Beruflich Dokumente

Kultur Dokumente

Virtual Experimental Modal Analysis of A Cantilever Beam: Mr. Saju Joseph

Hochgeladen von

ankurshah1986Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Virtual Experimental Modal Analysis of A Cantilever Beam: Mr. Saju Joseph

Hochgeladen von

ankurshah1986Copyright:

Verfügbare Formate

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 06, June - 2017

Virtual Experimental Modal Analysis of a

Cantilever Beam

Mr. Saju Joseph Mr. Deepak B.S

Mechanical Engineering Department Assistant Professor

Mar Baselios College of Engineering and Technology Mechanical Engineering Department

Thiruvananthapuram, India Mar Baselios College of Engineering and Technology

Thiruvananthapuram, India

Abstract— Experimental modal analysis (EMA) is an The initial step in experimental modal analysis is to obtain

accepted methodology for identifying modal parameters of the response of a structure to a certain kind of excitation. This

complex system assemblies, but large channel counts and might be accomplished under operational conditions or from

multiple references are usually required to perform a thorough modal testing within a controlled test environment. Once the

modal survey of such structures. In these cases, modal testing

response measurement has been completed, the next step to

can become very costly and time consuming. Moreover, success

in accurately defining all the modes of interest from be performed is the identification of the modal parameters of

experimental data depends on a variety of factors, including the structure from the measured data. For this task a broad

how and where the excitation is applied, how and where range of modal analysis techniques have been developed over

measurement data is acquired, and how boundary conditions or the past decades. The decision which technique to apply in a

other environmental conditions are simulated. This presentation given situation is to be based on diverse considerations, the

suggest a methodology for virtual experimental modal analysis most important of which are: Is the excitation known (which

(VEMA). is generally the case in experimental modal analysis) or

unknown (which is generally the case in operational modal

I. INTRODUCTION analysis where the response of the structure to an ambient

excitation under operational conditons is measured)? Is the

Experimental modal analysis has grown steadily in data available just in the frequency domain or also in the time

popularity since the advent of the digital FFT spectrum domain? Does a reasonable estimation of the parameters exist

analyser in the early 1970’s. Today, impact testing (or bump as a starting point for an iterative procedure to improve the

testing) has become widespread as a fast and economical initial guess? Are the structural modes well seperated or

means of finding the modes of vibration of a machine or closely spaced? Is it reasonable to assume a lightly damped

structure. Modes are used as a simple and efficient means of structure?

characterizing resonant vibration. The majority of structures

can be made to resonate. That is, under the proper conditions, There are several critera for the classification of modal

a structure can be made to vibrate with excessive, sustained, analysis techniques. He and Fu distinguish between single-

oscillatory motion. Resonant vibration is caused by an degree-of-freedom (SDoF) and multi-degree-of-freedom

interaction between the inertial and elastic properties of the (MDoF) methods [7]. Natke classifies modal analysis

materials within a structure. Resonant vibration is often the techniques as either phase resonance methods or phase

cause of, or at least a contributing factor to many of the separation methods [8]. Phase resonance methods are based on

vibration related problems that occur in structures and an adaption of the excitation in such a way that only one

operating machinery. single mode is excited which simplifies the post-processing of

the thus obtained data quite a lot but is experimentally very

To better understand any structural vibration problem, the extensive. Phase separation methods on the other hand shift

resonances of a structure need to be identified and quantified. most of the effort to the post-processing of the data as quite

A common way of doing this is to define the structure’s elaborate and computationally expensive numerical methods

are required to extract reliable modal information from data

modal parameters. Modes (or resonances) are inherent

comprising the coexistent contribution of several modes. The

properties of a structure. Resonances are determined by the

most widely-used classification however distinguishes

material properties (mass, stiffness, and damping properties), between frequency domain methods and time domain

and boundary conditions of the structure. Each mode is methods. The following list gives an overview of some

defined by a natural (modal or resonant) frequency, modal popular modal analysis techniques as presented in [7],[8] and

damping, and a mode shape. If either the material properties [9].

or the boundary conditions of a structure change, its modes

will change. At or near the natural frequency of a mode, the

overall vibration shape (operating deflection shape) of a I - Frequency domain methods

machine or structure will tend to be dominated by the mode Peak-picking method

shape of the resonance. Circle-fit method

Inverse FRF method

IJERTV6IS060420 www.ijert.org 921

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 06, June - 2017

II - Time domain methods The chances of performing a successful EMA are

Least-squares time domain method significantly improved if answers to the following critical

Ibrahim time domain (ITD) method questions are known beforehand:

Random Decrement (RD) method What type of excitation signals should be used.

ARMA Time Series method What analysis frequency range should be used.

Least-squares Complex Exponential (LSCE) method How much frequency resolution is needed.

How the boundary conditions are accounted.

III - Analysis methods

How do operating conditions, such as internally

Least-square method

generated forces, excite the modes.

Dobson’s method

The Fourier Transformation or Fourier Transform is a very A key advantage of the VEMA approach is that it

fundamental mathematical instrument of signal analysis. simulates multi-channel data acquisition. Multiple transducer

Originally developed by Fourier for the solution of and excitation locations and directions can be easily

differential equations in the area of heat conduction, it soon introduced into the model. Transducer sensitivities and signal

was applied to totally different problems throughout the processing can also be simulated. All of the excitation and

various disciplines of science and engineering. Initially response data can be simultaneously sampled, for as many

developed as an analytical instrument and therefore channels as desired at any desired rate. A set of simulated test

constrained to the application to analytically defined and data can be acquired in only a few minutes, whereas

integrable functions, the real power of the Fourier Transform acquisition of the actual data in a laboratory environment

could only be exploited with the advent of modern might take hours or even days.

computers.

Andrew S. Elliott, Mark H. Richardson [1] have A. Frequency Range and Resolution (FRR)

introduced a new method for simulating an Experimental One of the fundamental questions in any EMA is, What

Modal Analysis (EMA) using a combination of two frequency range and resolution is needed to adequately

commercially available software tools, ADAMS and

estimate the parameters of the fundamental modes.

ME’scope and named this new simulation method Virtual

In many real EMAs, the easiest way to answer this question is

Experimental Modal Analysis, or VEMA. The primary

to impact the structure with an instrumented hammer,

advantage of this completely analytical approach is that many measure a few Frequency Response Functions (FRFs), and

important questions regarding modal testing of very complex examine the FRFs for resonance peaks. Also, a preliminary

structures can be addressed before the actual testing is done.

look at the mode shapes is helpful if a sufficient number of

Brian J. Schwarz, Mark H. Richardson [2],gives a review FRFs are measured over the surface of the structure so that

on all the main topics associated with experimental modal one shape can be distinguished from another.

analysis, including making FRF measurements with a FFT

analyser modal excitation techiniques and modal parameter B. Frequency Response Function (FRF)

estimation from a set of FRFs (curve fitting). The Frequency Response Function (FRF) is a

fundamental measurement that isolates the inherent dynamic

Peter Avitabile [3], presents a non-mathematical properties of a mechanical structure. Experimental modal

presentation of Experimental Modal Analysis, which give an parameters (frequency, damping, and mode shape) are also

idea on modal analysis, Frequency Response Functions, obtained from a set of FRF measurements.

difference between shaker test and impact test, effect of The FRF describes the input-output relationship between

window. He describes structural vibration and the use of some two points on a structure as a function of frequency, as shown

of the available tools for the solution of structural dynamic in Fig 3.1. Since both force and motion are vector quantities,

problems. they have directions associated with them. Therefore, an FRF

Experimental modal analysis (EMA) is an accepted is actually defined between a single input DOF (point &

methodology for identifying modal parameters of complex direction), and a single output DOF.

system assemblies, but large channel counts and multiple An FRF is a measure of how much displacement,

references are usually required to perform a thorough modal velocity, or acceleration response a structure has at an output

survey of such structures. In these cases, modal testing can DOF, per unit of excitation force at an input DOF.

become very costly and time consuming. Moreover, success

in accurately defining all the modes of interest from Fig. 1 also indicates that an FRF is defined as the ratio of

experimental data depends on a variety of factors. the Fourier transform of an output response ( X(ω) ) divided

by the Fourier transform of the input force ( F(ω) ) that

How and where the excitation is applied. caused the output.

How and where measurement data is acquired.

How boundary conditions or other environmental

conditions are given.

IJERTV6IS060420 www.ijert.org 922

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 06, June - 2017

Fig. 1. Block Diagram of FRF

An FRF is a complex valued function of frequency that is

displayed in various formats, as shown in Fig. 2. Fig. 3. Response as Summation of Modal Responses

D. Fast Fourier Transform (FFT)

Any waveform is actually just the sum of a series of simple

sinusoids of different frequencies, amplitudes, and phases. A

Fourier series is that series of sine waves and we use Fourier

analysis or spectrum analysis to deconstruct a signal into its

individual sine wave components. The result is vibration

amplitude as a function of frequency, which lets us perform

analysis in the frequency domain (or spectrum) to gain a

deeper understanding of our vibration profile. Most vibration

analysis will typically be done in the frequency domain.

Fourier analysis converts a signal from its original domain

(often time) to a representation in the frequency domain. FFT

representation of a mixture of Sin wave is as shown in Fig. 4.

Fig. 2. Alternate Formats of FRF

C. Vibration is Easier to Understand in Terms of Modes

Fig. 3 points out a reason why vibration is easier to

understand in terms of modes of vibration. It is a plot of the

Log Magnitude of an FRF measurement (the solid curve), but

several resonance curves are also plotted as dotted lines

below the FRF magnitude. Each of these resonance curves is

the structural response due to a single mode of vibration. Fig. 4. FFT representation of a mixture of Sin wave

The overall structural response (the solid curve) is in fact,

the summation of resonance curves. In other words, the II. METHODOLOGY

overall response of a structure at any frequency is a

summation of responses due to each of its modes. It is also A. Theoretical Route of Vibration Analysis

evident that close to the frequency of one of the resonance The theoretical route is as shown in Fig. 4. The usual

peaks, the response of one mode will dominate the frequency procedure for getting the natural frequencies and mode shapes

response. is by modelling the system, followed by meshing the system,

then followed by Eigen value analysis.

Fig. 4. Theoretical Route of Vibration Analysis

IJERTV6IS060420 www.ijert.org 923

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 06, June - 2017

B. Experimental Route of Vibration Analysis D. Modal Analysis Using Ansys

The experimental route is as shown in Fig. 5. The

Procedure is as follows:

procedure for getting the natural frequencies and mode shapes

is by modeling of the system, followed by meshing the Step 1: Pre-processor→ Element type→ Add→ Beam→

system, then followed by response analysis of shaker test and 2node188→ OK

impact test. Least square curve fitting technique is used get the Step 2: Pre-processor→ Modelling→ Create→ Keypoints→

natural frequencies and mode shapes. In Active CS

X= 1

Pre-processor→ Modelling→ Create→ Lines→

Straight Line→ OK

Step 3: Pre-processor→ Meshing→ Mesh Tools→ Set

Fig. 5. Experimental Route of Vibration Analysis

Lines→OK

Number of element division = 10

Mesh Tools→ Mesh→ OK

Step 4: Plot Ctrls→ Numbering→ Node Numbers→ On→

C. Modal Analysis of Cantilever Beam OK

Step 5: Pre-processor→ Material Properties→ Material

Modal analysis of a cantilever beam was done in both

Models→ Structural→ Linear→

ANSYS and MATLAB and a comparison of the natural

Elastic→ Isotropic

frequencies were done.

Elastic Modulus = 210 * 109

Poissons Ratio = 0.3

Density = 7800

Step 6: Pre-processor→ Sections→ Beam→ Common

Sections→

Breadth = 20 * 10-3

Height = 1.5 * 10-3

Apply→ OK

Step 7: Solutions→ Define Loads→ Apply→ Structural→

Displacement→ On Nodes→ Select Node 1→ OK

DOFs to be constrained→ All DOF

Fig. 6. Structural View of Cantilever Beam

Value of Displacement = 0→ OK

Step 8: Solution→ Analysis Type→ New Analysis→

TABLE I. DETAILS OF THE BEAM

Modal→ OK

Length (l) 1000 mm Step 9: Solution→ Analysis Type→ Analysis Options→

DIMENSIONS Mode Extraction Method→ Block Lanczos

Breadth (b) 20 mm

Number of Modes to extract = 10

Height (h) 1.5 mm

Number of Modes to expand = 10

Step 10: Solution→ Solve→ Current LS→ OK

Elastic Modulus (E) 210 * 109 Pa Step 11: General Postproc→ Result Summary

PROPERTIES Density (ρ) 7800 kg/m3

Moment of Inertia (I) 5.625 * 10-12 m4

Moment of Inertia, I = (b*h3)/12 E. Modal Analysis with MATLAB

Program is as follows:

A 3D analysis of the cantilever beam was done in ANSYS

and the element taken was 3D-2Node 188 beam element. The

% Variable descriptions:

3D-2Node 188 beam element is a 3D element with 2 nodes

% nel = number of elements

and each node is having 6 degree of freedom (DOF)(ie..

% nnel = number of nodes per element

rotation about x,y,z axis and translation along x,y,z axis). The

% ndof = number of dofs per node

beam was divided into 10 sections of equal length, with each

% nnode = total number of nodes in system

element having 2 nodes, thus resulting in a total of 11 nodes.

% sdof = total system dofs

At node 1 All DOFs were constrained. % el = elastic modulus

A 2D analysis of the cantilever beam was done using % b = breadth

MATLAB program. The beam was assumed to have only 2 % h = height

DOFs per node (ie.. rotation about z-axis and translation along % xi = moment of inertia of cross-section

y-axis) The beam was divided into 10 sections of equal length. % rho = mass density

Thus each element is having 2 nodes and so a total of 11 % tleng = total length of beam

nodes where required. Since each node is having 2 DOFs, so % leng = length of each element

the total DOF of the system was 22. At node 1 all DOFs were % area = cross-sectional area

constrained. % k = element stiffness matrix

% m = element mass matrix

IJERTV6IS060420 www.ijert.org 924

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 06, June - 2017

% kk = system stiffness matrix

% mm = system mass matrix Functions written in the above programme are feeldof1,

% index = a vector containing system dofs febeam1, feasmbl1, feaplycs.

associated with each element

% bcdof = a vector containing dofs feeldof1 function is defined as follows:

associated with boundary conditions

% bcval = a vector containing boundary function [index]=feeldof1(iel,nnel,ndof)

condition values associated with % Purpose: Compute system dofs associated

the dofs in 'bcdof' with each element in one dimensional

problem

clear % Variable Description:

clc % index - system dof vector associated

with element "iel"

format long; % iel - element number whose system dofs

nel=10; are to be determined

nnel=2 % nnel - number of nodes per element

ndof=2 % ndof - number of dofs per node

nnode=(nnel-1)*nel+1; edof = nnel*ndof;

sdof=nnode*ndof start = (iel-1)*(nnel-1)*ndof;

el=210e9; for

b=20e-3; i=1:edof

h=1.5e-3; index(i)=start+i;

xi=(b*(h^3))/12 end

rho=7800;

febeam1 function is defined as follows:

tleng=1

function [k,m]=febeam1(el,xi,leng,area,rho,ipt)

leng=tleng/nel;

% Variable Description:

area=b*h;

% k - element stiffness matrix (size of

bcdof(1)=1;

4x4)

bcdof(2)=2;

% m - element mass matrix (size of 4x4)

% el - elastic modulus

kk=zeros(sdof,sdof);

% xi - second moment of inertia of cross-

mm=zeros(sdof,sdof);

section

index=zeros(nnel*ndof,1);

% leng - element length

% area - area of beam cross-section

% rho - mass density (mass per unit

for iel=1:nel volume)

index=feeldof1(iel,nnel,ndof); % ipt = 1: consistent mass matrix

% extract system dofs associated with

element % stiffness matrix

[k,m]=febeam1(el,xi,leng,area,rho,1);

% computes element stiffness & mass c=el*xi/(leng^3);

mtrix

kk=feasmbl1(kk,k,index); % assemble k=c*[(12) (6*leng) (-12) (6*leng);

element stiffness matrices into (6*leng)(4*leng^2) (-6*leng) (2*leng^2);

system matrix (-12) (-6*leng) (12) (-6*leng);

mm=feasmbl1(mm,m,index); % assemble (6*leng)(2*leng^2) (-6*leng)

element mass matrices into system (4*leng^2)];

matrix

end

% consistent mass matrix

[kn,mn]=feaplycs(kk,mm,bcdof); % apply

the boundary conditions. if ipt==1

fsol=eig(kn,mn); % solve the matrix

equation and print mm=rho*area*leng/420;

fsol=sqrt(fsol);

freqhz=fsol/(2*pi); m=mm*[(156) (22*leng) (54) (-13*leng);

sort(freqhz) (22*leng)(4*leng^2)(13*leng)(-3*leng^2);

(54) (13*leng) (156) (-22*leng);

IJERTV6IS060420 www.ijert.org 925

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 06, June - 2017

(-13*leng)(-3*leng^2)(-22*leng)(4*leng^2)]; dimensions of the beam and also applicable for any number of

end elements.

feasmbl1 function is defined as follows:

function [kk]=feasmbl1(kk,k,index) Element Stiffness Matrix (k) =

% Purpose:Assembly of element matrices

into the system matrix

% Variable Description:

% kk - system matrix Where E = el = 210 * 109 Pa

% k - element matri I = xi = 5.625 * 10-12 m4

% index - d.o.f. vector associated with l = leng = 0.1 m

an element

Element Mass Matrix (m) =

edof = length(index);

for i=1:edof

ii=index(i);

for j=1:edof

jj=index(j);

kk(ii,jj)=kk(ii,jj)+k(i,j); Where ρ = rho = 7800 kg/m3

end

A = area = 3 * 10-5 m2

end

l = leng = 0.1 m

feaplycs function is defined as follows: therefore,

function [kk,mm]=feaplycs(kk,mm,bcdof)

% Purpose:Apply constraints to eigenvalue = 1181.25 N/m

matrix equation

% [kk]{x}=lamda[mm]{x} = 5.571 * 10-5 kg

% Variable Description:

% kk - system stiffness matrix before

applying constraints k= 1181.25 *

% mm - system mass matrix before applying

constraints

% bcdof - a vector containging constrained

d.o.f

n=length(bcdof);

sdof=size(kk); m= 5.571*10-5 *

for i=1:n

c=bcdof(i);

for j=1:sdof

kk(c,j)=0; System Stiffness Matrix, kk = 1181.25 *

kk(j,c)=0;

mm(c,j)=0;

mm(j,c)=0;

end

mm(c,c)=1;

end

In short, our system is a cantilever beam (Euler Bernoulli

beam) of 1m long, which is uniformly meshed into 10 equal

parts and each element is having 2 nodes. So there are a total

of 11 nodes in the system. We assumed 2 Degrees of Freedom

(DOFs) per node(translation along y-axis and rotation about z-

axis), therefore each element Degrees of Freedom is 4 and the

system Degrees of Freedom is 22. This means that the size of

both element stiffness matrix and element mass matrix are

(4x4) and thae size of system stiffness matrix and system

mass matrix are (22x22). Our task is to assemble the ten

element matrices of size (4x4) into a single system matrix of

size (22x22) and also to constrain all degrees of freedom at

node 1. The above code is applicable for any value for

IJERTV6IS060420 www.ijert.org 926

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 06, June - 2017

System Mass Matrix, mm = 5.571 * 10 -5 * III. Third Mode Shape is as shown in Fig. 9

III. RESULTS

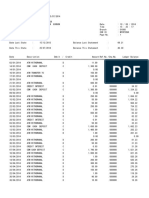

A. Results obtained in ANSYS

Fig. 9. Third Mode Shape

I. First Mode Shape is as shown in Fig. 7. The first three natural frequencies obtained in ANSYS is

as follows:

f1 = 1.2573 Hz

f2 = 7.8792 Hz

f3 = 22.062 Hz

B. Results obtained in MATLAB

The first three natural frequencies obtained in MATLAB

is as follows:

f1 = 1.25728645 Hz

f2 = 7.87953378 Hz

f3 = 22.0678097 Hz

Fig. 7. First Mode Shape C. Comparison of the results

A comparison of the first three natural frequencies IN Hz

II. Second Mode Shape is as shown in Fig. 8. obtained from both ANSYS-16 and MATLAB 2008 is as

shown in Table 2.

TABLE II. FIRST THREE NATURAL FREQUENCIES

Fig. 8. Second Mode Shape

IJERTV6IS060420 www.ijert.org 927

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Published by : International Journal of Engineering Research & Technology (IJERT)

http://www.ijert.org ISSN: 2278-0181

Vol. 6 Issue 06, June - 2017

IV. CONCLUSION and encouragement this project would not have materialized. I

Modal analysis of a Cantilever beam was done in both take this opportunity to express my deep sense of gratitude

ANSYS-16 and MATLAB 2008 and the first three natural and love to my friends for their inspiration, strength and help.

frequencies obtained in both the platforms are almost same.

Hence the MATLAB code is validated. REFERENCES

[1] Andrew S. Elliott, Mark H. Richardson, Virtual Experimental Modal

ACKNOWLEDGMENT Analysis, (1998) 1-7

[2] Brian J. Schwarz, Mark H. Richardson, Experimental Modal Analysis

I thank God, The Almighty for providing me strength and (1999), 1- 12

motivation. I acknowledge and express my profound sense of [3] Peter Avitabile, Experimental Modal Analysis, 1-15

gratitude and thanks to everybody who have been [4] Young W. Kwon, Hyochoong Bang, The Finite Element Method using

instrumental in the presentation of this Report. I express my MATLAB, Second Edition, CRC Press.

thanks to Dr.K.Muraleedharan Nair (Head of Mechanical [5] Singiresu S. Rao, Mechanical Vibration, Fourth Edition, Pearson.

Engineering department). I am extremely grateful and remain [6] Daryl L. Logan, A First Course in the Finite Element Method, Fifth

indebted to my guide Asst. Prof. Mr. Deepak B.S for his Edition, Cengage Learning.

constant supervision, for providing necessary information [7] J. He and Z.-F. Fu, Modal Analysis, Butterworth-Heinemann, 2001.

regarding the subject and correcting various documents of [8] H. G. Natke, Einführung in Theorie und Praxis der Zeitreihen- und

mine with attention and care. My deepest thanks to, Asst. Modalanalyse: Identifikation schwingungsfähiger elastomech. Systeme,

Prof. Mr. Hari Venkit (Project Coordinator) whose support Braunschweig; Wiesbaden: Vieweg, 1983.

and suggestions have proven to be essential. Without his help [9] D. J. Ewins, Modal Testing: Theory and Practice, Research Studies

Press Ltd., 1984.

IJERTV6IS060420 www.ijert.org 928

(This work is licensed under a Creative Commons Attribution 4.0 International License.)

Das könnte Ihnen auch gefallen

- Mechanical Systems and Signal Processing: Lingmi Zhang, Tong Wang, Yukio TamuraDokument13 SeitenMechanical Systems and Signal Processing: Lingmi Zhang, Tong Wang, Yukio TamuraGiacomo EspositoNoch keine Bewertungen

- Cantilever Beam With Tip Mass at Free enDokument14 SeitenCantilever Beam With Tip Mass at Free enanirbanNoch keine Bewertungen

- Morales Perez2018Dokument11 SeitenMorales Perez2018Mal TitiNoch keine Bewertungen

- Dynamic Load Testing of Bridges PDFDokument6 SeitenDynamic Load Testing of Bridges PDFankurshah1986Noch keine Bewertungen

- 2020-IEEE-Intelligence Bearing Fault Diagnosis Model Using Multiple Feature Extraction and Binary Particle Swarm Optimization With Extended MemoryDokument14 Seiten2020-IEEE-Intelligence Bearing Fault Diagnosis Model Using Multiple Feature Extraction and Binary Particle Swarm Optimization With Extended MemorykanuvietNoch keine Bewertungen

- Sensors, Degrees of Freedom, and Generalized Modeshape Expansion Methods, #8Dokument9 SeitenSensors, Degrees of Freedom, and Generalized Modeshape Expansion Methods, #8sumatrablackcoffee453Noch keine Bewertungen

- Detection and Estimation TheoryDokument29 SeitenDetection and Estimation TheoryMohammadHoseyniNoch keine Bewertungen

- Robust and Inexpensive Six-Axis Force-Torque Sensors Using Mems BarometersDokument7 SeitenRobust and Inexpensive Six-Axis Force-Torque Sensors Using Mems BarometerswsfNoch keine Bewertungen

- Preprocessing-Free Gear Fault Diagnosis Using Small Datasets With Deep Convolutional Neural Network-Based Transfer LearningDokument13 SeitenPreprocessing-Free Gear Fault Diagnosis Using Small Datasets With Deep Convolutional Neural Network-Based Transfer LearningCesar Vargas ArayaNoch keine Bewertungen

- Extracting Modal Parameters of Ultrasonic Bar Horns From ESPI FRF DataDokument8 SeitenExtracting Modal Parameters of Ultrasonic Bar Horns From ESPI FRF Datag mailNoch keine Bewertungen

- 2009 - Damping Estimation Using Free Decays and Ambient Vibration Tests - 2009Dokument17 Seiten2009 - Damping Estimation Using Free Decays and Ambient Vibration Tests - 2009Guille Ciprian NoaNoch keine Bewertungen

- Adaptive Leading-Edge Detection in UWB Indoor Localization: February 2010Dokument5 SeitenAdaptive Leading-Edge Detection in UWB Indoor Localization: February 2010KEVIN LNoch keine Bewertungen

- Guaranteed Passive Parameterized Admittance-Based MacromodelingDokument8 SeitenGuaranteed Passive Parameterized Admittance-Based MacromodelingAyoub KhelifatiNoch keine Bewertungen

- Machine Learning and Applications in Ultrafast PhotonicsDokument11 SeitenMachine Learning and Applications in Ultrafast PhotonicsmahadimasnadNoch keine Bewertungen

- C199 EWSHM 2012 Tu2e1Dokument9 SeitenC199 EWSHM 2012 Tu2e1mahesh MNoch keine Bewertungen

- Using Short-Time Fourier Transform in MachineryDokument8 SeitenUsing Short-Time Fourier Transform in MachineryhendranatjNoch keine Bewertungen

- Stacked Multilevel-Denoising Autoencoders: A New Representation Learning Approach For Wind Turbine Gearbox Fault DiagnosisDokument12 SeitenStacked Multilevel-Denoising Autoencoders: A New Representation Learning Approach For Wind Turbine Gearbox Fault Diagnosisaakash parasharNoch keine Bewertungen

- Fulltext01 PDFDokument59 SeitenFulltext01 PDFFrancisco CalderonNoch keine Bewertungen

- Stability of Absorbing Boundary Conditions: IEEE Transactions On Antennas and Propagation May 1999Dokument8 SeitenStability of Absorbing Boundary Conditions: IEEE Transactions On Antennas and Propagation May 1999Sahar SmNoch keine Bewertungen

- Experimental Modal Analysis of Reinforced Concrete Square SlabsDokument5 SeitenExperimental Modal Analysis of Reinforced Concrete Square SlabsBergson MatiasNoch keine Bewertungen

- C-Mechanical Systems and Signal Processing - Compressed-MinDokument22 SeitenC-Mechanical Systems and Signal Processing - Compressed-Minz mousaviNoch keine Bewertungen

- Modal AnalysisDokument10 SeitenModal Analysislrodriguez_892566Noch keine Bewertungen

- 1 s2.0 S0026271410005019 MainDokument9 Seiten1 s2.0 S0026271410005019 MainKệ ThôiNoch keine Bewertungen

- Experimental Modal Analysis ThesisDokument5 SeitenExperimental Modal Analysis ThesisBuyingEssaysOnlineNewark100% (2)

- Operational Modal Analysis - Another Way of Doing Modal TestingDokument6 SeitenOperational Modal Analysis - Another Way of Doing Modal TestingMarilene LobatoNoch keine Bewertungen

- Phase Array Ultrasonic PrincipleDokument13 SeitenPhase Array Ultrasonic PrinciplealexmontellNoch keine Bewertungen

- Ijrdet 0115 02Dokument6 SeitenIjrdet 0115 02Khurram ShehzadNoch keine Bewertungen

- Eren Et Al-2018-Journal of Signal Processing SystemsDokument12 SeitenEren Et Al-2018-Journal of Signal Processing SystemsIvana MilašNoch keine Bewertungen

- Akhtar Et Al 2020 High Vibration Diagnosis of Gas Turbines An Experimental InvestigationDokument15 SeitenAkhtar Et Al 2020 High Vibration Diagnosis of Gas Turbines An Experimental InvestigationIdris Zailani09Noch keine Bewertungen

- Reliability Analysis of Dynamic Systems: Efficient Probabilistic Methods and Aerospace ApplicationsVon EverandReliability Analysis of Dynamic Systems: Efficient Probabilistic Methods and Aerospace ApplicationsNoch keine Bewertungen

- A Review On Operational Modal Analysis Researches Classification of Methods and Applications Iomac 2009Dokument10 SeitenA Review On Operational Modal Analysis Researches Classification of Methods and Applications Iomac 2009masoudNoch keine Bewertungen

- Cunha e Caetano PDFDokument9 SeitenCunha e Caetano PDFLeticia Col DebellaNoch keine Bewertungen

- Experimental Modal Analysis of Reinforced Concrete Square SlabsDokument5 SeitenExperimental Modal Analysis of Reinforced Concrete Square SlabsAnonymous kBl0u3nNoch keine Bewertungen

- Implementation of Locally Weighted Projection Regression Network For Condition Monitoring of A Steam TurbineDokument4 SeitenImplementation of Locally Weighted Projection Regression Network For Condition Monitoring of A Steam Turbinepurushothaman sinivasanNoch keine Bewertungen

- Integrated Topology and Controller Optimization of Motion Systems in The Frequency DomainDokument13 SeitenIntegrated Topology and Controller Optimization of Motion Systems in The Frequency DomainSlijpselNoch keine Bewertungen

- Basics of Modal Testing and Analysis 2Dokument20 SeitenBasics of Modal Testing and Analysis 2DungNoch keine Bewertungen

- Paulo-Henrique - Chatter Detection in Turning Using Machine Learning and Similarity Measures of Time Series Via Dynamic Time WarpingDokument17 SeitenPaulo-Henrique - Chatter Detection in Turning Using Machine Learning and Similarity Measures of Time Series Via Dynamic Time WarpingRenata LisboaNoch keine Bewertungen

- IJERTV4IS030050Dokument6 SeitenIJERTV4IS030050Alireza AameriNoch keine Bewertungen

- Automatic Dynamic Depth Focusing For NDTDokument13 SeitenAutomatic Dynamic Depth Focusing For NDTSai Asrith PylaNoch keine Bewertungen

- A Crack Detection Method For Pipelines Using Wavelet-Based Decision-Level Data FusionDokument19 SeitenA Crack Detection Method For Pipelines Using Wavelet-Based Decision-Level Data Fusion朱波Noch keine Bewertungen

- 5 - A Transmissibility-Based Procedure To Estimate The Modal Properties of An On-Board Tuned Mass Damper (2020)Dokument12 Seiten5 - A Transmissibility-Based Procedure To Estimate The Modal Properties of An On-Board Tuned Mass Damper (2020)FabianaDaRosaSufiattiNoch keine Bewertungen

- Engineering Structures: Contents Lists Available atDokument9 SeitenEngineering Structures: Contents Lists Available atAnonymous sQGjGjo7oNoch keine Bewertungen

- Modal Analysis of Cantilever Beam Structure Using Finite Element Analysis and Experimental AnalysisDokument8 SeitenModal Analysis of Cantilever Beam Structure Using Finite Element Analysis and Experimental AnalysisAJER JOURNALNoch keine Bewertungen

- DBTS IEEE-ASME AcceptedDokument12 SeitenDBTS IEEE-ASME AcceptedkNoch keine Bewertungen

- Theoretical Model For Damage and Vibration Response in Concrete Bridges (FRGS 78007)Dokument113 SeitenTheoretical Model For Damage and Vibration Response in Concrete Bridges (FRGS 78007)Syahzanan Haunan FatharaniNoch keine Bewertungen

- Comparison Between Single and Multiple Degrees of Freedom Systems For The Seismic Response Estimation of Composite StructuresDokument9 SeitenComparison Between Single and Multiple Degrees of Freedom Systems For The Seismic Response Estimation of Composite StructuresMarco Flores ZuñigaNoch keine Bewertungen

- Fast Multivariate Empirical Mode Decomposition: IEEE Access October 2018Dokument18 SeitenFast Multivariate Empirical Mode Decomposition: IEEE Access October 2018Rhama DiantoNoch keine Bewertungen

- Ansys Lab TheoryDokument9 SeitenAnsys Lab TheoryNaveen S BasandiNoch keine Bewertungen

- Vibration FailuresDokument30 SeitenVibration Failuresejzuppelli8036Noch keine Bewertungen

- Era Paper1Dokument6 SeitenEra Paper1john_j7Noch keine Bewertungen

- Differential Transformation Method for Mechanical Engineering ProblemsVon EverandDifferential Transformation Method for Mechanical Engineering ProblemsNoch keine Bewertungen

- System Thesis PDFDokument4 SeitenSystem Thesis PDFykramhiig100% (2)

- Advanced Matrix Phased Arrays Settings For InspectionDokument8 SeitenAdvanced Matrix Phased Arrays Settings For InspectionAngel IanaNoch keine Bewertungen

- 1 s2.0 S0263224120302050 MainDokument12 Seiten1 s2.0 S0263224120302050 MainCristian BastiasNoch keine Bewertungen

- Optimization of Wearable Microwave Antenna With SiDokument6 SeitenOptimization of Wearable Microwave Antenna With SiMirela CimpanuNoch keine Bewertungen

- Combined Deterministic-Stochastic Frequency-Domain Subspace Identification For Experimental and Operational Modal AnalysisDokument11 SeitenCombined Deterministic-Stochastic Frequency-Domain Subspace Identification For Experimental and Operational Modal AnalysismasoudNoch keine Bewertungen

- Nonlinear System Identification For Damage Detection: LA-14353-MSDokument161 SeitenNonlinear System Identification For Damage Detection: LA-14353-MSankurshah1986Noch keine Bewertungen

- University of California, Irvine Bridge Column Tests OverviewDokument17 SeitenUniversity of California, Irvine Bridge Column Tests Overviewankurshah1986Noch keine Bewertungen

- Shmtools: A New Embeddable Software Package For SHM ApplicationsDokument11 SeitenShmtools: A New Embeddable Software Package For SHM Applicationsankurshah1986Noch keine Bewertungen

- Irc SP60Dokument84 SeitenIrc SP60ankurshah1986100% (1)

- 7.0 Overview of Vibrational Structural Health Monitoring With Representative Case StudiesDokument9 Seiten7.0 Overview of Vibrational Structural Health Monitoring With Representative Case Studiesankurshah1986Noch keine Bewertungen

- Stress Strain RebarDokument1 SeiteStress Strain Rebarankurshah1986Noch keine Bewertungen

- Workshop On Staad Pro PDFDokument4 SeitenWorkshop On Staad Pro PDFankurshah1986Noch keine Bewertungen

- Semi-Rigid Connection Structural ResponsesDokument15 SeitenSemi-Rigid Connection Structural Responsesankurshah1986Noch keine Bewertungen

- 1991-1-Damage Detection From Changes in Mode Shape - Pandey Biswas Samman PDFDokument12 Seiten1991-1-Damage Detection From Changes in Mode Shape - Pandey Biswas Samman PDFankurshah1986Noch keine Bewertungen

- Assessment of Vibration-Based Damage Identification TechniquesDokument24 SeitenAssessment of Vibration-Based Damage Identification Techniquesankurshah1986Noch keine Bewertungen

- Improved Bridge Evaluation Through Finit PDFDokument9 SeitenImproved Bridge Evaluation Through Finit PDFankurshah1986Noch keine Bewertungen

- Bridge Time Period, FrequencyDokument6 SeitenBridge Time Period, Frequencyankurshah1986Noch keine Bewertungen

- 522R-10 Report On Pervious Concrete PDFDokument43 Seiten522R-10 Report On Pervious Concrete PDFankurshah1986Noch keine Bewertungen

- Torsion TutorialDokument2 SeitenTorsion Tutorialankurshah1986Noch keine Bewertungen

- V Series: Three Wheel, Counterbalanced Lift TruckDokument126 SeitenV Series: Three Wheel, Counterbalanced Lift TruckВиктор МушкинNoch keine Bewertungen

- Fletcher Theophilus Ato CVDokument7 SeitenFletcher Theophilus Ato CVTHEOPHILUS ATO FLETCHERNoch keine Bewertungen

- Data Sheet: Elcometer 108 Hydraulic Adhesion TestersDokument3 SeitenData Sheet: Elcometer 108 Hydraulic Adhesion TesterstilanfernandoNoch keine Bewertungen

- Fracture and FatigueDokument15 SeitenFracture and FatigueZou JiaweiNoch keine Bewertungen

- 6 AsianregionalismDokument32 Seiten6 AsianregionalismChandria Ford100% (1)

- Frigidaire Parts and Accessories CatalogDokument56 SeitenFrigidaire Parts and Accessories CatalogPedro RuizNoch keine Bewertungen

- CPE Cisco LTE Datasheet - c78-732744Dokument17 SeitenCPE Cisco LTE Datasheet - c78-732744abds7Noch keine Bewertungen

- 3.13 Regional TransportationDokument23 Seiten3.13 Regional TransportationRonillo MapulaNoch keine Bewertungen

- CRC Implementation Code in CDokument14 SeitenCRC Implementation Code in CAtul VermaNoch keine Bewertungen

- Heat Exchanger Designing Using Aspen PlusDokument6 SeitenHeat Exchanger Designing Using Aspen PlusMeethiPotterNoch keine Bewertungen

- Mounting BearingDokument4 SeitenMounting Bearingoka100% (1)

- Econ 1006 Summary Notes 1Dokument24 SeitenEcon 1006 Summary Notes 1KulehNoch keine Bewertungen

- BMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Dokument9 SeitenBMT6138 Advanced Selling and Negotiation Skills: Digital Assignment-1Siva MohanNoch keine Bewertungen

- Oxygen BarrierDokument20 SeitenOxygen BarrierKarina ArdizziNoch keine Bewertungen

- Descriptive Statistics - SPSS Annotated OutputDokument13 SeitenDescriptive Statistics - SPSS Annotated OutputLAM NGUYEN VO PHINoch keine Bewertungen

- A Religious LeadershipDokument232 SeitenA Religious LeadershipBonganiNoch keine Bewertungen

- Introduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions ManualDokument12 SeitenIntroduction To Wireless and Mobile Systems 4th Edition Agrawal Solutions Manualethelbertsangffz100% (34)

- Gmo EssayDokument4 SeitenGmo Essayapi-270707439Noch keine Bewertungen

- Supreme Court of The United StatesDokument296 SeitenSupreme Court of The United StatesABC News PoliticsNoch keine Bewertungen

- Bank Statement SampleDokument6 SeitenBank Statement SampleRovern Keith Oro CuencaNoch keine Bewertungen

- BSBOPS601 Develop Implement Business Plans - SDokument91 SeitenBSBOPS601 Develop Implement Business Plans - SSudha BarahiNoch keine Bewertungen

- T3A-T3L Servo DriverDokument49 SeitenT3A-T3L Servo DriverRodrigo Salazar71% (7)

- Guidelines Use of The Word AnzacDokument28 SeitenGuidelines Use of The Word AnzacMichael SmithNoch keine Bewertungen

- PW Unit 8 PDFDokument4 SeitenPW Unit 8 PDFDragana Antic50% (2)

- Exoskeleton ArmDokument5 SeitenExoskeleton Armc214ocNoch keine Bewertungen

- (ENG) Visual Logic Robot ProgrammingDokument261 Seiten(ENG) Visual Logic Robot ProgrammingAbel Chaiña Gonzales100% (1)

- Mercury 150HPDokument5 SeitenMercury 150HP이영석0% (1)

- Journal of Economic LiteratureDokument28 SeitenJournal of Economic LiteratureEkoKurniadiNoch keine Bewertungen

- Unit 5 Andhra Pradesh.Dokument18 SeitenUnit 5 Andhra Pradesh.Charu ModiNoch keine Bewertungen

- Kicks: This Brochure Reflects The Product Information For The 2020 Kicks. 2021 Kicks Brochure Coming SoonDokument8 SeitenKicks: This Brochure Reflects The Product Information For The 2020 Kicks. 2021 Kicks Brochure Coming SoonYudyChenNoch keine Bewertungen