3

(1) No weld defect as per ISO 8501-3 P3 Grade (Table 1. Imperfections and Preparation Grade).

9.5 Repairs

9.5.1 General

Defects shall be repaired in accordance with the criteria and methods

below. If the number of defects is more than 3 holidays on any girth

Saudi Aramco: Company General Use

Page 12 of 13

Document Responsibility: Paints and Coatings Standards Committee SAES-H-201

Issue Date: 7 February 2017 General Specifications for External and Internal

Next Planned Update: 7 February 2020 FBE Coatings of Pipeline Field Girth Welds

weld, the coating shall be completely blasted off and the area recoated at

no cost to Saudi Aramco.

9.5.2 Preparation of Surface

The pipe surface to be recoated shall be cleaned to remove all dirt and

damaged or disbonded coating using abrasive blasting or other approved

and suitable means. The edges of the original coatings shall be

“feathered out” approximately 50 mm around the specific area to be

coated, and all dust wiped off before applying the patch coating.

9.5.3 To repair holidays in un-accessible internal girth weld FBE coatings, use

the cleaning machine to lightly abrade the existing girth weld coating for

band width of 200 mm (8 inches) to create enough roughness, 1.0 mil,

for the adhesion of FBE powder coating. The coating shall be inspected

for holidays and thickness. If a holiday is detected, the field joint should

be cut out to determine the cause. Cold cutting method shall be used to

prevent damaging the internal pipe coating. Flame cutting is not allowed.

9.5.4 To repair holidays in an accessible internal or external girth weld

coating, two part epoxy should be used in accordance with the coating

manufacturer’s requirement. The surface should be prepared as specified

in 9.5.2.

9.5.5 All repairs shall be holiday tested.

9.6 Vendor Responsibilities

The Vendor shall be responsible for all quality control processes including

visual inspection, surface cleanliness and profile checking, thickness

measurements, and holiday testing. The Vendor shall keep daily records of the

work progress and results of all inspection activities in a form suitable to the

Saudi Aramco Inspector surveillance and approval.

Revision Summary

16 November 2011 Editorial revision to remove the committee members list and change the primary contact.

Revised the "Next Planned Update."

7 February 2017 Major revision to clarify some of the requirements, summarize required tests in tables,

specify coating thickness for each system, revise acceptance criteria, highlight safety

requirements, clarify tasks of involved vendors, and add new tests.

Saudi Aramco: Company General Use

Page 13 of 13

Das könnte Ihnen auch gefallen

- 09 Samss 089-2016Dokument26 Seiten09 Samss 089-2016lhanx2Noch keine Bewertungen

- 01 Samss 012 2014Dokument10 Seiten01 Samss 012 2014lhanx2Noch keine Bewertungen

- Saep 1200Dokument9 SeitenSaep 1200Anonymous 4IpmN7On100% (1)

- Saes-H-002 - ArmacoDokument29 SeitenSaes-H-002 - ArmacoVenkat Gokila DT100% (1)

- 09 SAMSS 089 (Final Draft - 2018)Dokument28 Seiten09 SAMSS 089 (Final Draft - 2018)lhanx2Noch keine Bewertungen

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Dokument9 Seiten09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- Gas QCP Pac 003 Apcs 113 CDokument18 SeitenGas QCP Pac 003 Apcs 113 Cfawad ali0% (1)

- Method Statement For APCS-113A For Alloy Steel - Otc - Fbe-002Dokument7 SeitenMethod Statement For APCS-113A For Alloy Steel - Otc - Fbe-002sharif339100% (2)

- SAIC-H-2010 Rev 7Dokument1 SeiteSAIC-H-2010 Rev 7Satheesh Rama SamyNoch keine Bewertungen

- Materials System SpecificationDokument6 SeitenMaterials System SpecificationAjeetKumarNoch keine Bewertungen

- Apcs 113a-87550Dokument2 SeitenApcs 113a-87550jojo_32350% (6)

- Saes H 204Dokument34 SeitenSaes H 204heartbreakkid132Noch keine Bewertungen

- 09 Samss 060Dokument4 Seiten09 Samss 060asimazami69Noch keine Bewertungen

- SATIP H 002 08 Pipe Internal CoatingDokument3 SeitenSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyNoch keine Bewertungen

- SAIC-H-2014 Rev 7Dokument3 SeitenSAIC-H-2014 Rev 7mohammed siddiqNoch keine Bewertungen

- 09 Samss 091Dokument19 Seiten09 Samss 091Sohail Tisekar100% (1)

- CBT Questions 26022020Dokument43 SeitenCBT Questions 26022020Shawn LeoNoch keine Bewertungen

- SAIC-H-2032 Rev 7Dokument4 SeitenSAIC-H-2032 Rev 7Satheesh Rama SamyNoch keine Bewertungen

- Saudi Aramco Test ReportDokument2 SeitenSaudi Aramco Test ReportMoghal AliNoch keine Bewertungen

- Saes H 101V PDFDokument389 SeitenSaes H 101V PDFQA QCNoch keine Bewertungen

- Saic H 1003Dokument2 SeitenSaic H 1003Hussain Nasser Al- NowiesserNoch keine Bewertungen

- Apcs 113a Rev 3 Pid ApprovalDokument19 SeitenApcs 113a Rev 3 Pid ApprovalMedel Cay De Castro50% (2)

- CBT 06.02.2020Dokument3 SeitenCBT 06.02.2020Nidhin Joseph100% (1)

- Process Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistDokument7 SeitenProcess Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistCristian Jhair PerezNoch keine Bewertungen

- APCS DeatailsDokument3 SeitenAPCS DeatailsnasirNoch keine Bewertungen

- Saes H 102Dokument10 SeitenSaes H 102Kaleelur RahmanNoch keine Bewertungen

- Satip H 002 02Dokument10 SeitenSatip H 002 02Rijwan MohammadNoch keine Bewertungen

- Saep 316 2016 PDFDokument25 SeitenSaep 316 2016 PDFAllan LindoNoch keine Bewertungen

- SATIP SAIC SATR IndexDokument87 SeitenSATIP SAIC SATR Indexlhanx2100% (8)

- Materials System SpecificationDokument10 SeitenMaterials System SpecificationAjeetKumar100% (1)

- Paint System Recommendations PDFDokument6 SeitenPaint System Recommendations PDFKumarNoch keine Bewertungen

- Saic H 2023Dokument2 SeitenSaic H 2023Sivaratnam NavatharanNoch keine Bewertungen

- Materials System SpecificationDokument7 SeitenMaterials System SpecificationAjeetKumarNoch keine Bewertungen

- 175 091300Dokument2 Seiten175 091300Abu Anas M.SalaheldinNoch keine Bewertungen

- SATR-H-2006 Rev 8Dokument3 SeitenSATR-H-2006 Rev 8ravi ajith100% (1)

- Saes H 004Dokument8 SeitenSaes H 004kaleeswaran s100% (1)

- SAES-H-102-Safety Requirements For Coating Applications2Dokument12 SeitenSAES-H-102-Safety Requirements For Coating Applications2محمد العيسوىNoch keine Bewertungen

- SAEP-303: 2 Conflicts and DeviationsDokument19 SeitenSAEP-303: 2 Conflicts and DeviationsnasirNoch keine Bewertungen

- Coating Inspector Interview QuestionsDokument14 SeitenCoating Inspector Interview Questionshabib81% (16)

- Saes A 134Dokument13 SeitenSaes A 134Mohamed Soliman100% (1)

- APCS DeatailsDokument3 SeitenAPCS DeatailsDandaman100% (3)

- Saes H 101VDokument83 SeitenSaes H 101Vacolombel100% (2)

- COATING Aramco QuestionsDokument24 SeitenCOATING Aramco QuestionsDavid Salguero100% (13)

- Satr H 1003Dokument2 SeitenSatr H 1003Thouseef MaNoch keine Bewertungen

- CBT 3Dokument9 SeitenCBT 3SUNIL RAJPUT100% (1)

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDokument2 SeitenSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNoch keine Bewertungen

- Aramco Painting SpecificationDokument6 SeitenAramco Painting Specificationvicky100% (1)

- SATIP-H-100-01 Rev 8Dokument4 SeitenSATIP-H-100-01 Rev 8SajjadPervaiz100% (2)

- Saep 347Dokument27 SeitenSaep 347Qaiser Mahmood100% (2)

- Coating Inspector Interview QuestionsDokument11 SeitenCoating Inspector Interview Questionshabib100% (3)

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDokument5 SeitenTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcNoch keine Bewertungen

- Coating Crew SupervisorDokument4 SeitenCoating Crew Supervisorimtiaz100% (1)

- SATIP H 002 08 Rev 4.unlockedDokument2 SeitenSATIP H 002 08 Rev 4.unlockedMohamed Farhan B PositiveNoch keine Bewertungen

- CBT 2Dokument2 SeitenCBT 2SUNIL RAJPUT100% (1)

- Ad 036821 001Dokument1 SeiteAd 036821 001AmolNoch keine Bewertungen

- SAMSS New StandardDokument25 SeitenSAMSS New Standardlhanx2100% (1)

- 09 Samss 091Dokument30 Seiten09 Samss 091Aravind BabuNoch keine Bewertungen

- 09 Samss 091Dokument27 Seiten09 Samss 091AbhilashNoch keine Bewertungen

- 09 Samss 089Dokument32 Seiten09 Samss 089Aravind BabuNoch keine Bewertungen

- 09 Samss 087 PDFDokument8 Seiten09 Samss 087 PDFMohamed SolimanNoch keine Bewertungen

- ECA Application Checklist PDFDokument2 SeitenECA Application Checklist PDFdanishNoch keine Bewertungen

- ECA Application Checklist PDFDokument2 SeitenECA Application Checklist PDFdanishNoch keine Bewertungen

- ECA Application Checklist PDFDokument2 SeitenECA Application Checklist PDFdanishNoch keine Bewertungen

- Pipe Weld TipsDokument1 SeitePipe Weld TipsdanishNoch keine Bewertungen

- Result Sheet FormationDokument7 SeitenResult Sheet FormationdanishNoch keine Bewertungen

- Without BlastingAfter Proper BlastingDokument1 SeiteWithout BlastingAfter Proper BlastingdanishNoch keine Bewertungen

- 15553Dokument2 Seiten15553danish100% (1)

- Result Sheet FormationDokument10 SeitenResult Sheet FormationdanishNoch keine Bewertungen

- PDS Hempel's Silicone Aluminium 56910 en-GBDokument2 SeitenPDS Hempel's Silicone Aluminium 56910 en-GBdanishNoch keine Bewertungen

- Hempel ProductsDokument1 SeiteHempel ProductsdanishNoch keine Bewertungen

- CAL END AR: February SatDokument2 SeitenCAL END AR: February SatdanishNoch keine Bewertungen

- Excel Training 001Dokument14 SeitenExcel Training 001danishNoch keine Bewertungen

- Excel Training UpdatedDokument34 SeitenExcel Training UpdateddanishNoch keine Bewertungen

- Result Sheet FormationDokument10 SeitenResult Sheet FormationdanishNoch keine Bewertungen

- Chalan Form FormatingDokument1 SeiteChalan Form FormatingdanishNoch keine Bewertungen

- Today Dob 200 Marks Each Days Name English Years Months Weeks Hours Minutes SecondsDokument14 SeitenToday Dob 200 Marks Each Days Name English Years Months Weeks Hours Minutes SecondsdanishNoch keine Bewertungen

- Pervaiz Akhtar Butt So Atta Muhammad Butt H No 305 Kucha Lath Marran Mochi Gate LahoreDokument4 SeitenPervaiz Akhtar Butt So Atta Muhammad Butt H No 305 Kucha Lath Marran Mochi Gate LahoredanishNoch keine Bewertungen

- Result Sheet FormationDokument5 SeitenResult Sheet FormationdanishNoch keine Bewertungen

- 16.3 - Precipitation and The Solubility Product - Chemistry LibreTextsDokument14 Seiten16.3 - Precipitation and The Solubility Product - Chemistry LibreTextsThereNoch keine Bewertungen

- Data Sheet 6GK5213-3BB00-2TB2: Transfer RateDokument6 SeitenData Sheet 6GK5213-3BB00-2TB2: Transfer RateClaudiu VlasceanuNoch keine Bewertungen

- Model-Checking: A Tutorial Introduction: January 1999Dokument26 SeitenModel-Checking: A Tutorial Introduction: January 1999Quý Trương QuangNoch keine Bewertungen

- Fluid Mechanics and Machinery Laboratory Manual: by Dr. N. Kumara SwamyDokument4 SeitenFluid Mechanics and Machinery Laboratory Manual: by Dr. N. Kumara SwamyMD Mahmudul Hasan Masud100% (1)

- Micron Serial NOR Flash Memory: 3V, Multiple I/O, 4KB Sector Erase N25Q256A FeaturesDokument92 SeitenMicron Serial NOR Flash Memory: 3V, Multiple I/O, 4KB Sector Erase N25Q256A FeaturesAENoch keine Bewertungen

- Akebono NVH White PaperDokument4 SeitenAkebono NVH White Paperapi-3702571100% (1)

- Datasheet d801001Dokument6 SeitenDatasheet d801001Hammad HussainNoch keine Bewertungen

- The Messenger 190Dokument76 SeitenThe Messenger 190European Southern ObservatoryNoch keine Bewertungen

- Pex 03 02Dokument5 SeitenPex 03 02aexillis0% (1)

- Annual Premium Statement: Bhupesh GuptaDokument1 SeiteAnnual Premium Statement: Bhupesh GuptaBhupesh GuptaNoch keine Bewertungen

- BIO CH04 FoundationsDokument12 SeitenBIO CH04 FoundationsDyuana Stevenson0% (1)

- Matter and Materials (Grade 6 English)Dokument80 SeitenMatter and Materials (Grade 6 English)Primary Science Programme100% (5)

- O RTIZDokument2 SeitenO RTIZKhimberly Xylem OrtizNoch keine Bewertungen

- Math912 2Dokument7 SeitenMath912 2Mbq ManbriquaNoch keine Bewertungen

- 1353apni KakshaDokument43 Seiten1353apni KakshaArush GautamNoch keine Bewertungen

- AM2020-AFP1010 Installation Programming OperatingDokument268 SeitenAM2020-AFP1010 Installation Programming OperatingBaron RicthenNoch keine Bewertungen

- Waste SM4500-NH3Dokument10 SeitenWaste SM4500-NH3Sara ÖZGENNoch keine Bewertungen

- RK3066 Mid PDFDokument17 SeitenRK3066 Mid PDFSharon MurphyNoch keine Bewertungen

- 2-Amino-5-Aryl-2-Oxazolines.: (,ee TableDokument7 Seiten2-Amino-5-Aryl-2-Oxazolines.: (,ee TableChristopher HowellNoch keine Bewertungen

- Vibration Absorbers: Scan This QR CodeDokument4 SeitenVibration Absorbers: Scan This QR CodeMohamed RaafatNoch keine Bewertungen

- Advertisement For Recruitment of Non-Teaching StaffDokument3 SeitenAdvertisement For Recruitment of Non-Teaching StaffGoogle AccountNoch keine Bewertungen

- Search WaiverDokument1 SeiteSearch WaiverHacer Gungoray100% (1)

- Definition of Surface Texture and Stylus InstrumentDokument5 SeitenDefinition of Surface Texture and Stylus InstrumenthosseinNoch keine Bewertungen

- Examples of Consonant BlendsDokument5 SeitenExamples of Consonant BlendsNim Abd MNoch keine Bewertungen

- 2.fundamentals of MappingDokument5 Seiten2.fundamentals of MappingB S Praveen BspNoch keine Bewertungen

- Bird Beak Adaptations: PurposeDokument9 SeitenBird Beak Adaptations: PurposelilazrbNoch keine Bewertungen

- Roundtracer Flash En-Us Final 2021-06-09Dokument106 SeitenRoundtracer Flash En-Us Final 2021-06-09Kawee BoonsuwanNoch keine Bewertungen

- SpeechGeek H.I.-larious Volume 3Dokument9 SeitenSpeechGeek H.I.-larious Volume 3SpeechGeekNoch keine Bewertungen

- Microsoft 365 LicensingDokument18 SeitenMicrosoft 365 Licensingwendy yohanesNoch keine Bewertungen