Beruflich Dokumente

Kultur Dokumente

T6 Type Designations PDF

Hochgeladen von

Lambert G. RequinaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

T6 Type Designations PDF

Hochgeladen von

Lambert G. RequinaCopyright:

Verfügbare Formate

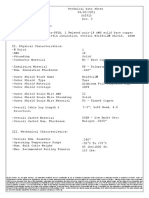

T6 Technical Tables

Type designations

ÖLFLEX®

Type designations for control cables and harmonised cables (excerpts)

Control cables Harmonised cables Telecommunications cables

UNITRONIC®

x – – x x

1 2 3 4 5 6 7 8 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 10

1. Basic type 1. Basic type 1. Basic type

N VDE standard H Harmonised type A - Outdoor cable

(N) in line with VDE A National type G - Mining cable

X or S in the style of a harmonized type J - Installation cable

ETHERLINE®

Li Stranded conductor, flexible cable

2. Insulating material S - Jumper cable

Y Thermoplastic resins 2. Nominal voltage

X Cross-linked thermoplastic resins 01 100/100 volts

G Elastomers 03 300/300 volts 2. Additional designation

HX Halogen-free materials 05 300/500 volts J Induction protection

07 450/750 volts E Electronics

3. Cable designation

A Core cable 3. Insulating material 3. Insulating material

HITRONIC®

D Solid wire V PVC Y PVC

AF Fine-wire core cable V2 PVC +90 °C 11Y PUR

F Socket core V3 PVC flexible at cold temperatures 2Y Polyethylene

L Fluorescent tube cable B Ethylene propylene rubber O2Y Cellular PE

LH Connecting cable, E PE polyethylene 9Y PP

light mechanical loads X XPE, cross-linked PE 5Y PTFE

MH Connecting cable, R Rubber 6Y FEP

moderate mechanical loads S Silicone rubber 7Y ETFE

SH Connecting cable, H Halogen-free compound

heavy mechanical loads

SSH Connecting cable for special loads 4. Outer/inner sheath material

SL Control cable/welding cable V PVC 4. Special features

EPIC®

S Control cable V2 PVC +90 °C C Copper screen braiding

LS Light control cable V3 PVC flexible at cold temperatures D Copper wrapping

FL Flat cable V5 PVC with enhanced oil resistance (ST) Metal foil screening

Si Silicone cable R Rubber (L) Aluminium strip

Z Twin cable N Chloroprene based rubber F Petroleum jelly filling

GL Glass fibre Q Polyurethane LD Corrugated aluminium sheath

Li Braided conductor as per VDE 0812 J Glass fibre braiding (K) Copper strip screening

SKINTOP®

LiF Braided conductor as per VDE 0812, T Textile braiding (Z) Steel wire braiding

extra-fine wire S Silicone rubber W Corrugated steel sheath

b Armouring

4. Special features 5. Special features

T Supporting element C4 Copper wire screen braiding 5. Sheathing

Ö Enhanced oil resistance H Flat cable, divisible (see point 3. “Insulating material”)

U Flame-retardant H2 Flat cable, not divisible

w Heat-resistant, weather-resistant H6 Flat cable, not divisible,

for lifts 6. Number of elements

FE Insulation retained for a limited time

SILVYN®

H8 Helical/spiral cable … number of stranding elements

C Screening braid

D Screening as Cu wire wrapping

S Steel wire braiding as mech. protection 7. Stranding element

6. Conductor type

U Single-wire 1 Single core

5. Sheaths R Multi-wire 2 Pair

K Fine-wire (fixed installation) 3 Triple

As point 2.

FLEXIMARK®

“Insulating material” P/PUR polyurethane F Fine-wire (flexible installation)

H Extra-fine wire

8. Conductor diameter or cross section

Y Tinsel wire

6. Protective conductor … in mm or mm2

D Fine-wire conductor

- O Without protective conductor for welding cable

- J With protective conductor E Extra-fine wire conductor 9. Stranding element

for welding cable St Star quad (phantom)

7. Number of cores StI Star quad (trunk cable)

ACCESSORIES

7. Number of cores StIII Star quad (local cable)

… number of cores

TF Star quad for TF

… number of cores

S Signal cable (railway)

8. Conductor cross-section PiMF Screened pair

Figures in mm2 8. Protective conductor (TP) Twisted Pair

X Without protective conductor PiD Pairs in copper wrapping

G With protective conductor

10. Stranding type

9. Conductor cross-section Lg Twisted into layers

Figures in mm2 Bd Twisted into bundles

APPENDIX

EXAMPLE: NSHTÖU 24G 1.5 EXAMPLE: H05 VV-F 3G 1.5 EXAMPLE: A2Y(L)2Y 6 x 2 x 0.8 Bd

ÖLFLEX® CRANE NSHTÖU cable, 24-core, Medium PVC hose, 3-core, Telephone cable for local network

with protective cond., cross-section: 1.5 mm2 with protective cond., cross-section: 1.5 mm2 with PE insulation and layered sheath

1116 For current information see: www.lappgroup.com

Technical Tables T6

Type designations

ÖLFLEX®

Type designations for telecommunications cables and fibre-optic cables

Fibre-optic cables Type designations for UNITRONIC® field bus

UNITRONIC®

– S/A cables Connection

Cable

Connection

e.g. item no. 22260339 on left on right

1 2 3 4 5 6 7 8 9 10

AB- C4- M12MS- 2.0PUR- M12FA-2L

1. Basic type

Automation Bus

A Outdoor cable Cordset

AT Outdoor cable, divisible Number of pins (4)

J Indoor cable Connector/thread (M12)

J/A or U Indoor/outdoor cable, universal cable Connector/design (straight connector)

ETHERLINE®

Cable length in m (2.0 m)

Cable material – outer sheath (PUR)

2. Fibres

Connector/thread (M12)

B Loose tube, unfilled Connector/design (angled socket)

D Loose tube, filled Status display/number of LEDs (2L)

V Tight-buffered fibres

MS – straight connector M12Y – M12 Y connector

3. Design elements MA – angled connector B – bridged

F Petroleum jelly filling FS – straight socket 3-, 4-, 5-, 8-, .. number of pins

HITRONIC®

Q Swelling tape FA – angled socket A, AD, B, BI, C, CI – valve connector type

M8, M12, M16, M23 – thread S – valve connector with Z diode

L – status display/LEDs SV – valve connector with varistor

4. Further design elements SH – screened version SVC – valve connector with varistor and commutator

S Metal element in cable core HD – Hygienic Design SUP – valve connector with suppressor diode

VA – stainless steel knurl

5. Sheath

2Y PE sheath

11Y PUR sheath Ready-made connector e.g. item no. 22260127

H Halogen-free sheath

(ZM) With metallic strain relief elements AB- C5- M12FS-PG7-SH

EPIC®

(ZN) With non-metallic strain relief elements

(ZN)2Y PE sheath with non-metallic Automation Bus

strain relief elements Connector

Number of pins (5)

Connector/thread (M12)

6. Armouring Connector/design (straight connector)

B Armouring Cable connection/screw connection (PG7)

B2Y Armouring with PE casing Screened version (SH)

SKINTOP®

(BN) Glass yarn armouring

(SG) Steel sheath

(SR) Corrugated steel sheath MS – straight connector PG7, PG9, PG11, PG13 – cable connection

MA – angled connector F0.34 (fast connection, max. 0.34 mm² cond. cross-sec.)

(SR)2Y Corrugated steel sheath with PE casing

FS – straight socket F0.75 (fast connection, max. 0.75 mm² cond. cross-sec.)

FA – angled socket M16-0.5 (M16 flush-type conn. with 0.5 m PUR strand)

7. Number of fibres P – piercing connection PG9-0.5 (PG9 flush-type conn. with 0.5 m PUR strand)

SH – screened version DSI – flush-type connector (rear wall mounting)

Number of fibres

M8, M12, M16, M23 – thread PO – flush-type connector (can be positioned)

3-, 4-, 5-, 8-, .. number of pins

8. Fibre type

SILVYN®

E Single-mode fibre glass/glass (SM GOF)

G Gradient fibre glass/glass (MM GOF)

K Step fibre glass/plastic (PCF) S/A passive distributor box e.g. item no. 22260025

P Polymer optical fibre/plastic (POF)

AB- B8-M12L-16-10.0PUR

9. Core diameter/fibre sheath diameter Automation Bus

FLEXIMARK®

50/125 Multimode glass fibre Box

62.5/125 Multimode glass fibre Number of slots (8)

9/125 Single-mode glass fibre S/A connection/thread (M12)

200/230 Plastic-coated glass fibre Status display/LED signals (L)

980/1000 Polymer optical fibre Number of inputs/outputs (16)

Length of master cable in m (10.0)

Cable material – outer sheath (PUR)

0.

1 Category: fibre quality

OM4 For 50/125 OM4 multimode fibres (number of inputs/outputs)

ACCESSORIES

OM3 For 50/125 OM3 multimode fibres INFO: S/A box with double assignment ➞ (number of slots) = 2

OM2 For 50/125 OM2 multimode fibres

OM1 For 62.5/125 OM1 multimode fibres

OS2 For 9/125 OS2 Single-mode fibres (G 652D) PUR - distributor box with perm. connected master cable (PUR)

C - distributor box with master cable conn. (pluggable screw connection)

M8L - distributor box with M8 slots and LED signals

M16 - distributor box with M16 master cable conn.

EXAMPLE 1: A-DQ(ZN)(SR)2Y 12G 50/125 OM3 M12 - distributor box with M12 master cable conn.

Outdoor cable with corrugated steel sheath, central loose tube,

non-metallic strain relief made of glass yarn, 12 fibres,

50/125 µm OM3 multimode fibres Further abbreviations:

APPENDIX

EXAMPLE 2: J-V2Y(ZN)11Y 2P 980/1000 AB-PC – Automation Bus Power Cable AB-ASI-J – AS-Interface distributor

Plastic fibre-optic cable, two-fibre (duplex), indoor cable AB-PB – Automation Bus PROFIBUS DI – Digital Inputs

AB-DN – Automation Bus DeviceNet DO – Digital Outputs

with PE inner sheath, non-metallic strain relief,

AB-CAN – Automation Bus CAN R – Relay outputs

PUR outer sheath AB-ASI – Automation Bus AS-Interface

For current information see: www.lappgroup.com 1117

Das könnte Ihnen auch gefallen

- Chinese Cable Code DesignationsDokument1 SeiteChinese Cable Code DesignationsSibin Novakovic0% (1)

- American+European+Jap Automotive CableDokument119 SeitenAmerican+European+Jap Automotive CableKarthi ManoNoch keine Bewertungen

- Session 9 & 10 Introduction To The Fashion IndustryDokument50 SeitenSession 9 & 10 Introduction To The Fashion IndustrySonalika Nair100% (1)

- Economic Indicators: Downloadthecepcf Two Weeks S O 0 N E I Î L F P Q A I SDokument2 SeitenEconomic Indicators: Downloadthecepcf Two Weeks S O 0 N E I Î L F P Q A I SsunliasNoch keine Bewertungen

- T6: Type Abbreviations: Selection TableDokument1 SeiteT6: Type Abbreviations: Selection TableRicardo MotaNoch keine Bewertungen

- Kurzzeichen eDokument1 SeiteKurzzeichen eUros CarNoch keine Bewertungen

- Cable InfoDokument50 SeitenCable InfoSyed ZainNoch keine Bewertungen

- Code-Designation-explanations For Cables and InsulatedDokument1 SeiteCode-Designation-explanations For Cables and InsulatedSnzy Del0% (1)

- Harmonized CODEDokument7 SeitenHarmonized CODEvinayak.khorate2707Noch keine Bewertungen

- Cable Identification Codes For PVC, XLPE, PILCDokument3 SeitenCable Identification Codes For PVC, XLPE, PILCsunny55krNoch keine Bewertungen

- Type Codes For Optical Fiber Cables Acc. To The Din / Vde 0888-3Dokument2 SeitenType Codes For Optical Fiber Cables Acc. To The Din / Vde 0888-3Seba GonzálezNoch keine Bewertungen

- Designacion VDE EkabelDokument2 SeitenDesignacion VDE EkabelCarlos liceaNoch keine Bewertungen

- Low Voltage Electrical Cable's Designations (0.6 - 1 KV) - Top CableDokument8 SeitenLow Voltage Electrical Cable's Designations (0.6 - 1 KV) - Top CableNathan NiuNoch keine Bewertungen

- O RouteDokument100 SeitenO RouteJuan Camilo MonguiNoch keine Bewertungen

- Automotive CablesDokument11 SeitenAutomotive Cableshachemia talibiNoch keine Bewertungen

- Multicore Armoured Shaped Conductor - XLPE InsulatedDokument1 SeiteMulticore Armoured Shaped Conductor - XLPE InsulatedMohamed InshafNoch keine Bewertungen

- Completed Datasheet For Fiber Optic Cable - LS KoreaDokument11 SeitenCompleted Datasheet For Fiber Optic Cable - LS Korealam266Noch keine Bewertungen

- Automotive CableDokument46 SeitenAutomotive CableDanu MamlukatNoch keine Bewertungen

- ELV Guide To Electric Cables and Cables Which Cable Cable To Use For WhatDokument4 SeitenELV Guide To Electric Cables and Cables Which Cable Cable To Use For WhatAKISNoch keine Bewertungen

- HT Power Cable Copper ConductorDokument4 SeitenHT Power Cable Copper Conductoraniket chaturvediNoch keine Bewertungen

- Vdocuments - MX TMC Cable CatalogDokument71 SeitenVdocuments - MX TMC Cable CatalogDaniel Eduardo AguirreNoch keine Bewertungen

- 59922profinet Ethernet Ind 2010Dokument8 Seiten59922profinet Ethernet Ind 2010JulianoNoch keine Bewertungen

- Prefabricated Branch Cable: 1 Brief IntroductionDokument10 SeitenPrefabricated Branch Cable: 1 Brief IntroductionKerr AgotNoch keine Bewertungen

- Tourline PDFDokument9 SeitenTourline PDF2022A Micha Michela FitrianaNoch keine Bewertungen

- Cable For Electrical Equipment of Ship & Mobile & Offshore UnitDokument56 SeitenCable For Electrical Equipment of Ship & Mobile & Offshore Unitlyma maNoch keine Bewertungen

- Abbreviations of The Cable TechnologyDokument2 SeitenAbbreviations of The Cable TechnologyKshitish SahooNoch keine Bewertungen

- Contacts Link Download Technical Information Applications Products About Caledonian HomeDokument3 SeitenContacts Link Download Technical Information Applications Products About Caledonian HomespurscoukNoch keine Bewertungen

- Catalogue HeizkaDokument48 SeitenCatalogue Heizkavotinh20687Noch keine Bewertungen

- 507-178 EMI/RFI Micro-D Split Banding Backshell: With Eliptical Banding PorchDokument2 Seiten507-178 EMI/RFI Micro-D Split Banding Backshell: With Eliptical Banding PorchZach DuffNoch keine Bewertungen

- 500-010 EMI/RFI Micro-D Banding Backshell: Round Cable EntryDokument2 Seiten500-010 EMI/RFI Micro-D Banding Backshell: Round Cable EntryZach DuffNoch keine Bewertungen

- CF31 Sort110 EU Data Sheetchainflex CF31Dokument6 SeitenCF31 Sort110 EU Data Sheetchainflex CF31Luiz Felipe OliveiraNoch keine Bewertungen

- Amphenol PCD System Attachments - 0-553433Dokument33 SeitenAmphenol PCD System Attachments - 0-553433davpaffNoch keine Bewertungen

- Cable Single Pair - TriadDokument2 SeitenCable Single Pair - TriadAmir Ali TariqNoch keine Bewertungen

- Form To Determine MV-CONNEX Cable ConnectorsDokument1 SeiteForm To Determine MV-CONNEX Cable ConnectorsChristian EstebanNoch keine Bewertungen

- Industrial Ethernet Cat.5+: Leoni Special Cables GMBHDokument2 SeitenIndustrial Ethernet Cat.5+: Leoni Special Cables GMBHLeodoletaNoch keine Bewertungen

- EU Data Sheet Chainflex CF113.DDokument12 SeitenEU Data Sheet Chainflex CF113.DvfernandezNoch keine Bewertungen

- Catalog DHF DSF enDokument2 SeitenCatalog DHF DSF enRUTHNoch keine Bewertungen

- 05oilandgasoffshore - PDF HmwpeDokument12 Seiten05oilandgasoffshore - PDF HmwpeAmina Malek AyaNoch keine Bewertungen

- Handbook On Jelly Filled Cable PDFDokument49 SeitenHandbook On Jelly Filled Cable PDFakibNoch keine Bewertungen

- Oman Cable Building Wire ProfileDokument24 SeitenOman Cable Building Wire Profilemasood jilaniNoch keine Bewertungen

- TQJNFV 6 WR 8 Z Xe LTMeubeDokument28 SeitenTQJNFV 6 WR 8 Z Xe LTMeubeJohan MayaNoch keine Bewertungen

- Section ADokument23 SeitenSection ARajesh ChoudharyNoch keine Bewertungen

- Wseries BrochureDokument6 SeitenWseries Brochurehuane1978Noch keine Bewertungen

- Cables Designation Codes ITA - SB - 1Dokument1 SeiteCables Designation Codes ITA - SB - 1Duy Phạm VănNoch keine Bewertungen

- FAR EAST POWER CABLE CO - XLPE Cable Systems Users Guide (Far East Cable...Dokument16 SeitenFAR EAST POWER CABLE CO - XLPE Cable Systems Users Guide (Far East Cable...César Díaz LiberonaNoch keine Bewertungen

- Katalog Ogranicznikow Przepiec Serii 3hsrDokument20 SeitenKatalog Ogranicznikow Przepiec Serii 3hsrakhilNoch keine Bewertungen

- Welding Tubing CatalogDokument4 SeitenWelding Tubing Catalogthanh_121Noch keine Bewertungen

- Cilpsal Ti Series Part 1Dokument29 SeitenCilpsal Ti Series Part 1Meor SyaediNoch keine Bewertungen

- Catalogue - Cat5e - Purenet 2023Dokument2 SeitenCatalogue - Cat5e - Purenet 2023Le NghiNoch keine Bewertungen

- Y63915 TD Rev 3Dokument2 SeitenY63915 TD Rev 3ALAN ARVANoch keine Bewertungen

- NullDokument11 SeitenNullapi-20512651Noch keine Bewertungen

- Cables and WiresDokument124 SeitenCables and WiresAlbertNoch keine Bewertungen

- Ölflex CLASSIC 110/110 CY: Flexible Number-Coded Power & Control CableDokument2 SeitenÖlflex CLASSIC 110/110 CY: Flexible Number-Coded Power & Control CableDarwin YupaNoch keine Bewertungen

- Electrical FloodlightDokument2 SeitenElectrical Floodlightavk99Noch keine Bewertungen

- Submarine Cable CatalogDokument36 SeitenSubmarine Cable CatalogMoon YapNoch keine Bewertungen

- Oman WireDokument24 SeitenOman Wireirfan vpNoch keine Bewertungen

- Mining TFCA Na StronęDokument12 SeitenMining TFCA Na StronęPrabhat RanjanNoch keine Bewertungen

- Marineflex Yzp 0,6/1 KV: Low Voltage Power Cables 16098Dokument2 SeitenMarineflex Yzp 0,6/1 KV: Low Voltage Power Cables 16098Javier EverestNoch keine Bewertungen

- Wire AccessoriesDokument5 SeitenWire AccessoriesHari HaranNoch keine Bewertungen

- Code-Designation-Explanations For Cables and Insulated WireDokument1 SeiteCode-Designation-Explanations For Cables and Insulated WirerocketvtNoch keine Bewertungen

- Electronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionVon EverandElectronic Components, Tubes and Transistors: The Commonwealth and International Library: Electrical Engineering DivisionNoch keine Bewertungen

- T22 Protection Ratings To en 60529Dokument1 SeiteT22 Protection Ratings To en 60529Lambert G. RequinaNoch keine Bewertungen

- Basic Nec Code Rules and Design PracticeDokument13 SeitenBasic Nec Code Rules and Design PracticeSiswoyo Suwidji100% (1)

- Zelio Logic 2 Smart Relay User ManualDokument192 SeitenZelio Logic 2 Smart Relay User ManualLambert G. RequinaNoch keine Bewertungen

- Valtorc Valve Full Line CatalogDokument8 SeitenValtorc Valve Full Line CatalogLambert G. RequinaNoch keine Bewertungen

- T29 Using UL-Approved CablesDokument5 SeitenT29 Using UL-Approved CablesLambert G. RequinaNoch keine Bewertungen

- T21 Thread Dimensions For Cable Glands - Tightening Torques and Installation Dimensions For Cable GlandsDokument2 SeitenT21 Thread Dimensions For Cable Glands - Tightening Torques and Installation Dimensions For Cable GlandsLambert G. RequinaNoch keine Bewertungen

- Atlanta PP Compression PDFDokument4 SeitenAtlanta PP Compression PDFLambert G. RequinaNoch keine Bewertungen

- A1 Flexible Connecting and Control CablesDokument3 SeitenA1 Flexible Connecting and Control CablesLambert G. RequinaNoch keine Bewertungen

- T23 Cable GlandsDokument4 SeitenT23 Cable GlandsLambert G. RequinaNoch keine Bewertungen

- A4 Halogen-Free CablesDokument3 SeitenA4 Halogen-Free CablesLambert G. RequinaNoch keine Bewertungen

- T6 Type DesignationsDokument2 SeitenT6 Type DesignationsLambert G. RequinaNoch keine Bewertungen

- ABB Electronic TimersDokument52 SeitenABB Electronic TimersLambert G. RequinaNoch keine Bewertungen

- 9 PVC Pipe FittingsDokument9 Seiten9 PVC Pipe FittingsLambert G. RequinaNoch keine Bewertungen

- Valex Tube&FittingsDokument32 SeitenValex Tube&FittingsLambert G. RequinaNoch keine Bewertungen

- Burkert Type 0131 Plastic Solenoid ValveDokument9 SeitenBurkert Type 0131 Plastic Solenoid ValveLambert G. RequinaNoch keine Bewertungen

- DS1078 Mechanical EU enDokument4 SeitenDS1078 Mechanical EU enLambert G. RequinaNoch keine Bewertungen

- Atlanta DWV - LWDokument2 SeitenAtlanta DWV - LWLambert G. RequinaNoch keine Bewertungen

- XB5AD912R1K: Product Data SheetDokument4 SeitenXB5AD912R1K: Product Data SheetLambert G. RequinaNoch keine Bewertungen

- Training TC Theory SaafgDokument6 SeitenTraining TC Theory SaafgMuhammad Ikhsan HermasNoch keine Bewertungen

- Schneider Timer CCT15838Dokument2 SeitenSchneider Timer CCT15838Lambert G. RequinaNoch keine Bewertungen

- Compact Home: Technical CatalogDokument48 SeitenCompact Home: Technical Catalogawong_911374Noch keine Bewertungen

- CCT FittingsDokument8 SeitenCCT FittingsLambert G. RequinaNoch keine Bewertungen

- 8719 HGFFDokument3 Seiten8719 HGFFNoe Ojeda AlvarezNoch keine Bewertungen

- Aircraft Corrosion CleaningDokument26 SeitenAircraft Corrosion CleaningselenezgiNoch keine Bewertungen

- Eddie SorianoDokument3 SeitenEddie SorianoHarry DemeterioNoch keine Bewertungen

- Operations Management Week 2 New1Dokument112 SeitenOperations Management Week 2 New1Arjun KhoslaNoch keine Bewertungen

- Afsheen, Anum, Shaena, SamenaDokument26 SeitenAfsheen, Anum, Shaena, SamenaSyed M. Fakharullah KazmiNoch keine Bewertungen

- Roof Slab SystemDokument42 SeitenRoof Slab SystemGelyn Macasieb100% (1)

- NB-CPD 12 544 - EOTA Report To SCC October 2012 - Status of ETAGs, Guidelines For European Technical Approvals, and ETAsDokument6 SeitenNB-CPD 12 544 - EOTA Report To SCC October 2012 - Status of ETAGs, Guidelines For European Technical Approvals, and ETAsmingulNoch keine Bewertungen

- Lean ManufacturingDokument20 SeitenLean ManufacturingPranav SharmaNoch keine Bewertungen

- Hot Dip Galvanizing - GDLCDokument13 SeitenHot Dip Galvanizing - GDLCaselabollegalaNoch keine Bewertungen

- Liners and Wearates10 - 4 AskoDokument12 SeitenLiners and Wearates10 - 4 AskoSos de HoyosNoch keine Bewertungen

- ElectropolishingDokument4 SeitenElectropolishinggopinath_rgsNoch keine Bewertungen

- Din 470 PDFDokument6 SeitenDin 470 PDFLuciano FontesNoch keine Bewertungen

- Spin Casting RunnerDokument7 SeitenSpin Casting RunnerTri WidayatnoNoch keine Bewertungen

- 3d Printing PresentationDokument27 Seiten3d Printing PresentationaftabNoch keine Bewertungen

- NOBLE Bahrain For GRP SiteDokument40 SeitenNOBLE Bahrain For GRP SiteAntony PiousNoch keine Bewertungen

- Downstream 201206Dokument74 SeitenDownstream 201206EfosaUwaifoNoch keine Bewertungen

- Homeless Serving Land Use Overnight Shelter Parcel DataDokument14 SeitenHomeless Serving Land Use Overnight Shelter Parcel DataAbhishekh GuptaNoch keine Bewertungen

- 09 Samss 071Dokument6 Seiten09 Samss 071inatt101100% (1)

- Liming Heavy Industry Introduction NewDokument7 SeitenLiming Heavy Industry Introduction NewJohnny DoeNoch keine Bewertungen

- Rules & Guidelines: Code EditionDokument7 SeitenRules & Guidelines: Code EditionDestaRifkyAldaraNoch keine Bewertungen

- ASTM-A-325-02 Standard Specification For Structural Bolts. Steel, Heat Treated, 120 - 105 Ksi Minimum Tensile Strength PDFDokument8 SeitenASTM-A-325-02 Standard Specification For Structural Bolts. Steel, Heat Treated, 120 - 105 Ksi Minimum Tensile Strength PDFFattahi KarimNoch keine Bewertungen

- Palm Kernel Oil Mill ProjectDokument8 SeitenPalm Kernel Oil Mill Projectsjr141071100% (2)

- Primary Wastewater TreatmentDokument12 SeitenPrimary Wastewater TreatmentJAY4029364Noch keine Bewertungen

- Cost of Goods Manufactured ScheduleDokument4 SeitenCost of Goods Manufactured ScheduleMary82% (11)

- Chapter 4 Plant LayoutDokument11 SeitenChapter 4 Plant LayoutpawanNoch keine Bewertungen

- Guidelines For Safe IncinerationDokument2 SeitenGuidelines For Safe IncinerationSylvek91Noch keine Bewertungen

- Final Snowman LogisticDokument10 SeitenFinal Snowman LogisticAtanuMajiNoch keine Bewertungen

- Metallurgy: Muhammad Talha Reg #: 16PWMIN0770Dokument13 SeitenMetallurgy: Muhammad Talha Reg #: 16PWMIN0770Muhammad TalhaNoch keine Bewertungen

- Rib Boom ImplementationDokument7 SeitenRib Boom ImplementationgygjhkjnlNoch keine Bewertungen