Beruflich Dokumente

Kultur Dokumente

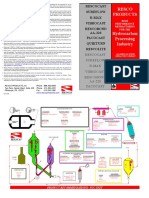

Dissimilar Weld Decision Matrix

Hochgeladen von

canakyuz0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

23 Ansichten2 SeitenDissimilar decision

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenDissimilar decision

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

23 Ansichten2 SeitenDissimilar Weld Decision Matrix

Hochgeladen von

canakyuzDissimilar decision

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

W. F. Newell, Jr.

Page 1 of 2

Dissimilar Weld Decision Matrix

Procedure

1. List information for Material A & B columns and identify similarities and

differences.

2. List details for a proposed weld metal. If a proper transition of properties or

repair scenario cannot be done, consider buttering one or both materials or

use a pup or transition piece.

3. A transition piece is usually required when substantially different material

strengths or PWHT/lower critical transition temperatures are involved.

4. Buttering is oftentimes used when joining two materials of substantially

different properties such as a CrMo to Stainless Steel.

5. When all the materials and details are listed above, review will either suggest

that design, operation and fabrication or installation goals have been achieved

or that a different approach is required.

Material A Butter Pup or Transition Weld Metal Butter Material B

Alloy

P or A No,

Thickness

Yield, RT

Coef Exp

Lower Critical Trans. Temp.

Operating Temp

Yield Stress

Allowable Stress

Creep Range

Toughness

Corrosion

Groove Geometry

Restraint

PWHT, Code

Temp

Time

Restrictions

Strain/Bending

Carbon Migration

Sensitization

Hardness

W. F. Newell, Jr. Page 2 of 2

Definitions: Intent for the technical details are as follows:

Alloy: ASTM, ASME, AWS, ISO, EN, designation for the alloy or weld

metal.

P-No. or A-No.: Designation assigned per ASME IX.

Thickness: Thickness of weld metal. Sharp transitions should be

considered.

Yield, RT: Room Temperature yield strength.

Coefficient of Expansion: Behavior at operating temperature.

Lower Critical Transformation Temperature: Also referred to as the AC 1.

PWHT should not exceed this value.

Operating Temperature: System design operating temperature.

a. Yield Stress: Yield stress at design operating temperature.

b. Allowable Stress: At operating temperature, per ASME Section

II, Part D or other applicable code.

Creep Range: Is the material operating in it’s creep range? If not, then

alternate considerations may apply.

Toughness: Is ductility needed during startup or shutdown or code?

Corrosion: Will the choice of weld metal or transition materials impact

corrosion considerations?

Groove Geometry: Are welding process chosen and access to the

groove affected?

Restraint: Geometry will affect restrain which will affect issues such as

crater and root cracking.

PWHT, Code: ASME I, PW-39 or ASME B31.1, etc.

a. Temperature: Code required temperature

b. Time: Code minimum versus actual

Restrictions

a. Strain/Bending: Will PWHT have an adverse effect on material

that has been strained?

b. Carbon Migration: Given time and temperature, may be an issue.

c. Sensitization: An issue where austenitic stainless steel involved.

d. Hardness: Normally limited to weld metal or heat-affected zone

where stress corrosion cracking is an issue.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- SCE Man1Dokument2 SeitenSCE Man1canakyuzNoch keine Bewertungen

- APM WhitepaperDokument17 SeitenAPM WhitepapercanakyuzNoch keine Bewertungen

- Organic ChlorideDokument2 SeitenOrganic ChloridecanakyuzNoch keine Bewertungen

- Rockwool ProcessDokument179 SeitenRockwool ProcesscanakyuzNoch keine Bewertungen

- Hot Bolting and The Morsafe™ Clamp Thomas Lamb1, Ian Thompson2Dokument4 SeitenHot Bolting and The Morsafe™ Clamp Thomas Lamb1, Ian Thompson2canakyuzNoch keine Bewertungen

- RockwoolDokument20 SeitenRockwoolcanakyuzNoch keine Bewertungen

- Corrosion Solutions: Sridhar SrinivasanDokument54 SeitenCorrosion Solutions: Sridhar SrinivasancanakyuzNoch keine Bewertungen

- Tank Inspection Check ListDokument8 SeitenTank Inspection Check ListwalidNoch keine Bewertungen

- Brochure and Operator InstructionsDokument6 SeitenBrochure and Operator InstructionscanakyuzNoch keine Bewertungen

- Piping InspectionDokument15 SeitenPiping InspectioncanakyuzNoch keine Bewertungen

- Material Selection For Flare TipsDokument200 SeitenMaterial Selection For Flare Tipscanakyuz100% (2)

- Sample CylinderDokument9 SeitenSample CylindercanakyuzNoch keine Bewertungen

- Ultracorr: Ultracorr 2 IS Wall Thickness MonitorDokument2 SeitenUltracorr: Ultracorr 2 IS Wall Thickness MonitorcanakyuzNoch keine Bewertungen

- RescoDokument2 SeitenRescocanakyuzNoch keine Bewertungen

- Welding QuestionnairDokument44 SeitenWelding QuestionnairmqblahmdNoch keine Bewertungen

- Plasite 4550Dokument4 SeitenPlasite 4550canakyuzNoch keine Bewertungen

- Toe GrindingDokument3 SeitenToe GrindingcanakyuzNoch keine Bewertungen

- Alloy 890Dokument4 SeitenAlloy 890canakyuzNoch keine Bewertungen

- Steel Grades 2 PDFDokument2 SeitenSteel Grades 2 PDFcanakyuz0% (1)

- Plasma Cutting TipsDokument1 SeitePlasma Cutting TipsPepsNoch keine Bewertungen

- Weld SurveillanceDokument33 SeitenWeld SurveillancecanakyuzNoch keine Bewertungen

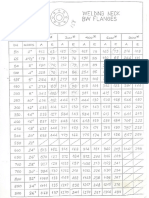

- Welding Neck FlangesDokument1 SeiteWelding Neck FlangescanakyuzNoch keine Bewertungen

- Certification Guideline for Welding Manufacturers of Railway VehiclesDokument50 SeitenCertification Guideline for Welding Manufacturers of Railway Vehiclesrameshqc100% (1)

- Arc WeldingDokument10 SeitenArc Weldingmetals1358Noch keine Bewertungen

- Railway line failure modeling and maintenance optimizationDokument14 SeitenRailway line failure modeling and maintenance optimizationcanakyuzNoch keine Bewertungen

- Welding-Asme P Material NumbersDokument2 SeitenWelding-Asme P Material NumberscanakyuzNoch keine Bewertungen

- MIG Brazing PaperDokument7 SeitenMIG Brazing PapercanakyuzNoch keine Bewertungen

- Consider Penetration When Determining Fillet Weld SizeDokument3 SeitenConsider Penetration When Determining Fillet Weld SizecanakyuzNoch keine Bewertungen

- Design of Welded JointsDokument8 SeitenDesign of Welded JointscanakyuzNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Electrode ManualDokument18 SeitenElectrode ManualAnonymous 4e7GNjzGWNoch keine Bewertungen

- Reverse Osmosis ExplainedDokument16 SeitenReverse Osmosis Explainedmochamad iwanNoch keine Bewertungen

- Rotogravure Printing Learn MoreDokument15 SeitenRotogravure Printing Learn Moreumangashling100% (1)

- Taper Chart 1Dokument3 SeitenTaper Chart 1alim fakihNoch keine Bewertungen

- Ecostar - Compact Aer STP Using LevaporDokument5 SeitenEcostar - Compact Aer STP Using LevaporAmit ChristianNoch keine Bewertungen

- Alloy c22 Round BarDokument2 SeitenAlloy c22 Round BarSTEEL TUBES INDIANoch keine Bewertungen

- Material Selection For Swimming PoolsDokument3 SeitenMaterial Selection For Swimming PoolsMandar KadamNoch keine Bewertungen

- Refinery Report 1Dokument16 SeitenRefinery Report 1akamNoch keine Bewertungen

- MT Form Asme PDFDokument1 SeiteMT Form Asme PDFTrung Tinh HoNoch keine Bewertungen

- Fccu PDFDokument2 SeitenFccu PDFSumit KaushikNoch keine Bewertungen

- Arch-3.1-Aluminium Doors and WindowsDokument3 SeitenArch-3.1-Aluminium Doors and WindowsSherazNoch keine Bewertungen

- Welding Procedure 6GDokument5 SeitenWelding Procedure 6GTrinh DungNoch keine Bewertungen

- Midterm - Exam CHEM4012 2010 2011Dokument7 SeitenMidterm - Exam CHEM4012 2010 2011Zezo AlNoch keine Bewertungen

- Howco Global BrochureDokument10 SeitenHowco Global BrochureKilonboNoch keine Bewertungen

- NC Block NaamsDokument46 SeitenNC Block NaamseldibujanteNoch keine Bewertungen

- Module 6Dokument33 SeitenModule 6ILSHA ANDIANINoch keine Bewertungen

- Rotary Table For Radial Drilling MachineDokument30 SeitenRotary Table For Radial Drilling Machinehardish_trivedi7005Noch keine Bewertungen

- JDM A22 - Rev 06-1987Dokument8 SeitenJDM A22 - Rev 06-1987Reginaldo SantosNoch keine Bewertungen

- Prestige Engineering L.L.C: Welding Procedure Specification (WPS)Dokument24 SeitenPrestige Engineering L.L.C: Welding Procedure Specification (WPS)Sarathiraja SekarNoch keine Bewertungen

- TVET 1 Worksheet 8 Rivera, JomareDokument7 SeitenTVET 1 Worksheet 8 Rivera, JomareJomare RiveraNoch keine Bewertungen

- Gum Copal: General InformationDokument1 SeiteGum Copal: General InformationHaris FazaNoch keine Bewertungen

- 3056-Article Text-9055-1-10-20230119Dokument15 Seiten3056-Article Text-9055-1-10-20230119Agum GumelarNoch keine Bewertungen

- Vanlube Ri-Zsn Vanlube TK-100 Vanlube W-324: R R SO 2 ZNDokument1 SeiteVanlube Ri-Zsn Vanlube TK-100 Vanlube W-324: R R SO 2 ZNAnalista De CalidadNoch keine Bewertungen

- Unit-4 Sheet Metal ProcessDokument39 SeitenUnit-4 Sheet Metal ProcessKarthikeyan Murugananthan100% (6)

- Shutdown JobDokument6 SeitenShutdown JobsyeedismailNoch keine Bewertungen

- ASME B16.34-2009 Valves-Flanged-Threaded-Welding End - ExtractDokument72 SeitenASME B16.34-2009 Valves-Flanged-Threaded-Welding End - ExtractMahmoud Al HomranNoch keine Bewertungen

- Sikalastomer 710Dokument1 SeiteSikalastomer 710Eliza ManNoch keine Bewertungen

- Catalogo de Partes Moto Yamaha Fino 115 AF115S 2bn2 Modelo 2013Dokument63 SeitenCatalogo de Partes Moto Yamaha Fino 115 AF115S 2bn2 Modelo 2013Rwbfwhfcb Bskdbcvdhbs100% (1)

- Rate Laws and Methods for Determining Reaction OrderDokument3 SeitenRate Laws and Methods for Determining Reaction OrderJbreNoch keine Bewertungen