Beruflich Dokumente

Kultur Dokumente

JC Catalogue Gate Valves BB PDF

Hochgeladen von

Mahdi DalyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

JC Catalogue Gate Valves BB PDF

Hochgeladen von

Mahdi DalyCopyright:

Verfügbare Formate

PDS – JC-VC150BB Rev.

Gate Valves Type Bolted Bonnet

Class 150 DN 50-900 (2” – 36”)

Carbon, Alloy and Stainless Steel

Fig. VC150BB

Design:

API 600, API 603,

ASME B16.34 and BS 1414

600-0016

JC Fábrica de válvulas, s.a. SERIES

E-Mail: jc@jc-valves.com

Internet: www.jc-valves.com Page 1 / 4 Data given can be changed without notice. VC

PDS – JC-VC150BB Rev.3

Gate Valves Class 150

Type Bolted Bonnet

Parts and materials

Trim Material

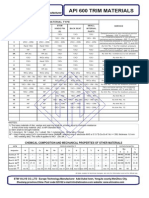

API 600 Nominal Stem / Seating Surface

Trim No. Trim Backseat ( 1) Body / Wedge

1 F6 13Cr 13Cr

2 304 18Cr-8Ni 18Cr-8Ni

3 F310 25Cr-20Ni 25Cr-20Ni

4 Hard F6 13Cr Hard 13Cr

5 Hardfaced 13Cr Co -Cr A (2)

5A Hardfaced 13Cr Ni-Cr

6 F6 and Cu-Ni 13Cr 13Cr and Cu-Ni

7 F6 and Hard F6 13Cr 13Cr and Hard 13Cr

8 F6 and Hardfaced 13Cr 13Cr and Co -Cr A (2)

8A F6 and Hardfaced 13Cr 13Cr and Ni-Cr

9 M o nel Ni-Cu A llo y Ni-Cu A llo y

10 316 18Cr-8Ni-M o 18Cr-8Ni-M o

11 M o nel and Hardfaced Ni-Cu A llo y Ni-Cu A llo y and Trim 5 o r 5A

12 316 and Hardfaced 18Cr-8Ni-M o 18Cr-8Ni-M o and Trim 5 o r 5A

13 A llo y 20 19Cr-29Ni 19Cr-29Ni

14 A llo y 20 and Hardfaced 19Cr-29Ni 19Cr-29Ni and Trim 5 o r 5A

15 Hardfaced 18Cr-8Ni Co -Cr A (2)

16 Hardfaced 18Cr-8Ni-M o Co -Cr A (2)

17 Hardfaced 18Cr-10Ni-Cb Co -Cr A (2)

18 Hardfaced 19Cr-29Ni Co -Cr A (2)

(1) and small internal parts that no rmally co ntact the service fluid

(2) Trademark material Stellite 6

Carbon & Alloy Stainless Steel

Steel Construction Construction

Material of construction *

Item Description

Carbon Steel Carbon Steel (Low Tem p.) Alloy Steel Stainless Steel

1 Body A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

2 Bonnet A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

3 Wedge A 216 Gr.WCB + ER410 A 352 Gr.LCB + ER308 A 217 Gr.C5 + ER410 A 351 Gr.CF8M

4 Yoke A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

5 Stem A 182 Gr.F6a A 182 Gr.F304 A 182 Gr.F6a A 182 Gr.F316

6 Seat Ring A 105 + Stellite A 182 Gr.F304 A 182 Gr.F6a + Stellite -----

7 Stem Nut B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2

8 Backseat A182 Gr.F6a A182 Gr.F304 A 182 Gr.F6a -----

9 Gland A 105 A 105 A 182 Gr.F6a A 182 Gr.F316

10 Gland Flange A 105 A 105 A 105 A 182 Gr.F304

11 Stem Packing Graphite Graphite Graphite Graphite

12 Gasket SS 304 / Graphite SS 304 / Graphite SS 304 / Graphite SS 316 / Graphite

13 Bonnet Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A320 Gr. L7 / A194 Gr. 7 A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H ( 3 )

14 Eye Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H

15 Handw heel Carbon Steel Carbon Steel Carbon Steel Carbon Steel

(3) Zinc coating

* Standard constructions with Trim 8, 2 and 10, other options are available

SERIES

Page 2 / 4 Data given can be changed without notice. VC

PDS – JC-VC150BB Rev.3

Gate Valves Class 150

Type Bolted Bonnet

Dimensions

DN A B C ØD WEIGHT

50 (2”) 178 216 386 200 17

65 (2½") 190 241 435 200 27

80 (3”) 203 282,5 483 250 33

100 (4”) 229 305 587 250 48

125 (5") 254 381 673 300 65

150 (6”) 267 403 767 300 78

200 (8”) 292 419 955 350 120

250 (10”) 330 457 1146 450 176

300 (12”) 356 502 1328 500 260

350 (14") 381 572 1519 460 380

400 (16") 406 610 1721 460 530

450 (18") 432 660 1900 460 620

500 (20") 457 711 2116 610 810

550 (22") 483 762 2315 610 1050

600 (24") 508 813 2480 610 1150

650 (26") 559 -- 2700 610 1380

700 (28") 610 -- 2975 610 1980

750 (30") 610 -- 3102 610 2200

900 (36") 711 -- 3668 710 2800

(*) Dimensions in mm and weight in kg

For other sizes consult to the technical department.

SERIES

Page 3 / 4 Data given can be changed without notice. VC

PDS – JC-VC150BB Rev.3

Gate Valves Class 150

Type Bolted Bonnet

General Characteristics, Cv, P&T Rating

GENERAL CHARACTERISTICS Fig. VC150BB

DESIGN STANDARDS

Valves design API 600, API 603, ASME B16.34 & EN ISO 10434

End to End Dim ensions ASME B16.10 & ISO 5752

Flanged Dim ensions ASME B16.5 & ISO 7005-1 Part. 1 ASME B16.47 BS 3293 MSS SP-44

Buttw eld Dim ensions ASME B16.25

Visual Inspection MSS SP- 55

Marking MSS SP-25 & ISO 5209

TESTS AND CERTIFICATES

Pressure testing API 598 & ISO 5208 EN 12266-1 MSS SP-61

Other ATEX, CE

Cv Values in U.S. Gallons/min.

DN Cv DN Cv

50 (2”) 250 400 (16") 20300

65 (2½") 450 450 (18") 26100

80 (3”) 620 500 (20") 33500

100 (4”) 1160 550 (22") 42000

125 (5") 1900 600 (24") 50000

150 (6”) 2700 650 (26") 59500

200 (8”) 5100 700 (28") 69200

250 (10”) 8050 750 (30") 79000

300 (12”) 12050 900 (36") 115500

350 (14") 15100

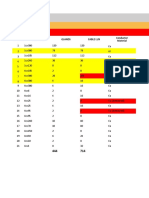

Pressure-Temperature (STANDARD CLASS According to ASME B16.34)

MATERIAL

Temp

A216 WCB A352 LCB A217 C5 A351 CF8M (**)

ºC Bar Bar Bar Bar

-29 to 38 19,6 18,3 20,0 18,9

95 17,9 17,2 17,9 16,2

150 15,8 15,8 15,8 14,8

205 13,8 13,8 13,8 13,4

260 11,7 11,7 11,7 11,7

315 9,6 9,6 9,6 9,6

345 8,6 8,6 8,6 8,6

375 7,6 7,6 7,6

400 6,5 6,5 6,5

425 5,5 5,5 5,5

450 4,5 4,5 4,5

485 3,4 3,4 3,4

510 2,4 2,4 2,4

540 1,4 1,4 1,4

565 1,4 * 1,4 *

595 1,4 * 1,4 *

620 1,4 * 1,4 *

650 1,4 * 1,4 *

675 1,4 *

705 1,4 *

735 1,4 *

760 1,4 *

790 1,4 *

815 1,4 *

* FOR WELD END VALVES ONLY. FLANGED END RATINGS TERMINATE AT 540ºC

** A351 CF8M at temparetures over 538ºC (1000ºF) to b e used only if Carb on contents is 0,04% or higher.

SERIES

Page 4 / 4 Data given can be changed without notice. VC

PDS – JC-VC300BB Rev.3

Gate Valves Type Bolted Bonnet

Class 300 DN 50-600 (2” – 24”)

Carbon, Alloy and Stainless Steel

Fig. VC300BB

Design:

API 600, API 603

ASME B16.34 and BS1414

600-0016

JC Fábrica de válvulas, s.a. SERIES

E-Mail: jc@jc-valves.com

Internet: www.jc-valves.com Page 1 / 4 Data given can be changed without notice. VC

PDS – JC-VC300BB Rev.3

Gate Valves Class 300

Type Bolted Bonnet

Parts and materials

Trim Material

API 600 Nominal Stem / Seating Surface

Trim No. Trim Backseat ( 1) Body / Wedge

1 F6 13Cr 13Cr

2 304 18Cr-8Ni 18Cr-8Ni

3 F310 25Cr-20Ni 25Cr-20Ni

4 Hard F6 13Cr Hard 13Cr

5 Hardfaced 13Cr Co -Cr A (2)

5A Hardfaced 13Cr Ni-Cr

6 F6 and Cu-Ni 13Cr 13Cr and Cu-Ni

7 F6 and Hard F6 13Cr 13Cr and Hard 13Cr

8 F6 and Hardfaced 13Cr 13Cr and Co -Cr A (2)

8A F6 and Hardfaced 13Cr 13Cr and Ni-Cr

9 M o nel Ni-Cu A llo y Ni-Cu A llo y

10 316 18Cr-8Ni-M o 18Cr-8Ni-M o

11 M o nel and Hardfaced Ni-Cu A llo y Ni-Cu A llo y and Trim 5 o r 5A

12 316 and Hardfaced 18Cr-8Ni-M o 18Cr-8Ni-M o and Trim 5 o r 5A

13 A llo y 20 19Cr-29Ni 19Cr-29Ni

14 A llo y 20 and Hardfaced 19Cr-29Ni 19Cr-29Ni and Trim 5 o r 5A

15 Hardfaced 18Cr-8Ni Co -Cr A (2)

16 Hardfaced 18Cr-8Ni-M o Co -Cr A (2)

17 Hardfaced 18Cr-10Ni-Cb Co -Cr A (2)

18 Hardfaced 19Cr-29Ni Co -Cr A (2)

Carbon & Alloy Steel Stainless Steel (1) and small internal parts that no rmally co ntact the service fluid

Construction Construction (2) Trademark material Stellite 6

Material of construction*

Item Description

Carbon Steel Carbon Steel (Low Tem p.) Alloy Steel Stainless Steel

1 Body A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

2 Bonnet A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

3 Wedge A 216 Gr.WCB + ER410 A 352 Gr.LCB + ER308 A 217 Gr.C5 + ER410 A 351 Gr.CF8M

4 Yoke A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

5 Stem A 182 Gr.F6a A 182 Gr.F304 A 182 Gr.F6a A 182 Gr.F316

6 Seat Ring A 105 + Stellite A 182 Gr.F304 A 182 Gr.F6a + Stellite -----

7 Stem Nut B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2

8 Backseat A182 Gr.F6a A182 Gr. F304 A 182 Gr.F6a -----

9 Gland A 105 A 105 A 182 Gr.F6a A 182 Gr.F316

10 Gland Flange A 105 A 105 A 105 A 182 Gr.F304

11 Stem Packing Graphite Graphite Graphite Graphite

12 Gasket SPW SS304 / Graphite SPW SS304 / Graphite SPW SS304 / Graphite SPW SS316 / Graphite

13 Bonnet Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H ( 3 )

14 Eye Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H

15 Handw heel Carbon Steel Carbon Steel Carbon Steel Carbon Steel

(3) Zinc coating

* Standard constructions with Trim 8, 2 and 10, other options are available

SERIES

Page 2 / 4 Data given can be changed without notice. VC

PDS – JC-VC300BB Rev.3

Gate Valves Class 300

Type Bolted Bonnet

Dimensions

DN A (RF/BW) B ØC WEIGHT

50 (2”) 216 417 200 24

65 (2½") 241 460 250 35

80 (3”) 282,5 526 250 49

100 (4”) 305 650 250 69

125 (5") 381 694 300 92

150 (6”) 403 824 350 130

200 (8”) 419 987 450 208

250 (10”) 457 1192 500 333

300 (12”) 502 1431 560 536

350 (14") 762 1559 460 699

400 (16") 838 1758 460 1010

450 (18") 914 1942 610 1205

500 (20") 991 2145 610 1720

550 (22") 1092 2340 610 1920

600 (24") 1143 2526 610 2580

(*) Dimensions in mm and weight in kg

For other sizes consult to the technical department.

SERIES

Page 3 / 4 Data given can be changed without notice. VC

PDS – JC-VC300BB Rev.3

Gate Valves Class 300

Type Bolted Bonnet

General Characteristics, Cv, P&T Rating

GENERAL CHARACTERISTICS Fig. VC300BB

DESIGN STANDARDS

Valves design API 600, API 603, ASME B16.34 & EN ISO 10434

End to End Dim ensions ASME B16.10 & ISO 5752

Flanged Dim ensions ASME B16.5 & ISO 7005-1 Part. 1 BS 3293 MSS SP-44

Buttw eld Dim ensions ASME B16.25

Visual Inspection MSS SP- 55

Marking MSS SP-25 & ISO 5209

TESTS AND CERTIFICATES

Pressure testing API 598 & ISO 5208 EN 12266-1 MSS SP-61

Others ATEX, CE

Cv Values in U.S. Gallons/min.

DN Cv DN Cv

50 (2”) 250 300 (12”) 12050

65 (2½") 450 350 (14") 15100

80 (3”) 620 400 (16") 20300

100 (4”) 1160 450 (18") 25000

125 (5") 1900 500 (20") 32500

150 (6”) 2700 550 (22") 40000

200 (8”) 5100 600 (24") 48500

250 (10”) 8050

Pressure-Temperature (STANDARD CLASS According ASME B16.34)

MATERIAL

Temp

A216 WCB A352 LCB A217 C5 A351 CF8M (**)

ºC Bar Bar Bar Bar

-29 to 38 51,0 47,9 51,7 49,6

95 46,5 45,1 51,3 42,7

150 45,1 44,1 49,3 38,6

205 43,8 42,7 48,6 35,5

260 41,3 40,3 45,8 33,1

315 37,9 36,9 41,7 31,0

345 36,9 36,2 40,7 30,7

375 36,9 39,3 29,6

400 34,8 36,5 29,3

425 28,2 35,1 28,9

450 18,6 33,4 28,9

485 11,7 25,5 28,6

510 7,2 18,9 26,5

540 3,4 13,8 24,1

565 10,0 * 23,8 *

595 6,9 * 21,0 *

620 4,1 * 16,2 *

650 2,4 * 12,7 *

675 10,0 *

705 7,9 *

735 6,5 *

760 5,2 *

790 4,1 *

815 2,8 *

* FOR WELD END VALVES ONLY. FLANGED END RATINGS TERMINATE AT 540ºC

** A351 CF8M at temparetures over 538ºC (1000ºF) to be used only if Carbon contents is 0,04% or higher.

SERIES

Page 4 / 4 Data given can be changed without notice. VC

PDS – JC-VC600BB Rev.3

Gate Valves Type Bolted Bonnet

Class 600 DN 50-600 (2” – 24”)

Carbon, Alloy and Stainless Steel

Fig. VC600BB

Design:

API 600, API 603,

ASME B16.34 and BS 1414

600-0016

JC Fábrica de válvulas, s.a. SERIES

E-Mail: jc@jc-valves.com

Internet: www.jc-valves.com Page 1 / 4 Data given can be changed without notice. VC

PDS – JC-VC600BB Rev.3

Gate Valves Class 600

Type Bolted Bonnet

Parts and materials

Trim Material

API 600 Nominal Stem / Seating Surface

Trim No. Trim Backseat ( 1) Body / Wedge

1 F6 13Cr 13Cr

2 304 18Cr-8Ni 18Cr-8Ni

3 F310 25Cr-20Ni 25Cr-20Ni

4 Hard F6 13Cr Hard 13Cr

5 Hardfaced 13Cr Co -Cr A (2)

5A Hardfaced 13Cr Ni-Cr

6 F6 and Cu-Ni 13Cr 13Cr and Cu-Ni

7 F6 and Hard F6 13Cr 13Cr and Hard 13Cr

8 F6 and Hardfaced 13Cr 13Cr and Co -Cr A (2)

8A F6 and Hardfaced 13Cr 13Cr and Ni-Cr

9 M o nel Ni-Cu A llo y Ni-Cu A llo y

10 316 18Cr-8Ni-M o 18Cr-8Ni-M o

11 M o nel and Hardfaced Ni-Cu A llo y Ni-Cu A llo y and Trim 5 o r 5A

12 316 and Hardfaced 18Cr-8Ni-M o 18Cr-8Ni-M o and Trim 5 o r 5A

13 A llo y 20 19Cr-29Ni 19Cr-29Ni

14 A llo y 20 and Hardfaced 19Cr-29Ni 19Cr-29Ni and Trim 5 o r 5A

15 Hardfaced 18Cr-8Ni Co -Cr A (2)

16 Hardfaced 18Cr-8Ni-M o Co -Cr A (2)

17 Hardfaced 18Cr-10Ni-Cb Co -Cr A (2)

18 Hardfaced 19Cr-29Ni Co -Cr A (2)

Carbon & Alloy Steel Stainless Steel (1) ,,,and small internal parts that no rmally co ntact the service fluid

Construction Construction (2) Trademark material Stellite 6

Material of construction*

Item Description

Carbon Steel Carbon Steel (Low Tem p.) Alloy Steel Stainless Steel

1 Body A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

2 Bonnet A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

3 Wedge A 216 Gr.WCB + ER410 A 352 Gr.LCB + ER308 A 217 Gr.C5 + ER410 A 351 Gr.CF8M

4 Yoke A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

5 Stem A 182 Gr.F6a A 182 Gr.F304 A 182 Gr.F6a A 182 Gr.F316

6 Seat Ring A 105 + Stellite A 182 Gr.F304 A 182 Gr.F6a + Stellite -----

7 Stem Nut B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2

8 Backseat A182 Gr.F6a A182 Gr.F304 A 182 Gr.F6a -----

9 Gland A 105 A 105 A 182 Gr.F6a A 182 Gr.F316

10 Gland Flange A 105 A 105 A 105 A 182 Gr.F304

11 Stem Packing Graphite Graphite Graphite Graphite

12 Gasket SPW SS304 / Graphite SPW SS304 / Graphite SPW SS304 / Graphite SPW SS316 / Graphite

13 Bonnet Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H (3)

14 Eye Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H

15 Handw heel Carbon Steel Carbon Steel Carbon Steel Carbon Steel

(3) Zinc coating

* Standard constructions with Trim 8, 2 and 10, other options are available

SERIES

Page 2 / 4 Data given can be changed without notice. VC

PDS – JC-VC600BB Rev.3

Gate Valves Class 600

Type Bolted Bonnet

Dimensions

DN A (RF/BW) B ØC WEIGHT

50 (2”) 292 427 250 33

65 (2½") 330 473 250 58

80 (3”) 356 538 300 63

100 (4”) 432 657 350 131

125 (5") 508 770 400 182

150 (6”) 559 872 500 253

200 (8”) 660 1101 560 413

250 (10”) 787 1279 720 623

300 (12”) 838 1486 610 784

350 (14") 889 1643 610 1288

400 (16") 991 1798 610 1820

450 (18") 1092 2101 610 2150

500 (20") 1194 2259 710 2540

550 (22") 1295 2405 760 2800

600 (24") 1397 2545 760 3350

(*) Dimensions in mm and weight in kg

For other sizes consult to the technical department.

SERIES

Page 3 / 4 Data given can be changed without notice. VC

PDS – JC-VC600BB Rev.3

Gate Valves Class 600

Type Bolted Bonnet

General Characteristics, Cv, P&T Rating

GENERAL CHARACTERISTICS Fig. VC600BB

DESIGN STANDARDS

Valves design API 600, API 603, ASME B16.34 & EN ISO 10434

End to End Dim ensions ASME B16.10 & ISO 5752

Flanged Dim ensions ASME B16.5 & ISO 7005-1 Part. 1 BS 3293 MSS SP-44

Buttw eld Dim ensions ASME B16.25

Visual Inspection MSS SP- 55

Marking MSS SP-25 & ISO 5209

TESTS AND CERTIFICATES

Pressure testing API 598 & ISO 5208 EN 12266-1 MSS SP-61

Others ATEX, CE

Cv Values in U.S. Gallons/min.

DN Cv DN Cv

50 (2”) 250 300 (12”) 11500

65 (2½") 450 350 (14") 14000

80 (3”) 620 400 (16") 18500

100 (4”) 1160 450 (18") 23000

125 (5") 1900 500 (20") 28500

150 (6”) 2700 550 (22") 35000

200 (8”) 5100 600 (24") 43000

250 (10”) 7800

Pressure-Temperature (STANDARD CLASS ACCORDING TO ASME B16.34)

MATERIAL

Temp

A216 WCB A352 LCB A217 C5 A351 CF8M (**)

ºC Bar Bar Bar Bar

-29 to 38 102,0 95,8 103,4 99,2

95 93,0 90,6 102,7 85,4

150 90,6 87,8 98,5 77,2

205 87,5 85,1 87,1 70,6

260 82,7 80,3 91,6 65,8

315 75,4 73,4 83,4 62,0

345 74,1 72,0 81,0 61,3

375 73,4 78,2 59,9

400 69,6 72,7 58,9

425 56,8 69,9 58,2

450 36,9 66,5 57,5

485 23,8 51,0 57,2

510 14,1 37,9 53,4

540 7,2 27,6 48,2

565 20,0 * 47,2 *

595 13,8 * 42,0 *

620 8,6 * 32,7 *

650 4,8 * 25,5 *

675 20,3 *

705 16,2 *

735 13,1 *

760 10,3 *

790 7,9 *

815 5,9 *

* FOR WELD END VALVES ONLY. FLANGE END RATINGS TERMINATE AT 540ºC

** A351 CF8M at temparetures over 538ºC (1000ºF) to b e used only if Carb on contents is 0,04% or higher.

SERIES

Page 4 / 4 Data given can be changed without notice. VC

PDS – JC-VC900BB Rev.3

Gate Valves Type Bolted Bonnet

Class 900 DN 50-500 (2” – 20”)

Carbon, Alloy and Stainless Steel

Fig. VC900BB

Design:

API 600,

ASME B16.34 and BS 1414

600-0016

JC Fábrica de válvulas, s.a. SERIES

E-Mail: jc@jc-valves.com

Internet: www.jc-valves.com Page 1 / 4 Data given can be changed without notice. VC

PDS – JC-VC900BB Rev.3

Gate Valves Class 900

Type Bolted Bonnet

Parts and materials

Trim Material

API 600 Nominal Stem / Seating Surface

Trim No. Trim Backseat ( 1) Body / Wedge

1 F6 13Cr 13Cr

2 304 18Cr-8Ni 18Cr-8Ni

3 F310 25Cr-20Ni 25Cr-20Ni

4 Hard F6 13Cr Hard 13Cr

5 Hardfaced 13Cr Co -Cr A (2)

5A Hardfaced 13Cr Ni-Cr

6 F6 and Cu-Ni 13Cr 13Cr and Cu-Ni

7 F6 and Hard F6 13Cr 13Cr and Hard 13Cr

8 F6 and Hardfaced 13Cr 13Cr and Co -Cr A (2)

8A F6 and Hardfaced 13Cr 13Cr and Ni-Cr

9 M o nel Ni-Cu A llo y Ni-Cu A llo y

10 316 18Cr-8Ni-M o 18Cr-8Ni-M o

11 M o nel and Hardfaced Ni-Cu A llo y Ni-Cu A llo y and Trim 5 o r 5A

12 316 and Hardfaced 18Cr-8Ni-M o 18Cr-8Ni-M o and Trim 5 o r 5A

13 A llo y 20 19Cr-29Ni 19Cr-29Ni

14 A llo y 20 and Hardfaced 19Cr-29Ni 19Cr-29Ni and Trim 5 o r 5A

15 Hardfaced 18Cr-8Ni Co -Cr A (2)

16 Hardfaced 18Cr-8Ni-M o Co -Cr A (2)

17 Hardfaced 18Cr-10Ni-Cb Co -Cr A (2)

18 Hardfaced 19Cr-29Ni Co -Cr A (2)

(1) ,,,and small internal parts that no rmally co ntact the service fluid

Carbon & Alloy Steel Stainless Steel

(2) Trademark material Stellite 6

Construction Construction

Material of construction*

Item Description

Carbon Steel Carbon Steel (Low Tem p.) Alloy Steel Stainless Steel

1 Body A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

2 Bonnet A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

3 Wedge A 216 Gr.WCB + ER410 A 352 Gr.LCB + ER308 A 217 Gr.C5 + ER410 A 351 Gr.CF8M

4 Yoke A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

5 Stem A 182 Gr.F6a A 182 Gr.F304 A 182 Gr.F6a A 182 Gr.F316

6 Seat Ring A 105 + Stellite A 182 Gr.F304 A 182 Gr.F6a + Stellite -----

7 Stem Nut B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2

8 Backseat A182 Gr.F6a A182 Gr.F304 A 182 Gr.F6a -----

9 Gland A 105 A 105 A 182 Gr.F6a A 182 Gr.F316

10 Gland Flange A 105 A 105 A 105 A 182 Gr.F304

11 Stem Packing Graphite Graphite Graphite Graphite

12 Gasket Soft Iron SS 304 SS 304 SS 316

13 Bonnet Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H ( 3 )

14 Eye Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H

15 Handw heel Carbon Steel Carbon Steel Carbon Steel Carbon Steel

(3) Zinc coating

* Standard constructions with Trim 8, 2 and 10, other options are available

SERIES

Page 2 / 4 Data given can be changed without notice. VC

PDS – JC-VC900BB Rev.3

Gate Valves Class 900

Type Bolted Bonnet

Dimensions

DN A (RF/BW) B ØC WEIGHT

50 (2”) 368 547 300 90

65 (2½") 419 700 350 110

80 (3”) 381 648 400 123

100 (4”) 457 729 450 148

125 (5") 559 890 500 280

150 (6”) 610 1041 560 420

200 (8”) 737 1260 460 650

250 (10”) 838 1590 610 1160

300 (12”) 965 1795 610 1700

350 (14") 1029 2025 760 2300

400 (16") 1130 2170 760 2750

450 (18") 1219 2345 760 3120

500 (20") 1321 2610 760 3550

(*) Dimensions in mm and weight in kg

For other sizes consult to the technical department.

SERIES

Page 3 / 4 Data given can be changed without notice. VC

PDS – JC-VC900BB Rev.3

Gate Valves Class 900

Type Bolted Bonnet

General Characteristics, Cv, P&T Rating

GENERAL CHARACTERISTICS Fig. VC900BB

DESIGN STANDARDS

Valves design API 600 ASME B16.34 EN ISO 10434

End to End Dim ensions ASME B16.10 & ISO 5752

Flanged Dim ensions ASME B16.5 & ISO 7005-1 Part. 1 BS 3293 MSS SP-44

Buttw eld Dim ensions ASME B16.25

Visual Inspection MSS SP- 55

Marking MSS SP-25 & ISO 5209

TESTS AND CERTIFICATES

Pressure testing API 598 & ISO 5208 EN 12266-1 MSS SP-61

Other ATEX, CE

Cv Values in U.S. Gallons/min.

DN Cv DN Cv

50 (2”) 230 250 (10”) 7050

65 (2½") 410 300 (12”) 10000

80 (3”) 580 350 (14") 13100

100 (4”) 1050 400 (16") 18200

125 (5") 1820 450 (18") 21500

150 (6”) 2550 500 (20") 26500

200 (8”) 4400

Pressure-Temperature (STANDARD CLASS ACCORDING TO ASME B16.34)

MATERIAL

Temp

A216 WCB A352 LCB A217 C5 A351 CF8M (**)

ºC Bar Bar Bar Bar

-29 to 38 153,0 143,7 155,0 148,8

95 139,5 135,7 154,0 128,2

150 135,7 131,9 148,1 115,8

205 130,9 127,5 145,7 106,1

260 123,7 120,2 137,5 98,9

315 113,0 110,2 125,1 93,4

345 110,9 108,2 121,6 91,6

375 110,2 117,5 89,9

400 104,0 109,2 88,2

425 85,1 105,1 87,2

450 55,5 99,9 86,5

485 35,5 76,5 85,8

510 21,4 56,8 79,9

540 10,7 41,0 72,3

565 29,6 * 71,0 *

595 20,7 * 63,0 *

620 12,7 * 48,9 *

650 7,2 * 38,2 *

675 30,3 *

705 24,1 *

735 20,0 *

760 15,5 *

790 12,1 *

815 8,6 *

* FOR WELD END VALVES ONLY. FLANGED END RATINGS TERMINATE AT 540ºC

** A351 CF8M at temparetures over 538ºC (1000ºF) to be used only if Carbon contents is 0,04% or higher.

SERIES

Page 4 / 4 Data given can be changed without notice. VC

PDS – JC-VC1500BB Rev.3

Gate Valves Type Bolted Bonnet

Class 1500 DN 50-400 (2” – 16”)

Carbon, Alloy and Stainless Steel

Fig. VC1500BB

Design:

API 600,

ASME B16.34 and BS 1414

600-0016

JC Fábrica de válvulas, s.a. SERIES

E-Mail: jc@jc-valves.com

Internet: www.jc-valves.com Page 1 / 4 Data given can be changed without notice. VC

PDS – JC-VC1500BB Rev.3

Gate Valves Class 1500

Type Bolted Bonnet

Parts and materials

Trim Material

API 600 Nominal Stem / Seating Surface

Trim No. Trim Backseat ( 1) Body / Wedge

1 F6 13Cr 13Cr

2 304 18Cr-8Ni 18Cr-8Ni

3 F310 25Cr-20Ni 25Cr-20Ni

4 Hard F6 13Cr Hard 13Cr

5 Hardfaced 13Cr Co -Cr A (2)

5A Hardfaced 13Cr Ni-Cr

6 F6 and Cu-Ni 13Cr 13Cr and Cu-Ni

7 F6 and Hard F6 13Cr 13Cr and Hard 13Cr

8 F6 and Hardfaced 13Cr 13Cr and Co -Cr A (2)

8A F6 and Hardfaced 13Cr 13Cr and Ni-Cr

9 M o nel Ni-Cu A llo y Ni-Cu A llo y

10 316 18Cr-8Ni-M o 18Cr-8Ni-M o

11 M o nel and Hardfaced Ni-Cu A llo y Ni-Cu A llo y and Trim 5 o r 5A

12 316 and Hardfaced 18Cr-8Ni-M o 18Cr-8Ni-M o and Trim 5 o r 5A

13 A llo y 20 19Cr-29Ni 19Cr-29Ni

14 A llo y 20 and Hardfaced 19Cr-29Ni 19Cr-29Ni and Trim 5 o r 5A

15 Hardfaced 18Cr-8Ni Co -Cr A (2)

16 Hardfaced 18Cr-8Ni-M o Co -Cr A (2)

17 Hardfaced 18Cr-10Ni-Cb Co -Cr A (2)

18 Hardfaced 19Cr-29Ni Co -Cr A (2)

Carbon & Alloy Steel Stainless Steel (1) ,,,and small internal parts that no rmally co ntact the service fluid

Construction Construction (2) Trademark material Stellite 6

Material of construction*

Item Description

Carbon Steel Carbon Steel (Low Tem p.) Alloy Steel Stainless Steel

1 Body A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

2 Bonnet A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

3 Wedge A 216 Gr.WCB + ER410 A 352 Gr.LCB + ER308 A 217 Gr.C5 + ER410 A 351 Gr.CF8M

4 Yoke A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

5 Stem A 182 Gr.F6a A 182 Gr.F304 A 182 Gr.F6a A 182 Gr.F316

6 Seat Ring A 105 + Stellite A 182 Gr.F304 A 182 Gr.F6a + Stellite -----

7 Stem Nut B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2

8 Backseat A182 Gr.F6a A182 Gr.F304 A 182 Gr.F6a -----

9 Gland A 105 A 105 A 182 Gr.F6a A 182 Gr.F316

10 Gland Flange A 105 A 105 A 105 A 182 Gr.F304

11 Stem Packing Graphite Graphite Graphite Graphite

12 Gasket Soft Iron SS 304 SS 304 SS 316

13 Bonnet Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H ( 3 )

14 Eye Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H

15 Handw heel Carbon Steel Carbon Steel Carbon Steel Carbon Steel

(3) Zinc coating

* Standard constructions with Trim 8, 2 and 10, other options are available

SERIES

Page 2 / 4 Data given can be changed without notice. VC

PDS – JC-VC1500BB Rev.3

Gate Valves Class 1500

Type Bolted Bonnet

Dimensions

DN A (RF/BW) B ØC WEIGHT

50 (2”) 368 574 350 117

65 (2½") 419 700 400 175

80 (3”) 470 806 450 240

100 (4”) 546 887 560 337

125 (5") 673 995 560 485

150 (6”) 705 1079 305 680

200 (8”) 832 1370 610 1228

250 (10”) 991 1520 760 2218

300 (12”) 1130 1651 760 3260

350 (14") 1257 1825 760 3990

400 (16") 1384 1995 760 5420

(*) Dimensions in mm and weight in kg

For other sizes consult to the technical department.

SERIES

Page 3 / 4 Data given can be changed without notice. VC

PDS – JC-VC1500BB Rev.3

Gate Valves Class 1500

Type Bolted Bonnet

General Characteristics, Cv, P&T Rating

GENERAL CHARACTERISTICS Fig. VC1500BB

DESIGN STANDARDS

Valves design API 600 ASME B16.34 EN ISO 10434

End to End Dim ensions ASME B16.10 & ISO 5752

Flanged Dim ensions ASME B16.5 & ISO 7005-1 Part. 1 BS 3293 MSS SP-44

Buttw eld Dim ensions ASME B16.25

Visual Inspection MSS SP- 55

Marking MSS SP-25 & ISO 5209

TESTS AND CERTIFICATES

Pressure testing API 598 & ISO 5208 EN 12266-1 MSS SP-61

Other ATEX, CE

Cv Values in U.S. Gallons/min.

DN Cv DN Cv

50 (2”) 230 200 (8”) 3800

65 (2½") 380 250 (10”) 6050

80 (3”) 520 300 (12”) 9100

100 (4”) 930 350 (14") 11500

125 (5") 1600 400 (16") 15100

150 (6”) 2250

Pressure-Temperature (STANDARD CLASS According to ASME B16.34)

MATERIAL

Temp

A216 WCB A352 LCB A217 C5 A351 CF8M (**)

ºC Bar Bar Bar Bar

-29 to 38 255,3 239,1 258,4 248,0

95 232,5 226,0 256,7 213,2

150 226,0 219,8 246,7 192,6

205 218,4 212,6 243,2 177,1

260 206,4 200,5 229,1 164,7

315 188,4 183,6 208,4 155,4

345 185,0 180,2 202,6 153,0

375 183,6 195,7 149,5

400 173,6 181,9 147,1

425 141,9 175,0 145,4

450 92,3 166,4 144,0

485 59,3 127,5 143,0

510 35,5 94,4 133,0

540 17,9 68,6 120,6

565 49,6 * 118,5 *

595 34,1 * 105,1 *

620 21,4 * 81,6 *

650 11,7 * 63,7 *

675 50,6 *

705 40,3 *

735 33,1 *

760 26,2 *

790 20,0 *

815 14,1 *

* FOR WELD END VALVES ONLY. FLANGED END RATINGS TERMINATE AT 540ºC

** A351 CF8M at temparetures over 538ºC (1000ºF) to b e used only if Carb on contents is 0,04% or higher.

SERIES

Page 4 / 4 Data given can be changed without notice. VC

PDS – JC-VC2500BB Rev.3

Gate Valves Type Bolted Bonnet

Class 2500 DN 50-300 (2” – 12”)

Carbon, Alloy and Stainless Steel

Fig. VC2500BB

Design:

API 600,

ASME B16.34 and BS 1414

600-0016

JC Fábrica de válvulas, s.a. SERIES

E-Mail: jc@jc-ballvalves.com

Internet: www.jc-ballvalves.com Page 1 / 4 Data given can be changed without notice. VC

PDS – JC-VC2500BB Rev.3

Gate Valves Class 2500

Type Bolted Bonnet

Parts and materials

Trim Material

API 600 Nominal Stem / Seating Surface

Trim No. Trim Backseat ( 1) Body / Wedge

1 F6 13Cr 13Cr

2 304 18Cr-8Ni 18Cr-8Ni

3 F310 25Cr-20Ni 25Cr-20Ni

4 Hard F6 13Cr Hard 13Cr

5 Hardfaced 13Cr Co -Cr A (2)

5A Hardfaced 13Cr Ni-Cr

6 F6 and Cu-Ni 13Cr 13Cr and Cu-Ni

7 F6 and Hard F6 13Cr 13Cr and Hard 13Cr

8 F6 and Hardfaced 13Cr 13Cr and Co -Cr A (2)

8A F6 and Hardfaced 13Cr 13Cr and Ni-Cr

9 M o nel Ni-Cu A llo y Ni-Cu A llo y

10 316 18Cr-8Ni-M o 18Cr-8Ni-M o

11 M o nel and Hardfaced Ni-Cu A llo y Ni-Cu A llo y and Trim 5 o r 5A

12 316 and Hardfaced 18Cr-8Ni-M o 18Cr-8Ni-M o and Trim 5 o r 5A

13 A llo y 20 19Cr-29Ni 19Cr-29Ni

14 A llo y 20 and Hardfaced 19Cr-29Ni 19Cr-29Ni and Trim 5 o r 5A

15 Hardfaced 18Cr-8Ni Co -Cr A (2)

16 Hardfaced 18Cr-8Ni-M o Co -Cr A (2)

17 Hardfaced 18Cr-10Ni-Cb Co -Cr A (2)

18 Hardfaced 19Cr-29Ni Co -Cr A (2)

Carbon & Alloy Steel Stainless Steel (1) ,,,and small internal parts that no rmally co ntact the service fluid

Construction Construction (2) Trademark material Stellite 6

Material of construction*

Item Description

Carbon Steel Carbon Steel (Low Tem p.) Alloy Steel Stainless Steel

1 Body A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

2 Bonnet A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

3 Wedge A 216 Gr.WCB + ER410 A 352 Gr.LCB + ER308 A 217 Gr.C5 + ER410 A 351 Gr.CF8M

4 Yoke A 216 Gr.WCB A 352 Gr.LCB A 217 Gr.C5 A 351 Gr.CF8M

5 Stem A 182 Gr.F6a A 182 Gr.F304 A 182 Gr.F6a A 182 Gr.F316

6 Seat Ring A 105 + Stellite A 182 Gr.F304 A 182 Gr.F6a + Stellite -----

7 Stem Nut B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2 B 148 / A 439 Gr.D2

8 Backseat A182 Gr.F6a A182 Gr.F304 A 182 Gr.F6a -----

9 Gland A 105 A 105 A 182 Gr.F6a A 182 Gr.F316

10 Gland Flange A 105 A 105 A 105 A 182 Gr.F304

11 Stem Packing Graphite Graphite Graphite Graphite

12 Gasket Soft Iron SS 304 SS 304 SS 316

13 Bonnet Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H( 3 )

14 Eye Bolt & Nut A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H A 193 Gr.B7 / A 194 Gr.2H

15 Handw heel Carbon Steel Carbon Steel Carbon Steel Carbon Steel

(3) Zinc coating

* Standard constructions with Trim 8, 2 and 10, other options are available

SERIES

Page 2 / 4 Data given can be changed without notice. VC

PDS – JC-VC2500BB Rev.3

Gate Valves Class 2500

Type Bolted Bonnet

Dimensions

DN A (RF/BW) B ØC WEIGHT

50 (2”) 451 595 400 155

65 (2½") 508 675 450 215

80 (3”) 578 750 560 285

100 (4”) 673 805 610 405

125 (5") 794 1010 610 715

150 (6”) 914 1200 460 1050

200 (8”) 1022 1346 610 1700

250 (10”) 1270 1500 760 2950

300 (12”) 1422 1700 760 4120

350 (14”) 1575 1950 760 5790

(*) Dimensions in mm and weight in kg

For other sizes consult to the technical department.

SERIES

Page 3 / 4 Data given can be changed without notice. VC

PDS – JC-VC2500BB Rev.3

Gate Valves Class 2500

Type Bolted Bonnet

General Characteristics, Cv, P&T Rating

GENERAL CHARACTERISTICS Fig. VC2500BB

DESIGN STANDARDS

Valves design API 600 ASME B16.34 EN ISO 10434

End to End Dim ensions ASME B16.10 & ISO 5752

Flanged Dim ensions ASME B16.5 & ISO 7005-1 Part. 1 BS 3293 MSS SP-44

Buttw eld Dim ensions ASME B16.25

Visual Inspection MSS SP- 55

Marking MSS SP-25 & ISO 5209

TESTS AND CERTIFICATES

Pressure testing API 598 & ISO 5208 EN 12266-1 MSS SP-61

Other ATEX, CE

Cv Values in U.S. Gallons/min.

DN Cv DN Cv

50 (2”) 160 150 (6”) 1500

65 (2½") 265 200 (8”) 2650

80 (3”) 370 250 (10”) 4500

100 (4”) 630 300 (12”) 6000

125 (5") 1070

Pressure-Temperature (STANDARD CLASS According to ASME B16.34)

MATERIAL

Temp

A216 WCB A352 LCB A217 C5 A351 CF8M (**)

ºC Bar Bar Bar Bar

-29 to 38 425,1 398,6 430,6 413,4

95 387,6 376,9 427,5 355,5

150 376,9 366,2 411,0 321,1

205 363,8 354,5 405,1 294,9

260 343,8 334,2 381,7 274,2

315 314,2 305,9 347,3 259,1

345 308,3 300,1 338,0 254,9

375 305,9 325,9 249,4

400 289,4 303,2 245,3

425 236,3 291,4 242,5

450 153,6 277,7 239,8

485 98,5 212,6 238,4

510 59,3 157,4 221,9

540 29,6 114,0 200,8

565 82,7 * 197,4 *

595 57,2 * 175,4 *

620 35,5 * 135,7 *

650 19,6 * 106,5 *

675 84,7 *

705 66,8 *

735 55,1 *

760 43,4 *

790 33,4 *

815 23,8 *

* FOR WELD END VALVES ONLY. FLANGED END RATINGS TERMINATE AT 540ºC

** A351 CF8M at temparetures over 538ºC (1000ºF) to be used only if Carbon contents is 0,04% or higher.

SERIES

Page 4 / 4 Data given can be changed without notice. VC

Das könnte Ihnen auch gefallen

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

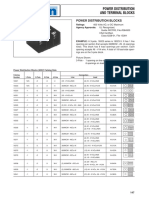

- Wes Mosler - The Piping and Tubing Design Guide For SolidWorks Routing 2011 - 2011Dokument160 SeitenWes Mosler - The Piping and Tubing Design Guide For SolidWorks Routing 2011 - 2011Mahdi Daly100% (7)

- Gate Valve VC1500BBDokument4 SeitenGate Valve VC1500BBDanielle JohnsonNoch keine Bewertungen

- JC Catalogue Globe Valves BBDokument24 SeitenJC Catalogue Globe Valves BBarnettoNoch keine Bewertungen

- VR300BC-Rev 3Dokument4 SeitenVR300BC-Rev 3Nourdine EL-HASANYNoch keine Bewertungen

- API 600 Trim Materials Disc Wedge Seat RDokument1 SeiteAPI 600 Trim Materials Disc Wedge Seat RManan DesaiNoch keine Bewertungen

- Etm Api 600 Trim Material PDFDokument1 SeiteEtm Api 600 Trim Material PDFbenabdallah131Noch keine Bewertungen

- Z&J Technologies GMBH: Conversion Table of EN - Materials vs. US Materials (Assorted by ASTM No.)Dokument1 SeiteZ&J Technologies GMBH: Conversion Table of EN - Materials vs. US Materials (Assorted by ASTM No.)Nattapong PongbootNoch keine Bewertungen

- Etm API 600 Trim MaterialDokument1 SeiteEtm API 600 Trim Materialmayukhguhanita2010Noch keine Bewertungen

- Clarification Classification of Steel Products in Relation To The Steel and Steel Products (Quality Control), (Amendment), Order, 2016 - 1Dokument10 SeitenClarification Classification of Steel Products in Relation To The Steel and Steel Products (Quality Control), (Amendment), Order, 2016 - 1S. VeeravelNoch keine Bewertungen

- Norma AISIDokument21 SeitenNorma AISImaria elena castañedaNoch keine Bewertungen

- Fmeman Rev 1Dokument36 SeitenFmeman Rev 1SATHISH KUMARNoch keine Bewertungen

- Trim API Materials PDFDokument1 SeiteTrim API Materials PDFleonjoanNoch keine Bewertungen

- Global Marketing For Tube & Pipe: JIS G3441 Alloy Steel Tubes For Machine PurposesDokument5 SeitenGlobal Marketing For Tube & Pipe: JIS G3441 Alloy Steel Tubes For Machine PurposesdonghoangvuNoch keine Bewertungen

- MC1413, MC1413B, NCV1413B High Voltage, High Current Darlington Transistor ArraysDokument8 SeitenMC1413, MC1413B, NCV1413B High Voltage, High Current Darlington Transistor ArraysPanagiotis PanagosNoch keine Bewertungen

- MC1413 D PDFDokument8 SeitenMC1413 D PDFAnonymous oyUAtpKNoch keine Bewertungen

- W.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden RussiaDokument1 SeiteW.-Nr. DIN UNI Afnor B.S. UNE Aisi/Sae/Astm JIS SS Gost EN: Italy France England Spain U.S.A. Japan Sweden RussiaDouglas CortezziNoch keine Bewertungen

- Section 10 Useful Information: Steel GuideDokument1 SeiteSection 10 Useful Information: Steel GuideEasun - MR TechnicalNoch keine Bewertungen

- Electrodes, Rods and FluxesDokument37 SeitenElectrodes, Rods and FluxesSchuldich Schwarz100% (1)

- Axial Flow Check ValveDokument2 SeitenAxial Flow Check ValveProject MarsysNoch keine Bewertungen

- Stainless System DiagramDokument1 SeiteStainless System DiagramAmr YousryNoch keine Bewertungen

- Beric Valves Trim ChartDokument1 SeiteBeric Valves Trim ChartPoncho RmzNoch keine Bewertungen

- Aramco Approved Bit Types InTouch 6904075 - v2 - 11 Oct 2016 - 6904075 - 01Dokument6 SeitenAramco Approved Bit Types InTouch 6904075 - v2 - 11 Oct 2016 - 6904075 - 01Muhammad Zikry Alfindy HazNoch keine Bewertungen

- StandardDokument1 SeiteStandardluisA1923Noch keine Bewertungen

- Power Plant: Better Life Created by SteelDokument4 SeitenPower Plant: Better Life Created by SteelAlejandro Jose Garcia FernandezNoch keine Bewertungen

- Welding Dissimilar MetalsDokument1 SeiteWelding Dissimilar MetalsmanishkapriNoch keine Bewertungen

- OK Tigrod 316LDokument1 SeiteOK Tigrod 316Lbevara santhoshkumarNoch keine Bewertungen

- Drawing 6.6 KV (Single Line)Dokument14 SeitenDrawing 6.6 KV (Single Line)ashu_2787Noch keine Bewertungen

- JC Catalogue Gate Valves BBDokument24 SeitenJC Catalogue Gate Valves BBMahdi DalyNoch keine Bewertungen

- Quick Sheet: API 594 Cast Steel Swing Check ValveDokument3 SeitenQuick Sheet: API 594 Cast Steel Swing Check ValveUmesh chandra PancholiNoch keine Bewertungen

- FlowBiz Cast Steel Angle Type Globe ValvesDokument2 SeitenFlowBiz Cast Steel Angle Type Globe ValvesShakir AnsariNoch keine Bewertungen

- AK9ch - АК9ч Aluminium Casting Alloys gost standardDokument2 SeitenAK9ch - АК9ч Aluminium Casting Alloys gost standardVivek GoudNoch keine Bewertungen

- Table of Steel Grades: Astm ISO EN Alphanumeric (EN10088) Aisi UNSDokument4 SeitenTable of Steel Grades: Astm ISO EN Alphanumeric (EN10088) Aisi UNSPSNMYNoch keine Bewertungen

- Storage TanksDokument8 SeitenStorage Tanksshashwatchaurasia83Noch keine Bewertungen

- Manual de Fundicion - StandardsDokument1 SeiteManual de Fundicion - StandardsFederico MoranNoch keine Bewertungen

- NADCA StdXref PDFDokument2 SeitenNADCA StdXref PDFAnonymous CAf29eNoch keine Bewertungen

- Manual de Fundicion - Cross - ReferenceDokument2 SeitenManual de Fundicion - Cross - ReferenceFederico MoranNoch keine Bewertungen

- Gate Valve Class 1500Dokument1 SeiteGate Valve Class 1500Hamdi Al-sarooryNoch keine Bewertungen

- Globe Valve: Fundamental of Engineering DataDokument16 SeitenGlobe Valve: Fundamental of Engineering Datarieza_fNoch keine Bewertungen

- Cast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDDokument3 SeitenCast Steel Swing Check Valves-Bs 1868, Api-6D, Asme B16.34: M.M.K. Engineering Co. Pvt. LTDAnonymous 6ZWS6IG2J9Noch keine Bewertungen

- RTJ PDFDokument5 SeitenRTJ PDFEmiliano ZappaterraNoch keine Bewertungen

- Major Project-1Dokument177 SeitenMajor Project-1api-19884175Noch keine Bewertungen

- Single Line Area Arrival&RetailDokument10 SeitenSingle Line Area Arrival&Retailcrisma tariNoch keine Bewertungen

- Laboratory Evaluation of PDC Drill Bits Under High-Speed and High-Wear ConditionsDokument6 SeitenLaboratory Evaluation of PDC Drill Bits Under High-Speed and High-Wear ConditionspendexxNoch keine Bewertungen

- User Manual: Stop Valve Zglo Fig. 215 216 Edition: 01/2021 Date: .15.01.2021Dokument13 SeitenUser Manual: Stop Valve Zglo Fig. 215 216 Edition: 01/2021 Date: .15.01.2021Emiro Revilla CatariNoch keine Bewertungen

- Valve Material Specifications: Forged Cast Key Physical PropertiesDokument1 SeiteValve Material Specifications: Forged Cast Key Physical PropertiesdenyNoch keine Bewertungen

- Hard CoatingsDokument1 SeiteHard Coatingskutts76Noch keine Bewertungen

- High Precision Ball Bearings: Sapporo Precisiq/J IncDokument20 SeitenHigh Precision Ball Bearings: Sapporo Precisiq/J IncAnonymous m6A7tNaMgfNoch keine Bewertungen

- Asme Ii Part D Table 1a SSDokument28 SeitenAsme Ii Part D Table 1a SSyar_nlNoch keine Bewertungen

- Material Comparisons For Astm and JisDokument2 SeitenMaterial Comparisons For Astm and JisNitesh GargNoch keine Bewertungen

- Cross ReferenceDokument2 SeitenCross ReferenceluisA1923Noch keine Bewertungen

- Cross Reference To NADCA Standards & Guidelines PDFDokument2 SeitenCross Reference To NADCA Standards & Guidelines PDFEd IthNoch keine Bewertungen

- Coois00931 1-2264177Dokument4 SeitenCoois00931 1-2264177Luz BarradasNoch keine Bewertungen

- Material Comparisons For Studs Astm and JisDokument3 SeitenMaterial Comparisons For Studs Astm and JisguluuNoch keine Bewertungen

- Material Comparisons For Astm and JisDokument2 SeitenMaterial Comparisons For Astm and JisFeri Setiawan Efendi100% (1)

- CABLEDokument10 SeitenCABLEkhalidNoch keine Bewertungen

- Tabel Persamaan Bahan Dasar Dan Presisi Roda GigiDokument1 SeiteTabel Persamaan Bahan Dasar Dan Presisi Roda GigiboschNoch keine Bewertungen

- Material Specifications: P-No. / Group No. Nominal Steel Designation Forgings Wrought Fittings Pipe Plate RemarksDokument1 SeiteMaterial Specifications: P-No. / Group No. Nominal Steel Designation Forgings Wrought Fittings Pipe Plate RemarksSIVAPATHASEKARAN100% (2)

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Von EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Noch keine Bewertungen

- Steel and Its Heat Treatment: Bofors HandbookVon EverandSteel and Its Heat Treatment: Bofors HandbookBewertung: 2.5 von 5 Sternen2.5/5 (3)

- CHAP1 - 2 (Well and Reservoir-Chouikhi Mounir)Dokument105 SeitenCHAP1 - 2 (Well and Reservoir-Chouikhi Mounir)Mahdi Daly100% (1)

- Valves and PipingDokument118 SeitenValves and PipingMahdi Daly100% (1)

- PM - HSE Plan Session 6Dokument33 SeitenPM - HSE Plan Session 6Mahdi DalyNoch keine Bewertungen

- Piping and Pipe Support SystemsDokument178 SeitenPiping and Pipe Support Systemssaisssms9116Noch keine Bewertungen

- Tube Turns INC. - Piping EngineeringDokument224 SeitenTube Turns INC. - Piping EngineeringDebelme60% (5)

- Tyco Fig.110-190 Ball Valves DatasheetDokument24 SeitenTyco Fig.110-190 Ball Valves DatasheetMahdi Daly100% (1)

- Actuators Uses, Types and Failure Modes: Posted by Ankit Chugh On 11:57 PMDokument3 SeitenActuators Uses, Types and Failure Modes: Posted by Ankit Chugh On 11:57 PMMahdi DalyNoch keine Bewertungen

- CADWorx 2013 SpecificationsDokument97 SeitenCADWorx 2013 SpecificationsMahdi DalyNoch keine Bewertungen

- Welding Defect TWI CSWIPDokument54 SeitenWelding Defect TWI CSWIPMahdi Daly100% (4)

- 199 00 00 EL DR TD 000501 B1 0 03/08/2010 13 03 24: Caroline Liegeois 2010.08.04 13:17:04 +02'00'Dokument11 Seiten199 00 00 EL DR TD 000501 B1 0 03/08/2010 13 03 24: Caroline Liegeois 2010.08.04 13:17:04 +02'00'Mahdi DalyNoch keine Bewertungen

- PM - HSE Plan Session 6Dokument33 SeitenPM - HSE Plan Session 6Mahdi DalyNoch keine Bewertungen

- Silver and Its UsesDokument44 SeitenSilver and Its Usessharif100% (2)

- Minecraft MetallurgyDokument5 SeitenMinecraft MetallurgyBrian BarkerNoch keine Bewertungen

- Roller Conveyor ChainsDokument36 SeitenRoller Conveyor Chainsaiyubi2Noch keine Bewertungen

- Yamaha RX V480Dokument17 SeitenYamaha RX V480AnthonyNoch keine Bewertungen

- Ilnas-En Iso 14713-2:2020Dokument8 SeitenIlnas-En Iso 14713-2:2020Marcelo LópezNoch keine Bewertungen

- 571 TemperaturesDokument1 Seite571 TemperaturesBilal GhazanfarNoch keine Bewertungen

- Twi RtfiDokument35 SeitenTwi RtfiGoutam Kumar DebNoch keine Bewertungen

- Certificado de Materiales Picos de RonchiDokument1 SeiteCertificado de Materiales Picos de RonchiGuillermo Rafael Tranquini CarrascoNoch keine Bewertungen

- PNS49Dokument14 SeitenPNS49jbcast86Noch keine Bewertungen

- CQI-9 Special Process: Heat Treat System AssessmentDokument35 SeitenCQI-9 Special Process: Heat Treat System AssessmentrajarajanNoch keine Bewertungen

- SSW Ce LR PDFDokument9 SeitenSSW Ce LR PDFankitniranjan1390Noch keine Bewertungen

- Common Metallurgical Defects in Ductile Iron EnglishDokument1 SeiteCommon Metallurgical Defects in Ductile Iron EnglishedgarestevessNoch keine Bewertungen

- Mpif 35Dokument39 SeitenMpif 35Anonymous jNf3LjNoch keine Bewertungen

- Astm E1268Dokument28 SeitenAstm E1268annayya.chandrashekar Civil EngineerNoch keine Bewertungen

- Powder MetallurgyDokument24 SeitenPowder MetallurgyMilan PanchalNoch keine Bewertungen

- RhodiumDokument14 SeitenRhodiumTari Netrisia Ayusari100% (1)

- Petro-Chemical Fastener Solutions: Interactive Contents: 1 2 3 4 5 6 7 8Dokument9 SeitenPetro-Chemical Fastener Solutions: Interactive Contents: 1 2 3 4 5 6 7 8René Galbraith BerraNoch keine Bewertungen

- Assignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Dokument8 SeitenAssignment-5 Enmt610029 Welding ANDARADHI NARARYA/1206291992Andaradhi NararyaNoch keine Bewertungen

- 106 04 PDFDokument6 Seiten106 04 PDFAbdul Aziz NasutionNoch keine Bewertungen

- Class 125 Iron Y-StrainerDokument1 SeiteClass 125 Iron Y-StrainerNarendra Reddy BhumaNoch keine Bewertungen

- Lec2 PDFDokument24 SeitenLec2 PDFKiran Kumar AatyamNoch keine Bewertungen

- Unit 8 The D-And F - Block Elements I. Answer The Following Questions. Each Question Carries One MarkDokument9 SeitenUnit 8 The D-And F - Block Elements I. Answer The Following Questions. Each Question Carries One MarkDeva RajNoch keine Bewertungen

- GB Flintec Flyer ProductsDokument8 SeitenGB Flintec Flyer ProductsFarit ArdiansyahNoch keine Bewertungen

- Cadwell MoldesDokument34 SeitenCadwell MoldesjaimeyzNoch keine Bewertungen

- Indian Standard: Specification For Fognozzle For Fire Brigade UseDokument9 SeitenIndian Standard: Specification For Fognozzle For Fire Brigade UseTushal DiyoraNoch keine Bewertungen

- Effects of Alloying ElementsDokument5 SeitenEffects of Alloying ElementsKevin TarlaNoch keine Bewertungen

- LADWER API 510 - API 571 April 2017Dokument12 SeitenLADWER API 510 - API 571 April 2017Luthfi ArdiansyahNoch keine Bewertungen

- Mineral PDFDokument57 SeitenMineral PDFMasuda SultanaNoch keine Bewertungen

- Electrowinning and Smelting BasicsDokument13 SeitenElectrowinning and Smelting BasicsJohann Rene Meddrano100% (2)

- Op Hammerite 612Dokument1 SeiteOp Hammerite 612Sinead1990Noch keine Bewertungen