Beruflich Dokumente

Kultur Dokumente

SI RT: Only To B Us DB PR F Sion Ls

Hochgeladen von

barbarabluOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

SI RT: Only To B Us DB PR F Sion Ls

Hochgeladen von

barbarabluCopyright:

Verfügbare Formate

•m~

NEVER arrcrnpr to clean a used

II!IBII!B

l Hydraulic Filters

cellulosc or synthetic filtcr elemento

Thc filter media will be damaged

ONLY lise genuine replacernenr parts. Service Instructions

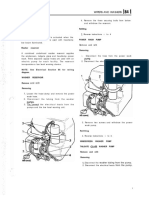

3. Remove the cover.

~rl'...w i=! l.

I ....= NEVER substiture an incorrecr part

evcn if ir is of the sa me size. Only to be used by professionals

tP~t

"r217

NEVER fit a damaged replacement filter

4. Removc rhc filrcr c1cmcnt as geutly as possible avoiding

1

conranunanr drops

7~L27[

in che clean side of the housing.

elemenr (e.g. Denred canister, warped

end caps, ripped media).

Once rhe spin-on or cartridge has been replaced,

if rhere are the condirions (filter insralled vertically

Discard rhc cartridge, the seal and che spring.

wirh head poinring upwards], we rccommend ro

fili thc filrer with dea n oil before pressurizing

the sysrem.

:"JEVER run rhe system wirhour a filter

elemcnr - thcre would be no sysrem

prorection.

ALWAYS dispose of used filrer elemenrs

5. Clean out any sediment

,5

from rhe inside of the housmg/bowl. and old oi! in accordance with local

regularions.

ALWAYS wear prorective equipmenr such

:, ' as safcry glasscs and glovcs during filtcr

replacemenr.

, ,

l_C.f-' --- This equipmenr has been assessed in accordance

with thc guidelines laid down in rhe Europcan

6. Clean out any sedimenr from rhe cover side and lubricate rhe seal. Pressure Direetive 97/23/C .

~.~ .~ Wc hcreby declare the equipmenr meets the

requiremenrs of artide 3, section 3, thus meeting

~·Ò Ò

tbc directive requiremenrs.

Under the provisions of this directivc the filrer

assembly is suirablc for LIsewith group 2 fluids

only.

7. Lubricare elemcnt o-ring with clean system oil aud insrall rhc elcrncnt.

Reasscmble the cover until the threads end.

Manufacturcd by:

Donnldson Italia S.r.l

l

Via dell'Industria 17

I 46035 Ostiglia (MN) SGS

SI RT

~::'p;;;~;;~

Italy

~~g1ò's°211 •••••••.•••••••

OstigliaRD@emca.donaldson.com

European Headquarters:

Donaldson Europc DEBVBA

Interleuvenlaan 1

B 3001 Leuven

Bc1gium

Telephone +32 16 383811

Fax. +3216400077

Enginc-curopc@cmca.donaldson.com

For further infcrmaticn conracr your loeal

Donaldson dealer

www.Donaldson.corn

E507943 rev.3

-

Filter Replacement Instructions Filter I Filter FLK

HMK-FBK o

1. Thc filrer rcquires servicing when the indicator

shows rhe elernenr tu be clogged or in accordance

with the service inrerval instrucnons of the OEM.

3. Remove the spin-on filrer.

~~"~":O"M"le~.

. Clean out any sedimenr from rhe inside of the 4. Remove and discard the carrridge • the seal

andth~t(g

2. Turn oH nnd check thar thcrc is no pressure.

I~I'''~ · 11 •• ••

3. Remove filter

~,~;:::,,"~,",".,,"""

5. Clean

-'Is;" '~'"'~'"'~....

the surfaces of rhe filter head. 5. Check the seal inregriry, lubricare the seal and the

c:x,::

5. Clean out any sediment

-:

from the inside of the

HMK FBK

? 0-

6. Screw the spin-on filter rill upper surface and rum

"1[j"'~~I~~ --~---

6. Lubricare element o-ring with dean system oi1 and 6. Clean out any sedirnent from the head side and

spin-on as shown on filter. install element . lubricate the seal.

Reassembly the housing until rhreads end.

FLK FPK-FMK FCK

7. Lubricate element o-ring wirh dea n system oil

and insrall element . Reassemble the housing .

FIK FDK

7. Bleed rhe hydraulic sysrcm and chcck for leaks.

FIK FHK

FLK

Das könnte Ihnen auch gefallen

- FSOG 13-005 General Insp TenarisDokument10 SeitenFSOG 13-005 General Insp TenarisJanderson Sanchez Castañeda0% (1)

- SRX - 201Dokument32 SeitenSRX - 201darwin_mdozaNoch keine Bewertungen

- Madera25 100 2Dokument89 SeitenMadera25 100 2martin789Noch keine Bewertungen

- GE Auxiliary Relay NGA15A ManualDokument10 SeitenGE Auxiliary Relay NGA15A ManualMauricioNoch keine Bewertungen

- Husqvarna/Viking Zig Zag Sewing Machine Instruction ManualDokument27 SeitenHusqvarna/Viking Zig Zag Sewing Machine Instruction ManualiliiexpugnansNoch keine Bewertungen

- Clean Centrifuge CareDokument1 SeiteClean Centrifuge CareShahid AkhterNoch keine Bewertungen

- Service Manual Anestesi Drager PerseusDokument2 SeitenService Manual Anestesi Drager Perseus-- Khoiry Ismono100% (1)

- 9 Cleaning of Cooler: Turn Hepower OmDokument9 Seiten9 Cleaning of Cooler: Turn Hepower OmQuy HoangNoch keine Bewertungen

- Yacht Annual Maintenance ListDokument2 SeitenYacht Annual Maintenance ListCapt. Cole SislerNoch keine Bewertungen

- ', Sec'I'Ioni Wlalntenanceanddlsasse: Arg-D14'Traction GeneratorDokument8 Seiten', Sec'I'Ioni Wlalntenanceanddlsasse: Arg-D14'Traction Generatoremmsh71Noch keine Bewertungen

- Rtts Packer: Simple, Versatile Means For Testing, Treating and Squeeze Cement OperationsDokument4 SeitenRtts Packer: Simple, Versatile Means For Testing, Treating and Squeeze Cement OperationsEmad JamshidiNoch keine Bewertungen

- PRD Doc Epr 7555-00001 Sen Ain V2Dokument5 SeitenPRD Doc Epr 7555-00001 Sen Ain V2Gabriel Marcos Zoratti RucciNoch keine Bewertungen

- YOKOGAWA CMZ700 OverhaulDokument35 SeitenYOKOGAWA CMZ700 OverhaulHardik NandaNoch keine Bewertungen

- RFLweldedversionEN7104 E1 08 17Dokument5 SeitenRFLweldedversionEN7104 E1 08 17althafacmNoch keine Bewertungen

- Tissu Tek FilmDokument4 SeitenTissu Tek Filmramsesjasso4Noch keine Bewertungen

- LG Service Manual PDFDokument23 SeitenLG Service Manual PDFMarius OlteanuNoch keine Bewertungen

- Dual F U E L Filter?!4 ASSEMBLY NW: 8141239: I Illers (LuclDokument2 SeitenDual F U E L Filter?!4 ASSEMBLY NW: 8141239: I Illers (Luclamir barekatiNoch keine Bewertungen

- Astm d1633 17 PDFDokument4 SeitenAstm d1633 17 PDFAbel CameoNoch keine Bewertungen

- Care of Ophthalmic Surgical Instruments HiresDokument1 SeiteCare of Ophthalmic Surgical Instruments HiresAnkur SinghNoch keine Bewertungen

- Air CompressorDokument6 SeitenAir CompressorAmanuNoch keine Bewertungen

- Spare Parts List Pressure Filter DF Pressure Filter For Reversible Oil Flow DFF/DFFXDokument5 SeitenSpare Parts List Pressure Filter DF Pressure Filter For Reversible Oil Flow DFF/DFFXLee Thanh HaNoch keine Bewertungen

- FT 15 LV 14Dokument15 SeitenFT 15 LV 14jadungNoch keine Bewertungen

- Windscreen Wiper and Washer Removal GuideDokument8 SeitenWindscreen Wiper and Washer Removal GuideLeonardo VieiraNoch keine Bewertungen

- Flow Dynamics Conveyor BrochureDokument8 SeitenFlow Dynamics Conveyor BrochureMarcos Aurélio PintoNoch keine Bewertungen

- Maintenance Recommended Maintenance Schedule: PM Coil C.L.MN), by Toggling The Value From NO To YESDokument2 SeitenMaintenance Recommended Maintenance Schedule: PM Coil C.L.MN), by Toggling The Value From NO To YESVelmar diseño y construccionNoch keine Bewertungen

- I08-0581 January 2018 Update WebDokument4 SeitenI08-0581 January 2018 Update WebJULIAN VALDERRAMANoch keine Bewertungen

- 1 Stainless Steel Inset Sink Installation GuideDokument2 Seiten1 Stainless Steel Inset Sink Installation GuideJoeNoch keine Bewertungen

- Cook Compression PackingDokument2 SeitenCook Compression PackingMuhammad Imran100% (1)

- The Strength of Plant Fibres1015Dokument3 SeitenThe Strength of Plant Fibres1015hassbanasghar39Noch keine Bewertungen

- Resistoflex Rubber PadsDokument2 SeitenResistoflex Rubber PadsAnderson SNoch keine Bewertungen

- 14-Wing - Tube Care and RepairDokument3 Seiten14-Wing - Tube Care and Repaircarlos morales100% (1)

- Activated Carbon Filter PDFDokument10 SeitenActivated Carbon Filter PDFDon Clerance Denzil WeerakkodyNoch keine Bewertungen

- Kitchen Accessories GuideDokument6 SeitenKitchen Accessories Guidevaio readerNoch keine Bewertungen

- Trombone 7Dokument3 SeitenTrombone 7api-478072129Noch keine Bewertungen

- Bill of Quantity For Guard HouseDokument2 SeitenBill of Quantity For Guard HouseMiko AbiNoch keine Bewertungen

- Norris Recommended Makeup Procedures T003 V02 081908 PDFDokument2 SeitenNorris Recommended Makeup Procedures T003 V02 081908 PDFHamed GeramiNoch keine Bewertungen

- Norris Recommended Makeup Procedures T003 V02 081908Dokument2 SeitenNorris Recommended Makeup Procedures T003 V02 081908Hamed Gerami100% (1)

- Asse Plumbing Dictionary 6thed PDFDokument202 SeitenAsse Plumbing Dictionary 6thed PDFAbbey Guias AquinoNoch keine Bewertungen

- Centrifugal Pump ChecklistDokument1 SeiteCentrifugal Pump ChecklistApneryanus LepingNoch keine Bewertungen

- Report FRCDokument23 SeitenReport FRCRakibul HassanNoch keine Bewertungen

- 2 15A Airframe & Power Plant Mechanics (001-606) (201-400)Dokument200 Seiten2 15A Airframe & Power Plant Mechanics (001-606) (201-400)AdrianNoch keine Bewertungen

- Centrifugation Poster Maintenance-Centrifuges Maintenance-CentrifugesDokument2 SeitenCentrifugation Poster Maintenance-Centrifuges Maintenance-CentrifugesBook BookNoch keine Bewertungen

- PropellerDokument4 SeitenPropellerangielolesNoch keine Bewertungen

- Operating Instructions Cleaver A8Dokument2 SeitenOperating Instructions Cleaver A8عبدالله الشهاريNoch keine Bewertungen

- 民用航空器维修人员执照英语参考试题(核对版)Dokument505 Seiten民用航空器维修人员执照英语参考试题(核对版)大雄弗里曼Noch keine Bewertungen

- MI 434 - Auxiliary Generator Model A-8102Dokument16 SeitenMI 434 - Auxiliary Generator Model A-8102Jesse BarnettNoch keine Bewertungen

- Y-Strainer IOM Rev A (03!26!18)Dokument6 SeitenY-Strainer IOM Rev A (03!26!18)Dominic V. PantigNoch keine Bewertungen

- SU HIF-6 ServiceinfoDokument9 SeitenSU HIF-6 ServiceinfoPatrick StivénNoch keine Bewertungen

- PRD_DOC_EPR_7106-00001__SEN__AIN__V3 (2)Dokument5 SeitenPRD_DOC_EPR_7106-00001__SEN__AIN__V3 (2)gabrieldarochaaNoch keine Bewertungen

- CARBURETOR CLINIC GUIDEDokument4 SeitenCARBURETOR CLINIC GUIDEviktor ronvegNoch keine Bewertungen

- NorrisDokument2 SeitenNorrisGhodbunderNoch keine Bewertungen

- Expeuer Slurry Pump: Sealéd Without Wat R.: TionalDokument6 SeitenExpeuer Slurry Pump: Sealéd Without Wat R.: TionalFelipe CidNoch keine Bewertungen

- CatalogVol15 MCDokument191 SeitenCatalogVol15 MCAlberto Celleri BravoNoch keine Bewertungen

- Brother P-Touch 1000 PDFDokument1 SeiteBrother P-Touch 1000 PDFJohnNoch keine Bewertungen

- Sub Terra Rulebook V3.0 CompressedDokument22 SeitenSub Terra Rulebook V3.0 CompressedarkcaverNoch keine Bewertungen

- Valve Body ServiceDokument2 SeitenValve Body ServiceABHISHEK SINGHNoch keine Bewertungen

- Fuel and maintenance checkDokument1 SeiteFuel and maintenance checkDPNoch keine Bewertungen

- Refrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsVon EverandRefrigeration Processes: A Practical Handbook on the Physical Properties of Refrigerants and their ApplicationsBewertung: 3 von 5 Sternen3/5 (2)

- Shale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementVon EverandShale Shaker and Drilling Fluids Systems:: Techniques and Technology for Improving Solids Control ManagementBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Geometric Knit Blankets: 30 Innovative and Fun-to-Knit DesignsVon EverandGeometric Knit Blankets: 30 Innovative and Fun-to-Knit DesignsBewertung: 5 von 5 Sternen5/5 (2)

- Structural Engineer - Issue 9 - 2010Dokument76 SeitenStructural Engineer - Issue 9 - 2010ntatar90Noch keine Bewertungen

- Palam Realty Pvt. LTDDokument10 SeitenPalam Realty Pvt. LTDKamal RaoNoch keine Bewertungen

- Tunnelling in Bukit Timah Granite Formation - Challenges in Tunnelling From Newton To Stevens StationDokument14 SeitenTunnelling in Bukit Timah Granite Formation - Challenges in Tunnelling From Newton To Stevens StationfreezefreezeNoch keine Bewertungen

- Bgi Pertemuan 4Dokument26 SeitenBgi Pertemuan 4tilda 1701Noch keine Bewertungen

- Practical Applications of Remote Sensing: DistinguishedDokument8 SeitenPractical Applications of Remote Sensing: DistinguisheddishankmpatelNoch keine Bewertungen

- Focus4 2E Unit Test Dictation Listening Reading Unit8 GroupADokument2 SeitenFocus4 2E Unit Test Dictation Listening Reading Unit8 GroupAIgor OsipenkoNoch keine Bewertungen

- MASTERSEAL 345 Design Guideline 2009Dokument11 SeitenMASTERSEAL 345 Design Guideline 2009Sandro MendesNoch keine Bewertungen

- AASHTO GeoTechnical Design of PileDokument6 SeitenAASHTO GeoTechnical Design of PileTee Bun PinNoch keine Bewertungen

- Alberta 1 Fact Sheet Summer 2013Dokument3 SeitenAlberta 1 Fact Sheet Summer 2013Don BonnerNoch keine Bewertungen

- Water is essential for lifeDokument2 SeitenWater is essential for lifeJuniorxito Camacho JavesNoch keine Bewertungen

- Soil Resistivity ProcedureDokument7 SeitenSoil Resistivity Procedurephelo1100% (1)

- Trilobites: Fossilized Arthropods of the Paleozoic EraDokument31 SeitenTrilobites: Fossilized Arthropods of the Paleozoic EraSumatNoch keine Bewertungen

- Applications of Oxygen and Carbon Isotopes in Quaternary-Laptop-5hhlb844Dokument13 SeitenApplications of Oxygen and Carbon Isotopes in Quaternary-Laptop-5hhlb844Anagha mohanNoch keine Bewertungen

- Cable Route Survey DictionaryDokument18 SeitenCable Route Survey DictionaryginziroNoch keine Bewertungen

- Unu GTP 2013 27Dokument34 SeitenUnu GTP 2013 27Damir Merima MuslicNoch keine Bewertungen

- Philippine HistoryDokument386 SeitenPhilippine Historyinfoman201064% (14)

- MCQ on Watershed Management ConceptsTITLE Short Answer Questions on Rainwater Harvesting and River Flow ManagementDokument4 SeitenMCQ on Watershed Management ConceptsTITLE Short Answer Questions on Rainwater Harvesting and River Flow ManagementRitu Raj AryanNoch keine Bewertungen

- CV Summary for GeophysicistDokument6 SeitenCV Summary for GeophysicistavisenicNoch keine Bewertungen

- Clay Mineral Elastic PropertiesDokument4 SeitenClay Mineral Elastic PropertiesmufazzalkabuliNoch keine Bewertungen

- Migration HistoryDokument68 SeitenMigration Historyrjain_56Noch keine Bewertungen

- SM GOST 16557-78 En-Mineral PowderDokument6 SeitenSM GOST 16557-78 En-Mineral PowderSilvia Simona PapanagaNoch keine Bewertungen

- Pittsburgh Post-Gazette 019a Sept. 22, 2021Dokument36 SeitenPittsburgh Post-Gazette 019a Sept. 22, 2021Pittsburgh Post-GazetteNoch keine Bewertungen

- Geography Class 7th NcertDokument21 SeitenGeography Class 7th NcertPrashant RayNoch keine Bewertungen

- Bearing SettlementDokument4 SeitenBearing SettlementBahaismail100% (1)

- MT Lyell Copper Mine Prefeasibility Study Demonstrates Strong Economics Over Multi-Decade LifeDokument47 SeitenMT Lyell Copper Mine Prefeasibility Study Demonstrates Strong Economics Over Multi-Decade LifeLeo PalNoch keine Bewertungen

- Test Bank For Earth Science 14th Edition by Tarbuck and Lutgens Test BankDokument108 SeitenTest Bank For Earth Science 14th Edition by Tarbuck and Lutgens Test BankKavita KrishnamorthiNoch keine Bewertungen

- Earth's History and Geologic TimeDokument13 SeitenEarth's History and Geologic TimedhonaNoch keine Bewertungen

- Flexco Conveyor ProductsDokument32 SeitenFlexco Conveyor ProductsDaniel KrismantoroNoch keine Bewertungen

- GTK Map Explanation Volume1 PDFDokument376 SeitenGTK Map Explanation Volume1 PDFArcenio Artur Munguambe100% (1)

- Historical - Geography - Armenia - Hewson PDFDokument42 SeitenHistorical - Geography - Armenia - Hewson PDFAnonymous WpMUZCb935Noch keine Bewertungen