Beruflich Dokumente

Kultur Dokumente

Client Hpcl-Mittal Energy Ltd. Project Offsite Unit PPU Stress Lp-Header Line System

Hochgeladen von

Ishu VohraOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Client Hpcl-Mittal Energy Ltd. Project Offsite Unit PPU Stress Lp-Header Line System

Hochgeladen von

Ishu VohraCopyright:

Verfügbare Formate

Document No.

LP-HEADER LINE Rev.0

Page 1 of 5

CLIENT HPCL- MITTAL ENERGY LTD.

PROJECT OFFSITE

UNIT PPU

STRESS LP-HEADER LINE

SYSTEM

0 15/05/17 ISSUED FOR RECORDS ADITHYA AC MK

Rev.No Date Purpose Prepared by Reviewed by Approved by

Format No. 8-00-0001-F2 Rev. 0 Copyright EIL – All rights reserved

Document No.

LP-HEADER LINE Rev.0

Page 2 of 5

TABLE OF CONTENTS

1.0 CHECKLIST 3

2.0 DESIGN PARAMETERS 4

3.0 RESULTS 4

4.0 SPRING DATA 4

5.0 CONCLUSION 4

6.0 STRESS ANALYSIS OUTPUT 5

7.0 ATTACHMENTS 5

Format No. 8-00-0001-F2 Rev. 0 Copyright EIL – All rights reserved

Document No.

LP-HEADER LINE Rev.0

Page 3 of 5

1.0 CHECKLIST

Sl. YES/NO

CHECK POINT REMARKS

No (Y/N)

1 Stress Isometric attached Y

Pipe specification & corrosion allowance taken as

2

per PMS Y

3 Line conditions taken as per Process data Y

4 Input is as per actual/planned configuration Y

Structural supports/ Restraints/ Anchors

5

Are adequate for withstanding piping loads Y

All displacements and frequencies in order; no Y

6 fouling in extreme conditions; no shoe offsetting;

proper shoe length ensured.

7 Flange leakage calculations checked NA

Loads and any special considerations/information N

8 conveyed to Structural/Static Equipment/Rotating

Equipment/Fired Equipment Department if required

9 Analog Study comments, if any, incorporated NA

6 Cases considered in the analysis

Design Y

Operating Y

Steam out N

Hydro test Y

Wind Y

Seismic N

Note : User to add applicable Cases considered for analysis depending on requirements of the system.

Format No. 8-00-0001-F2 Rev. 0 Copyright EIL – All rights reserved

Document No.

LP-HEADER LINE Rev.0

Page 4 of 5

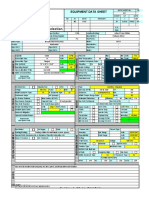

2.0 DESIGN PARAMETERS

INSULATION DESIGN OPERATING HYDRO/

SERVICE

MEDIUM

STEAM

STATE

FLUID

PNUEMATI

TEST

SIZE SERIAL PIPE OUT DENSITY

C TEST

(inch) NO. CLASS PRESS. TEMP (kg/m3)

THK TEMP. PRESS.( TEMP. PRESSURE

TYPE (kg/cm2 (°C)

(mm) (°C) kg\cm2g) (°C) (kg\cm2g)

g)

26 V - - G22G IH 50 5.5 190 3 150 - H 8.25 10

Nominal Pipe Size 20”

Class G22G

Rating 2500#

Material A 691 GR.P91

CL.42

Corrosion

1.5 mm

Allowance

Schedule /

STD

Thickness

NOZZLE DISPLACEMENTS (mm)

No Equipment Nozzles are considered.

RESULTS

The following tables compare the allowable and actual nozzle loadings. The actual loading is the

maximum of sustained and operating load cases.

ALLOWABLE ACTUAL STATUS

SUS 19246.2 10420.1 54.1

EXP 41474.0 33021.6 79.6

3.0 SPRING DATA

REQUIRED / NOT REQUIRED

4.0 CONCLUSION

All stresses and loads are within allowables.

Format No. 8-00-0001-F2 Rev. 0 Copyright EIL – All rights reserved

Document No.

LP-HEADER LINE Rev.0

Page 5 of 5

5.0 STRESS ANALYSIS OUTPUT

5.1 STRESS ANALYSIS OUTPUT (COMPLETE)

a. Input Echo with list of Load cases

b. Restraint Summary

c. Displacements

d. Stress Summary

e. Flange Leakage Calculations

5.2 STRESS ANALYSIS OUTPUT (HOOK-UP PART)

a. Input Echo with list of Load cases

b. Restraint Summary

c. Displacements

d. Stress Summary

e. Flange Leakage Calculations

6.0 ATTACHMENTS

a. SYSTEM ISOMETRICS

b. EQUIPMENT DRAWINGS

c. P&IDs

d. Trunnion Calculations (if applicable)

e. Relevant PMS Classes

f. Slug Force Calc (if applicable)

g. PSV reaction force Calc (if applicable)

h. Stress Analysis Index (for relevant lines)

Format No. 8-00-0001-F2 Rev. 0 Copyright EIL – All rights reserved

Das könnte Ihnen auch gefallen

- Client Hpcl-Mittal Energy Ltd. Project Offsite Unit PPU Stress Svh-Header Line SystemDokument5 SeitenClient Hpcl-Mittal Energy Ltd. Project Offsite Unit PPU Stress Svh-Header Line SystemIshu VohraNoch keine Bewertungen

- 04 Datasheet Control ValveDokument8 Seiten04 Datasheet Control ValveFadlila MuhammadNoch keine Bewertungen

- Test Manifold Package No:: Client Saudi Aramco Oil CoDokument7 SeitenTest Manifold Package No:: Client Saudi Aramco Oil CosarangpuneNoch keine Bewertungen

- Io ListDokument4 SeitenIo ListsswahyudiNoch keine Bewertungen

- DS - Flow Element (Orifice)Dokument5 SeitenDS - Flow Element (Orifice)Nawfel ArafathNoch keine Bewertungen

- 000 in DTS 401Dokument6 Seiten000 in DTS 401zsmithNoch keine Bewertungen

- DS - DP Type Level TransmitterDokument5 SeitenDS - DP Type Level TransmitterNawfel ArafathNoch keine Bewertungen

- Cpsf-El-Dat-01-Cp2017-014-00 A1Dokument3 SeitenCpsf-El-Dat-01-Cp2017-014-00 A1Siro BabiroNoch keine Bewertungen

- 02 Datasheet Pressure TransmitterDokument2 Seiten02 Datasheet Pressure TransmitterFadlila MuhammadNoch keine Bewertungen

- Index of Revisions Rev. Description And/Or Revised Sheets: ProcedureDokument7 SeitenIndex of Revisions Rev. Description And/Or Revised Sheets: ProcedureThiagoNoch keine Bewertungen

- OSP078 IC DAS 8009 Rev.0 Pressure Differential Indicator DatasheetDokument4 SeitenOSP078 IC DAS 8009 Rev.0 Pressure Differential Indicator DatasheetAhmedNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- Pressure Differential Transmitter Datasheet for LNG Terminal ProjectDokument3 SeitenPressure Differential Transmitter Datasheet for LNG Terminal ProjectsswahyudiNoch keine Bewertungen

- Example Pump Selection: Equipment Data SheetDokument4 SeitenExample Pump Selection: Equipment Data SheetMohamed Yassine LahianiNoch keine Bewertungen

- PT. PERTAMINA EP & PT. ELNUSA Pressure Transmitter Data SheetDokument8 SeitenPT. PERTAMINA EP & PT. ELNUSA Pressure Transmitter Data SheetOktavianusHeruNoch keine Bewertungen

- Reliance Industries heat exchanger inspection procedureDokument3 SeitenReliance Industries heat exchanger inspection procedureRajnikant PatelNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- Specification table for 3-phase squirrel cage induction motorDokument1 SeiteSpecification table for 3-phase squirrel cage induction motorHary FadlyNoch keine Bewertungen

- Instrument ScheduleDokument1 SeiteInstrument ScheduleSaid Hajril AulizaNoch keine Bewertungen

- Instrument ScheduleDokument1 SeiteInstrument ScheduleSaid Hajril AulizaNoch keine Bewertungen

- Annexure To FORMAT - IDokument3 SeitenAnnexure To FORMAT - IrajuNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- LBII ParametrosDokument37 SeitenLBII ParametrosPolinho Donacimento100% (1)

- 00000-Jds-003 (Level Trans DS) Rev 0Dokument4 Seiten00000-Jds-003 (Level Trans DS) Rev 0sithulibraNoch keine Bewertungen

- BB2 Rev03Dokument8 SeitenBB2 Rev03Ahmed El-AzharyNoch keine Bewertungen

- Line List SKDokument168 SeitenLine List SKRaul Humberto Mora VillamizarNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataShubham kgc100% (1)

- Zppg-Aico-Sas-Rt-0611 - 02-07-2018 (Pew)Dokument1 SeiteZppg-Aico-Sas-Rt-0611 - 02-07-2018 (Pew)Ahmed ThaerNoch keine Bewertungen

- Inspection Checklist for Suction Bell CastingsDokument8 SeitenInspection Checklist for Suction Bell CastingsCheeragNoch keine Bewertungen

- Inspection and Test Paln For LSAWDokument4 SeitenInspection and Test Paln For LSAWkbpatel123Noch keine Bewertungen

- PTSC Mechanical and Construction Welding SummaryDokument4 SeitenPTSC Mechanical and Construction Welding Summary123aefNoch keine Bewertungen

- Example Pump Selection: Hoja de Datos de EquiposDokument2 SeitenExample Pump Selection: Hoja de Datos de EquiposAlonso DIAZNoch keine Bewertungen

- KOC FIRE & GAS PIPE THREAD SUMMARYDokument1 SeiteKOC FIRE & GAS PIPE THREAD SUMMARYKuwait Gulf CircleNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- Specification for Offshore Cone MeterDokument2 SeitenSpecification for Offshore Cone MeterShakeel AhmedNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- Quality Assurance Plan: NEW AGE FAB Technologies Pvt. LTDDokument6 SeitenQuality Assurance Plan: NEW AGE FAB Technologies Pvt. LTDRajnikant PatelNoch keine Bewertungen

- 1312FT 8702 - I03 ADokument2 Seiten1312FT 8702 - I03 AAnonymous fdAqmDGHINoch keine Bewertungen

- IBL-I-DS-001 - 017 - C - Instrument Datasheet Signed AGa 20201230 - CompressedDokument49 SeitenIBL-I-DS-001 - 017 - C - Instrument Datasheet Signed AGa 20201230 - Compresseddandi zlk100% (1)

- NDE Procedure: Leak Test and Test No. /Z 07-FiDokument4 SeitenNDE Procedure: Leak Test and Test No. /Z 07-FiVũ Lê NguyênNoch keine Bewertungen

- Public Health and Municipal Engineering Department - NelloreDokument3 SeitenPublic Health and Municipal Engineering Department - Nellorejuliyet strucNoch keine Bewertungen

- I Et 30101m 1200 200 p4x 001 - 0 - Prelim PDFDokument821 SeitenI Et 30101m 1200 200 p4x 001 - 0 - Prelim PDFluizsavinoNoch keine Bewertungen

- Radiography Examination Report SummaryDokument1 SeiteRadiography Examination Report SummaryAhmed ThaerNoch keine Bewertungen

- 35-3000RKA-LEL Sample Draw Combustible Gas Detector: SpecificationsDokument18 Seiten35-3000RKA-LEL Sample Draw Combustible Gas Detector: SpecificationspcatruongNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Koc Feed Pipeline ProjectDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Koc Feed Pipeline ProjectKuwait Gulf CircleNoch keine Bewertungen

- Egyptian steel plant valve listDokument6 SeitenEgyptian steel plant valve listMohamed Elsaid El ShallNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- Checklist Fire StopDokument9 SeitenChecklist Fire StopAnonymous DMdGdsOENoch keine Bewertungen

- Cosmo Instruments PresentationDokument23 SeitenCosmo Instruments PresentationNguyễn Văn ĐộNoch keine Bewertungen

- Standards Mentioned at PETROBRAS Offshore Basic DesignsDokument11 SeitenStandards Mentioned at PETROBRAS Offshore Basic DesignsErnestoSalMarNoch keine Bewertungen

- Thread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataDokument1 SeiteThread Summary - Fire & Gas Suppression Pipe: Production Data NDT DataKuwait Gulf CircleNoch keine Bewertungen

- NHT Loop 05 18-1693783Dokument1 SeiteNHT Loop 05 18-1693783AKASH BNoch keine Bewertungen

- Sultanate's ultrasonic flowmeter standardsDokument3 SeitenSultanate's ultrasonic flowmeter standardsaltipatlarNoch keine Bewertungen

- EGPM10-PIT-I-DAT-001 Pressure TransmitterDokument2 SeitenEGPM10-PIT-I-DAT-001 Pressure TransmitterdrkongalaNoch keine Bewertungen

- Zppg-Aico-Sas-Rt-0608 - 01-07-2018 (Pew)Dokument1 SeiteZppg-Aico-Sas-Rt-0608 - 01-07-2018 (Pew)Ahmed ThaerNoch keine Bewertungen

- GRP Drainage Piping System FabricationDokument5 SeitenGRP Drainage Piping System FabricationkahootNoch keine Bewertungen

- Final Report UT Inspection BearingDokument5 SeitenFinal Report UT Inspection BearingEko PurwantoNoch keine Bewertungen

- Work InstructionDokument114 SeitenWork Instructiondevan_andNoch keine Bewertungen

- Laporan CemsDokument17 SeitenLaporan CemsairhabieNoch keine Bewertungen

- Instrumentation and Test Gear Circuits ManualVon EverandInstrumentation and Test Gear Circuits ManualBewertung: 5 von 5 Sternen5/5 (1)

- DOJO AwarenessDokument2 SeitenDOJO AwarenessIshu VohraNoch keine Bewertungen

- DEP 31.22.00.12-Gen - UT in Lieu of RT For Construction of Pressure EquipmentDokument16 SeitenDEP 31.22.00.12-Gen - UT in Lieu of RT For Construction of Pressure EquipmentIshu VohraNoch keine Bewertungen

- Trunnion Calculation SheetDokument2 SeitenTrunnion Calculation SheetIshu Vohra0% (1)

- Customers & Manufacturing LocationsDokument3 SeitenCustomers & Manufacturing LocationsIshu VohraNoch keine Bewertungen

- Filter LoadsDokument2 SeitenFilter LoadsIshu VohraNoch keine Bewertungen

- Steam LineDokument123 SeitenSteam LineIshu VohraNoch keine Bewertungen

- Screw NozzleDokument3 SeitenScrew NozzleIshu VohraNoch keine Bewertungen

- Stress Report - LP LineDokument5 SeitenStress Report - LP LineIshu VohraNoch keine Bewertungen

- CavitationDokument5 SeitenCavitationIshu VohraNoch keine Bewertungen

- Training Need IdentificationDokument42 SeitenTraining Need IdentificationIshu VohraNoch keine Bewertungen

- Vipin Sharma: Equipment Division EIB-5Dokument2 SeitenVipin Sharma: Equipment Division EIB-5Ishu VohraNoch keine Bewertungen

- 01 Cover PagesDokument4 Seiten01 Cover PagesIshu VohraNoch keine Bewertungen

- CavitationDokument5 SeitenCavitationIshu VohraNoch keine Bewertungen

- 03 End Pages PDFDokument2 Seiten03 End Pages PDFIshu VohraNoch keine Bewertungen

- 03 End Pages PDFDokument2 Seiten03 End Pages PDFIshu VohraNoch keine Bewertungen

- Bamboo fiberboard properties from Phyllostachys pubescensDokument76 SeitenBamboo fiberboard properties from Phyllostachys pubescenskanha15102003Noch keine Bewertungen

- 02 Employee Handbook Safe Work Practices. Rev 2Dokument53 Seiten02 Employee Handbook Safe Work Practices. Rev 2Ishu VohraNoch keine Bewertungen

- E-Billing Solutions PVT LTD - Payment PageDokument1 SeiteE-Billing Solutions PVT LTD - Payment PageIshu VohraNoch keine Bewertungen

- Elements of Continuum Elasticity: David M. Parks Mechanics and Materials II 2.002 February 25, 2004Dokument22 SeitenElements of Continuum Elasticity: David M. Parks Mechanics and Materials II 2.002 February 25, 2004BalajeeNoch keine Bewertungen

- Annexure 28 - Employee Details FormDokument2 SeitenAnnexure 28 - Employee Details FormIshu VohraNoch keine Bewertungen

- 03 End PagesDokument2 Seiten03 End PagesIshu VohraNoch keine Bewertungen

- Cementys Mail DraftDokument1 SeiteCementys Mail DraftIshu VohraNoch keine Bewertungen

- Application Form: Selected / Rejected / HoldDokument3 SeitenApplication Form: Selected / Rejected / HoldIshu VohraNoch keine Bewertungen

- Requisition Form Business Development PESDokument2 SeitenRequisition Form Business Development PESIshu VohraNoch keine Bewertungen

- Review Article: Properties of Concrete at Elevated TemperaturesDokument16 SeitenReview Article: Properties of Concrete at Elevated TemperaturesNeak Chandara100% (1)

- Elements of Continuum Elasticity: David M. Parks Mechanics and Materials II 2.002 February 25, 2004Dokument22 SeitenElements of Continuum Elasticity: David M. Parks Mechanics and Materials II 2.002 February 25, 2004BalajeeNoch keine Bewertungen

- Union Government Launches Indian Bridge Management System - Current Affairs TodayDokument1 SeiteUnion Government Launches Indian Bridge Management System - Current Affairs TodayIshu VohraNoch keine Bewertungen

- II 00 2.6.1 Annexure-1 SOW LDS or Leak Detection SystemDokument22 SeitenII 00 2.6.1 Annexure-1 SOW LDS or Leak Detection SystemIshu VohraNoch keine Bewertungen

- Rheological Investigation of Suspensions and Ceramic Pastes: Characterization of Extrusion PropertiesDokument13 SeitenRheological Investigation of Suspensions and Ceramic Pastes: Characterization of Extrusion PropertiesChandrasekarNoch keine Bewertungen

- Epoxy Connection TimberDokument6 SeitenEpoxy Connection TimberJeffery RoweNoch keine Bewertungen

- 2 1-Simplestrain PDFDokument21 Seiten2 1-Simplestrain PDFMarkVincentTulinaoNoch keine Bewertungen

- Models For Metals Subjected To Cyclic Loading - ABAQUS PDFDokument13 SeitenModels For Metals Subjected To Cyclic Loading - ABAQUS PDFMohamed AhmedNoch keine Bewertungen

- Stress Analysis of Steel PlateDokument5 SeitenStress Analysis of Steel Platetanvir04104Noch keine Bewertungen

- In Situ SEM-EBSD Analysis of Plastic Deformation Mechanisms in Neutron-Irradiated Austenitic SteelDokument27 SeitenIn Situ SEM-EBSD Analysis of Plastic Deformation Mechanisms in Neutron-Irradiated Austenitic SteelChin-Min YangNoch keine Bewertungen

- Direct Shear Test Lab ManualDokument6 SeitenDirect Shear Test Lab Manualmm0% (1)

- Paper Morin1995 - Analysis of In-Service Aged Stator BarsDokument10 SeitenPaper Morin1995 - Analysis of In-Service Aged Stator BarsArmando MartinezNoch keine Bewertungen

- MJ July 2020 V. 117 No. 4 PDFDokument146 SeitenMJ July 2020 V. 117 No. 4 PDFbfgsdfgNoch keine Bewertungen

- Input Data For Test Cases Used in Triaxial Failure Theories PDFDokument18 SeitenInput Data For Test Cases Used in Triaxial Failure Theories PDFRohitMadkeNoch keine Bewertungen

- Basic Seismology-Shearer (USGS)Dokument61 SeitenBasic Seismology-Shearer (USGS)jcpchin2Noch keine Bewertungen

- Wind Tunnel Analysis of SubmarineDokument58 SeitenWind Tunnel Analysis of SubmarineRanjeet Singh100% (1)

- Lecture 3 TorsionDokument24 SeitenLecture 3 TorsionJacob BaltazarNoch keine Bewertungen

- Astm A1012-2002Dokument4 SeitenAstm A1012-2002Jorge ToribioNoch keine Bewertungen

- Analysis of Building Collapse Under Blast LoadDokument26 SeitenAnalysis of Building Collapse Under Blast LoadSinan NizarNoch keine Bewertungen

- FINITE ELEMENT ANALYSIS - Unit Wise - Question Bank (Part A & B) & Unitwise - Important FormulaeDokument49 SeitenFINITE ELEMENT ANALYSIS - Unit Wise - Question Bank (Part A & B) & Unitwise - Important FormulaeS A ABDUL SUKKUR83% (12)

- Buckling Commentary E-Mar18 PDFDokument132 SeitenBuckling Commentary E-Mar18 PDFthomas1313Noch keine Bewertungen

- How to treat twisting moments Mxy in concrete slab designDokument4 SeitenHow to treat twisting moments Mxy in concrete slab designMarekNoch keine Bewertungen

- STAADPro Verification Manual PDFDokument378 SeitenSTAADPro Verification Manual PDFAbdul HadhiNoch keine Bewertungen

- Out PDFDokument243 SeitenOut PDFDoan PhiNoch keine Bewertungen

- Practical Discussion On Fatigue PDFDokument5 SeitenPractical Discussion On Fatigue PDFcarlvigNoch keine Bewertungen

- Strength of Materials-IiDokument2 SeitenStrength of Materials-IiBOBBILI KRISHNA VISISHTANoch keine Bewertungen

- 2.principal Stress and Strain PDFDokument27 Seiten2.principal Stress and Strain PDFharshdeepNoch keine Bewertungen

- Tutorial Ansys ApdlDokument4 SeitenTutorial Ansys Apdlep_frenz100% (1)

- Piles Load Testing HandbookDokument28 SeitenPiles Load Testing HandbookMalcolm Gingell100% (2)

- Louis Kahn - Modernization and The New Monumentality - 1944-1972Dokument20 SeitenLouis Kahn - Modernization and The New Monumentality - 1944-1972康心浩Noch keine Bewertungen

- Strength of Materials - Torsion of Circular Cross Section - Hani Aziz AmeenDokument31 SeitenStrength of Materials - Torsion of Circular Cross Section - Hani Aziz AmeenHani Aziz Ameen80% (15)

- FLUID MECHANICS TITLEDokument24 SeitenFLUID MECHANICS TITLEChristine Mae Vea100% (1)

- WTC2005 63324 PDFDokument2 SeitenWTC2005 63324 PDFMarcelo VeronezNoch keine Bewertungen

- Plate Theory Slides From WEB PDFDokument20 SeitenPlate Theory Slides From WEB PDFHarish ShridharamurthyNoch keine Bewertungen