Beruflich Dokumente

Kultur Dokumente

1K/2K/4K 2.5V Microwire Serial EEPROM: Features: Package Types

Hochgeladen von

João PauloOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1K/2K/4K 2.5V Microwire Serial EEPROM: Features: Package Types

Hochgeladen von

João PauloCopyright:

Verfügbare Formate

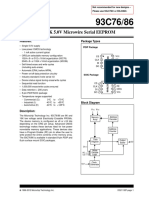

Not recommended for new designs –

Please use 93LC46C, 93LC56C or 93LC66C.

93LC46/56/66

1K/2K/4K 2.5V Microwire Serial EEPROM

Features: Package Types

• Single supply with programming operation down PDIP/SOIC

to 2.5V

• Low-power CMOS technology

CS 1 8 VCC

• 100 µA typical active read current at 2.5V

93LC66

93LC56

93LC46

CLK 2 7 NU

• 3 µA typical standby current at 2.5V

DI 3 6 ORG

• ORG pin selectable memory configuration

DO 4 5 VSS

• 128 x 8- or 64 x 16-bit organization (93LC46)

• 256 x 8- or 128 x 16-bit organization (93LC56) ROTATED SOIC

• 512 x 8 or 256 x 16 bit organization (93LC66)

• Self-timed erase and write cycles NU 1 8 ORG

93LC66X

93LC56X

93LC46X

(including auto-erase) VCC 2 7 VSS

• Automatic ERAL before WRAL CS 3 6 DO

• Power on/off data protection circuitry CLK 4 5 DI

• Industry standard 3-wire serial I/O

• Device status signal during erase/write cycles

• Sequential read function Block Diagram

• 1,000,000 E/W cycles ensured

VCC VSS

• Data retention > 200 years

• 8-pin PDIP/SOIC

Address

(SOIC in JEDEC standards) Memory Decoder

Array

• Temperature ranges supported:

- Industrial (I): -40°C to +85°C

Address

Counter

Description:

DO

Output

The Microchip Technology Inc. 93LC46/56/66 are 1K, Data Register

Buffer

2K and 4K low voltage serial Electrically Erasable DI

PROMs (EEPROM). The device memory is configured Mode

as x8 or x16 bits depending on the external logic of ORG Decode

CS Logic

levels of the ORG pin. Advanced CMOS technology

makes these devices ideal for low power nonvolatile

memory applications. The 93LC Series is available in Clock

CLK

standard 8-pin PDIP and surface mount SOIC Register

packages. The rotated pin-out 93LC46X/56X/66X are

offered in the “SN” package only.

2004 Microchip Technology Inc. DS21712B-page 1

93LC46/56/66

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings(†)

VCC .............................................................................................................................................................................6.5V

All inputs and outputs w.r.t. VSS ........................................................................................................ -0.6V to VCC + 1.0V

Storage temperature ...............................................................................................................................-65°C to +150°C

Ambient temperature with power applied ................................................................................................-40°C to +125°C

ESD protection on all pins ......................................................................................................................................................≥ 4 kV

† NOTICE: Stresses above those listed under “Maximum ratings” may cause permanent damage to the device. This

is a stress rating only and functional operation of the device at those or any other conditions above those indicated in

the operational listings of this specification is not implied. Exposure to maximum rating conditions for extended periods

may affect device reliability.

DC CHARACTERISTICS

VCC = +2.5V to +5.5V

DC CHARACTERISTICS

Industrial (I): TA = -40°C to +85°C

Param.

Sym Characteristic Min Typ Max Units Conditions

No.

D1 VIH1 High-level input voltage 2.0 — VCC +1 V VCC ≥ 2.7V

VIH2 0.7 VCC — VCC +1 V VCC ≥ 2.7V

D2 VIL1 Low-level input voltage -0.3 — 0.8 V VCC ≥ 2.7V

VIL2 -0.3 — 0.2 VCC V VCC ≥ 2.7V

D3 VOL1 Low-level output voltage — — 0.4 V IOL = 2.1 mA, VCC = 4.5V

VOL2 — — 0.3 V IOL = 100 µA, VCC = 2.5V

D4 VOH1 High-level output voltage 2.4 — — V IOL = 400 µA, VCC = 4.5V

VOH2 VCC -0.2 — — V IOL = 100 µA, VCC = 2.5V

D5 ILI Input leakage current — — ±10 µA VIN = 0.1V to VCC

D6 ILO Output leakage current — — ±10 µA VOUT = 0.1V to VCC

D7 CIN, Pin capacitance — — 7 pF VIN/VOUT = 0V (Note 1 & 2)

COUT (all inputs/outputs) TA = 25°C, FCLK = 1 MHz

D8 ICC write Operating current — — 3 mA FCLK = 2 MHz, VCC = 5.5V

(Note 2)

D9 ICC read — — 1 mA FCLK = 2 MHz, VCC = 5.5V

— — 500 µA FCLK = 1 MHz, VCC = 3.0V

— 100 — µA FCLK = 1 MHz, VCC = 2.5V

D10 ICCS Standby current — — 100 µA CLK = CS = 0V; VCC = 5.5V

— — 30 µA CLK = CS = 0V; VCC = 3.0V

— 3 — µA CLK = CS = 0V; VCC = 2.5V

ORG, DI = VSS or VCC

Note 1: This parameter is tested at TA = 25°C and FCLK = 1 MHz.

2: This parameter is periodically sampled and not 100% tested.

DS21712B-page 2 2004 Microchip Technology Inc.

93LC46/56/66

AC CHARACTERISTICS

VCC = +2.5V to +5.5V

AC CHARACTERISTICS

Industrial (I): TA = -40°C to +85°C

Param.

Sym Characteristic Min Typ Max Units Conditions

No.

1 FCLK Clock frequency — — 2 MHz VCC ≥ 4.5V

— — 1 MHz VCC < 4.5V

2 TCKH Clock high time 250 — — ns

3 TCKL Clock low time 250 — — ns

4 TCSS Chip select setup time 50 — — ns Relative to CLK

5 TCSH Chip select hold time 0 — — ns Relative to CLK

6 TCSL Chip select low time 250 — — ns

7 TDIS Data input setup time 100 — — ns Relative to CLK

8 TDIH Data input hold time 100 — — ns Relative to CLK

9 TPD Data output delay time — — 400 ns CL = 100 pF

10 TCZ Data output disable time — — 100 ns CL = 100 pf (Note 2)

11 TSV Status valid time — — 500 ns CL = 100 pF

12 TWC Program cycle time — 4 10 ms Erase/Write mode

13 TEC — 8 15 ms ERAL mode (VCC=5V ±10%)

14 TWL — 16 30 ms WRAL mode (VCC=5V ±10%)

15 — Endurance 1M — 1M cycles 25°C, VCC = 5.0V, Block

mode (Note 3)

Note 1: This parameter is tested at TA = 25°C and FCLK = 1 MHz.

2: This parameter is periodically sampled and not 100% tested.

3: This parameter is not tested but ensured by characterization. For endurance estimates in a specific

application, please consult the Total Endurance™ Model which can be obtained from Microchip’s web site

at: www.microchip.com.

FIGURE 1-1: SYNCHRONOUS DATA TIMING

VIH

CS

VIL 4 2 3

5

VIH

CLK

VIL

7 8

VIH

DI

VIL

9 9 10

DO VOH

(Read) 10

VOL 11

DO VOH

(Write) Status Valid

VOL

2004 Microchip Technology Inc. DS21712B-page 3

93LC46/56/66

TABLE 1-1: INSTRUCTION SET FOR 93LC46: ORG = 1 (X 16 ORGANIZATION)

Req. CLK

Instruction SB Opcode Address Data In Data Out

Cycles

READ 1 10 A5 A4 A3 A2 A1 A0 — D15 - D0 25

EWEN 1 00 1 1 XXXX — High-Z 9

ERASE 1 11 A5 A4 A3 A2 A1 A0 — (RDY/BSY) 9

ERAL 1 00 1 0 XXXX — (RDY/BSY) 9

WRITE 1 01 A5 A4 A3 A2 A1 A0 D15 - D0 (RDY/BSY) 25

WRAL 1 00 0 1 XXXX D15 - D0 (RDY/BSY) 25

EWDS 1 00 0 0 XXXX — High-Z 9

TABLE 1-2: INSTRUCTION SET FOR 93LC46: ORG = 0 (X 8 ORGANIZATION)

Req. CLK

Instruction SB Opcode Address Data In Data Out

Cycles

READ 1 10 A6 A5 A4 A3 A2 A1 A0 — D7 - D0 18

EWEN 1 00 11XXXXX — High-Z 10

ERASE 1 11 A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY) 10

ERAL 1 00 10XXXXX — (RDY/BSY) 10

WRITE 1 01 A6 A5 A4 A3 A2 A1 A0 D7 - D0 (RDY/BSY) 18

WRAL 1 00 01XXXXX D7 - D0 (RDY/BSY) 18

EWDS 1 00 00XXXXX — High-Z 10

TABLE 1-3: INSTRUCTION SET FOR 93LC56: ORG = 1 (X 16 ORGANIZATION)

Instruction SB Opcode Address Data In Data Out Req. CLK

Cycles

READ 1 10 X A6 A5 A4 A3 A2 A1 A0 — D15 - D0 27

EWEN 1 00 11XXXXXX — High-Z 11

ERASE 1 11 X A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY) 11

ERAL 1 00 10XXXXXX — (RDY/BSY) 11

WRITE 1 01 X A6 A5 A4 A3 A2 A1 A0 D15 - D0 (RDY/BSY) 27

WRAL 1 00 01XXXXXX D15 - D0 (RDY/BSY) 27

EWDS 1 00 00XXXXXX — High-Z 11

TABLE 1-4: INSTRUCTION SET FOR 93LC56: ORG = 0 (X 8 ORGANIZATION)

Req. CLK

Instruction SB Opcode Address Data In Data Out

Cycles

READ 1 10 X A7 A6 A5 A4 A3 A2 A1 A0 — D7 - D0 20

EWEN 1 00 11XXXXXXX — High-Z 12

ERASE 1 11 X A7 A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY) 12

ERAL 1 00 10XXXXXXX — (RDY/BSY) 12

WRITE 1 01 X A7 A6 A5 A4 A3 A2 A1 A0 D7 - D0 (RDY/BSY) 20

WRAL 1 00 01XXXXXXX D7 - D0 (RDY/BSY) 20

EWDS 1 00 00XXXXXXX — High-Z 12

DS21712B-page 4 2004 Microchip Technology Inc.

93LC46/56/66

TABLE 1-5: INSTRUCTION SET FOR 93LC66: ORG = 1 (X 16 ORGANIZATION)

Req. CLK

Instruction SB Opcode Address Data In Data Out

Cycles

READ 1 10 A7 A6 A5 A4 A3 A2 A1 A0 — D15 - D0 27

EWEN 1 00 11XXXXXX — High-Z 11

ERASE 1 11 A7 A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY) 11

ERAL 1 00 10XXXXXX — (RDY/BSY) 11

WRITE 1 01 A7 A6 A5 A4 A3 A2 A1 A0 D15 - D0 (RDY/BSY) 27

WRAL 1 00 01XXXXXX D15 - D0 (RDY/BSY) 27

EWDS 1 00 00XXXXXX — High-Z 11

TABLE 1-6: INSTRUCTION SET FOR 93LC66: ORG = 0 (X 8 ORGANIZATION)

Req. CLK

Instruction SB Opcode Address Data In Data Out

Cycles

READ 1 10 A8 A7 A6 A5 A4 A3 A2 A1 A0 — D7 - D0 20

EWEN 1 00 11XXXXXXX — High-Z 12

ERASE 1 11 A8 A7 A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY) 12

ERAL 1 00 10XXXXXXX — (RDY/BSY) 12

WRITE 1 01 A8 A7 A6 A5 A4 A3 A2 A1 A0 D7 - D0 (RDY/BSY) 20

WRAL 1 00 01XXXXXXX D7 - D0 (RDY/BSY) 20

EWDS 1 00 00XXXXXXX — High-Z 12

2004 Microchip Technology Inc. DS21712B-page 5

93LC46/56/66

2.0 FUNCTIONAL DESCRIPTION After power-up, the device is automatically in the

EWDS mode. Therefore, an EWEN instruction must be

When the ORG pin is connected to VCC, the (x16) performed before any ERASE or WRITE instruction can

organization is selected. When it is connected to be executed.

ground, the (x8) organization is selected. Instruc-

tions, addresses and write data are clocked into the 2.4 Read

DI pin on the rising edge of the clock (CLK). The DO

pin is normally held in a high-Z state except when The READ instruction outputs the serial data of the

reading data from the device, or when checking the addressed memory location on the DO pin. A dummy

Ready/Busy status during a programming operation. zero bit precedes the 16-bit (x16 organization) or 8-bit

The Ready/Busy status can be verified during an (x8 organization) output string. The output data bits will

erase/write operation by polling the DO pin; DO low toggle on the rising edge of the CLK and are stable

indicates that programming is still in progress, while after the specified time delay (TPD). Sequential read is

DO high indicates the device is ready. The DO will possible when CS is held high. The memory data will

enter the high-Z state on the falling edge of the CS. automatically cycle to the next register and output

sequentially.

2.1 Start Condition

2.5 Erase/Write Enable and Disable

The Start bit is detected by the device if CS and DI are

both high with respect to the positive edge of CLK for

(EWEN, EWDS)

the first time. The 93LC46/56/66 power up in the Erase/Write Disable

Before a Start condition is detected, CS, CLK and DI (EWDS) state. All programming modes must be

may change in any combination (except to that of a preceded by an Erase/Write Enable (EWEN) instruction.

Start condition), without resulting in any device opera- Once the EWEN instruction is executed, programming

tion (Read, Write, Erase, EWEN, EWDS, ERAL and remains enabled until an EWDS instruction is executed

WRAL). As soon as CS is high, the device is no longer or VCC is removed from the device. To protect against

in the Standby mode. accidental data disturb, the EWDS instruction can be

used to disable all erase/write functions and should

An instruction following a Start condition will only be

follow all programming operations. Execution of a READ

executed if the required amount of opcode, address

instruction is independent of both the EWEN and EWDS

and data bits for any particular instruction is clocked in.

instructions.

After execution of an instruction (i.e., clock in or out of

the last required address or data bit) CLK and DI 2.6 Erase

become “don't care” bits until a new Start condition is

detected. The ERASE instruction forces all data bits of the speci-

fied address to the logical “1” state. CS is brought low

2.2 Data In/Data Out (DI/DO) following the loading of the last address bit. This falling

edge of the CS pin initiates the self-timed programming

It is possible to connect the Data In and Data Out pins cycle.

together. However, with this configuration it is possible

The DO pin indicates the Ready/Busy status of the

for a “bus conflict” to occur during the “dummy zero”

device if CS is brought high after a minimum of 250 ns

that precedes the read operation, if A0 is a logic high

low (TCSL). DO at logical “0” indicates that program-

level. Under such a condition the voltage level seen at

ming is still in progress. DO at logical “1” indicates that

Data Out is undefined and will depend upon the relative

the register at the specified address has been erased

impedances of Data Out and the signal source driving

and the device is ready for another instruction.

A0. The higher the current sourcing capability of A0,

the higher the voltage at the Data Out pin. The erase cycle takes 4 ms per word typical.

2.3 Data Protection

During power-up, all programming modes of operation

are inhibited until VCC has reached a level greater than

1.4V. During power-down, the source data protection

circuitry acts to inhibit all programming modes when

VCC has fallen below 1.4V at nominal conditions.

The EWEN and EWDS commands give additional

protection against accidentally programming during

normal operation.

DS21712B-page 6 2004 Microchip Technology Inc.

93LC46/56/66

2.7 Write The DO pin indicates the Ready/Busy status of the

device if CS is brought high after a minimum of 250 ns

The WRITE instruction is followed by 16 bits (or by 8 low (TCSL) and before the entire write cycle is complete.

bits) of data which are written into the specified

address. After the last data bit is put on the DI pin, The ERAL cycle takes (8 ms typical).

CS must be brought low before the next rising edge

of the CLK clock. This falling edge of CS initiates the 2.9 Write All (WRAL)

self-timed auto-erase and programming cycle.

The WRAL instruction will write the entire memory array

The DO pin indicates the Ready/Busy status of the with the data specified in the command. The WRAL

device if CS is brought high after a minimum of 250 ns cycle is completely self-timed and commences at the

low (TCSL) and before the entire write cycle is complete. falling edge of the CS. Clocking of the CLK pin is not

DO at logical “0” indicates that programming is still in necessary after the device has entered the self clock-

progress. DO at logical “1” indicates that the register at ing mode. The WRAL command does include an auto-

the specified address has been written with the data matic ERAL cycle for the device. Therefore, the WRAL

specified and the device is ready for another instruction does not require an ERAL instruction but the

instruction. chip must be in the EWEN status. The WRAL instruction

The write cycle takes 4 ms per word typical. is ensured at 5V ±10%.

The DO pin indicates the Ready/Busy status of the

2.8 Erase All (ERAL) device if CS is brought high after a minimum of 250 ns

low (Tcsl).

The ERAL instruction will erase the entire memory array

to the logical “1” state. The ERAL cycle is identical to The WRAL cycle takes 16 ms typical.

the ERASE cycle except for the different opcode. The

ERAL cycle is completely self-timed and commences

at the falling edge of the CS. Clocking of the CLK pin is

not necessary after the device has entered the self

clocking mode. The ERAL instruction is ensured at 5V

±10%.

FIGURE 2-1: READ TIMING

CS

CLK

DI 1 1 0 An ••• A0

DO High-Z

0 Dx ••• D0 Dx ••• D0 Dx ••• D0

2004 Microchip Technology Inc. DS21712B-page 7

93LC46/56/66

FIGURE 2-2: EWEN TIMING

CS

1 0 0 1 1 X ••• X

DI

FIGURE 2-3: EWDS TIMING

6

CS

CLK

DI 1 0 0 0 0 X ••• X

FIGURE 2-4: WRITE TIMING

6

CS

CLK

DI 1 0 1 An ••• A0 Dx ••• D0

11

High-Z

DO Busy Ready

12

DS21712B-page 8 2004 Microchip Technology Inc.

93LC46/56/66

FIGURE 2-5: WRAL TIMING

6

CS

CLK

DI 1 0 0 0 1 X ••• X Dx ••• D0

11 10

High-Z Busy

DO Ready

High-Z

14

Ensured by Characterization at VCC = 4.5V to +5.5V.

FIGURE 2-6: ERASE TIMING

6

CS

Check Status

CLK

DI 1 1 1 An An-1 An-2 ••• A0

11 10

High-Z Busy

DO Ready

High-Z

12

FIGURE 2-7: ERAL TIMING

6

CS

Check Status

CLK

DI 1 0 0 1 0 X ••• X

11 10

High-Z

DO Busy Ready

High-Z

Ensured by Characterization at Vcc = 4.5V to +5.5V. 13

2004 Microchip Technology Inc. DS21712B-page 9

93LC46/56/66

3.0 PIN DESCRIPTION

The descriptions of the pins are listed in Table 3-1.

TABLE 3-1: PIN FUNCTION TABLE

ROTATED

Name PDIP SOIC Description

TSSOP

CS 1 1 3 Chip Select

CLK 2 2 4 Serial Data Clock

DI 3 3 5 Serial Data Input

DO 4 4 6 Serial Data Output

VSS 5 5 7 Ground

ORG 6 6 8 Memory Configuration

NU 7 7 1 Not Utilized

Vcc 8 8 2 +1.8V to 5.5V Power Supply

3.1 Chip Select (CS) Note: CS must go low between consecutive

A high level selects the device. A low level deselects instructions.

the device and forces it into Standby mode. However, a

programming cycle which is already initiated and/or in 3.3 Data In (DI)

progress will be completed, regardless of the CS input

Data In is used to clock in a Start bit, opcode, address

signal. If CS is brought low during a program cycle, the

and data synchronously with the CLK input.

device will go into Standby mode as soon as the

programming cycle is completed.

3.4 Data Out (DO)

CS must be low for 250 ns minimum (TCSL) between

consecutive instructions. If CS is low, the internal Data Out is used in the Read mode to output data syn-

control logic is held in a Reset status. chronously with the CLK input (TPD after the positive

edge of CLK).

3.2 Serial Clock (CLK) This pin also provides Ready/Busy status information

during erase and write cycles. Ready/Busy status infor-

The serial clock is used to synchronize the communica-

mation is available on the DO pin if CS is brought high

tion between a master device and the 93LC46/56/66.

after being low for minimum chip select low time (TCSL)

Opcode, address and data bits are clocked in on the

and an erase or write operation has been initiated.

positive edge of CLK. Data bits are also clocked out on

the positive edge of CLK. The Status signal is not available on DO, if CS is held

low or high during the entire write or erase cycle. In all

CLK can be stopped anywhere in the transmission

other cases DO is in the High-Z mode. If status is

sequence (at high or low level) and can be continued

checked after the write/erase cycle, a pull-up resistor

anytime with respect to clock high time (TCKH) and

on DO is required to read the Ready signal.

clock low time (TCKL). This gives the controlling master

freedom in preparing opcode, address and data.

3.5 Organization (ORG)

CLK is a “don't care” if CS is low (device deselected). If

CS is high, but Start condition has not been detected, When ORG is connected to VCC, the (x16) memory

any number of clock cycles can be received by the organization is selected. When ORG is tied to VSS, the

device without changing its status (i.e., waiting for Start (x8) memory organization is selected. ORG can only be

condition). floated for clock speeds of 1 MHz or less for the (x16)

CLK cycles are not required during the self-timed write memory organization. For clock speeds greater than

(i.e., auto erase/write) cycle. 1 MHz, ORG must be tied to VCC or VSS.

After detection of a Start condition the specified number

of clock cycles (respectively low-to-high transitions of

CLK) must be provided. These clock cycles are required

to clock in all required opcode, address and data bits

before an instruction is executed (see instruction set

truth table). CLK and DI then become “don't care” inputs

waiting for a new Start condition to be detected.

DS21712B-page 10 2004 Microchip Technology Inc.

93LC46/56/66

4.0 PACKAGING INFORMATION

4.1 Package Marking Information

8-Lead PDIP (300 mil) Example:

XXXXXXXX 93LC46

XXXXXNNN I/PNNN

YYWW YYWW

8-Lead SOIC (150 mil) Example:

XXXXXXXX 93LC46

XXXXYYWW I/SNYYWW

NNN NNN

8-Lead Rotated SOIC (150 mil) Example:

XXXXXXXX 93LC46X

XXXXYYWW I/SNYYWW

NNN NNN

Legend: XX...X Customer specific information*

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line thus limiting the number of available characters

for customer specific information.

* Standard OTP marking consists of Microchip part number, year code, week code, and traceability code.

2004 Microchip Technology Inc. DS21712B-page 11

93LC46/56/66

8-Lead Plastic Dual In-line (P) – 300 mil (PDIP)

E1

n 1

A A2

L

c

A1

β B1

p

eB B

Units INCHES* MILLIMETERS

Dimension Limits MIN NOM MAX MIN NOM MAX

Number of Pins n 8 8

Pitch p .100 2.54

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness A2 .115 .130 .145 2.92 3.30 3.68

Base to Seating Plane A1 .015 0.38

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width E1 .240 .250 .260 6.10 6.35 6.60

Overall Length D .360 .373 .385 9.14 9.46 9.78

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness c .008 .012 .015 0.20 0.29 0.38

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing § eB .310 .370 .430 7.87 9.40 10.92

Mold Draft Angle Top α 5 10 15 5 10 15

Mold Draft Angle Bottom β 5 10 15 5 10 15

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-018

DS21712B-page 12 2004 Microchip Technology Inc.

93LC46/56/66

8-Lead Plastic Small Outline (SN) – Narrow, 150 mil (SOIC)

E1

D

2

B n 1

h α

45×

c

A A2

f

β L A1

Units INCHES* MILLIMETERS

Dimension Limits MIN NOM MAX MIN NOM MAX

Number of Pins n 8 8

Pitch p .050 1.27

Overall Height A .053 .061 .069 1.35 1.55 1.75

Molded Package Thickness A2 .052 .056 .061 1.32 1.42 1.55

Standoff § A1 .004 .007 .010 0.10 0.18 0.25

Overall Width E .228 .237 .244 5.79 6.02 6.20

Molded Package Width E1 .146 .154 .157 3.71 3.91 3.99

Overall Length D .189 .193 .197 4.80 4.90 5.00

Chamfer Distance h .010 .015 .020 0.25 0.38 0.51

Foot Length L .019 .025 .030 0.48 0.62 0.76

Foot Angle f 0 4 8 0 4 8

Lead Thickness c .008 .009 .010 0.20 0.23 0.25

Lead Width B .013 .017 .020 0.33 0.42 0.51

Mold Draft Angle Top α 0 12 15 0 12 15

Mold Draft Angle Bottom β 0 12 15 0 12 15

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-012

Drawing No. C04-057

2004 Microchip Technology Inc. DS21712B-page 13

93LC46/56/66

APPENDIX A: REVISION HISTORY

Revision B

Added note to page 1 header (Not recommended for

new designs).

Updated document format.

DS21712B-page 14 2004 Microchip Technology Inc.

93LC46/56/66

ON-LINE SUPPORT SYSTEMS INFORMATION AND

Microchip provides on-line support on the Microchip UPGRADE HOT LINE

World Wide Web site. The Systems Information and Upgrade Line provides

The web site is used by Microchip as a means to make system users a listing of the latest versions of all of

files and information easily available to customers. To Microchip's development systems software products.

view the site, the user must have access to the Internet Plus, this line provides information on how customers

and a web browser, such as Netscape® or Microsoft® can receive the most current upgrade kits. The Hot Line

Internet Explorer. Files are also available for FTP Numbers are:

download from our FTP site. 1-800-755-2345 for U.S. and most of Canada, and

1-480-792-7302 for the rest of the world.

Connecting to the Microchip Internet

Web Site 042003

The Microchip web site is available at the following

URL:

www.microchip.com

The file transfer site is available by using an FTP

service to connect to:

ftp://ftp.microchip.com

The web site and file transfer site provide a variety of

services. Users may download files for the latest

Development Tools, Data Sheets, Application Notes,

User's Guides, Articles and Sample Programs. A vari-

ety of Microchip specific business information is also

available, including listings of Microchip sales offices,

distributors and factory representatives. Other data

available for consideration is:

• Latest Microchip Press Releases

• Technical Support Section with Frequently Asked

Questions

• Design Tips

• Device Errata

• Job Postings

• Microchip Consultant Program Member Listing

• Links to other useful web sites related to

Microchip Products

• Conferences for products, Development Systems,

technical information and more

• Listing of seminars and events

2004 Microchip Technology Inc. DS21712B-page 15

93LC46/56/66

READER RESPONSE

It is our intention to provide you with the best documentation possible to ensure successful use of your Microchip prod-

uct. If you wish to provide your comments on organization, clarity, subject matter, and ways in which our documentation

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this document.

To: Technical Publications Manager Total Pages Sent ________

RE: Reader Response

From: Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________ FAX: (______) _________ - _________

Application (optional):

Would you like a reply? Y N

Device: 93LC46/56/66 Literature Number: DS21712B

Questions:

1. What are the best features of this document?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this document easy to follow? If not, why?

4. What additions to the document do you think would enhance the structure and subject?

5. What deletions from the document could be made without affecting the overall usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

DS21712B-page 16 2004 Microchip Technology Inc.

93LC46/56/66

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. X /XX XXX

Examples:

Device Temperature Package Pattern a) 93LC46-I/P: 1K, 128x8 or 64x16 Serial

Range EEPROM, PDIP package

b) 93LC46-I/SN: 1K, 128x8 or 64x16 Serial

EEPROM, SOIC package

Device 93LC46: 1K 2.5V Microwire Serial EEPROM

c) 93LC46T-I/SN: 1K, 128x8 or 64x16

93LC46X: 1K 2.5V Microwire Serial EEPROM in

Serial EEPROM, SOIC package, tape

alternate pinouts (SN package only)

and reel

93LC46T: 1K 2.5V Microwire Serial EEPROM

d) 93LC46X-I/SN: 1K, 128x8 or 64x16

(Tape and Reel)

Serial EEPROM, Rotated SOIC package

93LC46XT: 1K 2.5V Microwire Serial EEPROM

(Tape and Reel) e) 93LC56-I/P: 2K, 256x8 or 128x16 Serial

93LC56: 2K 2.5V Microwire Serial EEPROM EEPROM, PDIP package

93LC56X: 2K 2.5V Microwire Serial EEPROM in f) 93LC56-I/SN: 2K, 256x8 or 128x16

alternate pinouts (SN package only) Serial EEPROM, SOIC package

93LC56T: 2K 2.5V Microwire Serial EEPROM g) 93LC56T-I/SN: 2K, 256x8 or 128x16

(Tape and Reel) Serial EEPROM, SOIC package, tape

93LC56XT:2K 2.5V Microwire Serial EEPROM and reel

(Tape and Reel) h) 93LC56X-I/SN: 2K, 256x8 or 128x16

93LC66: 4K 2.5V Microwire Serial EEPROM Serial EEPROM, Rotated SOIC package

93LC66X: 4K 2.5V Microwire Serial EEPROM in i) 93LC66-I/P: 4K, 512x8 or 256x16 Serial

alternate pinouts (SN package only) EEPROM, PDIP package

93LC66T: 4K 2.5V Microwire Serial EEPROM

j) 93LC66-I/SN: 4K, 512x8 or 256x16

(Tape and Reel)

Serial EEPROM, SOIC package

93LC66XT: 4K 2.5V Microwire Serial EEPROM

(Tape and Reel) k) 93LC66T-I/SN: 4K, 512x8 or 256x16

Serial EEPROM, SOIC package, tape

and reel

Temperature I = -40°C to +85°C l) 93LC66X-I/SN: 4K, 512x8 or 256x16

Range Serial EEPROM, Rotated SOIC package

Package P = Plastic DIP (300 mil body), 8-lead

SN = Plastic SOIC (150 mil body), 8-lead

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and

recommended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (480) 792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

2004 Microchip Technology Inc. DS21712B-page 17

93LC46/56/66

NOTES:

DS21712B-page 18 2004 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip’s Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break Microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device Trademarks

applications and the like is intended through suggestion only

The Microchip name and logo, the Microchip logo, Accuron,

and may be superseded by updates. It is your responsibility to

dsPIC, KEELOQ, microID, MPLAB, PIC, PICmicro, PICSTART,

ensure that your application meets with your specifications.

PRO MATE, PowerSmart, rfPIC, and SmartShunt are

No representation or warranty is given and no liability is

registered trademarks of Microchip Technology Incorporated

assumed by Microchip Technology Incorporated with respect

in the U.S.A. and other countries.

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such AmpLab, FilterLab, MXDEV, MXLAB, PICMASTER, SEEVAL,

use or otherwise. Use of Microchip’s products as critical SmartSensor and The Embedded Control Solutions Company

components in life support systems is not authorized except are registered trademarks of Microchip Technology

with express written approval by Microchip. No licenses are Incorporated in the U.S.A.

conveyed, implicitly or otherwise, under any intellectual Analog-for-the-Digital Age, Application Maestro, dsPICDEM,

property rights. dsPICDEM.net, dsPICworks, ECAN, ECONOMONITOR,

FanSense, FlexROM, fuzzyLAB, In-Circuit Serial

Programming, ICSP, ICEPIC, Migratable Memory, MPASM,

MPLIB, MPLINK, MPSIM, PICkit, PICDEM, PICDEM.net,

PICLAB, PICtail, PowerCal, PowerInfo, PowerMate,

PowerTool, rfLAB, rfPICDEM, Select Mode, Smart Serial,

SmartTel and Total Endurance are trademarks of Microchip

Technology Incorporated in the U.S.A. and other countries.

SQTP is a service mark of Microchip Technology Incorporated

in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2004, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in

October 2003. The Company’s quality system processes and

procedures are for its PICmicro® 8-bit MCUs, KEELOQ® code hopping

devices, Serial EEPROMs, microperipherals, nonvolatile memory and

analog products. In addition, Microchip’s quality system for the design

and manufacture of development systems is ISO 9001:2000 certified.

2004 Microchip Technology Inc. DS21712B-page 19

WORLDWIDE SALES AND SERVICE

AMERICAS China - Beijing Singapore

Unit 706B 200 Middle Road

Corporate Office

Wan Tai Bei Hai Bldg. #07-02 Prime Centre

2355 West Chandler Blvd.

No. 6 Chaoyangmen Bei Str. Singapore, 188980

Chandler, AZ 85224-6199

Beijing, 100027, China Tel: 65-6334-8870 Fax: 65-6334-8850

Tel: 480-792-7200

Tel: 86-10-85282100 Taiwan

Fax: 480-792-7277

Fax: 86-10-85282104 Kaohsiung Branch

Technical Support: 480-792-7627

Web Address: www.microchip.com China - Chengdu 30F - 1 No. 8

Rm. 2401-2402, 24th Floor, Min Chuan 2nd Road

Atlanta Ming Xing Financial Tower Kaohsiung 806, Taiwan

3780 Mansell Road, Suite 130 No. 88 TIDU Street Tel: 886-7-536-4816

Alpharetta, GA 30022 Chengdu 610016, China Fax: 886-7-536-4817

Tel: 770-640-0034 Tel: 86-28-86766200 Taiwan

Fax: 770-640-0307 Fax: 86-28-86766599 Taiwan Branch

Boston China - Fuzhou 11F-3, No. 207

2 Lan Drive, Suite 120 Unit 28F, World Trade Plaza Tung Hua North Road

Westford, MA 01886 No. 71 Wusi Road Taipei, 105, Taiwan

Tel: 978-692-3848 Fuzhou 350001, China Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

Fax: 978-692-3821 Tel: 86-591-7503506 Taiwan

Chicago Fax: 86-591-7503521 Taiwan Branch

333 Pierce Road, Suite 180 China - Hong Kong SAR 13F-3, No. 295, Sec. 2, Kung Fu Road

Itasca, IL 60143 Unit 901-6, Tower 2, Metroplaza Hsinchu City 300, Taiwan

Tel: 630-285-0071 223 Hing Fong Road Tel: 886-3-572-9526

Fax: 630-285-0075 Kwai Fong, N.T., Hong Kong Fax: 886-3-572-6459

Dallas Tel: 852-2401-1200

Fax: 852-2401-3431 EUROPE

16200 Addison Road, Suite 255

Addison Plaza China - Shanghai Austria

Addison, TX 75001 Room 701, Bldg. B Durisolstrasse 2

Tel: 972-818-7423 Far East International Plaza A-4600 Wels

Fax: 972-818-2924 No. 317 Xian Xia Road Austria

Shanghai, 200051 Tel: 43-7242-2244-399

Detroit Tel: 86-21-6275-5700 Fax: 43-7242-2244-393

Tri-Atria Office Building Fax: 86-21-6275-5060 Denmark

32255 Northwestern Highway, Suite 190 Regus Business Centre

Farmington Hills, MI 48334 China - Shenzhen

Rm. 1812, 18/F, Building A, United Plaza Lautrup hoj 1-3

Tel: 248-538-2250 Ballerup DK-2750 Denmark

Fax: 248-538-2260 No. 5022 Binhe Road, Futian District

Shenzhen 518033, China Tel: 45-4420-9895 Fax: 45-4420-9910

Kokomo Tel: 86-755-82901380 France

2767 S. Albright Road Fax: 86-755-8295-1393 Parc d’Activite du Moulin de Massy

Kokomo, IN 46902 China - Shunde 43 Rue du Saule Trapu

Tel: 765-864-8360 Batiment A - ler Etage

Room 401, Hongjian Building, No. 2

Fax: 765-864-8387 91300 Massy, France

Fengxiangnan Road, Ronggui Town, Shunde

Los Angeles District, Foshan City, Guangdong 528303, China Tel: 33-1-69-53-63-20

Tel: 86-757-28395507 Fax: 86-757-28395571 Fax: 33-1-69-30-90-79

25950 Acero St., Suite 200

Mission Viejo, CA 92691 China - Qingdao Germany

Tel: 949-462-9523 Steinheilstrasse 10

Rm. B505A, Fullhope Plaza,

Fax: 949-462-9608 D-85737 Ismaning, Germany

No. 12 Hong Kong Central Rd.

Tel: 49-89-627-144-0

San Jose Qingdao 266071, China

Fax: 49-89-627-144-44

1300 Terra Bella Avenue Tel: 86-532-5027355 Fax: 86-532-5027205

Italy

Mountain View, CA 94043 India

Via Salvatore Quasimodo, 12

Tel: 650-215-1444 Divyasree Chambers

20025 Legnano (MI)

Fax: 650-961-0286 1 Floor, Wing A (A3/A4)

Milan, Italy

No. 11, O’Shaugnessey Road

Toronto Tel: 39-0331-742611

Bangalore, 560 025, India

6285 Northam Drive, Suite 108 Fax: 39-0331-466781

Tel: 91-80-22290061 Fax: 91-80-22290062

Mississauga, Ontario L4V 1X5, Canada Netherlands

Japan

Tel: 905-673-0699 Waegenburghtplein 4

Fax: 905-673-6509 Yusen Shin Yokohama Building 10F

NL-5152 JR, Drunen, Netherlands

3-17-2, Shin Yokohama, Kohoku-ku,

Tel: 31-416-690399

Yokohama, Kanagawa, 222-0033, Japan

ASIA/PACIFIC Fax: 31-416-690340

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

United Kingdom

Australia Korea

505 Eskdale Road

Microchip Technology Australia Pty Ltd 168-1, Youngbo Bldg. 3 Floor

Winnersh Triangle

Unit 32 41 Rawson Street Samsung-Dong, Kangnam-Ku

Wokingham

Epping 2121, NSW Seoul, Korea 135-882

Berkshire, England RG41 5TU

Sydney, Australia Tel: 82-2-554-7200 Fax: 82-2-558-5932 or

Tel: 44-118-921-5869

Tel: 61-2-9868-6733 82-2-558-5934

Fax: 44-118-921-5820

Fax: 61-2-9868-6755

07/12/04

DS21712B-page 20 2004 Microchip Technology Inc.

Das könnte Ihnen auch gefallen

- 93C86Dokument20 Seiten93C86cgmannerheimNoch keine Bewertungen

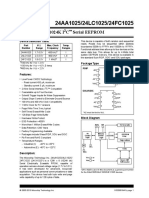

- 8K/16K 5.0V Microwire Serial EEPROM: Features: Package TypesDokument20 Seiten8K/16K 5.0V Microwire Serial EEPROM: Features: Package Typesfarhood ranjbarkhanghahNoch keine Bewertungen

- 93LC66A/B: 4K 2.5V Microwire Serial EEPROMDokument12 Seiten93LC66A/B: 4K 2.5V Microwire Serial EEPROMinsomnium86Noch keine Bewertungen

- 24AA64/24LC64/24FC64: 64K I C Serial EEPROMDokument28 Seiten24AA64/24LC64/24FC64: 64K I C Serial EEPROMJuan Luis Pineda GonzálezNoch keine Bewertungen

- 2K 5.0V Automotive Temperature Microwire Serial EEPROM: Features Package TypeDokument12 Seiten2K 5.0V Automotive Temperature Microwire Serial EEPROM: Features Package TypeDanielNoch keine Bewertungen

- AT93CXXDokument15 SeitenAT93CXXcallkalaiNoch keine Bewertungen

- Data SheetDokument12 SeitenData SheetPrasetyo Muhammad SaktiNoch keine Bewertungen

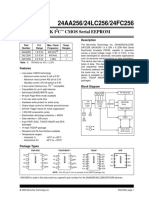

- 256 Bit/1K 5.0V CMOS Serial EEPROM: Features Package TypeDokument8 Seiten256 Bit/1K 5.0V CMOS Serial EEPROM: Features Package TypeAgustin AndrokaitesNoch keine Bewertungen

- 24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMDokument34 Seiten24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMKhalid BenaribaNoch keine Bewertungen

- 1K 5.0V Microwire Serial EEPROM: Features Block DiagramDokument12 Seiten1K 5.0V Microwire Serial EEPROM: Features Block Diagraminsomnium86Noch keine Bewertungen

- 93 LC 46 BDokument12 Seiten93 LC 46 Bwabp_23Noch keine Bewertungen

- 24LC21 1K 2.5V Dual Mode I2C Serial EEPROMDokument12 Seiten24LC21 1K 2.5V Dual Mode I2C Serial EEPROMVictor TruccoNoch keine Bewertungen

- 24l1026i Memoria EEPROM 1024kDokument28 Seiten24l1026i Memoria EEPROM 1024kMarta_d_eNoch keine Bewertungen

- 93C66Dokument12 Seiten93C66Alex AlvarezNoch keine Bewertungen

- 24C32Dokument12 Seiten24C32SilviuCocoloșNoch keine Bewertungen

- 24AA02/24LC02B: 2KI C Serial EEPROMDokument32 Seiten24AA02/24LC02B: 2KI C Serial EEPROMhanifNoch keine Bewertungen

- 24LC04B PDFDokument22 Seiten24LC04B PDFEddy RosarioNoch keine Bewertungen

- 24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-ProtectDokument24 Seiten24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-Protecta4rfanNoch keine Bewertungen

- 24AA16/24LC16B: 16K I C Serial EEPROMDokument25 Seiten24AA16/24LC16B: 16K I C Serial EEPROMDaniel VásquezNoch keine Bewertungen

- Ic PDFDokument36 SeitenIc PDFdharamNoch keine Bewertungen

- 24AA02/24LC02B: 2KI C Serial EEPROMDokument24 Seiten24AA02/24LC02B: 2KI C Serial EEPROMMayk OzNoch keine Bewertungen

- Bus Serial EEPROMDokument12 SeitenBus Serial EEPROMMatiasNoch keine Bewertungen

- 24FC1025 EepromDokument28 Seiten24FC1025 EepromAnirudh ReddyNoch keine Bewertungen

- 24aa512 Mic PDFDokument28 Seiten24aa512 Mic PDFkt2018Noch keine Bewertungen

- 24aa515, 24LC515, 24FC515Dokument20 Seiten24aa515, 24LC515, 24FC515dorudNoch keine Bewertungen

- 32K 5.0V I C Smart Serial EEPROM: Features Package TypesDokument12 Seiten32K 5.0V I C Smart Serial EEPROM: Features Package TypesRamon LopezNoch keine Bewertungen

- 24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738Dokument32 Seiten24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738İbrahim DemircioğluNoch keine Bewertungen

- Datasheet PDFDokument26 SeitenDatasheet PDFNicoli LourençoNoch keine Bewertungen

- 8K/16K 5.0V Microwire Serial EEPROM: FeaturesDokument12 Seiten8K/16K 5.0V Microwire Serial EEPROM: FeaturesStephensonNoch keine Bewertungen

- I2c EEPROM 24xx256 DsDokument28 SeitenI2c EEPROM 24xx256 DsRizwan AmirNoch keine Bewertungen

- 24 LC 256Dokument38 Seiten24 LC 256johnNoch keine Bewertungen

- 24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMDokument29 Seiten24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMSudhagarSubbiyanNoch keine Bewertungen

- Three-Wire Serial EEPROM: 1. FeaturesDokument17 SeitenThree-Wire Serial EEPROM: 1. FeatureskppsadiNoch keine Bewertungen

- 21711c PDFDokument24 Seiten21711c PDFAbdessamad EladakNoch keine Bewertungen

- 22131c PDFDokument24 Seiten22131c PDFAdilsonAmorimNoch keine Bewertungen

- 24aa08 - 24lc08 Eeprom PDFDokument40 Seiten24aa08 - 24lc08 Eeprom PDFEdgar DauzonNoch keine Bewertungen

- EEPROM 24LC256 - Microchip PDFDokument28 SeitenEEPROM 24LC256 - Microchip PDFValdir DerlannNoch keine Bewertungen

- 16K I C Serial EEPROM Extended (M) Operating Temperatures: Number V Range Max. Clock Frequency Temp. RangesDokument22 Seiten16K I C Serial EEPROM Extended (M) Operating Temperatures: Number V Range Max. Clock Frequency Temp. RangeshcarcaroNoch keine Bewertungen

- 24AA16 24LC16B 24FC16 16K I2C Serial EEPROM 20001703PDokument49 Seiten24AA16 24LC16B 24FC16 16K I2C Serial EEPROM 20001703Pmarko.jojicoo777Noch keine Bewertungen

- Three-Wire Automotive Temperature Serial Eeproms: 1. FeaturesDokument14 SeitenThree-Wire Automotive Temperature Serial Eeproms: 1. FeaturesJose MisselNoch keine Bewertungen

- 4 PDFDokument31 Seiten4 PDFAgus OrtizNoch keine Bewertungen

- MCP79410/MCP79411/MCP79412: I C™ Real-Time Clock/Calendar With EEPROM, SRAM, Unique ID and Battery SwitchoverDokument38 SeitenMCP79410/MCP79411/MCP79412: I C™ Real-Time Clock/Calendar With EEPROM, SRAM, Unique ID and Battery SwitchoverDaniel CortelettiNoch keine Bewertungen

- 2K Microwire Compatible Serial EEPROM: 93AA56A/B/C, 93LC56A/B/C, 93C56A/B/CDokument30 Seiten2K Microwire Compatible Serial EEPROM: 93AA56A/B/C, 93LC56A/B/C, 93C56A/B/CAndrea MartinezNoch keine Bewertungen

- 24Lc08B/16B Modules: 8K/16K I C Serial Eeproms in Iso MicromodulesDokument12 Seiten24Lc08B/16B Modules: 8K/16K I C Serial Eeproms in Iso MicromodulesarminNoch keine Bewertungen

- 24lc512 DatasheetDokument27 Seiten24lc512 DatasheetLeonardo QuevedoNoch keine Bewertungen

- 22122a.book - 11AA02E48T-I-TT-MicrochipDokument2 Seiten22122a.book - 11AA02E48T-I-TT-MicrochipIori CharaNoch keine Bewertungen

- En25qa64a EonDokument68 SeitenEn25qa64a Eongbjhasd344Noch keine Bewertungen

- 2-Wire Serial EEPROM Smart Card Module: FeaturesDokument12 Seiten2-Wire Serial EEPROM Smart Card Module: FeaturesMaikol DominguezNoch keine Bewertungen

- Datashet Etron TechDokument54 SeitenDatashet Etron TechAndres OrjuelaNoch keine Bewertungen

- 24C320-EP MicrochipTechnologyDokument12 Seiten24C320-EP MicrochipTechnologyMateus CorrêaNoch keine Bewertungen

- At25f512a 844895Dokument19 SeitenAt25f512a 844895mirage0706Noch keine Bewertungen

- 11aa02iud 1wire MicrochipDokument32 Seiten11aa02iud 1wire MicrochipManutenção eletrônicaNoch keine Bewertungen

- TMC93LC46Dokument15 SeitenTMC93LC46Agustin AndrokaitesNoch keine Bewertungen

- 24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMDokument45 Seiten24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMJuan Carlos CrespoNoch keine Bewertungen

- 32K 2.5V I C Serial EEPROM: Features Package TypesDokument12 Seiten32K 2.5V I C Serial EEPROM: Features Package Typesinsomnium86Noch keine Bewertungen

- 24LC08 PDFDokument30 Seiten24LC08 PDFJaime BarrancoNoch keine Bewertungen

- 32K 5.0V I C Serial EEPROM: Features Package TypesDokument12 Seiten32K 5.0V I C Serial EEPROM: Features Package Typesinsomnium86Noch keine Bewertungen

- Practical Digital Electronics for TechniciansVon EverandPractical Digital Electronics for TechniciansBewertung: 3 von 5 Sternen3/5 (1)

- Vdoc - Pub The Maple Handbook Maple V Release 3Dokument522 SeitenVdoc - Pub The Maple Handbook Maple V Release 3marceloNoch keine Bewertungen

- Intelligent Data Analysis (BooksRack - Net) PDFDokument431 SeitenIntelligent Data Analysis (BooksRack - Net) PDFleonor bungaNoch keine Bewertungen

- Lista Especial 31-08-2022Dokument36 SeitenLista Especial 31-08-2022Alejandra FerreroNoch keine Bewertungen

- ONEXAM Online Examination System Project SynopsisDokument4 SeitenONEXAM Online Examination System Project Synopsisbahubali king0% (1)

- CSEC Jan 2011 Paper 1Dokument8 SeitenCSEC Jan 2011 Paper 1R.D. KhanNoch keine Bewertungen

- MHW-N1964 Designing Healthcare Applications With NXPDokument111 SeitenMHW-N1964 Designing Healthcare Applications With NXPfrhuttonNoch keine Bewertungen

- Network Protocol Analyzer With Wireshark: March 2015Dokument18 SeitenNetwork Protocol Analyzer With Wireshark: March 2015Ziaul HaqueNoch keine Bewertungen

- DT-200 Bluewave2 Operators GuideDokument8 SeitenDT-200 Bluewave2 Operators GuideDragan KocijasevicNoch keine Bewertungen

- TM-3532 AVEVA Diagrams (14.1) Diagrams - PID Designer Rev 2.0Dokument208 SeitenTM-3532 AVEVA Diagrams (14.1) Diagrams - PID Designer Rev 2.0Adeniran Joshua100% (1)

- Mobile Print/Scan Guide For Brother Iprint&ScanDokument100 SeitenMobile Print/Scan Guide For Brother Iprint&ScanozarNoch keine Bewertungen

- Optimizing Cross-Dock Operations with Tabu SearchDokument7 SeitenOptimizing Cross-Dock Operations with Tabu Searchk5g83jg8hNoch keine Bewertungen

- IliosDokument883 SeitenIlioscolson_tksNoch keine Bewertungen

- d52541 PDFDokument37 Seitend52541 PDFskywalker crazyNoch keine Bewertungen

- Uws Threat Hunting 101 White Paper PDFDokument25 SeitenUws Threat Hunting 101 White Paper PDFJacob StamperNoch keine Bewertungen

- Color Iqc / Color Imatch Installation NotesDokument3 SeitenColor Iqc / Color Imatch Installation NotesSohel NomanNoch keine Bewertungen

- Robert Bosch Placement Pattern 2 - Freshers ChoiceDokument14 SeitenRobert Bosch Placement Pattern 2 - Freshers ChoicefresherschoiceNoch keine Bewertungen

- Apollo Roadmap and Test Plan For GTDDokument1 SeiteApollo Roadmap and Test Plan For GTDCristian GonzalezNoch keine Bewertungen

- Computational GeometryDokument5 SeitenComputational GeometryZvonko TNoch keine Bewertungen

- Weird Negative Float SituationsDokument15 SeitenWeird Negative Float SituationsSoham BanerjeeNoch keine Bewertungen

- Abandoned Cart Emails: A Data-Driven Guide To Recovering Lost SalesDokument37 SeitenAbandoned Cart Emails: A Data-Driven Guide To Recovering Lost SalesTochi Krishna AbhishekNoch keine Bewertungen

- 8.1 Mux 1Dokument6 Seiten8.1 Mux 1Maddy Trichy50% (2)

- JSE Certification 1 SyllabusDokument4 SeitenJSE Certification 1 SyllabusJohn P. GibsonNoch keine Bewertungen

- Timescaledb: SQL Made Scalable For Time-Series Data: 1 BackgroundDokument7 SeitenTimescaledb: SQL Made Scalable For Time-Series Data: 1 BackgroundpokechoNoch keine Bewertungen

- Mô Dem Quang TeleneticDokument2 SeitenMô Dem Quang TeleneticHongha ChauNoch keine Bewertungen

- RSA Archer 6.5 Platform User's Guide - 4Dokument182 SeitenRSA Archer 6.5 Platform User's Guide - 4veeshaalNoch keine Bewertungen

- Kyle Norris: Office Equipment: Handyman EquipmentDokument1 SeiteKyle Norris: Office Equipment: Handyman EquipmentElizabeth ThorntonNoch keine Bewertungen

- CAPTCHA - Seminar ReportDokument30 SeitenCAPTCHA - Seminar Reportbsbharath198767% (3)

- Syllabus Advanced Systemverilog TrainingDokument12 SeitenSyllabus Advanced Systemverilog TrainingSudhir SainiNoch keine Bewertungen

- Create your own Sony Xperia FTF firmware files using XperiFirm and FlashToolGuideDokument6 SeitenCreate your own Sony Xperia FTF firmware files using XperiFirm and FlashToolGuidemagexworldNoch keine Bewertungen

- Client-Server Technology, Practices of The Practical LayerDokument4 SeitenClient-Server Technology, Practices of The Practical LayerResearch ParkNoch keine Bewertungen