Beruflich Dokumente

Kultur Dokumente

TFP2180!01!2003 - Solenoid Valve

Hochgeladen von

Joseph R. F. DavidOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

TFP2180!01!2003 - Solenoid Valve

Hochgeladen von

Joseph R. F. DavidCopyright:

Verfügbare Formate

Close

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500

Solenoid Valves

For Deluge And Preaction Systems

Electric Release Service

General Technical

Description Data

The Solenoid Valves For Releasing Approvals

Service are intended for use with Tyco UL Listed and CSA Certified under the

Fire Products Deluge and Preaction name of Parker Hannifin Corporation,

Valves which are to be electrically ac- Skinner Valve Division. P/N 52-287-1-

tuated. The Solenoid Valves are used 024 (175 psi) and P/N 52-287-1-124

in conjunction with an electric releas- (250 psi) are FM Approved for release

ing panel that is listed or approved (as of Tyco Fire Products Deluge and Pre-

appropriate) for fire protection releas- action Valves.

ing service, and where the releasing

Working Water Pressure

panel is operated by listed or approved

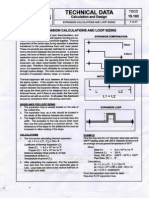

Refer to Figure 1.

(as appropriate) electric fire detectors.

Physical Characteristics chamber of the deluge or preaction

WARNING The body is brass, and the seal is valve, and the outlet port of the Sole-

The Solenoid Valves described herein Nitrile rubber. noid Valve is to piped to an open drain.

must be installed and maintained in For best life and optimum perform-

compliance with this document, as

well as with the applicable standards Operation ance the Solenoid Valve should be

mounted vertically upright, as illus-

of the National Fire Protection Asso- trated in Figure 2, so as to minimize

ciation, in addition to the standards of Operation of an electrical device such

wear and reduce the possibility of ac-

any other authorities having jurisdic- as a heat sensitive thermostat, smoke

cumulating foreign matter.

tion. Failure to do so may impair the detector, or electric manual pull station

integrity of this device. signals the releasing panel to energize Step 3. Only apply pipe thread sealant

the releasing circuit. Energizing the re- sparingly to the male pipe threads of

The owner is responsible for maintain- leasing circuit opens the normally the connecting pipe nipples.

ing their fire protection system and de- closed de-energized Solenoid Valve to

vices in proper operating condition. Step 4. To prevent distortion of the

release water pressure from the differ-

The installing contractor or sprinkler Solenoid Valve body, always wrench

ential chamber of the deluge or preac-

manufacturer should be contacted on the portion adjacent to the pipe to

tion valve, which in turn permits the

relative to any questions. which it is being connected. Do not use

deluge or preaction valve to open and

the Solenoid Valve to force a pipeline

allow a flow of water into the system

into position. Doing so may result in

piping.

distortion of the valve.

Step 5. Conduit and electrical connec-

Installation tions are to be made in accordance

with the requirements of the authority

The Solenoid Valves For Releasing having jurisdiction and/or the National

Service are to be installed in accord- Electric Code. The coil assembly may

ance with the following instructions: be reoriented, as necessary, by first

Step 1. Check the nameplate for the loosening the nut on top of the coil.

correct catalog number, NEMA classi- After repositioning the coil assembly,

fication, and voltage. tighten the nut with a torque of 43 to 53

inch-pounds (4,9 to 6,0 Nm).

Step 2. The Solenoid Valves are to be

installed as part of the deluge or pre- NOTE

action valve trim in accordance with Turn off electrical power before con-

the applicable instructions provided for necting the Solenoid Valve to the

the deluge valve or preaction valve. power source.

The inlet port of the Solenoid Valve is

to be connected to the differential

Page 1 of 4 JANUARY, 2003 TFP2180

Page 2 of 4 TFP2180

ENCLOSURE WORKING WATER AC VOLT-AMPS

DC

TYPE VOLTAGE PRESSURE WATTS CATALOG P/N

(a) (b) AMPS

(NEMA RATINGS) PSI (BAR) INRUSH HOLDING

120 VAC, 60 Hz 20-175

10 31 16 73218BN4UNLVN0C111P3 52-287-1-110

110 VAC, 50 Hz (1,4-12,1)

20-175

24 VDC 10 0.41 73218BN4UNLVN0C111C2 52-287-1-024

(1,4-12,1)

20-250

ORDINARY 24 VDC 22 0.83 73212BN4TNLVN0C322C2 52-287-1-124

(1,4-17,2)

LOCATION

(2, 4, and 4X) 20-175

48 VDC 10 0.21 73218BN4UNLVN0C111C4 52-287-1-048

(1,4-12,1)

20-175

125 VDC 11 0.08 73218BN4UNLVN0C1113N 52-287-1-125

(1,4-12,1)

20-175

250 VDC 10 0.04 73218BN4UNLVN0C111N9 52-287-1-015

(1,4-12,1)

20-175

110/120 VAC 10 31 16 73218BN4UNLVN0H111P3 52-287-1-210

(1,4-12,1)

20-175

HAZARDOUS 24 VDC 10 0.41 73218BN4UNLVN0H111C2 52-287-1-224

(1,4-12,1)

LOCATION

(4, 4X, 7, and 9) 20-175

125 VDC 11 0.08 73218BN4UNLVN0H1113N 52-287-1-225

(1,4-12,1)

20-175

250 VDC 10 0.04 73218BN4UNLVN0H111N9 52-287-1-215

(1,4-12,1)

NOTES:

(a) (b)

Current to start plunger moving. Current to hold plunger open.

FIGURE 1

ENCLOSURE AND VOLTAGE RATINGS

1/2" CONDUIT

Care and CONNECTION

Maintenance 3-13/16"

(96,8 mm)

The following inspection procedure

must be performed as indicated, in ad- ELECTRICAL 4-3/8"

dition to any specific requirements of LEADS (111,1 mm)

the NFPA, and any impairment must

be immediately corrected. 1/2" NPT

The owner is responsible for the in- 2-5/8" (TYPICAL) 2-9/16"

spection, testing, and maintenance of (66,7 mm) (65,1 mm)

their fire protection system and de-

vices in compliance with this docu- 175 PSI (12,1 BAR) MAXIMUM SERVICE PRESSURE

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

addition to the standards of any 1/2" CONDUIT

authority having jurisdiction. The in- CONNECTION

stalling contractor or product manufac- 3-7/8"

turer should be contacted relative to (98,4 mm)

any questions.

It is recommended that automatic ELECTRICAL 4-5/8"

sprinkler systems be inspected, LEADS (117,5 mm)

tested, and maintained by a qualified

Inspection Service.

1/2" NPT

NOTES (TYPICAL)

2-3/4" 2"

Before closing a fire protection system

control valve for inspection or mainte- (69,9 mm) (50,8 mm)

nance work on the fire protection sys- 250 PSI (17,2 BAR) MAXIMUM SERVICE PRESSURE

tem which it controls, permission to

shut down the effected fire protection

system must first be obtained from the

proper authorities and all personnel

FIGURE 2

who may be affected by this action

must be notified. SOLENOID VALVES FOR RELEASING SERVICE

After placing a fire protection system

TFP2180 Page 3 of 4

in service, notify the proper authorities

and advise those responsible for moni- Limited Ordering

toring proprietary and/or central sta-

tion alarms. Warranty Information

Products manufactured by Tyco Fire Orders for the Solenoid Valves must

INSPECTION PROCEDURE Products are warranted solely to the include the description and Par t

The Solenoid Valves must be in- original Buyer for ten (10) years Number (P/N).

spected quarterly in accordance with against defects in material and work-

the following instructions: manship when paid for and properly Solenois Valves:

installed and maintained under normal Specify: (Specify voltage), (Specify

Verify operation of the Solenoid Valve use and service. This warranty will ex- 175 or 250) psi pressure rating, Sole-

following the procedure outlined in the pire ten (10) years from date of ship- noid Valve with (specify ordinary or

Technical Data Sheet for the Tyco Fire ment by Tyco Fire Products. No war- hazardous) location enclosure, P/N

Products Deluge or Preaction Valve. ranty is given for products or (specify from Figure 1).

In general, if the voltage to the coil is components manufactured by compa-

correct, sluggish valve operation, ex- nies not affiliated by ownership with

cessive leakage, or noise will indicate Tyco Fire Products or for products and

that cleaning is required. Clean the components which have been subject

Solenoid Valve in accordance with the to misuse, improper installation, corro-

procedures outlined by Honeywell, Inc. sion, or which have not been installed,

Skinner Valve. maintained, modified or repaired in ac-

cordance with applicable Standards of

Causes of Improper Operation the National Fire Protection Associa-

• Faulty Control Circuit: Check the tion, and/or the standards of any other

electrical system by energizing the Authorities Having Jurisdiction. Mate-

releasing circuit to the Solenoid rials found by Tyco Fire Products to be

Valve. A metallic “click” signifies that defective shall be either repaired or

the solenoid is operating. Absence replaced, at Tyco Fire Products’ sole

of the “click” indicates loss of power option. Tyco Fire Products neither as-

supply. Check for loose or blown sumes, nor authorizes any person to

fuses, open-circuited or grounded assume for it, any other obligation in

coil, broken lead wires or broken connection with the sale of products or

splice connections. parts of products. Tyco Fire Products

shall not be responsible for sprinkler

• Burned-Out Coil: Check for open- system design errors or inaccurate or

circuited coil. Replace if necessary. incomplete information supplied by

Check supply voltage; it must be the Buyer or Buyer’s representatives.

same as specified on label or name-

plate. IN NO EVENT SHALL TYCO FIRE

PRODUCTS BE LIABLE, IN CON-

• Low Voltage: Check voltage across TRACT, TORT, STRICT LIABILITY OR

the coil leads. Voltage must be at UNDER ANY OTHER LEGAL THE-

least 85% of nameplate rating. ORY, FOR INCIDENTAL, INDIRECT,

SPECIAL OR CONSEQUENTIAL

DAMAGES, INCLUDING BUT NOT

LIMITED TO LABOR CHARGES, RE-

GARDLESS OF WHETHER TYCO

FIRE PRODUCTS WAS INFORMED

ABOUT THE POSSIBILITY OF SUCH

DAMAGES, AND IN NO EVENT

SHALL TYCO FIRE PRODUCTS’ LI-

ABILITY EXCEED AN AMOUNT

EQUAL TO THE SALES PRICE.

THE FOREGOING WARRANTY IS

MADE IN LIEU OF ANY AND ALL

OTHER WARRANTIES EXPRESS OR

IMPLIED, INCLUDING WARRANTIES

OF MERCHANTABILITY AND FIT-

NESS FOR A PARTICULAR PUR-

POSE.

Page 4 of 4 TFP2180

TYCO FIRE PRODUCTS, 451 North Cannon Avenue, Lansdale, Pennsylvania 19446

Das könnte Ihnen auch gefallen

- ESAB Welding HandbookDokument31 SeitenESAB Welding Handbookhooky1100% (4)

- Physics ExamDokument30 SeitenPhysics Examjomar bolasocNoch keine Bewertungen

- Fe Aid Engl Heft 092012Dokument80 SeitenFe Aid Engl Heft 092012DANE80Noch keine Bewertungen

- Tyco Sprinkler Catalog GPC 12-15 WebDokument100 SeitenTyco Sprinkler Catalog GPC 12-15 WebSandra Vazquez Iglesias100% (1)

- GemsSensors MasterCatalogDokument422 SeitenGemsSensors MasterCatalogJesus RodriguezNoch keine Bewertungen

- Automatic Sprinkler SystemsDokument25 SeitenAutomatic Sprinkler SystemsManishaDhimanNoch keine Bewertungen

- Capillary Tube Inst-Tubing PDFDokument4 SeitenCapillary Tube Inst-Tubing PDFEduardoNoch keine Bewertungen

- Fault CodesDokument72 SeitenFault CodesKyaw San Oo100% (1)

- Design of Hydraulic and Pneumatic Systems Lecture NotesDokument135 SeitenDesign of Hydraulic and Pneumatic Systems Lecture NotesvanajaNoch keine Bewertungen

- Caterpillar XQ1000 Containerized Diesel Generator SetDokument10 SeitenCaterpillar XQ1000 Containerized Diesel Generator SetMacAllister MachineryNoch keine Bewertungen

- RAI S ManualDokument2 SeitenRAI S ManualNesil Abiera0% (1)

- Especificação Técnica RM7800L1087 PDFDokument36 SeitenEspecificação Técnica RM7800L1087 PDFpedro netoNoch keine Bewertungen

- Fire Detection/Total Flooding Carbon Dioxide Suppression System Engineering Specifications Part 1 - General 1.01 Description of WorkDokument17 SeitenFire Detection/Total Flooding Carbon Dioxide Suppression System Engineering Specifications Part 1 - General 1.01 Description of Work張哲僑Noch keine Bewertungen

- Fundamentals of The RectennaDokument37 SeitenFundamentals of The RectennaWilfredo A MolinaNoch keine Bewertungen

- Solution Refrigeration Air Conditioning Stoecker and Jones PDFDokument2 SeitenSolution Refrigeration Air Conditioning Stoecker and Jones PDFPatient KatambayiNoch keine Bewertungen

- Maintaining Electrical SystemsDokument8 SeitenMaintaining Electrical SystemsHealthyCut FarmsNoch keine Bewertungen

- Sepam 20, 40, 80 Catalogue 2013 PDFDokument286 SeitenSepam 20, 40, 80 Catalogue 2013 PDFMeyga Pranata JuandaNoch keine Bewertungen

- Siemens - SolkorDokument32 SeitenSiemens - SolkorKiliardt ScmidtNoch keine Bewertungen

- T&C of Fire Supression SystemDokument5 SeitenT&C of Fire Supression Systemamg007100% (1)

- Saturation TablesDokument44 SeitenSaturation TablesPrathik KaundinyaNoch keine Bewertungen

- Catalogo Grinell RociadoresDokument88 SeitenCatalogo Grinell RociadoresJosé Martín Meza CabillasNoch keine Bewertungen

- Indian Standard - Design and Installation of Fixed Foam Fire Extinguishing System-Code of PracticeDokument43 SeitenIndian Standard - Design and Installation of Fixed Foam Fire Extinguishing System-Code of PracticeS DattaNoch keine Bewertungen

- 30XA Product Data PDFDokument36 Seiten30XA Product Data PDFanoopkumar1231150100% (2)

- Vigilon Repeat Panel (EN/BS) : VIG-RPT-72Dokument10 SeitenVigilon Repeat Panel (EN/BS) : VIG-RPT-72Mitsubishi FA Riyadh-Saudi ArabiaNoch keine Bewertungen

- ACRD6XXP SchematicDokument2 SeitenACRD6XXP SchematicMasab AnisNoch keine Bewertungen

- Sub Station Capacity & Short Circuit Current Limits by Voltage LevelDokument4 SeitenSub Station Capacity & Short Circuit Current Limits by Voltage LevelManish TiwariNoch keine Bewertungen

- Moldcast Bollards Brochure 1998Dokument14 SeitenMoldcast Bollards Brochure 1998Alan MastersNoch keine Bewertungen

- Process Control Lecture 9 (M2)Dokument53 SeitenProcess Control Lecture 9 (M2)lalusebanNoch keine Bewertungen

- Equipment Damage Curves CapacitorsDokument2 SeitenEquipment Damage Curves CapacitorsrobertoseniorNoch keine Bewertungen

- Magnetic FlowmetersDokument23 SeitenMagnetic FlowmetersMuhammad Usman TahirNoch keine Bewertungen

- Specifications For Switchboard and Commercial MeteringDokument7 SeitenSpecifications For Switchboard and Commercial MeteringchrisNoch keine Bewertungen

- TECS Water Cooled ChillerDokument8 SeitenTECS Water Cooled Chillerntt_121987Noch keine Bewertungen

- I 769n Preaction Dpa PSTDokument1 SeiteI 769n Preaction Dpa PSTdemdiinNoch keine Bewertungen

- End-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesDokument6 SeitenEnd-Suction Fire Pumpset Diesel Engine Driven: LBSD SeriesMuhammad MustafaNoch keine Bewertungen

- 38AH Carrier PDFDokument108 Seiten38AH Carrier PDFskmishra110100% (2)

- Tripp Lite Owners Manual 754016 PDFDokument24 SeitenTripp Lite Owners Manual 754016 PDFAbelardo GuadarramaNoch keine Bewertungen

- AERCO Boiler Benchmark 3.0Dokument129 SeitenAERCO Boiler Benchmark 3.0hfdadl100% (1)

- Fischer Fixings For Sprinkler SystemsDokument8 SeitenFischer Fixings For Sprinkler SystemsDejan DosljakNoch keine Bewertungen

- VFD PDFDokument16 SeitenVFD PDFMatthieuNoch keine Bewertungen

- Pump Catalogue PDFDokument48 SeitenPump Catalogue PDFShah Newaz KabirNoch keine Bewertungen

- Installation single-line diagram protection schemeDokument5 SeitenInstallation single-line diagram protection schemeAnonymous CO7aaHrNoch keine Bewertungen

- DZL Series Chain Grate Boiler OkDokument10 SeitenDZL Series Chain Grate Boiler OkCarlos LehmanNoch keine Bewertungen

- Water Based Fire Suppression Systems ExplainedDokument54 SeitenWater Based Fire Suppression Systems ExplainedKolos Char YiuNoch keine Bewertungen

- Catalogo de Compressor PDFDokument60 SeitenCatalogo de Compressor PDFFrankNoch keine Bewertungen

- Mechanical Heat Pump-2 PDFDokument9 SeitenMechanical Heat Pump-2 PDFRushikesh PatilNoch keine Bewertungen

- 160.49-PW14york Solid State StarterDokument4 Seiten160.49-PW14york Solid State StarterAwo Orumila Giraldolegra0% (1)

- CTV SLB041 en - 06292020Dokument2 SeitenCTV SLB041 en - 06292020Nguyen ThuongNoch keine Bewertungen

- 2000w PDFDokument48 Seiten2000w PDFaqobumNoch keine Bewertungen

- Iom 1202 082013Dokument137 SeitenIom 1202 082013Bianca L. Foliaco100% (1)

- A. Mitsubishi Generator Set Diesel Lineup From EuropeDokument8 SeitenA. Mitsubishi Generator Set Diesel Lineup From Europeyudi handokoNoch keine Bewertungen

- 11 System Sensor Ssm24Dokument4 Seiten11 System Sensor Ssm24samNoch keine Bewertungen

- 400 Series Instructions 051118 WebDokument4 Seiten400 Series Instructions 051118 Webzidan080606Noch keine Bewertungen

- Section 6 - ElectricalDokument9 SeitenSection 6 - ElectricalJonathanDavidDeLosSantosAdornoNoch keine Bewertungen

- Deluge ValveDokument8 SeitenDeluge ValveMOHNISHKUMARJHANoch keine Bewertungen

- Techniical DetailDokument42 SeitenTechniical DetailAhmed AbdelgawadNoch keine Bewertungen

- ATV 2008-015 OUTLANDER 400 EFI (Lights, Gauge and Accessories) - Shop Manual - 04FXemAAG - SM51Y08S10 - enDokument33 SeitenATV 2008-015 OUTLANDER 400 EFI (Lights, Gauge and Accessories) - Shop Manual - 04FXemAAG - SM51Y08S10 - enfeNoch keine Bewertungen

- 900 040 01Dokument8 Seiten900 040 01Alessandra FloresfarNoch keine Bewertungen

- Installation Instructions: CautionDokument4 SeitenInstallation Instructions: CautionVMNoch keine Bewertungen

- Model RC-1 Retard Chamber For Variable Pressure Wet Pipe Sprinkler Systems 300 Psi (20,7 Bar)Dokument4 SeitenModel RC-1 Retard Chamber For Variable Pressure Wet Pipe Sprinkler Systems 300 Psi (20,7 Bar)asimnaqvi2008Noch keine Bewertungen

- 1.07 K Controls E-Training - Solenoid Control of Pneumatic Actuators PDFDokument8 Seiten1.07 K Controls E-Training - Solenoid Control of Pneumatic Actuators PDFShantanu RoyNoch keine Bewertungen

- Installation, operation and maintenance guide for TP series pumpsDokument17 SeitenInstallation, operation and maintenance guide for TP series pumpsRamesh arumugamNoch keine Bewertungen

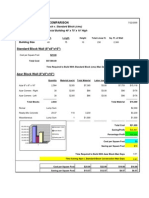

- Expansion Calculation and Loop Sizing001Dokument2 SeitenExpansion Calculation and Loop Sizing001Joseph R. F. DavidNoch keine Bewertungen

- CMMS PresentationDokument15 SeitenCMMS PresentationJoseph R. F. DavidNoch keine Bewertungen

- Final-Front Pages-2011 PME CodeDokument10 SeitenFinal-Front Pages-2011 PME CodeJoseph R. F. DavidNoch keine Bewertungen

- DOT Title 49Dokument78 SeitenDOT Title 49Joseph R. F. DavidNoch keine Bewertungen

- Regulate Master Plumbers ActDokument6 SeitenRegulate Master Plumbers ActJoseph R. F. DavidNoch keine Bewertungen

- TFP802!05!2009 - D3 Spray NozzlesDokument6 SeitenTFP802!05!2009 - D3 Spray NozzlesJoseph R. F. DavidNoch keine Bewertungen

- Manual Release StationDokument1 SeiteManual Release StationJoseph R. F. DavidNoch keine Bewertungen

- Cotta Transfer Case Lube PlanDokument3 SeitenCotta Transfer Case Lube PlanMatias Alfredo Contreras KöbrichNoch keine Bewertungen

- Guidelines For Planning Childcare Centers & Playground DesignDokument15 SeitenGuidelines For Planning Childcare Centers & Playground Design105auco100% (1)

- LMDQDokument601 SeitenLMDQMohd Azamuddin Mohd SaifullizanNoch keine Bewertungen

- DR System ConciseDokument37 SeitenDR System ConciseJiten KarmakarNoch keine Bewertungen

- Batch Profile - 2017Dokument57 SeitenBatch Profile - 2017Praneet TNoch keine Bewertungen

- Support Orca3D HelpDokument281 SeitenSupport Orca3D Helplavrik100% (1)

- Ashrae - 2009 I-P - F09 - AddDokument2 SeitenAshrae - 2009 I-P - F09 - AddSergio SemmNoch keine Bewertungen

- Achievements Under EpiraDokument6 SeitenAchievements Under EpiraLyn Dela Cruz DumoNoch keine Bewertungen

- LDX2101 Spec SheetDokument2 SeitenLDX2101 Spec SheetGaurav NarulaNoch keine Bewertungen

- Correlation Study and Regression Analysis of Water Quality Assessment of Nagpur City, IndiaDokument5 SeitenCorrelation Study and Regression Analysis of Water Quality Assessment of Nagpur City, IndiaShakeel AhmadNoch keine Bewertungen

- Operation Manual: Daikin Room Air ConditionerDokument92 SeitenOperation Manual: Daikin Room Air ConditionerbenNoch keine Bewertungen

- Siremobil Compact PDFDokument108 SeitenSiremobil Compact PDFhector anguiano100% (2)

- G. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFDokument2 SeitenG. ACI 360R-06 Brings Slabs On Ground Into The 21st Century - Art McKinney PDFinitbashNoch keine Bewertungen

- Propeller DesignDokument74 SeitenPropeller DesignBambang Teguh Setiawan75% (4)

- Department of Mechanical Engineering, Uet Lahore Refrigeration and Air Conditioning LaboratoryDokument7 SeitenDepartment of Mechanical Engineering, Uet Lahore Refrigeration and Air Conditioning LaboratoryTauQeer ShahNoch keine Bewertungen

- PDVSA Engineering Design Manual Volume 9–I Process AnalyzersDokument25 SeitenPDVSA Engineering Design Manual Volume 9–I Process AnalyzersAlberto Enrique De Santa Anna CampderáNoch keine Bewertungen

- ITILDokument16 SeitenITILelenviegas82Noch keine Bewertungen

- AZAR Block CostcomparisonDokument8 SeitenAZAR Block CostcomparisontckittuNoch keine Bewertungen

- SBBR - Star Rnav Obdog 2b Rwy 29l - 29r - Star - 20220811Dokument1 SeiteSBBR - Star Rnav Obdog 2b Rwy 29l - 29r - Star - 20220811vitor marianoNoch keine Bewertungen

- Seminar ReportDokument30 SeitenSeminar Reportshashank_gowda_7Noch keine Bewertungen

- GOT2000 - UserManual Monitor - SH 081196 I PDFDokument614 SeitenGOT2000 - UserManual Monitor - SH 081196 I PDFFanny Achmad Hindrarta KusumaNoch keine Bewertungen

- Wacker Neuson-Dpu - 25 KNDokument3 SeitenWacker Neuson-Dpu - 25 KNMilutin BožovićNoch keine Bewertungen

- 2022 Manufacture AnswerDokument8 Seiten2022 Manufacture AnswerChampika V SamarasighaNoch keine Bewertungen

- Rockaway Beach Branch Community Impact StudyDokument98 SeitenRockaway Beach Branch Community Impact StudyHanaRAlbertsNoch keine Bewertungen

- 01-01 Boltec S - SafetyDokument30 Seiten01-01 Boltec S - SafetyALVARO ANTONIO SILVA DELGADONoch keine Bewertungen

- YZ250 Off-Road Bike Parts CatalogDokument55 SeitenYZ250 Off-Road Bike Parts Catalogdwiyanti20Noch keine Bewertungen

- Fajs FSXDokument8 SeitenFajs FSXJunhy Bandeira CassandraNoch keine Bewertungen

- DC DC DC DC Iiii 6 6 6 6: Spec Spec Spec SpecDokument12 SeitenDC DC DC DC Iiii 6 6 6 6: Spec Spec Spec SpecarsolNoch keine Bewertungen