Beruflich Dokumente

Kultur Dokumente

Digital Bechtop Power Supply (2) : Part 2: Soldering, Sawing and Drilling

Hochgeladen von

Tariq ZuhlufOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Digital Bechtop Power Supply (2) : Part 2: Soldering, Sawing and Drilling

Hochgeladen von

Tariq ZuhlufCopyright:

Verfügbare Formate

POWERSUPPLY

Digital Bechtop

Power Supply (2)

Part 2: soldering, sawing and drilling

Design by R. Pagel

The construction of the Digital PSU requires extra care and precision.

Just like the electronics inside, the mechanical construction and overall

finish of the instrument should meet professional requirements.

VOLTAGE CURRENT

POWER

ON

OFF

DIGITAL POWER SUPPLY

0 - 25 V

0 - 2.5 A

000166 - F

Figure 1. Front panel layout for an elegant final appearance.

As indicated at the outset, there are two ver- sure 200 mm (width) by 180 mm the event of mains interference. The

sions of the power supply that you can build. (depth) by 100 mm (height) and a circuit board is fixed to the front

However, we have decided not to produce 24 V 80 VA toroidal transformer are panel with bolts, while the base sim-

special circuit board and front panel layouts used, with all the parts of the enclo- ply carries the toroidal transformer

for the smaller power supply and concen- sure securely connected to earth. A (and possibly also, as shown in the

trated on the larger 2.5 A unit. mains filter must also be fitted, or photograph, the mains filter). The

For the 2.5 A power supply a metal enclo- else the microcontroller may reset in heatsink, RS232 connector and next

98 Elektor Electronics 12/2001

POWERSUPPLY

to that the mains cable with strain and R=1.0 MΩ, and the filter must of advertisement for home-built test equipment.

relief are fitted to the rear panel. course have a suitable maximum The unpopulated circuit board can be used

Alternatively, a ‘cold condition’ IEC load specification. as a drilling template for the front panel. Take

mains inlet with fuse carrier can be Next we get our hands dirty with care to allow an adequate gap (at least

fitted. Ideally a mains inlet with the construction of the enclosure. 6 mm) between the mains switch connec-

built-in filter can be used. The spec- Preparing the front panel in particu- tions and the circuit board! The rectangular

ification of the filter we used was lar demands a lot of work and high hole for the LCD can be carefully cut out

2L=2.4 mH, Y=2200 pF, X2=0.1 µF accuracy since it constitutes an using an electric jigsaw or a fretsaw and the

000166-1

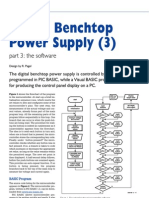

Figure 2a. Layout of the double sided circuit board for the power supply.

12/2001 Elektor Electronics 99

POWERSUPPLY

P3 P2

R39

H4

H3

R44

IC2

IC6 R38

R37

R35

R43

K2 C20 IC5

R41

C15

C16 C10 C11

R42

H5

K3

R36

H8

C18 R15 R18 C8

R34 R11 R21 R16

R22 R17

S2 S4 S6 S8

IC1

C13 R23 R19

IC3

IC8

R20

IC4

R40 C9 C6

C14 R13

R12

X1 R10 R14

R9

C17

C7 S3 S5 S7 S9

C19

R8

H6

H7 D1

+ IC7 F2

P1

R1

R3 T1 4A/T 250V

2A/T 250V

R2

R4

R5

D2

D3

D4

D6

D5

C4

K1 C3

C5

~

R7

R33

R32

R31

R30

R29

R28

R27

R26

R25

R24

R6

K4

E2 E3 E1

T6 T7 T5

~

R46

R47

R45

C2

C12 K5

B1

H2

H1

B

- + C C1’ C1

Figure 2b. Component mounting plan of the double sided circuit board for the power supply.

cuts can then be filed straight. If you are not flush with the panel. On the rear side The foil should not be attached to

confident of doing a professional job, you can fit nuts to the screws as tightly as the front panel until after the power

use a display with a bezel to cover the rough possible. Since the nuts should not supply has been fully tested. In order

edges. Cutting the hole for the mains switch (and indeed, without damaging the to avoid bubbles when attaching the

proceeds similarly. Use a taper drill for a cir- front panel, cannot) be undone again foil, it should always be smoothed

cular mains switch. The holes for the push it is a good idea to fix the nuts with out from the centre to the edge.

buttons can be drilled out in stages using var- superglue. The thread should pro- Finally, go over the foil with a rubber

ious twist drills until they have a diameter trude a few millimetres to ensure roller or a round pencil. The cutouts

0.5 mm bigger than the buttons, and then that the screws have adequate grip. and holes can now be carefully cut

filed smooth. Then four more holes are The fixing holes for the two terminal through using a knife. Work only

required for the mounting screws, which posts must also be suitably drilled. from the front of the foil making

should be countersunk so that the heads of If the anodised or brushed front many small cuts, especially when

the 3 mm countersunk screws are perfectly panel is presentable (free of making the holes for the push but-

scratches and other faults) it can be tons. An alternative way of making

annotated using rub-down lettering front panel foils using a PC and a

followed with a few coats of protec- printer was described in the

K4 tive spray. Alternatively you can July/August 2000 issue of Elektor

K1 make a front panel using the sug- Electronics.

1

gested layout in Figure 2. Photocopy

6

the layout onto paper at 1:1 scale

2

and apply a few coats of protective Component mounting

7

spray. Spray from a distance of at After the double-sided printed cir-

3

least 40 cm to ensure that the toner cuit board has served its purpose as

8

does not run. When completely dry a drilling template, the components

4

apply general-purpose glue to the can be fitted according to the plan in

9

back of the paper and glue it to a Figure 3. This should proceed with-

5

sheet of white self-adhesive labels. out difficulty since there are no sur-

Thus we have a robust front panel face-mount components, wire links,

000166 - 12

DB9 foil which is easy to work with and hairline tracks or tightly spaced sol-

which, thanks to the self-adhesive der pads to worry about. The board

Figure 3. Connections between K1 and the labels, will stick firmly to almost any should be populated in the usual

sub-D socket. surface. fashion. Before starting to solder,

100 Elektor Electronics 12/2001

POWERSUPPLY

the board. Ensure that any solder flux is

COMPONENTS LIST D3,D4,D5,D6 = 1N4148 removed from the area around IC1, IC2 and

2.5 A version B1 = B80C5000 (B80C1500)

IC4 after soldering, to avoid the effect of par-

(1 A version in brackets) T1 = BC557B

asitic resistance.

T2,T3,T4 = TIP142 (1 only)

Resistors: T5,T6,T7 = BC547B (not fitted) After checking all the soldered connec-

(* Metal film, 1% tolerance) IC1 = LT1491 tions the display can be suitably fixed using

R1 = 220Ω, 5W IC2 = TLC272 long bolts. The electrical connections are

R2 = 330Ω, 0.5W IC3 = PIC16F84A-04P, programmed, made using bare wire. Now the whole assem-

R3 = 150Ω order code 000166-42 bly can be fixed to the front panel, and the

R4 = 100kΩ IC4 = 4066 transformer and PC interface wired up as

R5 = 330Ω (1kΩ8) IC5, IC6 = 74HC164 shown in Figure 4.

R6 = 1kΩ, 0.5 W IC7 = 78L05 The power transistors are fitted with an

R7,R18,R23 = 1kΩ * IC8 = MAX232 insulating mica washer and fixed to the

R8,R17 = 39kΩ *

heatsink, the module being connected to the

R9,R10,R13,R14,R40,R41,R43 = Miscellaneous:

F1 = Fuse, 2A, time lag main circuit board using three 10 cm long

10kΩ

R11,R12 = 47kΩ F2 = Fuse, 4A, time lag (2A, time lag) 0.75 mm2 wires.

R15,R16 = 10kΩ * S1-S8 = pushbutton, C&K 3FTL6 +

R19 = 8kΩ2 1S09 22.5, or general-purpose

R20,R39 = 1kΩ 10×10×20mm, lead pitch 5mm Initial operation

R21 = 1kΩ * (0Ω) TR1 = mains transformer, toroid, 24V, Once everything has been assembled and

R22 = 18kΩ * (39kΩ *) 80VA, e.g. UI 39/1721 V, 2571 mA wired together, you will not want to wait a

R24-R34 = 1Ω * 0.6W X1 = ceramic resonator, 4MHz, 3 month for the description of the software and

R35-R38 = 100kΩ * pins operation of the unit; you will want to try your

R42 = 47kΩ LCD module 16×1, with backlight

power supply out immediately. With IC1 and

R44 = 3kΩ3 Fuse holder, PCB mount

Fuse holder, chassis mount, (alterna- the microcontroller not fitted, the mains can

R45,R46,R47 = 0Ω51, 0.5 W (not fit-

ted) tively IEC mains appliance socket be switched on for the first test. As long as

P1 = 10Ω multiturn preset with integral fuse) no smoke signals are emitted, the unit can be

P2 = 500Ω preset H Two wander sockets (red, black) left switched on.

P3 = 2kΩ5 preset H Fl1 = mains filter, 2A (not fitted) Between pins 4 and 11 of IC1 a voltage of

K1= 9-way SIL pinheader, with 9-way 27 V (for the 1 A power supply) or 32 V (for

Capacitors: sub-D socket (female), chassis the 2.5 A power supply) should be measured.

C1 = 10,000µF 50V (4,700µF 35V), mount There should be a voltage of 12 V across

axial K2 = 5-way pinheader Zener diode D2 and a voltage of 5.1 V

C2 = 470µF 50V, radial K4,K5 = 2-way PCB terminal block,

between pins 5 and 14 of the microcontroller.

C3,C13,C14,C15,C16,C17 = 10µF lead pitch 5mm

If all is well, turn off the power supply and fit

25V, radial 14-way IC socket with turned pins

C4,C7,C11 = 100nF, ceramic, 5mm 18- way IC socket with turned pins the remaining ICs. Turn P2 fully to the left.

lead pitch 12 solder pins When the unit is turned on again the display

C5 = 10nF, ceramic, 5mm lead pitch Heatsink, size 180×75×48 mm, spec should read:

C6 = 1nF, ceramic, 2.5mm lead pitch 0.6 K/W (100×50×31mm, spec

C8,C9 = 10µF, tantalum bead 2.4 K/W) 00.0V 0.00A

C10 = 4nF7, FKS-2 Enclosure (w×d×h) 200×180×100

C12 = 4µF7 63V, MKS-4 mm, e.g. Telet type LC950 When a push button is pressed (or held

Mains switch, mains cord down) the display should switch to ‘set

Semiconductors: PCB, order code 000166-1 mode’ and show the values as they are

D1 = P600D (1N4007)

adjusted either in milliamps or millivolts. To

D2 = zener diode 12V 1.3W

adjust the offset voltage, turn P2 gradually to

the right, checking whether the display

changes. When the display stops changing,

you have gone too far and you should back

the potentiometer off a little.

make sure that the push buttons under the display, such as C19, Alternatively, connect a PC to the interface

stand a good 10 mm higher than the must, where possible, be mounted and start up HyperTerminal with the follow-

electrolytic capacitors. A few com- flat. ing interface settings

ponents are soldered to the rear of If you know that you will never

the board: the bridge rectifier (for want to reprogram the microcon- 9600, 8, N, 1, hardware handshake

reasons of space), the trim poten- troller on the board, you can of

tiometers, the connectors, the solder course dispense with the program- Now adjust the trimmer so that the value rep-

tags for the transistors and the fuse ming connector K2. High-quality resented by the first five digits after the D is

(so that it can be changed easily). sockets should be used, at least for as small as possible, but not zero. A value of

The circuit board connector for the the two expensive ICs, IC1 and IC3. 2 is ideal, since the unit will then continue to

banana sockets is mounted on the R1, R2 and R6 can get hot and operate correctly even if the value should

component side. The components should be fitted raised slightly above change slightly as a result of ageing, mechan-

12/2001 Elektor Electronics 101

POWERSUPPLY

Figure 4. The main circuit board.

ical shock or temperature drift. actual output voltage of 19.03 V. The achieved, the first thing to check is

After this adjustment the output voltage output current adjustment and its that all the components are correctly

should be measured with the voltage setting displayed values will then automati- fitted and that there is no solder

at 0.00 V. It should be 30 mV (±15 mV). Next cally be correct. If the values are residue between the tracks.

set the voltage to 19.0 V and adjust P1 for an awry, or the above values cannot be (000166-2)

102 Elektor Electronics 12/2001

Das könnte Ihnen auch gefallen

- Make Your Own PCBs Form A To ZDokument17 SeitenMake Your Own PCBs Form A To Zbaliza1405Noch keine Bewertungen

- AudioXpress Thor ReviewDokument20 SeitenAudioXpress Thor ReviewGianpiero BoccatoNoch keine Bewertungen

- Mosfet Testing With Multi MeterDokument3 SeitenMosfet Testing With Multi MeterSalih AnwarNoch keine Bewertungen

- Ani C Bus Analyser To Let You Satisfy Your Curiosity: The Secrets of I CDokument7 SeitenAni C Bus Analyser To Let You Satisfy Your Curiosity: The Secrets of I CChico SouzaNoch keine Bewertungen

- Sae Ams 4027 SheetmetalDokument7 SeitenSae Ams 4027 Sheetmetaljuan100% (5)

- MyRoom Acoustics AES PaperDokument5 SeitenMyRoom Acoustics AES PaperMilan AnticNoch keine Bewertungen

- Jaes V60 9 AllDokument115 SeitenJaes V60 9 AllPhilipp Linder100% (1)

- Construction Article A Hi-Fi Vacuum Tube Phono PreampDokument18 SeitenConstruction Article A Hi-Fi Vacuum Tube Phono PreampΔημητριος Σταθης100% (1)

- 95-Wat Laptop PSU 12V in - 19V 5A Out PDFDokument7 Seiten95-Wat Laptop PSU 12V in - 19V 5A Out PDFArina ScăunașuNoch keine Bewertungen

- The - Campaigner Apr74 Tavistock 3Dokument1 SeiteThe - Campaigner Apr74 Tavistock 3poulpoulbotbotNoch keine Bewertungen

- My Four Years in Germany by Gerard, James W., 1867-1951Dokument188 SeitenMy Four Years in Germany by Gerard, James W., 1867-1951Gutenberg.org100% (1)

- Acoustic Measurement StandardsDokument30 SeitenAcoustic Measurement Standardsnikita011Noch keine Bewertungen

- Remote Control by Mobile Phone: Switch & Control Using DTMF SignallingDokument4 SeitenRemote Control by Mobile Phone: Switch & Control Using DTMF SignallingTariq Zuhluf100% (2)

- ETI Electronic Circuit Design No 1Dokument77 SeitenETI Electronic Circuit Design No 1IanNoch keine Bewertungen

- Pamphlet - EIR May131980 PDFDokument66 SeitenPamphlet - EIR May131980 PDFNielsen VegaNoch keine Bewertungen

- 1 - Tubes Versus Transistors - Is There An Audible DifferenceDokument5 Seiten1 - Tubes Versus Transistors - Is There An Audible DifferenceangelozuccoNoch keine Bewertungen

- Jaes V52 6 All PDFDokument124 SeitenJaes V52 6 All PDFtimosp1973Noch keine Bewertungen

- CNC G-Code and M-Code Reference For CNC MachinesDokument8 SeitenCNC G-Code and M-Code Reference For CNC MachinesShashank PathakNoch keine Bewertungen

- Evil in America (PDFDrive)Dokument110 SeitenEvil in America (PDFDrive)Miguel Angel Mociño GuadarramaNoch keine Bewertungen

- LM338KDokument20 SeitenLM338Kmaster55100% (1)

- Measuring Loudspeaker Low-Frequency Response by Joe D'AppolitoDokument21 SeitenMeasuring Loudspeaker Low-Frequency Response by Joe D'AppolitoTrajkoNoch keine Bewertungen

- Companion 3 Series Ii SM - R05Dokument30 SeitenCompanion 3 Series Ii SM - R05LUIS PETIT100% (1)

- Room AcousticsDokument88 SeitenRoom AcousticsArunNoch keine Bewertungen

- Tilting Pad BearingDokument2 SeitenTilting Pad BearingmojiryhamidNoch keine Bewertungen

- HY4008P/M/B/PS/PM: Pin Description F EaturesDokument14 SeitenHY4008P/M/B/PS/PM: Pin Description F EaturesElectrical Power Engineering100% (1)

- lm338 Mil PDFDokument28 Seitenlm338 Mil PDFNepomuceno Collazos100% (1)

- Textile Finishing IntroductionDokument14 SeitenTextile Finishing IntroductionSENTHIL KUMAR100% (6)

- Elektor (Nonlinear - Ir) 2015-11 - 12 PDFDokument106 SeitenElektor (Nonlinear - Ir) 2015-11 - 12 PDFxx67% (3)

- HighNote4 U6E Vocabulary Quiz BDokument1 SeiteHighNote4 U6E Vocabulary Quiz BZuza StarońNoch keine Bewertungen

- Aes V52 11 All PDFDokument92 SeitenAes V52 11 All PDFtimosp1973Noch keine Bewertungen

- UnilabDokument5 SeitenUnilabshoker4Noch keine Bewertungen

- Technical Manual 2011Dokument170 SeitenTechnical Manual 2011Aniie VaronaNoch keine Bewertungen

- Easy To Build CNC Mill Stepper Motor and Driver CircuitDokument12 SeitenEasy To Build CNC Mill Stepper Motor and Driver Circuitmarandan85Noch keine Bewertungen

- PP 2003 01Dokument84 SeitenPP 2003 01franciscocampoverde8224Noch keine Bewertungen

- Service Manual Vox Tb18C1: Schematic Diagram:2 Hookup:5 Test Mode:6 Parts List:7Dokument7 SeitenService Manual Vox Tb18C1: Schematic Diagram:2 Hookup:5 Test Mode:6 Parts List:7Jan KubalaNoch keine Bewertungen

- Concrete Design Exam-15Dec11Dokument6 SeitenConcrete Design Exam-15Dec11zci69Noch keine Bewertungen

- Invertor ProjektDokument13 SeitenInvertor ProjektFlorim GashiNoch keine Bewertungen

- DMM Mastech MS8268Dokument11 SeitenDMM Mastech MS8268ANdreuvinoBAss100% (1)

- Motorreductores BaldorDokument52 SeitenMotorreductores BaldorADRIAN MENDEZ RICARIONoch keine Bewertungen

- Technical Writeup For Jockey Pump PanelDokument3 SeitenTechnical Writeup For Jockey Pump PanelbhaveshbhoiNoch keine Bewertungen

- Elektor USA - October 2014 PDFDokument92 SeitenElektor USA - October 2014 PDFJean-Pierre Desrochers100% (4)

- Elektor en Article Easyavr5a Serial Ethernet BasicDokument2 SeitenElektor en Article Easyavr5a Serial Ethernet BasicIng. Mitchel Jammal S.Noch keine Bewertungen

- Step Motori PDFDokument10 SeitenStep Motori PDFthermosol5416Noch keine Bewertungen

- 4047Dokument4 Seiten4047rayanNoch keine Bewertungen

- Digital Benchtop Power Supply (3) : Part 3: The SoftwareDokument4 SeitenDigital Benchtop Power Supply (3) : Part 3: The SoftwareSchundaNoch keine Bewertungen

- Design and Modelling of A Universal CNC MachineDokument12 SeitenDesign and Modelling of A Universal CNC MachineАндэрь ЗорьгNoch keine Bewertungen

- BabbittDokument4 SeitenBabbitthrsreenathNoch keine Bewertungen

- 37 Piece Sensor Description PDFDokument7 Seiten37 Piece Sensor Description PDFMichael VincentNoch keine Bewertungen

- The Rise and Fall of Eskom - and How To Fi X It NowDokument22 SeitenThe Rise and Fall of Eskom - and How To Fi X It NowFadia Salie100% (2)

- TubeVsTransistor TextDokument7 SeitenTubeVsTransistor TextKevin Perez EscalanteNoch keine Bewertungen

- Audioxpress August 2022Dokument35 SeitenAudioxpress August 2022will scottNoch keine Bewertungen

- Proy. Electrónico DC Power MeterDokument20 SeitenProy. Electrónico DC Power Metervpol25Noch keine Bewertungen

- Image Method For Efficiently Simulating Small-Room Acoustics - DSP - ProjectDokument8 SeitenImage Method For Efficiently Simulating Small-Room Acoustics - DSP - Projectsepehr_240Noch keine Bewertungen

- E 90 A 054Dokument6 SeitenE 90 A 054A CristianNoch keine Bewertungen

- Complete EDM Handbook - 12Dokument10 SeitenComplete EDM Handbook - 12ks2000n1Noch keine Bewertungen

- Biblio AFTDokument3 SeitenBiblio AFTSandro JoséNoch keine Bewertungen

- Gould Dso400Dokument57 SeitenGould Dso400Beata TrefonNoch keine Bewertungen

- Humble Homemade Hifi - Mezzo ProteusDokument4 SeitenHumble Homemade Hifi - Mezzo ProteusCyril GoutaillerNoch keine Bewertungen

- Sams ComputerFacts - Apple IIeDokument73 SeitenSams ComputerFacts - Apple IIeOscar Arthur KoepkeNoch keine Bewertungen

- How To Make A Three Axis CNC Machine 2Dokument5 SeitenHow To Make A Three Axis CNC Machine 2mare_nsNoch keine Bewertungen

- Moto 360 Smartwatch Teardown PDFDokument14 SeitenMoto 360 Smartwatch Teardown PDFPhone 4uNoch keine Bewertungen

- Shaper, Slotter and PlanerDokument9 SeitenShaper, Slotter and PlanerRenjith RajendraprasadNoch keine Bewertungen

- 1985 MMI LSI Databook 6ed PDFDokument794 Seiten1985 MMI LSI Databook 6ed PDFgschadowNoch keine Bewertungen

- Tarjeta Reles 4 CanalesDokument2 SeitenTarjeta Reles 4 CanalesjbrunobNoch keine Bewertungen

- 100W Class D AmpDokument3 Seiten100W Class D AmpJuan Jose PonceNoch keine Bewertungen

- Linear Power Amplifier Using HEXFETDokument9 SeitenLinear Power Amplifier Using HEXFETRicardoCavalheiroNoch keine Bewertungen

- Mains Voltage Monitor: Goswin VisschersDokument1 SeiteMains Voltage Monitor: Goswin VisschersTariq Zuhluf100% (2)

- Practical Neural Networks (3) : Part 3 - Feedback Nets and Competitive NetsDokument5 SeitenPractical Neural Networks (3) : Part 3 - Feedback Nets and Competitive NetsTariq Zuhluf100% (2)

- Design Ideas: Keyboard CircuitDokument2 SeitenDesign Ideas: Keyboard CircuitTariq Zuhluf100% (3)

- E 905030Dokument4 SeitenE 905030Tariq ZuhlufNoch keine Bewertungen

- Ensors FOR Humans: Sensor Technology at MITDokument4 SeitenEnsors FOR Humans: Sensor Technology at MITTariq ZuhlufNoch keine Bewertungen

- E 01 C 093Dokument5 SeitenE 01 C 093Tariq ZuhlufNoch keine Bewertungen

- E 055077Dokument1 SeiteE 055077Tariq ZuhlufNoch keine Bewertungen

- Universal Power-On Delay: by J. RuffellDokument1 SeiteUniversal Power-On Delay: by J. RuffellTariq Zuhluf100% (2)

- Stereo Peak Indicator: Small CircuitscollectionDokument1 SeiteStereo Peak Indicator: Small CircuitscollectionTariq Zuhluf100% (1)

- Psd3Xx Chips: by A. Riet JensDokument3 SeitenPsd3Xx Chips: by A. Riet JensTariq Zuhluf100% (1)

- E 037028Dokument1 SeiteE 037028Tariq Zuhluf100% (2)

- Seven-Eleven: Ir NVDokument3 SeitenSeven-Eleven: Ir NVTariq Zuhluf100% (2)

- Slave Mains On-Off Control: Amplificationj Attenuation SelectorDokument3 SeitenSlave Mains On-Off Control: Amplificationj Attenuation SelectorTariq Zuhluf100% (2)

- E 05 B 040Dokument7 SeitenE 05 B 040Tariq Zuhluf100% (2)

- In Questof A PangramDokument5 SeitenIn Questof A PangramTariq Zuhluf100% (1)

- PC Interface For The CAN Bus: With New SoftwareDokument5 SeitenPC Interface For The CAN Bus: With New SoftwareTariq Zuhluf100% (2)

- E 02 CH 43Dokument1 SeiteE 02 CH 43Tariq Zuhluf100% (2)

- Noise of The The V /115.: R.rn.sDokument1 SeiteNoise of The The V /115.: R.rn.sTariq Zuhluf100% (1)

- Speed-Up For Darlingtons: Small CircuitscollectionDokument1 SeiteSpeed-Up For Darlingtons: Small CircuitscollectionTariq Zuhluf100% (1)

- Token Number Display: Small CircuitscollectionDokument1 SeiteToken Number Display: Small CircuitscollectionTariq Zuhluf100% (2)

- E 02 CH 04Dokument1 SeiteE 02 CH 04Tariq Zuhluf100% (2)

- Digital Bechtop Power Supply (2) : Part 2: Soldering, Sawing and DrillingDokument5 SeitenDigital Bechtop Power Supply (2) : Part 2: Soldering, Sawing and DrillingTariq ZuhlufNoch keine Bewertungen

- Wireless Museum: Components ListDokument1 SeiteWireless Museum: Components ListTariq Zuhluf100% (1)

- E05c070 PDFDokument4 SeitenE05c070 PDFTariq Zuhluf100% (1)

- E 986024Dokument1 SeiteE 986024Tariq Zuhluf100% (1)

- E 03 B 035Dokument1 SeiteE 03 B 035Tariq Zuhluf100% (1)

- E051042 PDFDokument2 SeitenE051042 PDFTariq ZuhlufNoch keine Bewertungen

- Current Probe: Parts ListDokument1 SeiteCurrent Probe: Parts ListTariq Zuhluf100% (2)

- Idc To Box Header Adaptor: ReferenceDokument2 SeitenIdc To Box Header Adaptor: ReferenceTariq Zuhluf100% (1)

- Layout Room INDUSTRI FARMASIDokument1 SeiteLayout Room INDUSTRI FARMASIDwi MeliniaNoch keine Bewertungen

- Ratliperl: The Modern Solution For Energy Efficient BuildingDokument18 SeitenRatliperl: The Modern Solution For Energy Efficient BuildingAdhil Ramsurup100% (1)

- Modern Equipment Ladles Brochure 6 14 PDFDokument20 SeitenModern Equipment Ladles Brochure 6 14 PDFCristian Osorio RonquiloNoch keine Bewertungen

- Alustar 300 eDokument3 SeitenAlustar 300 eThiago BerthaudNoch keine Bewertungen

- Manual Aire Acondicionado HaierDokument48 SeitenManual Aire Acondicionado Haierjguerrero.067100% (3)

- 10 Important Questions and Answers About Temperature Sensing Using Thermocouple SensorsDokument3 Seiten10 Important Questions and Answers About Temperature Sensing Using Thermocouple SensorsVignesh RajanNoch keine Bewertungen

- Gerb Formulas PDFDokument4 SeitenGerb Formulas PDFMuthu KumarNoch keine Bewertungen

- p1475 MisumiDokument1 Seitep1475 MisumidmalfazNoch keine Bewertungen

- AEC Air Eraser Parts ListDokument2 SeitenAEC Air Eraser Parts Listspaced_boyNoch keine Bewertungen

- Nano FiltrationDokument8 SeitenNano FiltrationEman El DsoukyNoch keine Bewertungen

- Motor+Running Lighting+CapacitorsDokument28 SeitenMotor+Running Lighting+Capacitorssokol_poleceNoch keine Bewertungen

- EnvisionTEC Lost Wax Casting GuideDokument7 SeitenEnvisionTEC Lost Wax Casting GuidedbpeNoch keine Bewertungen

- PFR PDFDokument3 SeitenPFR PDFezraNoch keine Bewertungen

- Air Conditioning NotesDokument6 SeitenAir Conditioning NotesYash TewariNoch keine Bewertungen

- Difference Between Static Relays and Electromagnetic RelaysDokument2 SeitenDifference Between Static Relays and Electromagnetic Relayskriitka86% (7)

- Ecological and Energetic Assessment of Re-Refining Used Oils To Base OilsDokument104 SeitenEcological and Energetic Assessment of Re-Refining Used Oils To Base OilsFernando SImonelliNoch keine Bewertungen

- Saw SoldaduraDokument17 SeitenSaw SoldaduraAnselmo C. RamirezNoch keine Bewertungen

- Baldor-Maska Catalog (MM) - CA6001Dokument20 SeitenBaldor-Maska Catalog (MM) - CA6001dark_followerNoch keine Bewertungen

- Drill String On A Drilling Rig Is A ColumnDokument9 SeitenDrill String On A Drilling Rig Is A ColumnETRNoch keine Bewertungen

- Tata Steel en 15804 Verified EPD ProgrammeDokument16 SeitenTata Steel en 15804 Verified EPD Programmeashutosh mishraNoch keine Bewertungen

- NKK SWITCHES ATseries PDFDokument33 SeitenNKK SWITCHES ATseries PDFcosNoch keine Bewertungen

- Asphalt and Asphalt Paving MaterialsDokument7 SeitenAsphalt and Asphalt Paving MaterialsjohnNoch keine Bewertungen

- 742 222Dokument2 Seiten742 222slymnNoch keine Bewertungen