Beruflich Dokumente

Kultur Dokumente

Loctite Ea 9430-En

Hochgeladen von

Dan AyalaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Loctite Ea 9430-En

Hochgeladen von

Dan AyalaCopyright:

Verfügbare Formate

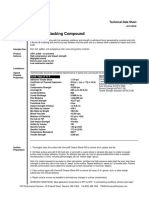

Product Description Sheet

LOCTITE® EA 9430

Known as

Hysol® Product 9430

August 2015

Description Shear Strength, ASTM D 1002 Cured 5 Days @ 77 oF

LOCTITE® EA 9430 is a modified epoxy adhesive that attains Test Temp oF Typical Value, psi

structural properties after room temperature cure. This two-part Degreased 77 3500

adhesive is formulated to give very high peel strength coupled Aluminum

with excellent shear strength. LOCTITE® EA 9430 bonds are FRP 77 1400

resistant to water, salt spray and many common industrial Bonderized Steel 77 2400

fluids. The tough, flexible nature of this adhesive makes it Mineral Filled PET 77 850

useful for bonding dissimilar substrates and for assemblies

requiring bondline thickness up to one-tenth inch. 30 Day Salt Spray 77 4000

30 Day @ 120 77 3700

oF/100% RH

Features

High peel and high shear strength

Room temperature cure

Peel Strength ASTM D 3167 Etched Aluminum, pli

Bonds variety of substrates

Long pot life 3 Days @ 77ºF 60

Excellent low temperature properties

GENERAL INFORMATION

This product is not recommended for use in pure oxygen

Typical Uncured Part A Part B Mixed and/or oxygen rich systems and should not be selected as

Properties a sealant for chlorine or other strong oxidizing materials.

Pot Life @ 77°F, 250 -- -- 50

grams mins For safe handling information on this product, consult the

Color Cream Clear Off White Material Safety Data Sheet, (MSDS).

Viscosity, cP 200,000 to 40 12,000

400,000

Specific Gravity 1.15 1.00 1.12 Application

Mix Ratio Mixing Combine Part A and Part B in the correct ratio and mix

By weight 100 23 -- thoroughly. THIS IS IMPORTANT! Heat buildup during or after

By volume 3.78 1 --

mixing is normal. Do not mix quantities greater than ten pounds

Density, lbs/Gal 9.64 8.35 9.3

(10 lb.), as excessive heat buildup can occur. Mixing smaller

quantities will minimize the heat buildup.

Applying Bonding surfaces should be clean and dry.

Typical Properties Typical Value

LOCTITE® EA 9430 can be applied with a spatula, brush or

Tensile Strength, psi, ASTM D 638 5300 dispensing machine. Once the adhesive is dispensed, the

Modulus, psi, ASTM D 638 380,000 bonded parts should be held in contact until the part has

Elongation, %, ASTM D 638 6.0 developed handling strength. Fixturing can be removed at this

Hardness, Shore D 75 point. Since full bond strength has not yet been attained, load

application should be small at this time.

Curing LOCTITE® EA 9430 will cure to ultimate properties in 5

Shear Strength, psi, ASTM D 1002 Etched Aluminum days at room temperature. Curing temperatures up to 180°F

Cure Schedule Test Temp oF Typical Value can be used to reduce cure time. For example, 1 hour at 180°F

o will give complete cure.

5 Days @ 77 F -67 5000

77 4700

140 1700 Cleanup It is important to remove excess adhesive from the

180 750 work area and application equipment before it hardens.

Denatured alcohol and many common solvents are suitable for

removing uncured adhesive. Consult with your supplier’s

information pertaining to the safe and proper use of solvents.

Product Description Sheet

LOCTITE® EA 9430

Known as

Hysol® Product 9430

August 2015

Storage In case Henkel would be nevertheless held liable, on whatever legal

Store product in unopened container in a cool dry location. ground, Henkel’s liability will in no event exceed the amount of the

Ideal conditions are within the range 8 to 21 degrees C (46 to concerned delivery.

70 degrees F) and are recommended for long term storage. In case products are delivered by Henkel Colombiana, S.A.S. the

Exposure to higher temperatures (greater than 28 degrees C) following disclaimer is applicable:

for prolonged periods should be avoided as extended exposure The information provided in this Technical Data Sheet (TDS) including

to warm conditions can adversely affect product properties. For the recommendations for use and application of the product are based

further specific shelf life information, contact your local on our knowledge and experience of the product as at the date of this

TDS. Henkel is not liable for the suitability of our product for the

Technical Service Center.

production processes and conditions in respect of which you use them,

as well as the intended applications and results. We strongly

Note recommend that you carry out your own prior trials to confirm such

The information provided in this Technical Data Sheet (TDS) including suitability of our product.

the recommendations for use and application of the product are based

on our knowledge and experience of the product as at the date of this

TDS. The product can have a variety of different applications as well as Any liability in respect of the information in the Technical Data Sheet or

differing application and working conditions in your environment that are any other written or oral recommendation(s) regarding the concerned

beyond our control. Henkel is, therefore, not liable for the suitability of product is excluded, except if otherwise explicitly agreed and except in

our product for the production processes and conditions in respect of relation to death or personal injury caused by our negligence and any

which you use them, as well as the intended applications and results. liability under any applicable mandatory product liability law.

We strongly recommend that you carry out your own prior trials to

confirm such suitability of our product. Trademark usage

Except as otherwise noted, all trademarks in this document are

Any liability in respect of the information in the Technical Data Sheet or trademarks of Henkel Corporation in the U.S. and elsewhere. ®

any other written or oral recommendation(s) regarding the concerned denotes a trademark registered in the U.S. Patent and Trademark

product is excluded, except if otherwise explicitly agreed and except in Office.

relation to death or personal injury caused by our negligence and any

liability under any applicable mandatory product liability law.

In case products are delivered by Henkel Corporation, Resin

Technology Group, Inc., or Henkel Canada, Inc.the following disclaimer

is applicable:

The data contained herein are furnished for information only and are

believed to be reliable. We cannot assume responsibility for the results

obtained by others over whose methods we have no control. It is the

user's responsibility to determine suitability for the user's purpose of

any production methods mentioned herein and to adopt such

precautions as may be advisable for the protection of property and of

persons against any hazards that may be involved in the handling and

use thereof. In light of the foregoing, Henkel Corporation specifically

disclaims all warranties expressed or implied, including warranties

of merchantability or fitness for a particular purpose, arising from

sale or use of Henkel Corporation’s products. Henkel Corporation

specifically disclaims any liability for consequential or incidental

damages of any kind, including lost profits. The discussion herein of

various processes or compositions is not to be interpreted as

representation that they are free from domination of patents owned by

others or as a license under any Henkel Corporation patents that may

cover such processes or compositions. We recommend that each

prospective user test his proposed application before repetitive

use, using this data as a guide. This product may be covered by one or

more United States or foreign patents or patent applications.

In case products are delivered by Henkel Belgium NV, Henkel

Electronic Materials NV, Henkel Nederland BV, Henkel Technologies

France SAS and Henkel France SA please additionally note the

following:

Das könnte Ihnen auch gefallen

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Von EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965Noch keine Bewertungen

- Ea 9340-EnDokument2 SeitenEa 9340-EnpokleNoch keine Bewertungen

- Technical Data Sheet - Loctite 596Dokument2 SeitenTechnical Data Sheet - Loctite 596VIVEK UPADHYAYNoch keine Bewertungen

- 2427 2428 Slow Infusion Epoxy Kit Tds 04 - 27 - 2020Dokument2 Seiten2427 2428 Slow Infusion Epoxy Kit Tds 04 - 27 - 2020darwin rolonNoch keine Bewertungen

- HQ 800 AF 45-gb Rev 10Dokument1 SeiteHQ 800 AF 45-gb Rev 10Marjan ArhNoch keine Bewertungen

- Irathane 155 Data SheetDokument2 SeitenIrathane 155 Data SheetSaboor HaiderNoch keine Bewertungen

- Loctite Ea 934na Aero (Known As Hysol Ea 934na) - TdsDokument5 SeitenLoctite Ea 934na Aero (Known As Hysol Ea 934na) - TdspokleNoch keine Bewertungen

- ASTERITE® LAR Embedment Technical-Data-Sheet.1569415928Dokument2 SeitenASTERITE® LAR Embedment Technical-Data-Sheet.1569415928Mamoon ShahidNoch keine Bewertungen

- Hcs2407 141 Henkel Resin Kit Loctite Ea 9394 AeroDokument6 SeitenHcs2407 141 Henkel Resin Kit Loctite Ea 9394 AeroTimmyNoch keine Bewertungen

- High Performance Backing Compound: Technical Data SheetDokument2 SeitenHigh Performance Backing Compound: Technical Data SheetNiku SamarthNoch keine Bewertungen

- Shell Gadus S5 T460: Previously Shell Stamina HdsDokument1 SeiteShell Gadus S5 T460: Previously Shell Stamina HdsShova MuhammadNoch keine Bewertungen

- Arakril Ak 840Dokument2 SeitenArakril Ak 840decopinturas rdNoch keine Bewertungen

- 4010 TDS EnglishDokument1 Seite4010 TDS EnglishJose Luis Ramirez RamirezNoch keine Bewertungen

- Ancamine 2739 TdsDokument8 SeitenAncamine 2739 Tdsnc5r8fkp6zNoch keine Bewertungen

- Besoflex - TX 000Dokument2 SeitenBesoflex - TX 000TRIFLOW INDIANoch keine Bewertungen

- Steel PuttyDokument1 SeiteSteel PuttySiva SubramaniNoch keine Bewertungen

- Jet-Lube Deacon PFPE GREASEDokument2 SeitenJet-Lube Deacon PFPE GREASEDon HowardNoch keine Bewertungen

- Atlas Copco Roto Inject Fluid JECDokument2 SeitenAtlas Copco Roto Inject Fluid JECアラファト イスラム教Noch keine Bewertungen

- Acronal 7079 PI EDADokument3 SeitenAcronal 7079 PI EDAGokul Basker100% (2)

- Lubricants: Unoba EPDokument2 SeitenLubricants: Unoba EPQC RegianNoch keine Bewertungen

- PCRS9309-QT TDSDokument5 SeitenPCRS9309-QT TDSDaniele CatacchioNoch keine Bewertungen

- TDS Acronal 7079 PDFDokument3 SeitenTDS Acronal 7079 PDFWahid Karol100% (1)

- Molylube Open Gear & Rope LubricantDokument2 SeitenMolylube Open Gear & Rope LubricantdhowardjNoch keine Bewertungen

- Interpon D1000 Sable TDSDokument2 SeitenInterpon D1000 Sable TDSRashid MohammedNoch keine Bewertungen

- ADCOTE 548-81R + Coreactant F (TDS)Dokument4 SeitenADCOTE 548-81R + Coreactant F (TDS)Wasif AzimNoch keine Bewertungen

- LOCTITE SI 5927 RED en - GLDokument2 SeitenLOCTITE SI 5927 RED en - GLOmer IkhlasNoch keine Bewertungen

- Carboguard 60 LH PDSDokument4 SeitenCarboguard 60 LH PDSRicardo SantosNoch keine Bewertungen

- Data Sheet 2935016922 - RotoSyntheticFluid - ULTRA - enDokument2 SeitenData Sheet 2935016922 - RotoSyntheticFluid - ULTRA - enMohamed Abd-alfattah100% (1)

- Deurheo 2810Dokument1 SeiteDeurheo 2810omerNoch keine Bewertungen

- Evo StikDokument1 SeiteEvo StikkkmajuteguhNoch keine Bewertungen

- TDS - Glenium Ace 340Dokument3 SeitenTDS - Glenium Ace 340Alexi ALfred H. TagoNoch keine Bewertungen

- TL 280 Spray Flake Glass Vinyl Ester Lining 6 14 22Dokument5 SeitenTL 280 Spray Flake Glass Vinyl Ester Lining 6 14 22ant1Noch keine Bewertungen

- Synolac 2700 WD 70Dokument2 SeitenSynolac 2700 WD 70I Love MusicNoch keine Bewertungen

- Roto Inject Fluid NDURANCE enDokument2 SeitenRoto Inject Fluid NDURANCE enMartín BaezaNoch keine Bewertungen

- Roto Synthetic Fluid ULTRA: High Quality Synthetic Oil For Demanding ApplicationsDokument2 SeitenRoto Synthetic Fluid ULTRA: High Quality Synthetic Oil For Demanding ApplicationsJoao BotasNoch keine Bewertungen

- Compressor Roto InjectDokument2 SeitenCompressor Roto InjectJeremias UtreraNoch keine Bewertungen

- Masterflow 400 TdsDokument3 SeitenMasterflow 400 TdsverNoch keine Bewertungen

- Sapphire Spray Grease - GBDokument2 SeitenSapphire Spray Grease - GBdiegogsouzzaNoch keine Bewertungen

- Trelleborg Datasheet EP661 A4 Jan16 Lo ResDokument2 SeitenTrelleborg Datasheet EP661 A4 Jan16 Lo ResMert KıraçNoch keine Bewertungen

- BASF MasterSeal NP 472Dokument2 SeitenBASF MasterSeal NP 472HJNoch keine Bewertungen

- Anquamine 728: Curing AgentDokument4 SeitenAnquamine 728: Curing AgentGreg PanganNoch keine Bewertungen

- Fire Stop Sealant - Specseal BrandDokument12 SeitenFire Stop Sealant - Specseal BrandAndrei SabaterNoch keine Bewertungen

- Aqualink 300F Ver2Dokument2 SeitenAqualink 300F Ver2Georgina SuleNoch keine Bewertungen

- Loctite Ea 9396 AeroDokument4 SeitenLoctite Ea 9396 AerobenNoch keine Bewertungen

- TL-280HT TDS 062120Dokument4 SeitenTL-280HT TDS 062120AlthafNoch keine Bewertungen

- Synolac 4100: Product Application DetailsDokument2 SeitenSynolac 4100: Product Application DetailsmonrmNoch keine Bewertungen

- Royalthane 450GLDokument2 SeitenRoyalthane 450GLSyed FaridNoch keine Bewertungen

- Henk Loctite Superflex Red TdsDokument2 SeitenHenk Loctite Superflex Red TdsMariano DomenechNoch keine Bewertungen

- Technical Data: P/S 870 Class A Corrosion Inhibitive SealantDokument2 SeitenTechnical Data: P/S 870 Class A Corrosion Inhibitive SealantKentNoch keine Bewertungen

- TDS Primer-Strenex-220Dokument3 SeitenTDS Primer-Strenex-220KOLOR MEXNoch keine Bewertungen

- Valplex EP NLGI 2: Specifications and Approvals ApplicationsDokument2 SeitenValplex EP NLGI 2: Specifications and Approvals Applicationsdiah ayuNoch keine Bewertungen

- Cepsa Arga SyntDokument1 SeiteCepsa Arga SyntRamonNoch keine Bewertungen

- Interfine 979: Polysiloxane FinishDokument4 SeitenInterfine 979: Polysiloxane FinishshnauserNoch keine Bewertungen

- Properties Foster S.M. Adhesive: Product Data SheetDokument2 SeitenProperties Foster S.M. Adhesive: Product Data SheetAamer Abdul MajeedNoch keine Bewertungen

- Loctite Ea 9395 Aero: Epoxy Paste AdhesiveDokument5 SeitenLoctite Ea 9395 Aero: Epoxy Paste AdhesiveFernando GarzonNoch keine Bewertungen

- Variable Resistive Inks (Vri) : Technical Data SheetDokument2 SeitenVariable Resistive Inks (Vri) : Technical Data SheetDebidas KunduNoch keine Bewertungen

- Irgaflo 6300vDokument3 SeitenIrgaflo 6300vmgamal1080Noch keine Bewertungen

- RS Ultra Latest MSDSDokument2 SeitenRS Ultra Latest MSDSRamraj EnterprisesNoch keine Bewertungen

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Creative Fabrications Cleans Julio Penrose Fountain With Ecoquip 2 Blasting EquipmentDokument3 SeitenCreative Fabrications Cleans Julio Penrose Fountain With Ecoquip 2 Blasting EquipmentDan AyalaNoch keine Bewertungen

- Road Lazer™Dokument24 SeitenRoad Lazer™Dan AyalaNoch keine Bewertungen

- 103 01a 2015 SepDokument2 Seiten103 01a 2015 SepDan AyalaNoch keine Bewertungen

- ONG Buyer's GuideDokument108 SeitenONG Buyer's GuideDan AyalaNoch keine Bewertungen

- Python® PDFDokument4 SeitenPython® PDFDan AyalaNoch keine Bewertungen

- Color Change ValvesDokument2 SeitenColor Change ValvesDan AyalaNoch keine Bewertungen

- Loctite e 20hp enDokument3 SeitenLoctite e 20hp enDan AyalaNoch keine Bewertungen

- AirPro™ PDFDokument4 SeitenAirPro™ PDFDan AyalaNoch keine Bewertungen

- Loctite Bonding Acrylic Adhesives PDFDokument4 SeitenLoctite Bonding Acrylic Adhesives PDFDan AyalaNoch keine Bewertungen

- Loctite Bonding Epoxy & Uretane AdhesivesDokument6 SeitenLoctite Bonding Epoxy & Uretane AdhesivesDan AyalaNoch keine Bewertungen

- Loctite Aa H8500-EnDokument4 SeitenLoctite Aa H8500-EnDan AyalaNoch keine Bewertungen

- Linex XS350Dokument4 SeitenLinex XS350Dan AyalaNoch keine Bewertungen

- Loctite Aa V5004-EnDokument4 SeitenLoctite Aa V5004-EnDan AyalaNoch keine Bewertungen

- 3M™ Scotch-Weld™ Structural AdhesivesDokument10 Seiten3M™ Scotch-Weld™ Structural AdhesivesDan AyalaNoch keine Bewertungen

- Aa 3295-En PDFDokument3 SeitenAa 3295-En PDFDan AyalaNoch keine Bewertungen

- Instructions-Parts List: Air Spray GunDokument20 SeitenInstructions-Parts List: Air Spray GunDan AyalaNoch keine Bewertungen

- Boiler Making Hints - by Mike PavieDokument2 SeitenBoiler Making Hints - by Mike Paviehbpr9999Noch keine Bewertungen

- Sci P367Dokument8 SeitenSci P367Nat Thana AnanNoch keine Bewertungen

- Efficacy Silica Gel BreatherDokument2 SeitenEfficacy Silica Gel BreatherMustafa ShahNoch keine Bewertungen

- Proejcr ManduaDokument552 SeitenProejcr ManduaDanny NguyenNoch keine Bewertungen

- SS Stub End Thickness CalculationDokument1 SeiteSS Stub End Thickness CalculationSrinivas KadivetiNoch keine Bewertungen

- My NoteDokument186 SeitenMy NotedianNoch keine Bewertungen

- Gas Flow Calculation Aga - 3 Base On L-10 Chart: U U U C NDokument1 SeiteGas Flow Calculation Aga - 3 Base On L-10 Chart: U U U C NDio Masera0% (1)

- Duragrout: Non-Shrink Cementitious GroutDokument3 SeitenDuragrout: Non-Shrink Cementitious GroutJohan ConradieNoch keine Bewertungen

- Instrumentation of HVACDokument20 SeitenInstrumentation of HVACthaiNoch keine Bewertungen

- Yoshitake SF-1S 1F Sight GlassDokument1 SeiteYoshitake SF-1S 1F Sight GlassJohn Marvin ValenzuelaNoch keine Bewertungen

- Composite ManufacturingDokument68 SeitenComposite ManufacturingSENTHIL KUMARNoch keine Bewertungen

- Trusses and Complex Problems Related To It.Dokument3 SeitenTrusses and Complex Problems Related To It.sukka100% (1)

- Formworks by UseDokument6 SeitenFormworks by UsePatrick Jake DimapilisNoch keine Bewertungen

- Polymer ConcreteDokument25 SeitenPolymer ConcreteLalithya100% (2)

- H030SGDokument2 SeitenH030SGLaxman AhirNoch keine Bewertungen

- Schedule of Loads and Computations: Riser Diagram/ Details of Circuit BreakersDokument1 SeiteSchedule of Loads and Computations: Riser Diagram/ Details of Circuit BreakersCarl Lou BaclayonNoch keine Bewertungen

- Partial Replacement of Cement With GGBS in ConcreteDokument10 SeitenPartial Replacement of Cement With GGBS in ConcreteE Hammam El MissiryNoch keine Bewertungen

- Residential Building Design Using Excel Program - FinalDokument28 SeitenResidential Building Design Using Excel Program - FinalGeneva Latorre92% (12)

- Concrete Ground Floors and Pavements Part 1Dokument99 SeitenConcrete Ground Floors and Pavements Part 1Sandu NicolaeNoch keine Bewertungen

- Table 8.7.2.2.1: TABLE 8.7.2.2.1 Protection Areas and Maximum Spacing (Standard Sidewall SprayDokument24 SeitenTable 8.7.2.2.1: TABLE 8.7.2.2.1 Protection Areas and Maximum Spacing (Standard Sidewall Sprayahmad adnanNoch keine Bewertungen

- Ceiling Cassette Indoor Unit Engineering ManualDokument138 SeitenCeiling Cassette Indoor Unit Engineering ManualcodefinderNoch keine Bewertungen

- Lab 3-Column BucklingDokument7 SeitenLab 3-Column BucklingMr. Danish SaeedNoch keine Bewertungen

- CTA TehnicDokument5 SeitenCTA TehnicLar Ionut AndreiNoch keine Bewertungen

- Positioning of Air Cooled CondensersDokument9 SeitenPositioning of Air Cooled CondensersAlexNoch keine Bewertungen

- Introduction To Coiled TubingDokument131 SeitenIntroduction To Coiled TubingAmin Dehghani100% (2)

- Data Sheet - Jindal Stainless Steelway LimitedDokument3 SeitenData Sheet - Jindal Stainless Steelway LimitedSitaram JhaNoch keine Bewertungen

- Seismic Design of RC Structures - SaatciogluDokument146 SeitenSeismic Design of RC Structures - SaatciogluAl MamunNoch keine Bewertungen

- Using IR For Iso-Phase Bus Duct-TheyerlDokument6 SeitenUsing IR For Iso-Phase Bus Duct-TheyerlalexanderNoch keine Bewertungen

- Katalog 2019 01 Eng PDFDokument302 SeitenKatalog 2019 01 Eng PDFAditya RameshNoch keine Bewertungen

- Thesis-Seismic Performance Assessment of High Rise Buildings With The Effect of Masonry InfillDokument81 SeitenThesis-Seismic Performance Assessment of High Rise Buildings With The Effect of Masonry Infillnirez14Noch keine Bewertungen