Beruflich Dokumente

Kultur Dokumente

Improving Solar Food Dryers

Hochgeladen von

podbaydoorOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Improving Solar Food Dryers

Hochgeladen von

podbaydoorCopyright:

Verfügbare Formate

Dennis Scanlin,

Marcus Renner,

David Domermuth, &

Heath Moody

©1999 Dennis Scanlin, Marcus Renner,

David Domermuth, and Heath Moody

Above, Photo 1: Three identical solar food dryers for testing against a control.

his article Figure 1: Cutaway View of the Appalachian Solar Food Dryer

describes a series of 7 feet

experiments 3/4 inch Plywood

Roof

conducted over the last 1/4 inch Plywood

Vent Covers

year and a half with

1/4 inch Plywood

three solar food dryers.

The food dryers were

constructed at Drying Shelves

0.040 Sun-Lite HP Glazing

Appalachian State

6 feet

University (ASU) using

1 1/2 x 1/8 inch

plans published in 1 1/2 x 3/4 inch

Aluminum Bar Trim

Pine

HP57. The goal of this 3/4 x 3/4 inch

Pine

research program was 3–6 Layers of Lath

or Screen

Screened Air Intake

to improve the design

1/4 inch Plywood

and to determine the 3/4 inch Foil-Faced

most effective ways to Foam Insulation

1 1/2 x 3/4 inch

Pine

use the dryer.

24 Home Power #69 • February / March 1999

Solar Dehydration

Figure 2: Multiple Views of the Appalachian Solar Food Dryer

Exhaust Vents

Reflective Surface

(one test case)

Access Door

to Drying Trays

Collector Surface

Drying Chamber (glazing)

Handles

Air Intake

Collector Chamber

Rear Side Front

These solar food dryers are basically wooden boxes

with vents at the top and bottom. Food is placed on

screened frames which slide into the boxes. A properly

sized solar air heater with south-facing plastic glazing

and a black metal absorber is connected to the bottom

of the boxes. Air enters the bottom of the solar air

heater and is heated by the black metal absorber. The

warm air rises up past the food and out through the

vents at the top (see Figure 1). While operating, these

dryers produce temperatures of 130–180° F (54–82°

C), which is a desirable range for most food drying and

for pasteurization. With these dryers, it’s possible to dry

food in one day, even when it is partly cloudy, hazy, and

very humid. Inside, there are thirteen shelves that will

hold 35 to 40 medium sized apples or peaches cut into

thin slices.

The design changes we describe in this article have

improved the performance, durability, and portability of

the dryer, and reduced construction costs. This work

could also help in designing and constructing solar air

heaters used for other purposes, such as home heating

or lumber drying. Most of our experiments were

conducted with empty dryers using temperature as the

measure of performance, though some of our

experiments also involved the drying of peaches and

apples. We have dried almost 100 pounds (45 kg) of

fruit in these dryers during the past year. Graduate

students in the ASU Technology Department

constructed the dryers, and students taking a Solar Above, Photo 2: Setting up the solar simulator.

Home Power #69 • February / March 1999 25

Solar Dehydration

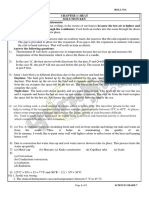

Graph 1: Single vs. Double Glazing measuring temperature, relative humidity, AC current,

180 voltage, light, and pressure. The logger does not have a

160

display, but it’s possible to download the data to a

computer. The software that comes with the logger

140 allows us to see and graph the data. The data can also

be exported to a spreadsheet for statistical analysis.

120

Degrees F

We measure air flows with a Kurz 490 series mini-

100

anemometer. We weigh the food before placing it in the

80 dryer, sometimes during the test, and at the end of each

day. We use an Ohaus portable electronic scale,

60

purchased from Thomas Scientific for $111. We

40

measure humidity with a Micronta hygrometer

purchased from Radio Shack for about $20.

20

8:00 9:00 10:00 11:00 Noon 13:00 14:00 15:00 16:00 17:00 Solar Simulator

Time In addition to outdoor testing with the actual food

Single Glazing Ambient Double Glazing dryers, we use a solar simulator (see Photo 2) built by

David Domermuth, a faculty member in the Technology

Energy Technology course modified them for individual Department at ASU. With the simulator, we can do

experiments. more rapid testing and replicate the tests performed on

Methodology the dryers, even on cloudy days. The simulator also lets

We began by constructing three identical food dryers. us control variables such as ambient temperature,

Having three dryers allowed us to test two hypotheses humidity, and wind effects. The unit can be altered

at one time. For example, to examine three versus six quickly because the glazing is not bolted on. The

layers of absorber mesh and single versus double simulator was constructed for $108. It was built in the

glazing, Dryer One might have three layers of black

aluminum window screening as an absorber with single Below, Photo 3: This dryer has both a vertical wall

glazing; Dryer Two, six layers of the same absorber reflector and side reflectors.

screen with single glazing; and Dryer Three, six layers

of the same absorber screen with two layers of glazing.

Once we set up an experiment, we collect data. This

lasts from several days to a couple of weeks until we

are confident that the data is reliable. Then we try

something different.

Using three food dryers also allows us to offer more

students hands-on experiences with solar air heaters.

Each semester, students take apart the dryers’ solar

collectors and rebuild them using different materials or

strategies. This classwork was supplemented with

experiments set up and completed by several graduate

students.

Equipment for Data Collection

We have two systems for measuring temperature. The

first system uses inexpensive indoor/outdoor digital

thermometers. One temperature sensor is placed inside

the dryer and the other one outside. Different locations

are used for the sensor inside the dryer. If food is being

dried, we normally place it under the bottom tray of food

and out of direct sunlight. This temperature data is

recorded on a data collection form every half hour or

whenever possible.

The other system uses a $600 data logger from Pace

Scientific to record temperature data. It is capable of

26 Home Power #69 • February / March 1999

Solar Dehydration

same way as the food dryer, but without the food drying Figure 3: Sun Angles 00

00

:00 oon

5:

3:0

4:

/1

/1

and Reflection with a

N

box at the top.

/1

00

9:

0

:00

:0

Vertical Reflector 16

10

/

11

The simulator uses three 500 watt halogen work lights 8 :00

to simulate the sun. The inlet and outlet temperatures

are measured with digital thermometers. The

temperature probes are shaded to give a true reading

of the air temperature. We conducted the simulator

tests inside a university building with an indoor

temperature of 62–64° F (17–18° C). As we changed

variables, we noticed significant differences in outlet air

temperatures. The simulator did produce temperatures Reflective Surface

comparable to those produced by the food dryers out in

the sun. However, we did not always achieve positive

correlations with our food dryers’ outdoor performance.

11

We may need to use different kinds of lights or alter our

:00

No

10

on

/1

procedures somewhat.

:0

3:0

0

/1

0

8:0

4

Experiments

:0

0/

0

16

We have done at least twenty different tests over the :00

9:

last year and a half. All were done outside with the 00

/1

5:

actual food dryers and some were also repeated with 00

the solar simulator. The dryers were set up outside the

Technology Department’s building on the ASU campus

in Boone, North Carolina. We collected some additional

information at one of the authors’ homes. Every test

was repeated to make sure we were getting consistent

performance. We tried to run the tests on sunny to

mostly sunny days, but the weather did not always As Graph 1 shows, the double glazing did result in

cooperate. The dips in many of the charts were caused higher dryer temperatures. This was on a sunny day

by passing clouds. with clear blue skies and white puffy clouds, low

humidity (30%), and light winds. The temperatures

Single vs. Double Glazing

throughout most of the day were slightly higher with

The original design published in HP57 used two layers

double glazing. However, the single glazed dryer works

of glazing separated by a 3/4 inch (19 mm) air gap. We

well and routinely reached temperatures of 130–180° F

used 24 inch (0.6 m) wide, 0.040 inch (1 mm) Sun-Lite

(54–82° C). When this test was replicated with the solar

HP fiberglass-reinforced polyester plastic for the outer

simulator, the double glazing also produced slightly

layer. For the inner layer, we used either another piece

higher temperatures.

of Sun-Lite, or Teflon glazing from Dupont. Sun-Lite

glazing is available from the Solar Components Our conclusion is that double glazing is not necessary

Corporation for about $2.40 per square foot ($25.83 per for effective drying. It does reduce some heat loss and

m2). These two layers cost over $50, or about one-third increases the dryer ’s temperature slightly, but it

of the total dryer cost. We wanted to see if the second increases the cost of the dryer significantly. Another

layer helped the performance significantly and justified problem is that some condensation forms between the

the added expense. two layers of glazing, despite attempts to reduce it by

caulking the glazing in place. The condensation

We set up two dryers with six layers of steel lath

detracts from the dryer’s appearance and may cause

painted flat black. One had single glazing and the other

maintenance problems with the wood that separates

had two layers of glazing. The outer glazing was Sun-

the two layers of glazing.

Lite HP on both dryers. The dryer with double glazing

used Teflon as the inner glazing. The two dryers were Reflectors

identical except for the number of glazing layers. The One possible way to improve the performance of these

tests were run on nine different days between February dryers is to use reflectors. We tried several strategies:

17 and March 26, 1998. We opened the bottom vent making the vertical south wall of the dryer box a

covers completely and the top vent covers to two reflective surface, hinging a single reflector at the

inches (51 mm). The ambient temperatures were cool bottom of the dryer, and adding reflectors on each side

and no food was being dried. of the collector.

Home Power #69 • February / March 1999 27

Solar Dehydration

Graph 2: Vertical Wall Reflector vs. No Reflector Look at the temperatures recorded on Graph 2. A slight

180 increase in dryer temperature was recorded in the dryer

having the south-facing reflective wall. The reflected

160

light covers the collector most completely at mid-

morning and afternoon. As the sun gets higher, the light

140

is reflected onto a smaller area of the collector.

120 Single Reflector

Degrees F

A single reflector was hinged to the bottom of the

100

collector (see Photo 4). This reflector was supported

80

with a string and stick arrangement, similar to one used

by Solar Cookers International. With all reflector

60 systems, the dryer has to be moved several times

throughout the day if performance is to be maximized.

40 This allows it to track the azimuth angle of the sun. The

9:30 10:00 10:30 11:00 11:30 Noon altitude angle of the reflector also needs to be adjusted

Time

during the day from about 15° above horizontal in the

With Reflector Without Reflector Ambient

Vertical Wall Reflector

We realized that the vertical south

wall of the dryer box could be

painted a light color or coated with

aluminum foil, a mirror, or reflective

Mylar (see Photo 3). A vertical

south-facing wall reflector would

reflect some additional energy into

the dryer’s collector, protect the

wood from cracking, and prevent

deterioration from UV radiation.

Considering the fact that the angle

of reflection equals the angle of

incidence, we were able to model

the performance of this reflector,

using a protractor and a chart of sun

altitude angles (see Figure 3). If the

dryer is moved several times

throughout the day to track the sun’s

azimuth angle, then the reflector

concentrates some additional solar

energy onto the dryer’s collector

during most of the day.

Above, Photo 4: Setting the front reflector angle.

Figure 4: Single Reflector at Low Sun Angle

morning and evening to 45° above

8:30 / 4:30 Sun

horizontal around noon (see Figures

4 and 5). The reflector added

10–20° F (2.4–4.8° C) to the

temperature of the dryer and

removed slightly more moisture from

35° the food than a dryer without a

Sun Angle

reflector.

Reflective Surface

Side Mounted Reflectors

15° Reflector Angle A third strategy was to add reflectors

to both sides of the collector. This

captures more solar energy than the

28 Home Power #69 • February / March 1999

Solar Dehydration

Figure 5: Single Reflector at High Sun Angle

Noon Sun

80°

Sun Angle

Reflective Surface

45° Reflector Angle

Right, Photo 5:

Side reflectors

folded onto

other two strategies. We determined that the ideal glazing for

reflector angle would be 120° from the collector surface transportation.

(see Figure 6). This assumes that the dryer is pointing

toward the sun’s azimuth orientation. reflectors would shade the collector in the morning and

the other in the afternoon.

We performed an experiment to compare a dryer with

two side reflectors and a vertical wall reflective surface We concluded that the vertical wall reflector and the

with a dryer having no reflectors (see Photo 3). Both single reflector mounted to the bottom of the collector

dryers were moved throughout the test period to track are the best ways to add reflectors, since tracking is not

the sun. The reflectors were mounted with hinges and crucial in these applications. However, these dryers

could be closed or removed when transporting the dryer routinely attain temperatures of 130–180° F (54–82° C)

(see Photo 5). Graph 3 shows the significant increase without reflectors, which is hot enough for food drying

in temperatures attained by using these reflectors. The and for pasteurization. Based on our work so far,

problem with this design was that if the dryer could not reflectors just don’t seem to be worth the trouble.

track the sun for one reason or another, one of the

Absorbers

All low temperature solar thermal collectors need

Figure 6: Ideal Angle for Side-Mounted Reflectors something to absorb solar radiation and convert it to

heat. The ideal absorber is made of a conductive

material, such as copper or aluminum. It is usually thin,

without a lot of mass, and painted a dark color, usually

black. The original dryer design called for five layers of

Graph 3: Vertical Wall & Side Reflectors

vs. No Reflector

180

160

140

Reflector Reflector 120

Degrees F

Surface Surface

100

Collector Surface

80

60

60°

Reflector

Angle 40

20

8:00 9:00 10:00 11:00 Noon 13:00 14:00 15:00 16:00

Time

With Reflectors Without Reflectors Ambient

Home Power #69 • February / March 1999 29

Solar Dehydration

Figure 7: Collector/Absorber

Configurations

Normal Diagonal Absorber Reverse Diagonal Absorber

Steeply Angled Sections Dual Pass U-Tube Through Pass

black aluminum window screening, which had proven to Lath vs. Screen

work well in other air heating collectors we had Next, we compared three layers of pre-painted black

constructed. Other designs call for metal lath, metal aluminum window screening to three layers of

plates such as black metal roofing, or aluminum or galvanized steel lath painted flat black. We found that

copper flashing. We decided to try some different the lath produced temperatures as much as 15° F (3.6°

materials and approaches to see if we could come up C) higher than the screen in our outdoor solar food

with a better absorber. dryer tests. We got the same results when we

compared six layers of screen to six layers of lath (see

Plate vs. Screen

Graph 4). While we found that the lath produced slightly

First, we compared five layers of black aluminum

higher temperatures, it was harder to work with, needed

window screen placed diagonally in the air flow channel

to be painted, and cost slightly more than the screen.

to one piece of black corrugated steel roofing placed in

the middle of the channel (see Figure 7). We found that When these tests were replicated with the solar

the mesh produced temperatures about 7° F (3.9° C) simulator, we had slightly better results with the screen

higher than the roofing in full sun. Other experiments than with the lath in both the three and six layer tests.

have shown that mesh type absorbers are superior to We were disappointed by the lack of positive correlation

plate type absorbers. These differences might be between our outdoor tests with the actual food dryers

reduced if we used a copper or aluminum plate instead and our indoor tests with the solar simulator. But there

of the steel roofing. are many variables to control and quite a few people

involved in setting things up and collecting data, so our

Graph 4: Lath vs. Screen Absorber control was not as tight as we would have liked. Despite

180

these problems, we are confident in concluding that

160

there is not a great deal of difference in performance

between lath and screen—both work effectively.

140

Layers of Absorber Mesh

We then compared three layers of lath to six layers of

Degrees F

120

lath, and three layers of screen to six layers of screen.

100 Obviously the more screen used, the greater the

expense. The literature on solar air heaters

80 recommends between five and seven layers. We

arbitrarily picked three and six layers. In our outdoor

60 tests, we found that six layers of screen produced

temperatures 5–10° F (1.2–2.4° C) higher than three

40

layers. Likewise, when we repeated these experiments

9:00 10:00 11:00 Noon 13:00 14:00 15:00 16:00 17:00 18:00 19:00

outdoors with lath, we found that six layers

Time

Lath Screen Ambient

outperformed both two and four layers (see Graph 5).

30 Home Power #69 • February / March 1999

Solar Dehydration

Graph 5: Two vs. Four vs. Six Layers of Absorber Graph 7: Absorber Installation Comparison

140 160

140

120

120

100

Degrees F

Degrees F

100

80

80

60

60

40 40

20 20

10:00 10:30 11:00 11:30 Noon 12:30 13:00 5:00 7:00 9:00 11:00 13:00 15:00 17:00 19:00 21:00

Time Time

2 Layers 6 Layers Bottom to Top Top to Bottom

4 Layers Ambient Ambient Steeply Angled Sections

Tests performed in the solar simulator showed very little of the 3/4 inch (19 mm) foil-faced insulation (Celotex

difference between three and six layers. We used the Tuff-R, polyisocyanurate). The flashing in one of the

simulator to test one and two layers and no absorber. dryers was painted flat black. The third dryer was left

With no absorber, the temperature decline was over 60° with just the reflective insulation board on the bottom of

F (33° C), dropping from 153 to 89° F (67 to 32° C) . the air flow channel. This test was done with both the

The temperatures for one, two, three, and six layers of actual dryers and the solar simulator. In both cases, the

lath after one half-hour were 145, 155, 159, and 160° F highest temperatures were attained with the reflective

(63, 68, 70, and 71° C). Based on our work, we feel that foil-faced insulation. The differences were substantial,

two or three layers of screen or lath are adequate for with the reflective insulation showing readings as much

effective performance, but adding a few more layers will as 25° F (14° C) higher than the dryer with the black

produce slightly higher temperatures. aluminum flashing (see Graph 6).

Reflective Is Effective Mesh Installation

When constructing a solar air heater, you must decide The original design called for the mesh to be inserted

what to do with the bottom of the air flow channel, into the collector diagonally from the bottom of the air

below the absorbing material. In the next part of our flow channel to the top (see Figure 7). This seemed the

research, we placed aluminum flashing in the bottom of best from a construction point of view. In this test, three

the air flow channels of two of the three dryers, on top configurations were compared: from bottom to top as

originally designed, from top to bottom, and a series of

Graph 6: Collector Bottom Material Comparison

more steeply angled pieces of mesh stretching from the

160

top to the bottom of the air flow channel. The

140 differences in temperatures attained were very small

(see Graph 7), and we concluded that there was not

120 much difference in performance.

Degrees F

100 U-Tube vs. Single Pass

Another characteristic of the original design is the U-

80 tube air flow channel. In addition to the air flow channel

right below the glazing, there is a second air flow

60 channel right below the first one, separated by a piece

of insulation board (see Figure 7). We compared a

40

dryer with this U-tube design to a dryer with just a

straight shot single channel and found no significance

20

11:45 12:15 12:45 13:15 13:45 14:15 14:45

difference in temperatures. We removed the insulation

Time board from our dryers and have completed all the

Black Flashing Aluminum Flashing experiments detailed in this article without the U-tube

Ambient Foil-faced Tuff-R setup.

Home Power #69 • February / March 1999 31

Solar Dehydration

Graph 8: PV Exhaust Fan vs. Vent removed and weighed the fruit. On all five days, the fruit

180 dried in the passive dryer weighed either the same or

less than the fruit dried in the active dryer.

160

Vent Opening

140 The dryers have vent covers at the top which can be

adjusted to regulate the air flow and temperature. The

Degrees F

120 smaller the opening, the higher the temperatures

attained. We wanted to know how much the vents

100

should be opened for maximum drying effectiveness.

80

We tried a variety of venting combinations while drying

fruit. For most of our experiments, we filled five to

60 seven of the thirteen shelves with 1/8 inch (3 mm) fruit

slices. We cut up, weighed, and placed an identical

40 quantity and quality of fruit in each of two dryers in the

9:00 11:00 13:00 15:00 17:00 19:00 21:00 morning. Sometime between 2 and 6 PM, we removed

Time the fruit from the dryers and weighed it again. We

PV-Powered Fan 3 Inch Vent Ambient

compared openings of different measurements: a one

Active vs. Passive inch (25 mm) to a seven inch (178 mm), a 3/4 inch (19

We experimented with several small, PV-powered fans mm) to a five inch (127 mm), a three inch (76 mm) to a

to see if they would generate higher air flows and six inch (152 mm), a three inch (76 mm) to a nine inch

possibly accelerate food dehydration. We tried three (229 mm), and a three inch (76 mm) to a five inch (127

different sizes: 0.08, 0.15, and 0.46 amps. We placed mm). During these experiments, the bottom vents were

the fans in the exhaust area of the dryer. Of the three, completely open.

the 0.15 amp fan seemed to work the best. It increased We found that higher temperatures were attained with

the air flow from about 25 to 50 feet per minute (8 to 15 smaller vent openings, but that drying effectiveness

meters per minute), but decreased temperatures was not always maximized. The best performance was

significantly (see Graph 8). The larger fan did not fit in observed when the vents were opened between three

the exhaust vent opening, and the smallest fan did not and six inches (76 and 152 mm), and temperatures

significantly increase the air flow. peaked at 135–180 °F (54–82° C) (see Graph 9). With

Even with the fans in use, the drying performance did the one inch (25 mm) and smaller openings and the

not improve. In every trial, the passive dryer either seven inch (178 mm) and larger openings, less water

matched or outperformed the active dryer. Each was removed from the fruit. There was no difference in

morning during a five-day experiment, we placed the water removed when we compared three inches to

exactly the same weight of fruit in each dryer. We used five inches (76 mm to 127 mm) and three inches to six

one to three pounds (0.4 to 1.4 kg) of apple or peach inches (76 mm to 152 mm).

slices. Each afternoon between 2:30 and 5 PM, we Based on this work, we would recommend opening the

Graph 9: Three Inch vs. Six Inch Exhaust Vent leeward exhaust vent cover between three and six

200 inches (76 and 152 mm), or between ten and twenty

square inches (65 and 129 cm2) of total exhaust area.

180 The exact size of the opening depends on the weather

160

conditions. With the vents opened between three and

six inches (76 and 152 mm), we have been able to

140 remove as much as sixty ounces (1.75 l) of water in a

Degrees F

single day from a full load of fruit and completely dry

120

about three and one-half pounds (1.5 kg) of apple slices

100 to 12–15% of the fruit’s wet weight.

80 Construction Improvements

As we experimented with the dryers, we came up with

60

some design improvements to simplify the construction,

40 reduce the cost, and increase the durability or

7:00 9:00 11:00 13:00 15:00 17:00 19:00 21:00 portability of the unit. To simplify the construction and

Time eliminate warping problems caused by wet weather, we

3 Inch Vent 6 Inch Vent Ambient decided to eliminate the intake vent covers during our

32 Home Power #69 • February / March 1999

Solar Dehydration

experiments. The vent covers at the top, if closed at

night, would prevent or reduce reverse thermosiphoning

and rehydration of food left in the dryer.

The redesigned air intake now has aluminum screen

secured to the plywood side pieces with wooden trim.

We also redesigned the top exhaust vent cover to

eliminate the warping problem caused by leaving the

vent covers opened during wet weather. The new

exhaust vent cover works very well (see Photo 6). It

spreads the exhaust air across the dryer’s width rather

than concentrating it in the center. This should improve

convective flows and performance. However, the vent

cover makes it more difficult to calculate the exhaust

area, and as a result, we mainly used the old design for

our research this past year.

We added wheels and handles to the unit, as it is heavy

and difficult to move around. It’s now easier to

maneuver, although it is still difficult to transport in a

small pickup truck. We purchased ten-inch (254 mm)

lawnmower-style wheels for $6 each. The axle cost $2.

With the wheels on the small legs at the bottom of the

collector, one person can move the dryer. Above, Photo 6: The new vent design.

The original design specified thin plywood for the roof of We made the unit more portable by adding wheels and

the dryer. We replaced that with 3/4 inch (19 mm) handles, and improved the durability by fastening the

plywood and covered the peak of the roof with legs with nuts and bolts, using aluminum bar to hold the

aluminum flashing. We also used 1/2 inch (38 mm) glazing in place, and using 3/4 inch (19 mm) plywood

wide by 1/8 inch (3 mm) thick aluminum bar stock and for the roof. We would also like to take the insulation

stainless steel screws to attach the glazing to the board out of a dryer to see if it significantly impacts the

dryer’s collector. Each collector used fourteen feet, performance. This would further decrease the cost of

eight inches (4.5 m) of aluminum bar at a cost of $23. the dryer. Soon, we hope to compare this design to

The 1/4 inch (6 mm) plywood strips used in the original direct solar dryers, which a Home Power reader has

design were adequate and less expensive, but would recently suggested can outperform our design. Thus

have required more maintenance. far, we have avoided direct dryers because of concerns

about vitamin loss in foods exposed to direct solar

Conclusions and Recommendations

radiation.

The dryer described in HP57 has worked well in our

tests. It produces temperatures of 130–180° F (54–82° We have tried to carefully explore all of the significant

C), and can dry up to 15 apples or peaches—about 3 variables affecting this dryer’s performance. We have

1/2 pounds (1.6 kg) of 1/8 inch (3 mm) thick slices—in been able to increase drying effectiveness with higher

one sunny to partly sunny day. The best performance in temperatures of approximately 30° F (16.6° C), while

our outdoor tests was attained with six layers of decreasing the cost by about $30. We have

expanded steel lath painted black, although aluminum demonstrated the best vent opening for drying

screen works almost as well and is easier to work with. effectiveness, and seen the impact that variables such

We also found that two or three layers of screen or lath as double glazing, fans, reflectors, and absorber type

would produce temperatures almost as high as six have on performance. We have also developed and

layers. The surface behind the absorber mesh should demonstrated a low cost solar simulator that can be

be reflective, and for best performance the exhaust vent used to test solar thermal collectors indoors.

covers should be opened three to six inches (76–152

Access

mm). The cost of the dryer and the time to construct it

Authors: Dennis Scanlin, Marcus Renner, David

can be reduced by eliminating the U-tube air flow

Domermuth, and Heath Moody, Department of

channel divider, the second or inner layer of glazing,

Technology, Appalachian State University, Boone, NC

and the intake vent covers, and by reducing the number

28608 • 704-262-3111 • scanlindm@appstate.edu

of layers of screen or lath to two or three.

Home Power #69 • February / March 1999 33

Solar Dehydration

Solar Cookers International (SCI), 1919 21st Street,

Sacramento, CA 95814 • 916-455-4499

Fax: 916-455-4498 • sci@igc.org

Sun-Lite HP glazing was purchased from Solar

Creating Peace

Components Corporation, 121 Valley Street,

Manchester, NH 03103-6211 • 603-668-8186

of Mind!

Fax: 603-668-1783 • solar2@ix.netcom.com

www.solar-components.com

Scales, anemometers, and other data collection

equipment were purchased from Thomas Scientific,

PO Box 99, Swedesboro, NJ 08085 • 800-345-2100

609-467-2000 • Fax: 800-345-5232

value@thomassci.com • www.thomassci.com

Data logger was purchased from Pace Scientific, Inc.,

6407 Idlewild Rd., Suite 2.214, Charlotte, NC 28212

704-568-3691 • Fax: 704-568-0278

sales@pace-sci.com • www.pace-sci.com

P eace of mind has become a

premium in today’s society. The Y2K

problem has created unrest, fear and

even panic in the minds of millions of

Americans. The global economy is

going berserk. But while the future is

definitely uncertain, one thing you can

count on is the fact that no matter

what happens, you will need food and

water! Emergency food storage is a

wise safeguard against all emergen-

cies from floods, earthquakes and

hurricanes to unemployment or illness.

Millennium III Foods offers nutritionally

balanced food plans for individuals,

families or communities at competitive

prices.

At Millennium III Foods, we don’t just

sell storage food…

WE CREATE PEACE OF MIND.

• TWO WEEK SHIPPING

• “One Year Supplies” are nutri-

tionally balanced to deliver over

1,900 calories per day

• Real food that’s easy to use!

• Awarded #1 Best Tasting

• A La Carte ordering or purchase One

Year Units for one, two or four per-

Fight Global Warming sons. Great value, simple planning!

Call for prices and information

SALES 888•883•1603

P.O. Box 1101, Arcata, CA 95518-1101

FAX 406•388•2603

Phone: 707-822-9095 • Fax: 707-822-6213 • www.sunfrost.com P.O. Box 10010

Bozeman, Montana 59719

WWW.M3MFOODS.COM

34 Home Power #69 • February / March 1999

Das könnte Ihnen auch gefallen

- Solar Cookers How To Make and Use ThemDokument55 SeitenSolar Cookers How To Make and Use Themjcarzola100% (1)

- Building A Solar Food DryerDokument19 SeitenBuilding A Solar Food DryerSTL_John100% (3)

- Construct Updraft GasifierDokument8 SeitenConstruct Updraft GasifierHariharan SivaramagopalakrishnanNoch keine Bewertungen

- How Did We Build The Garden Pool? Why Aquaponics? How Does The Garden Pool Work? Garden Pool ConceptsDokument28 SeitenHow Did We Build The Garden Pool? Why Aquaponics? How Does The Garden Pool Work? Garden Pool ConceptsDaniel PopNoch keine Bewertungen

- Biochar Rocket Stove Building InstructionsDokument4 SeitenBiochar Rocket Stove Building InstructionsDiogo Belo Freitas100% (2)

- Solar D DryerDokument50 SeitenSolar D DryerRamnarayan MeenaNoch keine Bewertungen

- Capturing Heat 3Dokument46 SeitenCapturing Heat 3AlexandruChivaranNoch keine Bewertungen

- Makin' Bacon from Scratch (It Is So Much Better Than Store-boughtDokument8 SeitenMakin' Bacon from Scratch (It Is So Much Better Than Store-boughtCarlos Baul DavidNoch keine Bewertungen

- Audels Engineers and Mechanics Guide Volume 5 From WWW Jgokey ComDokument556 SeitenAudels Engineers and Mechanics Guide Volume 5 From WWW Jgokey Comjdsa123Noch keine Bewertungen

- Package Question List: UPT Periode Exam Code Level Package CodeDokument5 SeitenPackage Question List: UPT Periode Exam Code Level Package CodeYoga Heru NNoch keine Bewertungen

- Rice husk quasi gasifier stove with side steam injectionDokument2 SeitenRice husk quasi gasifier stove with side steam injectionAmp AunyamoneNoch keine Bewertungen

- Micro Gasification ManualDokument175 SeitenMicro Gasification ManualMart KarmNoch keine Bewertungen

- Solar Dryer Manual General PDFDokument6 SeitenSolar Dryer Manual General PDFFrancisco BonillaNoch keine Bewertungen

- Solar Thermal Collectors GuideDokument36 SeitenSolar Thermal Collectors GuideSuperbVoiceNoch keine Bewertungen

- Mechanical Design of Smart Solar Tunnel DryerDokument5 SeitenMechanical Design of Smart Solar Tunnel DryerashisbhuniyaNoch keine Bewertungen

- Fruit Tree ProductionDokument15 SeitenFruit Tree Productionamol modakNoch keine Bewertungen

- BiomassDokument66 SeitenBiomassParjea Marius100% (4)

- Cambridge IGCSE: BiologyDokument14 SeitenCambridge IGCSE: BiologyAhmadElgindyNoch keine Bewertungen

- Holzer Sepp - Raised Beds and Ridges PDFDokument10 SeitenHolzer Sepp - Raised Beds and Ridges PDFMoxaline100% (1)

- Wood Conserving Cook Stoves A Design Guide 1980 PDFDokument117 SeitenWood Conserving Cook Stoves A Design Guide 1980 PDFzizi zizicNoch keine Bewertungen

- Machines ManufacturerDokument6 SeitenMachines ManufacturerArasan ArasanNoch keine Bewertungen

- Gasifier Stove ManualDokument36 SeitenGasifier Stove ManualMahesh Dulani100% (2)

- Homemade HRV, PDF, Jan 2004Dokument39 SeitenHomemade HRV, PDF, Jan 2004JohnNoch keine Bewertungen

- Building, Installing and Maintaining The HELPS International Nixtamal CookerDokument6 SeitenBuilding, Installing and Maintaining The HELPS International Nixtamal CookerTefera AdugnaNoch keine Bewertungen

- Solar Drying TechnologyDokument640 SeitenSolar Drying Technology11751175100% (1)

- Biogas Technology: Construction, Utilization and Operation ManualDokument52 SeitenBiogas Technology: Construction, Utilization and Operation ManualDwi Cahyo NugrohoNoch keine Bewertungen

- Biomass RetDokument122 SeitenBiomass RetRadison sierraNoch keine Bewertungen

- Process Dynamics and Control, Ch. 9 Solution ManualDokument17 SeitenProcess Dynamics and Control, Ch. 9 Solution ManualBen Spearman100% (3)

- Solar Drying Conference 2009Dokument24 SeitenSolar Drying Conference 2009ashisbhuniyaNoch keine Bewertungen

- Biomass Downdraft Gasifier Engine SystemsDokument148 SeitenBiomass Downdraft Gasifier Engine Systemssounds4uniqueNoch keine Bewertungen

- Wood Chip Compost Water HeaterDokument25 SeitenWood Chip Compost Water HeaterRoberto BekembauerNoch keine Bewertungen

- BiomassDokument5 SeitenBiomassAkshara K VijayNoch keine Bewertungen

- Beehive BriquettesDokument4 SeitenBeehive BriquettesRODRIGO TROCONIS100% (1)

- Solar DryingDokument9 SeitenSolar DryingNkem OkonkwoNoch keine Bewertungen

- A Simple Solar DryerDokument3 SeitenA Simple Solar DryerAllan HannaNoch keine Bewertungen

- Mola Energy Biogas Plant and Biogas Related Product.Dokument8 SeitenMola Energy Biogas Plant and Biogas Related Product.Carlos Fu100% (1)

- A-318 Apcseet 2011 Josh WilkeyDokument24 SeitenA-318 Apcseet 2011 Josh WilkeyJosh ApfelstrudelNoch keine Bewertungen

- Rudra Solar Box CookerDokument6 SeitenRudra Solar Box CookerchiralatNoch keine Bewertungen

- Productive Usage of BiomassDokument6 SeitenProductive Usage of BiomassN. Sasidhar100% (1)

- Science Business and Biotechnology in AgribusinessDokument36 SeitenScience Business and Biotechnology in AgribusinessBidur Prasad ChaulagainNoch keine Bewertungen

- Kon-Tiki Cone Kiln Produces Biochar Through Efficient PyrolysisDokument48 SeitenKon-Tiki Cone Kiln Produces Biochar Through Efficient PyrolysisAdolfo Figueroa LahayeNoch keine Bewertungen

- Low Input Food Nutrition ModelDokument226 SeitenLow Input Food Nutrition ModelMindy101Smith100% (5)

- Biomass Gasification PDFDokument29 SeitenBiomass Gasification PDFHotib PerwiraNoch keine Bewertungen

- Biomass EnergyDokument1 SeiteBiomass EnergyrapNoch keine Bewertungen

- PAES 2015 Master-Catalog PDFDokument532 SeitenPAES 2015 Master-Catalog PDFjrvalleca2Noch keine Bewertungen

- Waste Plactics To Useful Petroleum ProductsDokument6 SeitenWaste Plactics To Useful Petroleum ProductsNishant ChoubeyNoch keine Bewertungen

- Chapter-2 Various Design of Solar Cooker 2.1 Solar CookerDokument9 SeitenChapter-2 Various Design of Solar Cooker 2.1 Solar CookerappannusaNoch keine Bewertungen

- Blest Plastic To Fuel WebDokument22 SeitenBlest Plastic To Fuel Webarnabjyoti dasNoch keine Bewertungen

- Edible PlantsDokument89 SeitenEdible Plantsujyorndm67% (3)

- Rice Husker Construction Manual - Appropedia - The Sustainability Wiki PDFDokument17 SeitenRice Husker Construction Manual - Appropedia - The Sustainability Wiki PDFMarcos MorschNoch keine Bewertungen

- Wild Edible Plants PosterDokument1 SeiteWild Edible Plants PosterRadha DamodarNoch keine Bewertungen

- Cupboard Storage TimesDokument4 SeitenCupboard Storage TimesSonoftheSouth597Noch keine Bewertungen

- Optimization Test of Solar Dehumidifier Dryer in DryingDokument10 SeitenOptimization Test of Solar Dehumidifier Dryer in DryingAnonymous URH1fbQdNoch keine Bewertungen

- How To Make The Parabolic AMSI Solar CookerDokument19 SeitenHow To Make The Parabolic AMSI Solar CookerOffice of Energy and Environmental Affairs, MANoch keine Bewertungen

- Bean Sprout Cultivation Manual - Ed1 - BookDokument19 SeitenBean Sprout Cultivation Manual - Ed1 - BookShiva PastorNoch keine Bewertungen

- Booklet Solar DryingDokument4 SeitenBooklet Solar DryingdenifeliNoch keine Bewertungen

- A Mixed-Mode Natural Convection Solar Dryer With Biomass Burner and Heat Storage Back-Up HeaterDokument9 SeitenA Mixed-Mode Natural Convection Solar Dryer With Biomass Burner and Heat Storage Back-Up HeaterprinceNoch keine Bewertungen

- Plywood ReportDokument13 SeitenPlywood ReportJonas Nathan CadatalNoch keine Bewertungen

- Properties and Performance of Sweetgum and Southern Pine PlywoodDokument7 SeitenProperties and Performance of Sweetgum and Southern Pine PlywoodHanyNoch keine Bewertungen

- RRLDokument3 SeitenRRLrogelyn samilinNoch keine Bewertungen

- Thermal Paper Insulator Machine Reduces WasteDokument7 SeitenThermal Paper Insulator Machine Reduces WastepArTOfanoNimOsNoch keine Bewertungen

- Conduction, Convection, RadiationDokument5 SeitenConduction, Convection, RadiationOne_sofian2715Noch keine Bewertungen

- A Continous Press Veneer DryerDokument3 SeitenA Continous Press Veneer DryerFernandoNoch keine Bewertungen

- Casey Doran Lab Report Sand and WaterDokument2 SeitenCasey Doran Lab Report Sand and Waterapi-249915249Noch keine Bewertungen

- TemperatureDokument14 SeitenTemperatureFajar SanjayaNoch keine Bewertungen

- 7 Heat SolutionsDokument2 Seiten7 Heat Solutionssmi_santhoshNoch keine Bewertungen

- Math 16B Quiz 6 SolutionsDokument2 SeitenMath 16B Quiz 6 SolutionsKaren Keith TengcoNoch keine Bewertungen

- Archivo 2-Metodos ASTM Tema ViscosidadDokument85 SeitenArchivo 2-Metodos ASTM Tema ViscosidadMEGALOMANIACNoch keine Bewertungen

- Cannon CT-1000 Installation and Operation ManualDokument30 SeitenCannon CT-1000 Installation and Operation ManualmegacobNoch keine Bewertungen

- Electric Oven Calibration Setup and Procedure - Calibration AwarenessDokument19 SeitenElectric Oven Calibration Setup and Procedure - Calibration AwarenessAlberto Núñez CardezoNoch keine Bewertungen

- MLX90632 Datasheet Melexis PDFDokument45 SeitenMLX90632 Datasheet Melexis PDFVenkata Kiran Kumar SathikelaNoch keine Bewertungen

- 06 ASTM ThermometersDokument50 Seiten06 ASTM Thermometerssofian juniardiNoch keine Bewertungen

- Efectis Certificate Fire Rated Roof HatchDokument3 SeitenEfectis Certificate Fire Rated Roof HatchEMTC EMTCNoch keine Bewertungen

- TC65 TC15Dokument20 SeitenTC65 TC15suryaNoch keine Bewertungen

- ZM - Mercury in Steel ThermometerDokument1 SeiteZM - Mercury in Steel ThermometervjNoch keine Bewertungen

- SITXINV002 Maintain The Quality of Perishable Items: Assessment 2 - Written KnowledgeDokument8 SeitenSITXINV002 Maintain The Quality of Perishable Items: Assessment 2 - Written KnowledgeSubash UpadhyayNoch keine Bewertungen

- Sensor MCQsDokument3 SeitenSensor MCQsresourcesdoyenNoch keine Bewertungen

- Bry-Air Dehumidifier ManualDokument17 SeitenBry-Air Dehumidifier ManualMaulik33% (3)

- Introduction to Chemical Properties and ChangesDokument17 SeitenIntroduction to Chemical Properties and ChangesNari KangNoch keine Bewertungen

- SMK Seri Kampar (Question)Dokument2 SeitenSMK Seri Kampar (Question)chimlaiyernNoch keine Bewertungen

- Industrial Sensors and Control PDFDokument62 SeitenIndustrial Sensors and Control PDFSurendra SainiNoch keine Bewertungen

- Monitoring Environmental Parameters of Incubators, Fridge-Freezers QC-05-05 EPADokument17 SeitenMonitoring Environmental Parameters of Incubators, Fridge-Freezers QC-05-05 EPAAna M VrrNoch keine Bewertungen

- Distillation of Cutback Asphaltic D402 08Dokument5 SeitenDistillation of Cutback Asphaltic D402 08Pedro AlvelaisNoch keine Bewertungen

- ASTM D 70 - 03 Standard Test Method ForDokument3 SeitenASTM D 70 - 03 Standard Test Method ForBiswakalyan Mishra100% (1)

- Gross Calorific Value of Coal and Coke: Standard Test Method ForDokument19 SeitenGross Calorific Value of Coal and Coke: Standard Test Method ForTrung SơnNoch keine Bewertungen

- TE LabDokument37 SeitenTE Labpaddu116Noch keine Bewertungen

- Inspection Check Sheet of Reactor and Capacitor: Pt. Chandra Asri Petrochemical TBKDokument7 SeitenInspection Check Sheet of Reactor and Capacitor: Pt. Chandra Asri Petrochemical TBKIbnu RozaqNoch keine Bewertungen

- Measuring Temperature - 16 6Dokument3 SeitenMeasuring Temperature - 16 6api-265567244Noch keine Bewertungen