Beruflich Dokumente

Kultur Dokumente

M2 2007 Electrical Body Builder Manual Rev New

Hochgeladen von

andré GuilhermeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

M2 2007 Electrical Body Builder Manual Rev New

Hochgeladen von

andré GuilhermeCopyright:

Verfügbare Formate

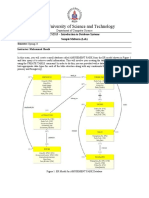

EPA 2007 Models

Electrical System Overview

2007 M2 Electrical

Body Builder Reference Guide

2007 M2 Electrical Body Builder Reference Title Page Rev New

EPA 2007 Models Tail Light

Electrical Component Overview Configurations

Body lighting (Module 294)

Interfaces

(Module 353)

Trailer Interfaces

(Module 296, 297)

Dash Switches

(Module 329)

Air Management

Unit (AMU)

(Multiple Modules )

Transmission Interfaces.

(Grey Plug)

(Plugs may also

be frame located

(Module , 34C)

Chassis Module

Engine Interface (CHM)

(Black Plug) (Module 335, 32K)

(Plugs may also

be frame located)

(Module 148, 163, 87L )

Bulk Head Module Power Supply

(BMH) Power Distribution (Module 281)

(Module 32A) (Module 285 PDM)

2007 M2 Electrical Body Builder Reference Page # 1 Rev: New

EPA 2007 Models

Electrical Harness Overview

ABS/AMU HARNESS Module 332

1) Connections to Forward chassis

harness and frame ground studs near

Chassis module

2) Connections to AMU (Mod 877 without ABS)

3) Connections to Wabco ABS ECU

4) Connections to rear combo valves

FORWARD CHASSIS HARNESS Module 288 AFT CHASSIS HARNESS Module 28A

1) Connections to Bulkhead module and Underhood PDM 1) Connections to Chassis Module

2) Connections to headlamps 2) Connections to tail lamps

3) Connections to side marker/turn lamps

4) Connections to Chassis Module

POWERTRAIN HARNESS Module 286, 283

1) Connections to the Bulkhead OVERHEAD CAB HARNESS Module 287

Module and Underhood PDM

1) Inline connection to Main cab Harness

(at bottom of A pillar)

2) Connections to Marker Lamps

3) Connections to Dome Lamp

MAIN CAB HARNESS Module 320

1) Connections to bulkhead connector

2) Connections to diagnostic connector (behind ignition switch)

3) Connections to MBE VCU or CPC

FRONTWALL HARNESS Module 321 4) Pass-thru connector to engine compartment

1) Connections to Bulkhead Module and Underhood PDM 5) Gauge Cluster

2) Connection to Starter Mag Switch

3) Connection to Wiper Motor

4) Connection to the low coolant level sensor and horn (under surge tank)

5) Connection under cab to Washer pump and level switch

6) Pass-thru connector to Main Cab Harness and Powertrain Harness

2007 M2 Electrical Body Builder Reference Page # 2 Rev: New

Power Distribution Module Fuse Specications*

Fuse MEGA Output VBAT Fuse Fuse

Connection Primary Function Secondary Function

Location Fuse Fuse Rating Rating

F1 1 Green A Vehicle Control Unit (MBE only) 10A Spare {

EPA 2007 Models F2

F3

1

2

Green B Blower Motor

Engine ECU (MBE or

30A

20A

{

Engine ECU (Caterpillar 3126, C11, C13,

{

30A

Green H Caterpillar C7 and C9) C15 ACERT, and Cummins ISC)

Main Power Distribution Module (PDM) F4 2 Green G Engine ECU (Caterpillar 2004 EPA) 20A Transmission ECU 30A

F5 1 Black D Ignition Switch 5A { {

F6 1 Black C { 30A { {

Pin part number for harness connection F7 1 Gray F Bulkhead Module VBAT 5 BHM 30A { {

23-13213-120 TERM-FEMALE,(20-16) PAC12077411 F8 2 Green C ICU3-M2 10A { {

F9 Green D Automatic Transmission ECU 10A Eaton AutoShift Transmission ECU 30A†

23-13213-121 TERM-FEMALE,(14-12) PAC12129493 2

Blue G

23-13213-122 TERM-FEMALE,(10) PAC12077413 F10 2 Spare { { {

Green F

F11 2 Blue H Spare { { {

F12 1 Black H Radio/Diagnostic 20A { {

F13 1 Grey E Chassis Module VBAT 3 CHM 30A { {

F14 1 Black B Spare { { {

F15 2 Black A Bulkhead Module VBAT 4 BHM 30A { {

F16 2 Blue A ABS ECU (pneumatic) 15A ABS ECU (hydraulic) 25A

F17 2 Blue C Chassis Module VBAT 2 CHM 30A { {

F18 2 Blue B Bulkhead Module VBAT 3 BHM 30A { {

F19 2 Grey G Chassis Module VBAT 1 CHM 30A { {

F20 1 Black E Bulkhead Module VBAT 2 BHM 30A { {

PDM Plugs F21 1 Black F Spare { { {

contain output F22 1 Black G

Grey H

Bulkhead Module VBAT 1 BHM 30A { {

wires F23 1

Blue E

Spare { { {

Hydraulic Pump and

F24 1 Grey D 25A Spare {

Motor (hydraulic ABS)

F25 2 Grey C Spare { { {

Grey A

F26 2 Grey B Spare { { {

Blue D

The main Power Distribution Module (PDM) distributes Engine Harness Forward Chassis

Multiple Wire output Plug (Green) Harness Plug (Blue)

battery power to the various control modules on the Pin A & B on Grey

vehicle. Plug and Pin D

on Blue Plug

The PDM contains mini fuses that protect

the power feed circuits to these modules.

B

For most trucks there will be spare fuse slots available Single Wire Output

Forward

for customers to add additional wiring to the truck after found on Green G H G

Chassis

it is purchased. Plug in Pin G G F B D AB Harness

H D C C

Plug

There are four Plugs attaching to the Module that supply (Grey)

C A D

output connections.

F A E H

Mega Fuse 1

Common Spare fuse sockets are listed below but may B B G

vary based on the options that have been requested. Front

C E F

Wall

Mega Fuse 2 A D H E Harness

Common Spare Fuse locations Plug

F6, F10, F11, F14, F21, F23, F25, F26 (Black)

2007 M2 Electrical Body Builder Reference Page # 3 Rev: New

EPA 2007 Models

PDM VBAT Fuse Coverage

BMH and CHM output pins are powered by multiple VBAT fuses through the

Main M2 PDM. If one of these fuses is tripped or blown then all pins in the circuit will

be affected. For this reason seemingly unrelated issues can occur at the same time

Power Supply Fuses and Associated Outputs for the Bulkhead Module if a fuse is overloaded and trips.

BHM Power Fuse Supplying BHM BHM

BHM Power Input BHM Outputs Supplied

Input Pin Power Input Output Pin The lists below show which pins are controlled with the VBAT fuses.

Power In Power Out

Battery (dome lamps) B5.A

Power Supply Fuses and Associated Outputs for the Chassis Module

Battery (smart switches) B7.A12

CHM Power CHM Power Fuse Supplying CHM CHM

Ignition (VCU) B6.A8 CHM Outputs Supplied

Input Input Pin Power Input Output Pin

Ignition (engine) B2.K Power In Power Out

Ignition (ABS) B1.P

Right Low Beam C3.L

Ignition (trans) B2.L

Turn Right Front/Side C3.R

Fuel Water Sensor Power B1.F

Dome Lamps Switched

Turn Right Rear C1.P

VBAT1 B3.D Fuse 22 (30A) B5.B

Left Low Beam B1.R Right Stop Lamp C1.L

A/C Clutch B2.M VBAT1 C4.P Fuse 19 (30A) Left Stop Lamp C1.N

Smart Switch 1 Indicator B7.B4 Right DRL C3.K

Smart Switch 2 Indicator B7.B8 Fog/Road Lamps C3.C/C3.D

Smart Switch 3 Indicator B7.A5 C2.E

Trailer Turn Right

Smart Switch 4 Indicator B7.A9

Left Park Lamp C4.C

Smart Switch 5 Indicator B7.B10

Right Park Lamp C4.L

Battery (smart switch) B7.A12

Accessory (HVAC) B6.A9 Left Marker Lamp C4.D

Accessory (radio) B6.A10 Right Marker Lamp C4.M

Wake Up (instrument cluster) B5.D Trailer Marker Relay C2.F

VBAT2 B4.G Fuse 20 (30A)

Left High Beam B1.L Right High Beam C4.K

Wiper High B3.F VBAT2 C3.J Fuse 17 (30A) Left Backup Lamp C1.A

Horn B3.E

Right Backup Lamp C1.J

Wiper Low B3.H

Backup Alarm C1.H

Spare 8.0A HSD (ignition) B5.G

VBAT3 B1.N Fuse 18 (30A) Turn Left Front/Side C3.N

Panel Lamps B5.H

Panel Lamps (smart switch) B7.A1 Turn Left Rear C1.G

Clearance Lamps B5.C Left DRL C4.F

Tail Lamps/License Plate B1.K* Trailer Turn Left C2.H

VBAT4 B4.K Fuse 15 (30A) Lamp/Trailer Tail Relay

Fuel Water Separator Heater C3.A

Washer Pump B3.G

12V Output (cigar lighter) B5.F AMU Solenoid 0 C5.H

Spare 8.5A (utility light/spotlight) B5.E / B4.M VBAT3 C4.J Fuse 13 (30A) AMU Solenoid 1 C5.J

VBAT5 B1.J Fuse 7 (30A) Left Heated Mirror B4.F AMU Solenoid 2 C5.L

Right Heated Mirror B4.E AMU Solenoid 3 C5.M

2007 M2 Electrical Body Builder Reference Page # 4 Rev: New

B3 Front B4 Front

EPA 2007 Models Wall Harness Wall Harness

Bulk Head Module (BHM)

B5 Dash

Pin part numbers for harness connection

Harness

Outside Cab Connections:

23-13212-120 TERM-FEMALE,(18-16) PAC153047191

23-13212-121 TERM-FEMALE,(14-12) PAC15304720

23-13212-122 TERM-FEMALE,(10) PAC15326004 B6 Dash

B2 Engine Harness

Inside Cab Connections: Harness

PAC12146448 TERM-FEMALE,(18-16)

B7 Dash

B1 Forward Chassis Harness

Harness

The Bulkhead Module (BHM) is the command module of the M2 electrical system.

As primary command the module controls the operation of the other component

modules in the system either directly or indirectly using messages sent over

the J1939 network.

Key Bulkhead Module Outputs

The Bulkhead Module is mounted on the driver side of the front wall and connects

to the interior wiring through an opening in the front wall. - Bulk Head Module outputs have defined amperage limits.

- If higher loads are required, bulkhead module outputs should be used as signal

The BHM has four harness connections on the engine side of the front wall and power in conjunction with a relay.

three harness connections to the cab interior.

The BHM Unit contains all system parameters and the unit controls power flow 20A B5.F - Cigar Lighter Output B6.A8 - Ignition (VCU)

B2.K - Ignition (Engine)

and circuit protection to the various components of the M2 electrical system. 12A B3.E - Horn 6.7A B1.P - Ignition (ABS)

Combined B2.L - Ignition (Trans)

12A B5.E - SPARE (Utility Light/Spotlight)

The BHM unit can also directly support up to 5 smart switches. The BHM is B4.M - SPARE (Utility Light/Spotlight) B1.F - Fuel Water Sensor Power

Combined

programable and can be changed and updated by flashing the unit through

service link. 12A B5.G - SPARE (Ignition) 6.7A B5.D - Wake Up (Instrument Cluster)

6.7A B5.B - Dome Lamps Switched

B5.H - Panel Lamps 6.7A B1.L - Left High Beam

Power supply for the BHM is supplied using VBAT fuses, which reside in the B7.A1 - Panel Lamps (Smart Switch) B1.R - Left Low Beam

Combined 6.7A

main PDM (see page 3)

12A B4.F - SPARE (Left Heated Mirror) 6.7A B5.C - Clearance Lamps

Combined B4.E - SPARE (Right Heated Mirror) Combined B1.K - Tail/License Plate/Trailer Relay

The BHM is programmable and the feature screen in service link can be used to

change or add parameters to the BHM 6.7A B6.A9 - Accessory (HVAC) 6.7A B3.F - Wiper High

Combined B6.A10 - Accessory (Radio) 6.7A B3.H - Wiper Low

B5.A - Battery (Dome Lamps) 6.7A B3.G - Washer Pump

6.7A B2.M - AC Clutch

Combined B7.A12 - Battery (Smart Switch) 6.7A

6.7A B4.B - Starter Relay (Crank)

2007 M2 Electrical Body Builder Reference Page # 5

Connector B4 Frontwall Harness Pinouts

Signal Name

ABCD B4 Front Connector Pin Signal Type

B3 Front B4-A Air Filter Restriction/Spare #9 Digital Input

EFGH

Wall Harness EPA 2007 Models Wall Harness B4-B

B4-C

Starter Relay

Ground

Digital Output

Ground

B4-D Spare Digital Input 2 Digital Input

Connector B3 Frontwall Harness Pinouts

Bulk Head Module (BHM) Detail B4-E Right Heated Mirror (spare digital output) Digital Output

Connector Pin Signal Name Signal Type

ABCDEF B4-F Left Heated Mirror (spare digital output) Digital Output

B3-A J1939{ Datalink Datalink GHJKLM B4-G Main Battery Power (VBAT2) Power

B3-B J1939+ Datalink Datalink B4-H Module Wake-Up Signal Digital Input/Output

B3-C Wiper Parked Position Digital Input B4-J

|

B3-D Main Battery Power (VBAT1) Power B4-K Main Battery Power (VBAT4) Power

B3-E Horn Digital Output B4-L Washer Fluid Level (spare digital input 8) Digital Input

B3-F Wiper Motor High Speed Digital Output B4-M Utility Light/Spotlight (spare digital output) Digital Output

B3-G Washer Pump Digital Output

B3-H Wiper Motor Low Speed Digital Output

B5 Dash

Harness

Connector B2 Engine Harness Pinouts Connector B5 Dash Harness Pinouts

Connector Pin Signal Name Signal Type B2 Engine Connector Pin Signal Name Signal Type

B5-A Dome Lamps Battery Digital Output

B2-A J1587+ Datalink Datalink

Harness B5-B Dome Lamps Switched Digital Output

B2-B J1939+ Datalink Datalink

HGFE

ABCD

B2-C J1587+ Datalink Datalink B5-C Clearance Lamps (cab) Digital Output

ABCDEFG

B5-D Instrument Cluster Wake-Up Digital Output

HJKLMNP

B2-D J1587{ Datalink Datalink

B2-E B5-E Utility Light/Spotlight (spare digital output) Digital Output

|

B2-F B5-F Cigar Lighter Digital Output

|

B2-G Backup Switch (spare digital input 3) Digital Input B5-G Ignition Power, Other (spare digital output) Digital Output

B2-H J1587{ Datalink Datalink B5-H Panel Lamps Digital Output

B2-J J1939{ Datalink Datalink

B2-K Engine ECU Ignition Power Digital Output

B2-L Transmission ECU Ignition Power Digital Output

B6 Dash

B2-M A/C Clutch Digital Output Harness

B2-N

|

B2-P Alternator Charging Digital Input

Connector B6 Dash Harness Pinouts

B7 Dash Connector Pin Signal Name Signal Type

Harness B6-A1 Ignition Switch Accessory Position Digital Input

B6-A2 Module Wake-Up Signal Digital Input

Connector B7 Dash Harness Pinouts

A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 A11 A12

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12

A1 A2 A3 A4 A5 A6 A7 A8 A9 A10 A11 A12

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11 B12

SRPNMLKJ B1 Forward Connector Pin Signal Name Signal Type B6-A3 Ignition Switch On Digital Input

B6-A4

HGFEDCBA Chassis Harness B7-A1 Panel Lamps (smart switch) Digital Output

|

B7-A2 Smart Switch 3 ID 1 Analog Input B6-A5 Ignition Switch Start Digital Input

B7-A3 Smart Switch 3 ID 2 Analog Input B6-A6 Passenger Door Open (spare digital input 10) Digital Input

Connector B1 Forward Chassis Harness Pinouts

B7-A4 Smart Switch 3 Input Analog Input B6-A7 Driver Door Open Digital Input

Connector Pin Signal Name Signal Type

B7-A5 Smart Switch 3 Indicator Digital Output B6-A8 VCU Ignition Power Digital Output

B1-A

|

B7-A6 Smart Switch 4 ID 1 Analog Input

B6-A9 HVAC Power Digital Output

Digital Input/ B7-A7 Smart Switch 4 ID 2 Analog Input

B1-B Module Wake-Up Signal

Output B6-A10 Radio Power Digital Output

B7-A8 Smart Switch 4 Input Analog Input

B1-C Spare Digital Input 4 Digital Input B6-A11 J1587{ Datalink Datalink

B7-A9 Smart Switch 4 Indicator Digital Output

B1-D B6-A12 J1587+ Datalink Datalink

|

B7-A10 Smart Switch 5 ID 1 Analog Input

B1-E Ground Power Ground B6-B1 Horn Switch Digital Input

B7-A11 Smart Switch 5 ID 2 Analog Input

B1-F Fuel/Water Sensor Ignition Power Digital Output B6-B2 Top of Clutch Switch (spare digital input 7) Digital Input

B7-A12 Smart Switch Battery Power Digital Output

B1-G Ground Signal Ground B6-B3 Bottom of Clutch Switch (spare digital input 6) Digital Input

B7-B1 Smart Switch 1 ID 1 Analog Input

B1-H J1587+ Datalink Datalink B7-B2 Smart Switch 1 ID 2 Analog Input B6-B4

|

B1-J Battery Power (VBAT5) Power B7-B3 Smart Switch 1 Input Analog Input B6-B5 Panel Lamps Increase Digital Input

B1-K Tail Lamps/License Plate Lamp/Trailer Tail Relay Digital Output B7-B4 Smart Switch 1 Indicator Digital Output B6-B6 Panel Lamps Decrease Digital Input

B1-L Left High Beam Digital Output B7-B5 Smart Switch 2 ID 1 Analog Input

B6-B7 A/C Clutch Request Digital Input

B1-M Fuel/Water Separator (spare digital input 5) Digital Input B7-B6 Smart Switch 2 ID 2 Analog Input

B6-B8 Hazard Switch Digital Input

B1-N Battery Power (VBAT3) Power B7-B7 Smart Switch 2 Input Analog Input

B6-B9 Headlamp Switch PARK Position Digital Input

B1-P ABS Ignition Power Digital Output B7-B8 Smart Switch 2 Indicator Digital Output

B6-B10 Headlamp Switch On Position Digital Input

B1-R Left Low Beam Digital Output B7-B9 Ground Signal Ground

B7-B10 Smart Switch 5 Indicator Digital Output B6-B11 Headlamp Switch On 2 Position Digital Input

B1-S J1587{ Datalink Datalink

B7-B11 Smart Switch 5 Input Analog Input B6-B12

|

B7-B12

|

2007 M2 Electrical Body Builder Reference Page # 6 Rev: New

C2 Trailer

C1 Tail Light Module Harness

EPA 2007 Models Harness

Chassis Module (CHM)

C3 Forward

Pin part number for harness connection

23-13212-120 TERM-FEMALE,(18-16) PAC153047191 Chassis

23-13212-121 TERM-FEMALE,(14-12) PAC15304720 Harness

23-13212-121 TERM-FEMALE,(10) PAC15326004

C4 Forward

C5 Air

General Information Chassis

Management Unit

Harness

The Chassis Module (CHM) and the Expansion Module

(EXM) both serve the same function in the M2 electrical

System by acting as slaves to the Bulkhead Module

(BHM). The CHM and EXM respond to commands Key Chassis Module Outputs

From the BHM and broadcast the status of the inputs 20A C3-A Optional Fuel Water Separator Heater C4-C Left Park Lamp

And outputs that are sent to and delivered by the module. C4-C Left Park Lamp C4-L Right Park Lamp

C4-L Right Park Lamp Combined C4-D Left Marker Lamp

10A C4-D Left Marker Lamp C4-M Right Marker Lamp

A Business Class M2 vehicle will always have a Combined C4-M Right Marker Lamp

Chassis Module, but will only have an Expansion C2-F Trailer Marker Relay

7.5A C3-N Turn Left Front/Side

Module when optional features require it. The CHM C3-N Turn Left Front/Side Combined C1-G Turn Left Rear

and EXM both have the same pin connections although 7.5A C1-G Turn Left Rear

They may not all be used. Combined C2-H TrailerTurn Left C3-R Turn Right Front/Side

7.5A

C3-R Turn Right Front/Side Combined C1-P Turn Right Rear

7.5A C1-P Turn Right Rear

Chassis Module Combined C2-E TrailerTurn Right C1-A Left Backup Lamp

C1-A Left Backup Lamp 6.7A C1-J Right Backup Lamp

6.7A C1-J Right Backup Lamp Combined C1-H Backup Alarm

The CHM is available in two configurations depending on Combined C1-H Backup Alarm

C3-L Right Low Beam

6.7A

The vehicle options: 6.7A C3-L Right Low Beam

6.7A C4-K Right High Beam

• Standard Chassis Module (rarely used) 6.7A C4-K Right High Beam

6.7A C1-N Left Stop Lamp

6.7A C1-N Left Stop Lamp

• Full Chassis Module 6.7A C1-L Right Stop Lamp

6.7A C1-L Right Stop Lamp

The vehicle will have either a standard CHM or a full 6.7A C3-K Right DRL *Maximum allowable combined current load when turn

CHM, but not both. The standard CHM uses only the 6.7A C4-F Left DRL

Signals are flashing.

C1, C3, and C4 harness connectors. The remaining C3-C Optional Fog/Road Lamps

6.7A

Harness connectors are sealed. Combined C3-D Optional Fog/Road Lamps

Both the standard CHM and full CHM are supported 0.85A C5-H AMU Solenoid #0

0.85A C5-J AMU Solenoid #1

The CHM is primarily mounted BOC on the LH rail

0.85A C5-L AMU Solenoid #2

but can also be located in an under cab position for

0.85A C5-M AMU Solenoid #3

frame packaging or environmental concerns.

0.2A C2-A Trailer Power Relay

Under cab data code 335-006

2007 M2 Electrical Body Builder Reference Page # 7 Rev: New

A B C D

C2 Trailer E F G H

EPA 2007 Models Module Harness

Trailer Module Harness Pinouts at Connector C2

A B C D E F G C1 Tail Light Chassis Module (CHM) Detail Connector and

Pin Numbers

Signal Name

Signal Type Full Standard

H J K L M N P

Harness C2-A Trailer Power Relay Digital Output X |

C2-C Ground Power Ground X |

Taillight Harness Pinouts at Connector C1 C2-D Trailer Stop Lamp Relay Pass-through Pass-through X |

Connector and Signal Type Full Standard C2-E Trailer Right Turn Lamp Digital Output X |

Signal Name

Pin Numbers X

C2-F Trailer Marker Lamps Relay Digital Output |

C1-A Left Backup Lamp Digital Output X X

C2-G Trailer Taillight Relay Pass-through Pass-through X |

C1-D Left Taillight Pass-through Pass-through X X

C2-H Trailer Left Turn Lamp Digital Output X |

C1-E Right Taillight Pass-through Pass-through X X

C1-F License Plate Lamp Digital Output X X

C1-G Left Rear Turn Lamp Digital Output X X

C1-H Backup Alarm Digital Output X X C3 Forward

C1-J Right Backup Lamp Digital Output X X Chassis Harness

C1-L Right Stop Lamp Digital Output X X Forward Chassis Harness Pinouts at Connector C3

C1-N Left Stop Lamp Digital Output X X Connector and Full Standard

Signal Name Signal Type

Pin Numbers

C1-P Right Rear Turn Lamp Digital Output X X

H G F E D C B A

J K L M N P R S

C3-A Fuel/Water Separator Heater Digital Output X |

C3-B J1587{ Datalink Datalink X X

C3-C Fog/Road Lamps Digital Output X |

C3-D Fog/Road Lamps Digital Output X |

C3-E Low Air Pressure Digital Input (active low) X X

C3-F Park Brake Digital Input (active low) X X

C3-G Service Brake Digital Input (active low) X X

C3-H Ground Power Ground X X

C3-J Main Battery Power (VBAT2) Power X X

C3-K Right DRL Digital Output X |

C3-L Right Low Beam Digital Output X X

C3-M Ignition Digital Input (active high) X X

C3-N Left Front/Side Turn Lamp Digital Output X X

C3-P Taillight/License Plate Lamps Pass-through Pass-through X X

C3-R Right Front/Side Turn Lamp Digital Output X X

C3-S J1587+ Datalink Datalink X X

M L K J H G

C4 Forward S R P N M L K J

C5 Air F E D C B A Chassis Harness H G F E D C B A

Management Unit

Forward Chassis Harness Pinouts at Connector C4

Connector C5 Air Management Unit (AMU) Harness Pinouts Connector and Full Standard

Signal Name Signal Type

Connector and Full Standard Pin Numbers

Signal Name Signal Type

Pin Numbers C4-A Module Wake-up Signal Digital Input/Output X X

C5-A AMU Analog Input 0 Digital Input (active low), Analog Input X | C4-B Address Identication A Analog Input X X

C5-B AMU Analog Input 1 Digital Input (active low), Analog Input X | C4-C Left Park Lamp Digital Output X X

C5-C Ground Signal Ground X | C4-D Left Marker Lamp Digital Output X X

C5-F AMU Analog Input 2 Digital Input (active low), Analog Input X | C4-E Address Identication C Analog Input X X

C4-F Left DRL Digital Output X |

C5-G AMU Analog Input 3 Digital Input (active low), Analog Input X |

C4-G J1939+ Datalink Datalink X X

C5-H AMU Solenoid 0 Digital Output X |

C4-H Ground (address identication D) Signal Ground X X

C5-J AMU Solenoid 1 Digital Output X |

C4-J Main Battery Power (VBAT3) Power X |

C5-L AMU Solenoid 2 Digital Output X |

C4-K Right High Beam Digital Output X X

C5-M AMU Solenoid 3 Digital Output X | C4-L Right Park Lamp Digital Output X X

C4-M Right Marker Lamp Digital Output X X

C4-N Address Identication B Analog Input X X

C4-P Main Battery Power (VBAT1) Power X X

C4-R J1939{ Datalink Datalink X X

C4-S Ground Power Ground X X

2007 M2 Electrical Body Builder Reference Page # 8 Rev: New

EPA 2007 Models

Multiplexing System Backbone The J1708/1587 Datalink

Outside of Cab Inside of Cab

BHM

Dash J1587 Junction Block

J1939 J1708/1587

CHM ABS TCU Non- AGS MBE ICU ABS Diag.

(Frame) (Allison/ MBE (Cab) Conn.

Display VCU

AGS) Engine CPC

Multiplexing System

Note: Solid lines represent required components

The term "multiplexing" describes how the Business Class® M2 Dashed lines represent optional components

electrical system works.

The J1939 Datalink

Multiplexing is defined as the process of sending multiple electronic messages

ABS TRANS ICU ENG

through the same signal path at the same time—in this case,

through the data link.

120 Ohm 120 Ohm

The system communicates using two primary forms of Terminating

Resistor

Terminating

Resistor

communication called data links: J1939 datalink (High speed)

and the J1708/J1587 datalink (low speed).

J1939 (Yellow J1939+ Green J1939– In a twisted pair covered with black loom) BHM

CHM DIAG

Branch

• A high speed vehicle communications network, which permits devices to broadcast Backbone Circuit

requests as well as receive information from all other devices on the network. Control Unit

• Each message includes an identifier much like a CB channel setting that defines the Terminology

message priority, who sent it, and what data is contained within it. Backbone The main J1939 datalink wiring that lies between the

• A terminating resistor is installed at each end of the network to dampen feedback signals. two terminating resistors. It does not include the branch circuits

to each ECU or to the diagnostic connector.

J1708/1587 (Dark green J1587+ Orange J1587– in a twisted pair to reduce interference) * Maximum recommended length between any 2 nodes = 3 meters

* Maximum recommended branch length = 1 meter

* Maximum recommended total backbone length = 30 meters

The J1587 datalink is a low-speed vehicle datalink that communicates network protocol

and provides simple information exchange, including diagnostic data between electronic Branch Circuit The section of J1939 datalink between the

control devices. backbone and each control unit that has J1939, and between the

backbone and the diagnostic connector.

Diagnostic Connector a 9-pin diagnostic connector is used for

troubleshooting the electrical system.

Control Unit connects to the J1939 datalink via a branch circuit.

2007 M2 Electrical Body Builder Reference Page # 9 Rev: New

Dash Tap Points Resistor Receptor Chassis resistor

located in chassis

Ignition Accessary Power, Ground and Dash Illumination Part FTL# DUFDM04 2P EP10

(accessary power from this location dims out during engine cranking) EPA 2007 Models Deutsch # DTM04 - 2P - EP10 frame rear of cab

Look for Yellow or

System Tap Points Red tape located

at breakout point

under cab Drivers side

Cab resistor

located in dash

behind ICU panel

The J1939 Datalink

Ignition

Circuit 81C

Max load: 5amps ABS TRANS ICU ENG

120 Ohm 120 Ohm

Terminating Terminating

Resistor Resistor

CHM BHM DIAG

Illumination Branch

Circuit 29A Backbone Circuit

Max load: 5amps

J1939 Multiplexing System connections

Tying into the J1939 backbone is accomplished by tapping into the system

using the terminating resistor tee’s located at each end of the backbone

Pin part number for harness connection

TERM-FEMALE,(18-16) PAC12110844 Ground The Chassis terminating resistor is located in a tee long the left frame

TERM-FEMALE,(14-12) PAC12110842 Circuit GND rail, usually behind the cab.

Max load: 10amps

J1939 Tee connection The cab terminating resistor is located in the dash tucked up above the

is used for Switch Expansion dash tap points for the J1587

Modules only and is not The correct datlink resistence measured at any device, or at the diagnostic

used on std assemblies plug should be 60ohmes with the battery disconnected.

(FTL # A06-37868-000)

IMPORTANT:

Dash Tap point - It is essential that both terminating resistors remain

The J1708/1587 Datalink connected to the ends of the J1939 backbone to dampen feedback signals.

Outside of Cab Inside of Cab

Numerous J1939 problems can be attributed when terminating resistors are

missing or disconnected.

- If connections under dash become disconnected. Connections should

BHM

never be connected back together IE ABS with ABS as this creates an

independent circuit in the system that is not connected to the backbone

Dash J1587 Junction Block

J1939 Connections for Body Builders

CHM ABS TCU Non- AGS MBE ICU ABS Diag. To connect easily to J1939 at dash or chassis locations

(Frame) Display (Cab)

(Allison/ MBE VCU Conn.

AGS) Engine CPC order the following parts:

(1) Tee and Jumper FTL# A06-37868-000

Note: Solid lines represent required components (1) Jumper Plug FTL# DUFDTM06 2S E004

Dashed lines represent optional components (2) Female Pins DUFWM2SB

Component Module Locations

The J1587 datalink

Component Module Number

G06-43822 found in Module 160 is the drawing

number of the J1587 wiring schematic. General J1939 harness drawings, schematics, and installation drawings 160

The dash J1587 junction block (shown above) is Engine harness and installation drawings and wiring diagrams 283 and 286

located behind the center dash panel. Transmission harness and installation drawings and wiring diagrams 34A, 34B and 343

ABS harness and installation drawings 330, 332, and 333

2007 M2 Electrical Body Builder Reference Page # 10 Rev: New

Smart switches:

Smart switches are low current switches that use signals

to communicate with the Bulk Head Module to tell what function

they effect and what state they are in (on or off etc.). EPA 2007 Models

There are two primary types of Smart Switch

Low Current Smart Switches

Two position switch: Supplies an on or off signal to the BHM

Three position switch: allows for an up down off signal to the BHM

(Used in applications where more than one input is required.)

Smart switches identify themselves by two voltage signals to the bulkhead module.

Each switch has a unique combination of resistors that control the voltage system

to the BHM allowing it to identify the switch.

Low Current Easily identified by the

Each channel can talk independently to the Bulkhead module at the same time. Smart Switch Black backing on the

In order for a smart switch to work on the vehicle the Bulk head module must be

trained to hear it, this is done through the features screen using service link. switch

Accessing the features screen can be accomplished on sight at the body

builder if they are set up with Freightliner Service link and the data link harness.

860-004 SMART SWITCH EXPANSION MODULE (SEM)

Three common faults can occur with Smart Switches

Extra Smart Switch fault indicates that a smart switch has been installed that A Switch Expansion Module (SEM) is available for the Business Class®

the vehicle is not programmed to utilize. M2 vehicle when more than five smart switches are installed on the vehicle. Each adds up to

Duplicate Smart Switch fault indicates that there are two or more identical smart 6 Smart Switches (beyond the standard 5 supported directly by BHM). System can handle

switches connected to either the BHM or SEM smart switch ports. To fix this error

up to 4 expansion modules on the M2 (Currently only one SEM is released)

the duplicate smart switches must be removed from the system.

Missing Smart Switch fault indicates that a smart switch has been

programmed but is not installed. The function of the SEM is to:

Read all smart switch IDs and positions; Transmit the smart switch IDs and position data

on the J1939 datalink; Turn on the smart switch indicator lights when commanded to do so

10

1

2

10 1 2 3 4 12

by the Bulkhead Module (BHM).

4

12

9 5 6 8 11

Smart Switch Pinout for Two Position Switch Pins

Pin Circuit Number Circuit Description

2 474B Switch Position Input

7 474C Switch Function ID 1 Input

8 474D Switch Function ID 2 Input

9 GND Ground

10 14E Indicator (+)

11 29A Backlighting (+)

12 474A Indicator ({)

Smart Switch Pinout for a 3 position Switch Pins

Pin Circuit Number Circuit Description

2 474B Switch Position Input

7 474C Switch Function ID 1 Input

8 474D Switch Function ID 2 Input

9 GND Ground

11 29A Backlighting (+)

Switch Expansion Module

Low Current Smart Switch Socket

2007 M2 Electrical Body Builder Reference Page # 11 Rev: New

High current Switch:

- Optional power switches are factory-installed, switch controlled

power provisions that can be ordered for a Business Class® M2 vehicle.

- Optional switches can be ordered in a one-, two-, or four-switch configuration. EPA 2007 Models

- All optional high current switches mount on the dash, provide fuse protected

battery power, and route to a customer access point ending in blunt cut wires. High Current Switches

- Optional switches are commonly used to provide battery-powered lighting,

such as dome, spot, or beacon lights. Other applications include using the

optional switch as a triggering mechanism to enable other features, such as

hydraulic lift operations or access panel locks.

Blunt cut power wires

Module 329 Options: from opt high current

329-007 ILLUMINATED ROCKER SWITCH WITH WIRE TO BACK OF CAB AND MARKER power switches located

LIGHT CIRCUIT TO JUNCTION BLOCK ON FRAME BACK OF CAB in frame BOC.

329-010 TWO EXTRA SWITCHES IN DASH WITH INDICATOR LAMP AND WIRE High Current Easily identified by the

TO CHASSIS AT BACK OF CAB/SLEEPER

329-012 FOUR EXTRA SWITCHES IN DASH WITH INDICATOR LAMP AND WIRE Switch White backing on the

TO CHASSIS AT BACK OF CAB/SLEEPER

329-015 ONE ILLUMINATED ROCKER SWITCH WITH WIRE TO CHASSIS AT BACK OF CAB switch

329-077 (8) EXTRA SWITCHES IN DASH; (4) WITH INDICATOR LAMPS AND WIRES

TO CHASSIS AT BACK OF CAB, (4) WIRED BY BODY BUILDER

Optional power switches:

329-082 (7) EXTRA SWITCHES IN DASH; (4) WITH INDICATOR LAMPS AND WIRES

TO CHASSIS AT BACK OF CAB, (3) WIRED BY BODY BUILDER Extra switches can be ordered and come mounted on the dash to the right

329-083 (6) EXTRA SWITCHES IN DASH; (4) WITH INDICATOR LAMPS AND WIRES

TO CHASSIS AT BACK OF CAB, (2) WIRED BY BODY BUILDER

of the steering column. Each switch is equipped with two LED lights; one LED

provides switch illumination and on position indication. Constant fused power

Optional-switch Current Capacity up to m15A is supplied to each switch from the Power Distribution Module (PDM).

No. of PDM Fuse F25 PDM Fuse F26 Switch Output Extra dash switches are not connected and require a customer supplied mating plug and

Switches Rating Switch Protected Rating Switch Protected Current Capacity pins to connect the switches to additional wiring. (See plug part numbers on this page)

1 15A Switch 1 | | 15A

Connecting a switch using a chassis Junction Block:

2 30A Shared by switch 1 and 2 | | 15A

4 20A Shared by switch 1 and 2 20A Shared by switch 3 and 4 10A Ref service bulletin Power Switches and Connections # SB-54.39

Optional Switch Connector Switches will be pre-wired to a Junction block attached to the frame rail

near the Chassis Module (CHM.)

Connector Circuit

Signal Name Signal Type Circuit Number

Pin Color

The red wire in the junction block receives power from the

Terminal Pin 23-13213-400 (20-18)

8 6 5B 5A 4 7 FTL Switch Socket PN Terminal Pin 23-13213-401 (16-14) output circuit of the optional switch.

Socket 06-42557-000 Terminal Pin 23-13213-402 (12-10)

Terminal Pin PAC12015869 (20-18)

IMPORTANT: The power distribution module (PDM)

Vndr Switch Socket PN Terminal Pin PAC12015870 (16-14) fuse supplying power to the optional switch is rated for

Socket PAC15393805 15 amps and this load should not be exceeded by the

10 3 2B 2A 1 9 Terminal Pin PAC12015830 (12-10) Ordered using

combined current load of the circuit. Option 329-007

1 | | | |

399 for optional switches 1 and 2. 399B for optional

2B Fused Battery Power Input T

switches 3 and 4.

399A for optional switch 1. 399C for optional switch 2.

3 Optional Switch Output Output T

399E for optional switch 3. 399G for optional switch 4.

4 | | | |

5B | | | |

6 | | | |

7 | | | |

8 Ground Ground BK GND

9 | | | |

10 Illumination Feed Input BR 29A

Junction Block

2007 M2 Electrical Body Builder Reference Page # 12 Rev: New

EPA 2007 Models

Electrical System Overview

High Current Switch Schematics

Four-switch Conguration Wiring Diagram One-switch Conguration Wiring Diagram With Junction Block and market light feed

L 29A BR 10 ILLUM

Hot at all times Hot at all times Illumination output

(Battery B+) (Battery B+)

Illumination OFF

PDM Hot at Fuse Splice Pack SP1

Fuse Fuse Located

F25 F26 Under all times F25 T 399

20A

C 399 T 2B

20A the hood (Battery B+)

15A

C

TA

PDM located ON

Illumination

Illumination 399A T 3

under the hood

T

Output Splice Pack SP1

399B

399

29A BR L

C GND BK 8 ON IND

Switch Dash Ground Dash-mounted

Battery Splice Pack SP9 Optional Switch

399B

399B

A R 399A Access T

10 BR 29A

10 BR 29A

10 BR 29A

10 BR 29A

399

399

Optional B 46F BR M

Marker lights output

Switch C Y 46B Marker BR C4

2B T

2B T

2B T

2B T

Marker D

Lights Light Chassis Module

E Access

CUST1

Customer Access

Junction Block

ON OFF ON OFF OFF OFF ON Ring Terminal Connections

One-switch Conguration Wiring Diagram Without Junction Block

IND ON ILLUM IND ON ILLUM ILLUM ON IND ILLUM ON IND

L 29A BR 10 ILLUM

Illumination output

Dash- Dash- Dash- Dash- T

T3

T3

3

8

8

Mounted Mounted Mounted Mounted Illumination

Optional Hot at OFF

GND BK

GND BK

GND BK

GND BK

Optional Optional Fuse Splice Pack SP1

399E T

Optional

Switch 1 Switch 2 Switch 3 Switch 4 399G all times F25 C T 399 399 T 2B

399A

399A

(Battery B+)

15A

PDM located ON

399A T 3

under the hood

C GND BK

OPT SW 1 OPT SW 2 OPT SW 3 OPT SW 4 Optional switch

10A MAX 10A MAX 10A MAX 10A MAX Output C GND BK 8 ON IND

T 399A

16 GA circuit

OPT SW 1

15A MAX

Heat-shrink Dash Ground

Protected Dash-mounted

Splice Pack SP9 Optional Switch

Optional switch outputs Dash Ground

ON

16 GA circuits Splice Pack SP9

Heat shrink protected

2007 M2 Electrical Body Builder Reference Page # 13 Rev: New

EPA 2007 Models Tail Lights and connections

Tail Lights

Body builders wishing to supply their own taillights can order

the connectors only options shown below.

Combination Stop/Turn/Tail/Backup Lights

Many connectors come with mating connectors included and

require only the terminals to be supplied by the body builder.

294-001 INTEGRAL STOP/TAIL/BACKUP LIGHTS

294-017 INTEGRAL STOP/TAIL/BACKUP LIGHTS Body builders utilizing factory lights and needing additional

WITH 7’ ADDITIONAL WIRE AT CHASSIS END OF FRAME lighting interface should use the 353 data codes for

body builder interfaces.

Combination Stop/Turn/Tail,

Separate Backup Lights Wiring Only Options

LED Combination Combination Stop/Turn/Tail,

294-042 FREIGHTLINER LED FLANGE MOUNTED

Separate Backup Light

STOP/TAIL/TURN LIGHTS WITH SEPARATE

INCANDESCENT BACKUP LIGHTS 294-090 OMIT STOP/TAIL/BACKUP LIGHTS AND PROVIDE

WIRING FOR COMBINED STOP/TURN LIGHTS

TO FOUR FEET BEYOND END OF FRAME

Incandescent Combination Combination Stop/Tail,

Separate Turn

294-002 TRUCK-LITE 40 STOP/TAIL WITH SEPARATE Separate Backup Light

BACKUP LIGHTS GROMMET MOUNTED

294-046 OMIT STOP/TAIL/BACKUP LIGHTS AND PROVIDE

WIRING WITH SEPARATE STOP/TURN WIRES

TO 4’ BEYOND END OF FRAME

294-094 OMIT STOP/TAIL/BACKUP LIGHTS AND PROVIDE

WIRING WITH SEPARATE STOP/TAIL WIRES

Combination Stop/Tail, TO 7’ BEYOND END OF FRAME

Separate Turn

Separate Backup Lights

294-021 TRUCK-LITE 3 CHAMBER MODULES WITH

45 SERIES SEALED BEAM LAMPS

2007 M2 Electrical Body Builder Reference Page # 14 Rev: New

All Plugs viewed from Front

Rear Light Connector (separate stop/turn signal)

G A Mating connector supplied with Chassis

G F E D C BA

P N M L K J H EPA 2007 Models C

D

A

E

F C

D

A

E

F

Packard Connector PAC 12110751

Terminal supplied by Body Builder

Packard Terminal PAC 15304719

P H

B G B G Freightliner Seal Part# 23-12497-282

Connector

Pinouts at CHM Connector C1

Signal Name Signal Type

Circuit Circuit Current

Tail Lights Detail Signal Circuit Circuit

Pin Color Number Capacity Connector

Signal Name Type Color Number

Pin

C1-A Left Backup Light (combination stop/turn signal) Digital Output LTBL 120B 7.45A*

A Backup Light Output DKBL 120B

C1-A Left Backup Light (separate stop/turn signal) Digital Output DKBL 120B 7.45A*

B Taillights and License Light Output BR 23

C1-B | | T OPTA |

C1-C | | T OPTB | Rear Lighting Connection (separate stop/turn signal) C Right Turn Signal Light Output DKG 38R

C1-D Left Taillight Pass-through Pass-through BR 23 1.0A† D Right Stop Light Output R-W 39R

C1-E Right Taillight Pass-through Pass-through BR 23A 1.0A†

1939+ G Y 1939+ 1939+ Y B 1939+ E Ground Ground BK GND

C1-F License Plate Light Digital Output BR 23C 1.0A† Data

Lines F Left Turn Signal Light Output Y 38L

C1-G Left Rear Turn Signal Light (separate stop/turn signal) Digital Output Y 38L 7.45A‡ 1939- R DKG 1939- 1939- DKG J 1939-

B2 G Left Stop Light Output R-W 39L

C1-H Backup Alarm Digital Output DKBL 120B 7.45A*

C1-J Right Backup Light Digital Output DKBL 120B 7.45A* P BR 23 23 BR K Tail/license

C1-K | | T OPTC |

C3 B1 Lights

Bulkhead Module Mating connector supplied by Body Builder

C1-L Right Stop Light (combination stop/turn signal) Digital Output LTG 39R 7.45A Packard Connector 12186400

Backup A DKBL120B A

C1-L Right Stop Light (separate stop/turn signal) Digital Output R-W 39R 7.45A E D C BA

Terminal supplied by Body Builder

Tail/license D BR 23 B Packard Terminal 12129497

C1-M | | T OPTD |

Lights E A Freightliner Part# 23-13213-131

C1-N Left Stop/Turn Signal Light (combination stop/turn signal) Digital Output Y 39L 7.45A P DKG 38R C

Right turn Rear Light Connector (combination stop/turn signal)

C1-N Left Stop Light (separate stop/turn signal) Digital Output R-W 39L 7.45A

C1-P Right Rear Turn Signal Light (separate stop/turn signal) Digital Output DKG 38R 7.45A§ L R-W 39R D

Right stop Connector Signal Circuit Circuit

Taillight GND Pin Signal Name Type Color Number

E BK

* Pins C1-A, C1-H, and C1-J are fed from the same CHM circuit board trace. The max combined current cap for all three pins is 7.45A.

† Pins C1-D, C1-E, and C1-F are fed from the same CHM circuit board trace. The max combined current cap for all three pins is 1A.

Ground A Backup Light Output LTBL 120B

‡ Pins C1-G, C2-H, and C3-N are fed by the same CHM circuit board trace. The max combined current cap for all three pins is 7.45A. Left turn G Y 38L F

Taillights and License Light Output BR 23

§ Pins C1-P, C2-E, and C3-R are fed by the same CHM circuit board trace. The max combined current cap for all three pins is 7.45A. B

Left stop N R-W 39L G C Left Stop/Turn Signal Light Output Y 39L

C1 Aft Harness Tail Harness

Lighting Outputs For Integrated Rear Lights Chassis Module D Right Stop/Turn Signal Light Output LTG 39R

(Combination stop/turn signal) E Ground Ground BK GND

Lighting Outputs For Individual Rear Lights

(Combination stop/turn signal)

39R LTG C R-W R 3 Stop/Turn

1 W

Tail/license K BR 23 DKBL DKBL A

K BR 23 23 BR B BR BK 2 Park With dual backup lights Right Backup Light

Tail/license lights Lights B1

B1

120B DKBL A DKBL R 2 1 W B Y 1939+ DKBL A

1939+ B Y 1939+ 1939+ DKBL

Backup

1939- J DKG 1939- GND BK E BK 1939- J DKG 1939-

B2 B2 With DKBL R 2 1 W

Bulkhead Module Bulkhead Module Center

Data Right Taillight Assembly Data Backup light

Lines Lines Backup Light

G Y 1939+ G Y 1939+

1939 + 1939+ R-W R 3

GND BK E BK 1 W BK

1939- R DKG 1939- 120B DKBL A DKBL 1939-

R DKG 1939-

BR BK 2

23 BR B BR

P BR 23 39R LTG C R-W P BR 23 Right Stop/Turn/Park Light

C3 Tail Harness C3

Right L LTG 39R D R-W

BK 2 1 W

Stop/turn

A LTBL 120B A DKBL R 2 1 W

Backup License Light

Backup

Backup A LTBL 120B A DKBL120B

Tail/license D BR 23 B BR BK 2 1 W

Lights License Right L LTG 39R D R-W 39R

BK 2 Park Stop/turn Left Stop/Turn/Park Light

1 W Tail/license D BR 23 B BR 23 BK 2

Left stop/turn N Y 39L C R-W R 3 Stop/Turn Lights 1 W

C1 Left stop/turn N Y 39L C R-W 39L R-W R 3

Chassis Module GND BK E BK Left Taillight Assembly C1

Taillight Aft Harness Chassis Module GND BK E BK GND

Ground Taillight Aft Harness Tail Harness

Ground

2007 M2 Electrical Body Builder Reference Page # 15 Rev: New

Engine Interface: Transmission interface:

Freightliner provides an engine interface harness when an - The transmission interface harness provides the VIW

rpm control system is ordered for optional body builder

features and PTO (power takeoff) applications. EPA 2007 Models connection for the current generation of 1000/2000

Series or 3000/4000 Series electronic controls, depending

The optional features provided by this harness include:

- Fast idle Engine & Transmission Interface on the transmission that is installed in the vehicle.

- Increment/decrement - The transmission interface harness provides most of the

- Multiple fixed speeds optional I/O circuits, in addition to the speedometer signal,

- Variable RPM title in a front wall connector that can be used by the body builder.

Mod 148 determines the type of remote engine throttle Data Book Codes for the EPA 2007 Transmission Interface Harnesses

Mod 163 determines the location of the interface connector

Mod 87L determines the interlock requirements Data Book Code Description

34C-001 Transmission Interface Harness at the Frontwall

Data Book Codes for Engine Remote Transmission 34C-002 Transmission Interface Harness at Back of Cab

Interface Harnesses (ERIH) (Grey Plug) 34C-003 Transmission Interface at End of Frame

Data Book Code Description

148-070 ERIH With Fixed Single Speed Transmission Interface Connector Pinout Assignments on M2 Vehicles

Allison Allison Transmission Function †

148-071 ERIH With Increment/Decrement Pin Freightliner

Transmission®

No. Circuit No. 1000/2000 Series 3000/4000 Series

148-072 ERIH With Multiple Set Speeds Circuit No.

1 232E 163 Ignition Signal Ignition Signal

148-073 ERIH for Remote Throttle 2 497C7 (O‡) 150 PTO Enable —

163-001 ERIH at Back of Cab Secondary Mode Indicator

163-002 ERIH at End of Frame 3 497C8 (O) 113 — Range Indicator

Engine Overspeed Indicator

163-003 ERIH at End of Frame w/6-ft Harness 4 497Y 103 Digital Ground Digital Ground

163-004 ERIHs in Engine Compartment Engine 5 497K (O) 125 Vehicle Speed Sensor Vehicle Speed Sensor

6 497C4 (O) 105 Output Speed Indicator A Output Speed Indicator A

163-005 ERIH Behind Front Bumper (Black Plug) Neutral Indicator for PTO Neutral Indicator for PTO

163-006 ERIH Inside the Cab Under the Dash 7 497C3 (O) 145

Two-Speed Axle Enable Two-Speed Axle Enable

87L-001 ERIH With Park Brake Interlock Direction Change Enable

87L-003 ERIH With Park Brake and Neutral Interlocks Engine Interface (Black Plug) 8

§

497D3 (I ) 143 PTO Enable PTO Enable

Reverse Enable

87L-005 ERIH Without Interlocks Engine Overspeed Indicator

FTL Male Part Number

Connector 23-13153-031 9 497C1 (O) 130 — PTO Enable

Engine Remote Interface Connector Pinout Assignments Terminal Pin 23-13211-031 Secondary Mode Indicator

Engine 1 2 3 4 5 6 7 8

Cavity Circuit Circuit Description 9 10 11 12 13 14 15 16 Vndr Male Part Number Auxiliary Hold

1 483Z Sensor Common Ground With Interlock All engines Connector 54241600 Secondary Mode Input

Terminal Pin 54001626 Two-Speed Axle Enable

2 439U Remote PTO All engines

Automatic Neutral-Dual Input With Park Brake

3 492U Cruise Control PTO Remote On/Off All engines except CAT 10 497D5 (I) 142 Secondary Mode Input Auto Neutral-Dual Input With Service Brake

4 483A PTO Set All engines FTL Female Part Number Status

5 483B PTO Resume All engines Connector 23-13153-030 Auxiliary Function Range Inhibit (special)

8 7 6 5 4 3 2 1 Terminal Pin 23-13211-021

Detroit Diesel, Mercedes, Auto Neutral-Dual Input With Service Brake

439V1 PTO Set Speed A Signal 16 15 14 13 12 11 10 9 Vndr Female Part Number Status

6 CAT (M2 only) Connector 54241630

Auxiliary Function Range Inhibit (standard)

483R Maximum Operating Speed/Governor Cummins only Terminal Pin 54001625

Automatic Neutral-Dual Input With Park Brake

Detroit Diesel, Mercedes, Shift Selector Transition

7 439V2 PTO Set Speed B Signal Auxiliary Function Range

CAT (M2 only) 11 497D6 (I) 101 Two-Speed Axle Enable

Inhibit (standard)

8 483E Tachometer + Signal, Engine rpm All engines Shift Selector Transition/Secondary Shift

483F Tachometer – Signal, Engine rpm Caterpillar only Schedule

9 Auxiliary Function Range Inhibit (special)

492Z Throttle Inhibit Detroit Diesel and

Mercedes-Benz only Automatic Neutral-Single Input

10 483N Remote Throttle On/Off All engines except CAT

Transmission Interface (Grey Plug) Direction Change Enable

Reverse Enable

12 497D10 (I) 117 —

11 483C Remote Throttle Signal All engines Automatic Neutral-Dual Input With Park Brake

FTL Male Part Number Auto Neutral-Dual Input With Service Brake

12 483D Remote Throttle Power All engines Connector 23-13153-057

13 492Y Remote Signal Ground All engines Terminal Pin 23-13211-031

Status

1 2 3 4 5 6 7 8 Sump Sump

14 492W PTO Active Caterpillar only 9 10 11 12 13 14 15 16 Vndr Male Part Number

Connector 54241601

13 497C6 (O) 164 Retarder Temperature Retarder Temperature Indicator

15 Optional Optional Circuit All engines Indicator

Terminal Pin 54001626

16 Optional Optional Circuit All engines 4th Lockup Pump Mode

14 497D1 (I) 123 3rd Lockup Pump Mode Kickdown

FTL Female Part Number Direction Change Enable

Connector 23-13153-056 4th Lockup Pump Mode

Terminal Pin 23-13211-021 3rd Lockup Pump Mode

8 7 6 5 4 3 2 1 15 497D4 (I) 122 Refuse Packer Step Switch

Transfer Case Low

16 15 14 13 12 11 10 9 Vndr Female Part Number Reduced Engine Load at Stop

Connector 54241631 Neutral Indicator for PTO Neutral Indicator for PTO

Terminal Pin 54001625 16 497C3 (O) 145

Two-Speed Axle Enable Two-Speed Axle Enable

† When more than one function is listed, see the Allison Transmission Vocational Model Guide for the applicable function.

§‡ Output

2007 M2 Electrical Body Builder Reference Page # 16 Rev: New

High-current Lighting Interface Harness A06-48218

Connector Circuit Circuit Current

Signal Name Signal Type

Pin Color Number Capacity

EPA 2007 Models 9 8 19

10 2 7 18 TERM-MALE 12/14 AWG DUF 046020412141

Body Builder Lighting Interfaces 11 3 1 6 17

TERM-MALE 16/18 AWG DUF 046020216141

Vehicle Interface Lighting 12

13

4

14

5

15

16

353-022 VEHICLE INTERFACE WIRING WITH BODY BUILDER

CONNECTOR MOUNTED BACK OF CAB 1-5 | | | | |

353-023 VEHICLE INTERFACE WIRING WITH BODY BUILDER 6 Ground Ground BK GND 2 |

CONNECTOR MOUNTED END OF FRAME 7 | | | | |

353-026 VEHICLE INTERFACE WIRING AND PDM WITH BODY 8* Backup Light

+12V via PDM Fuse 2 (20A)

With relay 1 (backup light) active. DKBL 120B 20A

BUILDER CONNECTOR, BACK OF CAB 9 | | | | |

353-027 VEHICLE INTERFACE WIRING AND PDM WITH BODY +12V via PDM Fuse 4 (20A)

10 Right Stop Light R-W 36 20A

BUILDER CONNECTOR AT END OF FRAME With relay 2 (right stop light) Active.

11 Ground Ground BK GND 1 |

353-038 MARKER LAMP CONNECTION FOR BODY BUILDERS

Right Stop Light

+12V via PDM Fuse 6 (20A)

12 or Right Stop/ DKG 38R 20A

Turn Light With relay 3 (right turn light) Active.

Stop Lamps Turn Lamps Backup Lamps Marker Lamps Connection Point 13 | | | | |

+12V via PDM Fuse 1 (20A)

Low Current 14 Left Taillight With relay 4 (left taillight) active. BR 23A 20A

Options 353 - 022 2.1 A per side 4.0 amps* 6.0 amps 6.0 amps BOC, Marker Lamps to C4 -M

15 Ground Ground BK GND 2 |

353 - 023 2.1 A per side 4.0 amps* 6.0 amps 6.0 amps EOF, Marker Lamps to C4 -M Left Stop Light

+12V via PDM Fuse 5 (20A)

16 or Left Stop/Turn Y 38L 20A

with relay 6 (left turn light) active.

High Current Light

Options 353 - 026 20 A per side 20 amps* 6.0 amps combine with tail Back of Cab, PDM 17 | | | | |

+12V via PDM Fuse 3 (20A)

18 Left Stop Light R-W 36 20A

353 - 027 20 A per side 20 amps* 6.0 amps combine with tail End of Frame, PDM With relay 5 (left stop light) active.

19 Ground Ground BK GND 1 |

353 - 038 MARKER LAMP CONNECTION FOR BODY BUILDERS

* Some early harnesses have pin 8 located in pin 17.

Low-current Lighting Interface Harness A06-44388

Circuit Circuit Current

Body Builder PDM also Connector Pin Signal Name Signal Type

Color Number Capacity

Tail Light Connector supplied with these options 1 2 3 4 5 6

TERM-MALE ,S16,SOL,16-18AWG (Solid)DUF 046020216141

1

2

TERM-MALE ,S16,SOL,14-16AWG (Solid)DUF 046021516141

DEUTSCH

3

4

5

DE

TERM-MALE ,S16,,16-18AWG (stamped) DUF 1060 16 0122 PS

6

U TS

12

11

CH

10

9

8

TERM-MALE ,S16,,14-16AWG (stamped) DUF 1060 14 0122 PS

12 11 10 9 8 7 7

1 Left Backup Light Digital Output DKBL 120B 7.45A*

2 Left Taillight Digital Output BR 23A 1.0A

3 Right Taillight Digital Output BR 23A 1.0A

4 Left Turn Light Digital Output Y 38L 7.45A

5 Backup Alarm Digital Output DKBL 120B 7.45A*

6 Right Backup Light Digital Output DKBL 120B 7.45A*

Right Stop Light or

7 Right Stop/Turn Light Digital Output R-W 36 6.7A

Left Stop Light or

8 Digital Output R-W 36 6.7A

Body builder low voltage lighting Body Builder Interface Connector Left Stop/Turn Light

interface connector Supplied with 353-026 & 353-027 9 Right Turn Light Digital Output DKG 38R 7.45A

supplied with 353-022 & 353-023 (See next page for schematics) 10 - 12 | | | | |

(See next page for schematics) * This pin is fed by CHM pins 1, 5, and 6. The maximum combined current capacity for all three pins is 7.45A.

2007 M2 Electrical Body Builder Reference Page # 17 Rev: New

EPA 2007 Models

Body Lighting Interface Schematics

High Current InterfaceRef Harness A06-48218

R 14E

Fuse Fuse Fuse Fuse Fuse Fuse Battery

1 2 3 4 5 6 MEGA

87A 20A 20A 20A 20A 20A 20A Fuse

150A

30

Right

Stop Light Low Current Interface Ref Harness A06-44388

Relay 2 86 36 R-W N

85 38R DKG P A DKBL 120B 120B DKBL A

87 120B DKBL A Left backup light

D

Inline Connector D BR 23A 23A BR D Left taillight

23A BR to Tail Harness

87 38L Y G E BR 23A 23A BR E Right taillight

87A 36 R-W L Inline G Y 38L 38L Y G

C2 Left rear turn light

30 Connector H DKBL 120B 120B DKBL H

Left Backup alarm

to Tail J DKBL 120B 120B DKBL J

Turn Light Harness Right backup light

Relay 6 A R-W 36 36 L Right stop light relay output

R-W L R-W 36 36 R-W L

86 B Y 38L 38L Y

G Left turn light relay output Right stop light

C BR 23A 23A BR

D Left taillight relay output N R-W 36 36 R-W N Left stop light

85 D BK GND P DKG 38R 38R DKG P Right

rearturnlight

E DKBL 120B 120B DKBL A Left backup light relay output C2 C1

F BK GND

87A

G DKG 38R 38R DKG P Right turn light relay output Chassis Module

30 H R-W 36 36 R-W H Left stop light relay output

Left BLK C1

Taillight Connector C2

Relay 4 86 Chassis Module

Left back of

DKBL 120B

DKBL 120B

DKBL 120B

85 cab (BOC1)

38R

23A

23A

38L

87 ground

R-W 36

R-W 36

87A

DKG

DE

BR

BR

UT

Y

Left 30 SC

Backup H 1 2 3 4 5 6 7 8 9 10 11 12

Light A BK GND1

Relay 1 86 B BK GND2 1 2 3 4 5 6 Low-current Lighting Interface

85 C BR 23A

87 D DKBL 120B DEUTSCH

E R-W 36

85 F R-W 36

G DKG 38R 12 11 10 9 8 7

86

GND1

BK 14 GND1

H Y 38L

38R

GND2

GND2

GRY

DKBL120B

Right

36

23A

38L

Turn Light 30 Connector C8

R-W 36

Relay 3

DKG

87A

R-W

BR

BK

BK

BK

87

Y

1 2 3 4 5 6 7 8 9101112 13 1516171819

85

86 High-current Lighting Interface

Left

Stop lIght 30

Relay 5 9 8 19

87A

87 10 2 7 18

11 3 1 6 17

12 4 5 16

13 14 15

2007 M2 Electrical Body Builder Reference Page # 18 Rev: New

Taillight Module

Mod 269

296-010 PRIMARY CONNECTOR/RECEPTACLE CENTER PIN EPA 2007 Models

POWERED THROUGH IGNITION

296-025 PRIMARY CONNECTOR/RECEPTACLE WIRED Trailer Electrical System

FOR COMBINATION STOP/TURN, CENTER PIN POWERED

THROUGH IGNITION

297-001 SAE J560 7-WAY PRIMARY TRAILER CABLE RECEPTACLE

MOUNTED END OF FRAME

297-005 SAE J560 7-WAY PRIMARY TRAILER CABLE RECEPTACLE

MOUNTED ON CHASSIS BACK OF CAB/SLEEPER

297-008 SAE J560 7-WAY PRIMARY TRAILER CABLE RECEPTACLE

BRACKET MOUNTED LH DECK BACK OF CAB

R 14E 14 376E R 14E

MEGA

Battery Fuse Fuse Fuse Fuse Fuse Fuse Battery

Fuse Fuse Fuse Fuse Fuse MEGA

1 2 3 4 5 6 Fuse 1 2 3 4 5 6

30A 30A 20A 20A 30A 30A 150A

30A 30A 20A 20A 30A 30A Fuse

86 86 150A

85 85

Trailer Trailer

Power 30 Power 30

Relay 4 Relay 4

87A 87A

87 87

87A

86 30 86

85 85

87

8 8

Tail 6 Tail

Lamp 30 A DKG 38R E 5 30 A DKG 38R E Trailer right turn relay ctrl

Relay 1 B BR 46A F

Trailer right turn relay ctrl Lamp B BR 46A F Trailer marker relay ctrl

O 376C2

87A C

Trailer marker relay ctrl Relay 1 87A C

O 376C

87 D PK 52C A To ABS 87 D PK 52C A

E BR 23A G

Trailer power relay ctrl

Trailer tail relay ctrl

DKBL 376E Controller E BR G Trailer power relay ctrl

Trailer tail relay ctrl

85 F BK GND O 376C4 85 F BK GND

86 G R-W 36 D

Trailer stop relay ctrl

86 G R-W 36 D Trailer stop relay ctrl

H Y 38L H

Trailer left turn relay ctrl

H Y 38L H Trailer left turn relay ctrl

BLK C2 BLK C2

Left

Connector C1

Chassis Module Left Connector C1 Chassis Module

Turn Lamp 30 Turn 30

Relay 5 PLC Filter Lamp

87A

Left Back-of-Cab Relay 5 87A Left Back-of-Cab

87 DKBL 376E 87 (BOC1)

ISO 3731 Receptacle

(BOC1)

Ground Y 376F2 To ABS Ground

85

Controller 85 A

86 86 B

DKBL 376E

C DKBL 45

Marker Optional Marker D BR 23 Without

30 30 E Y Trailer With Trailer

Lamp Lamp ABS

Y

Connections

Relay 6

Relay 6 F DKG 38R ABS NCA

87A GND 87A G R 36B DKBL NCA

DKG 38r DKBL

87

1 7 3 2 4 5 6 87 H BK 46A NCA

W

GRY

DKBL

85 85 Connector With trailer

DKG

BR

BK

ABS

W

86 C2 NCA

GND

Y

86

R

BK 46A

36B

38l

DKBL

DKBL 45

DKG

BR 23

NCAGND

AntilockB NCA

BR

BK

Right

Y

R

Right

Turn Lamp Turn Braking A NCA

2 4 5 3 6 7 1 System

30 30

W

Relay 2 Lamp

Y

R

1 Relay 2 PLC Filter

BK

87A

BL

87A 2 4 5 3 6 7 1

W

6 2

G

Y

R

87 87

With Trailer

7 ABS

BR

Left Back-of-Cab

BK

BL

W

Y

G

R

85 Trailer Receptacle 5 3 85 (BOC1)

86 86 Ground

4

J560

38L

Stop Stop

Lamp 30

Lamp 30

Relay 3 1 Relay 3

23A

87A 87A 1

87 6 2 87 6 2

7

7

Trailer Module 5 3

Trailer Module 5 3 Trailer

4

4 Receptacle

01/17/2006

Fig. 2, Wiring Diagram of the Trailer Electrical System With Both J560 and ISO 3731 Connectors (primary and Wiring Diagram of the Trailer Electrical System With Only a J560 Connector (primary receptacle)

secondary receptacles)

2007 M2 Electrical Body Builder Reference Page # 19 Rev: New

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- INTERNATIONAL MAXXFORCE DiagramaDokument2 SeitenINTERNATIONAL MAXXFORCE Diagramamiguel290890% (178)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Diagrama Electrico Caterpillar 3406E C10 & C12 & C15 & C16Dokument2 SeitenDiagrama Electrico Caterpillar 3406E C10 & C12 & C15 & C16Gerardo Diesel83% (99)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Ddec V Egr VGT Delete InstructDokument1 SeiteDdec V Egr VGT Delete InstructCharly Ramos70% (10)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- DD Calibration Tool PDFDokument6 SeitenDD Calibration Tool PDFRichard Centeno100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 1 Secm 03 92 PDFDokument10 Seiten1 Secm 03 92 PDFGreenline32Noch keine Bewertungen

- PasswordDokument1 SeitePasswordRoger Lechado GarciaNoch keine Bewertungen

- Transacciones: Fecha No. de Tarjeta Nom. Tarjeta Estacion Servicio Vehículo OdómetroDokument30 SeitenTransacciones: Fecha No. de Tarjeta Nom. Tarjeta Estacion Servicio Vehículo OdómetroRoger Lechado GarciaNoch keine Bewertungen

- Ddec IV Oem Wiring Diagram PDFDokument1 SeiteDdec IV Oem Wiring Diagram PDFRoger Lechado GarciaNoch keine Bewertungen

- 79-f Camion Rojo CenturyDokument13 Seiten79-f Camion Rojo CenturyRoger Lechado Garcia100% (1)

- Combustible Diesel Sept 2018Dokument401 SeitenCombustible Diesel Sept 2018Roger Lechado GarciaNoch keine Bewertungen

- Combustible San Benito 2018Dokument15 SeitenCombustible San Benito 2018Roger Lechado GarciaNoch keine Bewertungen

- Cistern AsDokument3 SeitenCistern AsRoger Lechado GarciaNoch keine Bewertungen

- 092Dokument6 Seiten092Roger Lechado GarciaNoch keine Bewertungen

- UntitledDokument4 SeitenUntitledRoger Lechado GarciaNoch keine Bewertungen

- 2007 User GuideDokument46 Seiten2007 User GuideRoger Lechado GarciaNoch keine Bewertungen

- 092Dokument6 Seiten092Roger Lechado GarciaNoch keine Bewertungen

- Outstanding INVOICE DVFM-5918319-5752Dokument1 SeiteOutstanding INVOICE DVFM-5918319-5752Roger Lechado GarciaNoch keine Bewertungen

- OutstandingDokument1 SeiteOutstandingRoger Lechado GarciaNoch keine Bewertungen

- Cummins Insite 7.X Keygen Credits and THNX Go To SND! Share It, But Dont Sale It !!!! Thank You! BlackpirateDokument1 SeiteCummins Insite 7.X Keygen Credits and THNX Go To SND! Share It, But Dont Sale It !!!! Thank You! BlackpirateRoger Lechado GarciaNoch keine Bewertungen

- 2007 User GuideDokument46 Seiten2007 User GuideRoger Lechado GarciaNoch keine Bewertungen

- 4328482Dokument75 Seiten4328482Roger Lechado GarciaNoch keine Bewertungen

- 092Dokument6 Seiten092Roger Lechado GarciaNoch keine Bewertungen

- 092Dokument6 Seiten092Roger Lechado GarciaNoch keine Bewertungen

- 092Dokument6 Seiten092Roger Lechado GarciaNoch keine Bewertungen

- Outstanding INVOICE DVFM-5918319-5752Dokument1 SeiteOutstanding INVOICE DVFM-5918319-5752Roger Lechado GarciaNoch keine Bewertungen

- 092Dokument6 Seiten092Roger Lechado GarciaNoch keine Bewertungen

- 121 - Pdfsam - Section 1 - EngineDokument60 Seiten121 - Pdfsam - Section 1 - EngineRoger Lechado Garcia100% (1)

- Libro 2Dokument3 SeitenLibro 2Roger Lechado GarciaNoch keine Bewertungen

- Ie36 FinalDokument35 SeitenIe36 FinalRoger Lechado GarciaNoch keine Bewertungen

- Readme ENGDokument1 SeiteReadme ENGRoger Lechado GarciaNoch keine Bewertungen

- Module 2 Global Youth: A Estrutura Do Teste Sintetiza-Se No Quadro SeguinteDokument11 SeitenModule 2 Global Youth: A Estrutura Do Teste Sintetiza-Se No Quadro SeguinteLaura HenriquesNoch keine Bewertungen

- Md. Shahriar Haque Mithun: GPH Ispat LimitedDokument3 SeitenMd. Shahriar Haque Mithun: GPH Ispat LimitedMd. Shahriar haque mithunNoch keine Bewertungen

- Flashattention: Fast and Memory-Efficient Exact Attention With Io-AwarenessDokument34 SeitenFlashattention: Fast and Memory-Efficient Exact Attention With Io-AwarenessMarcos CostaNoch keine Bewertungen

- Sample Midterm (Lab)Dokument3 SeitenSample Midterm (Lab)Shahab designerNoch keine Bewertungen

- MS Disc Brake CaliperDokument2 SeitenMS Disc Brake Caliperghgh140Noch keine Bewertungen

- General Purpose Relay: TA, TR Series Part Number DescriptionDokument17 SeitenGeneral Purpose Relay: TA, TR Series Part Number DescriptionMIKENoch keine Bewertungen

- Anil Laul BharaniDokument30 SeitenAnil Laul BharaniBharani MadamanchiNoch keine Bewertungen

- Cambridge International AS and A Level Economics Coursebook CD ROMDokument5 SeitenCambridge International AS and A Level Economics Coursebook CD ROMNana Budu Kofi HAYFORDNoch keine Bewertungen

- 4MATION SAM Module IO-IDokument54 Seiten4MATION SAM Module IO-IIkhuosho AbodeNoch keine Bewertungen

- HTML Project On Shopping WebsiteDokument2 SeitenHTML Project On Shopping WebsiteSunitha ManamNoch keine Bewertungen

- An Inflection Point For The Data-Driven Enterprise: Pulse SurveyDokument20 SeitenAn Inflection Point For The Data-Driven Enterprise: Pulse SurveyAndy BaneNoch keine Bewertungen

- Cama BajaDokument32 SeitenCama BajaCarlosSilvaYruretaNoch keine Bewertungen

- Discrete Mathematics - Propositional LogicDokument8 SeitenDiscrete Mathematics - Propositional LogicAldrich PanioNoch keine Bewertungen

- MECN5015A - Chapter 4 - Lecture Slides 6 AprilDokument61 SeitenMECN5015A - Chapter 4 - Lecture Slides 6 AprilGulain MayomboNoch keine Bewertungen

- Selling NDokument33 SeitenSelling NADITYA VARPENoch keine Bewertungen

- PMA A403Gr304L EN 13480Dokument1 SeitePMA A403Gr304L EN 13480CRISTIAN SILVIU IANUCNoch keine Bewertungen

- SBxx-1SP-US-40-IA-xx-16 Instruct ManDokument224 SeitenSBxx-1SP-US-40-IA-xx-16 Instruct ManSmellyDog360Noch keine Bewertungen

- Update Penjualan 2019 1Dokument941 SeitenUpdate Penjualan 2019 1Viar TimikaNoch keine Bewertungen

- IGCSE COMMERCE Chapter 10.1Dokument5 SeitenIGCSE COMMERCE Chapter 10.1Tahmid Raihan100% (1)

- 2020 - Roadroid University Registration FormDokument2 Seiten2020 - Roadroid University Registration FormAiidil SuwandiNoch keine Bewertungen

- Gyproc Regular BoardsDokument6 SeitenGyproc Regular BoardsRadhika Veerala100% (1)

- Indian Institute of Technology: Delhi Summary Sheet Consumable StoresDokument2 SeitenIndian Institute of Technology: Delhi Summary Sheet Consumable StoresSumit SinghNoch keine Bewertungen

- Yellampalli S. Wireless Sensor Networks - Design, Deployment..2021Dokument314 SeitenYellampalli S. Wireless Sensor Networks - Design, Deployment..2021Myster SceneNoch keine Bewertungen

- Woson TandaDokument46 SeitenWoson Tandapfe120Noch keine Bewertungen

- Guia de Usuario Sokkia LinkDokument81 SeitenGuia de Usuario Sokkia LinkEdwin VelasquezNoch keine Bewertungen

- Marketing Manager: at Aztec GroupDokument2 SeitenMarketing Manager: at Aztec GroupAgnish GhatakNoch keine Bewertungen

- Lesson 2Dokument10 SeitenLesson 2Anore James IvanNoch keine Bewertungen

- CSC662 - Computer Security Short NoteDokument10 SeitenCSC662 - Computer Security Short NoteMohamad YusriNoch keine Bewertungen

- Bomag BF 300 C2Dokument4 SeitenBomag BF 300 C2Vishwdeep VaidNoch keine Bewertungen

- Fractional Fourier TransformDokument12 SeitenFractional Fourier Transformvolly666Noch keine Bewertungen