Beruflich Dokumente

Kultur Dokumente

As 3600-09 RC-BM-001

Hochgeladen von

Bunkun15Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

As 3600-09 RC-BM-001

Hochgeladen von

Bunkun15Copyright:

Verfügbare Formate

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

EXAMPLE AS 3600-09 RC-BM-001

Flexural and Shear Beam Design

PROBLEM DESCRIPTION

The purpose of this example is to verify slab flexural design in SAFE. The load

level is adjusted for the case corresponding to the following conditions:

The stress-block extends below the flange but remains within the balanced

condition permitted by AS 3600-09.

The average shear stress in the beam is below the maximum shear stress

allowed by AS 3600-09, requiring design shear reinforcement.

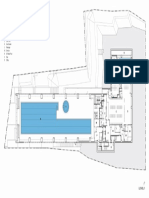

A simple-span, 6-m-long, 300-mm-wide, and 500-mm-deep T-beam with a

flange 100 mm thick and 600 mm wide is modeled using SAFE. The beam is

shown in Figure 1. The computational model uses a finite element mesh of frame

elements automatically generated by SAFE. The maximum element size has been

specified to be 200 mm. The beam is supported by columns without rotational

stiffnesses and with very large vertical stiffness (1 × 1020 kN/m).

The beam is loaded with symmetric third-point loading. One dead load case

(DL30) and one live load case (LL130), with only symmetric third-point loads of

magnitudes 30, and 130 kN, respectively, are defined in the model. One load

combinations (COMB130) is defined using the AS 3600-09 load combination

factors of 1.2 for dead load and 1.5 for live load. The model is analyzed for both

of these load cases and the load combination.

The beam moment and shear force are computed analytically. The total factored

moment and shear force are compared with the SAFE results and found to be

identical. After completing the analysis, the design is performed using the AS

3600-09 code in SAFE and also by hand computation. Table 1 shows the

comparison of the design longitudinal reinforcements. Table 2 shows the

comparison of the design shear reinforcements.

EXAMPLE AS 3600-09 RC-BM-001 - 1

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

600 mm

75 mm 100 mm

500 mm

75 mm

300 mm

Beam Section

2000 mm 2000 mm 2000 mm

Shear Force

Bending Moment

Figure 1 The Model Beam for Flexural and Shear Design

EXAMPLE AS 3600-09 RC-BM-001 - 2

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

GEOMETRY, PROPERTIES AND LOADING

Clear span, l = 6000 mm

Overall depth, h = 500 mm

Flange thickness, ds = 100 mm

Width of web, bw = 300 mm

Width of flange, bf = 600 mm

Depth of tensile reinf., dc = 75 mm

Effective depth, d = 425 mm

Depth of comp. reinf., d' = 75 mm

Concrete strength, f' c = 30 MPa

Yield strength of steel, fy = 460 MPa

Concrete unit weight, wc = 0 kN/m3

Modulus of elasticity, Ec = 25x105 MPa

Modulus of elasticity, Es = 2x108 MPa

Poisson’s ratio, v = 0.2

Dead load, Pd = 30 kN

Live load, Pl = 130 kN

TECHNICAL FEATURES OF SAFE TESTED

Calculation of flexural and shear reinforcement

Application of minimum flexural and shear reinforcement

RESULTS COMPARISON

Table 1 shows the comparison of the SAFE total factored moments in the design

strip with the moments obtained by the analytical method. They match exactly

for this problem. Table 1 also shows the design reinforcement comparison.

Table 1 Comparison of Moments and Flexural Reinforcements

Reinforcement Area (sq-cm)

Method Moment (kN-m) As+

SAFE 462 33.512

Calculated 462 33.512

A +s ,min = 3.00 sq-cm

EXAMPLE AS 3600-09 RC-BM-001 - 3

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

Table 2 Comparison of Shear Reinforcements

Av

Reinforcement Area,

s

(sq-cm/m)

Shear Force (kN) SAFE Calculated

231 12.05 12.05

COMPUTER FILE: AS 3600-09 RC-BM-001.FDB

CONCLUSION

The SAFE results show an exact comparison with the independent results.

EXAMPLE AS 3600-09 RC-BM-001 - 4

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

HAND CALCULATION

Flexural Design

The following quantities are computed for all the load combinations:

ϕ = 0.8

α=

2 1.0 − 0.003 f 'c = 0.91 > 0.85, Use α 2 = 0.85

γ 1.05 − 0.007 f 'c = 0.84 < 0.85, Use γ = 0.84

=

amax = γk u d = 0.84 • 0.36 • 425 = 128.52 mm

D f ′ct , f

2

Ast .min = α b bw d , where

d f sy

for L- and T-Sections with the web in tension:

1/4

b D b

α b = 0.20 + f − 1 0.4 s − 0.18 ≥ 0.20 f =0.2378

bw D bw

D f ′ct , f

2

Ast .min = 0.2378 bd

d f sy

= 0.2378 • (500/425)2 • 0.6 • SQRT(30)/460 • 300*425

= 299.8 sq-mm

COMB130

N* = (1.2Nd + 1.5Nt) = 231kN

N *l

M* = = 462 kN-m

3

The depth of the compression block is given by:

2M *

a =−

d d2 − = 100.755 mm (a > Ds)

0.85 f 'c φ bef

The compressive force developed in the concrete alone is given by:

The first part is for balancing the compressive force from the flange, C f , and the

second part is for balancing the compressive force from the web, C w , 2. C f is

given by:

EXAMPLE AS 3600-09 RC-BM-001 - 5

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

C f = 0.85 f 'c (bef − bw )× min (Ds , amax ) = 765 kN

Cf

Therefore, As1 = and the portion of M* that is resisted by the flange is given by:

f sy

min (Ds , amax )

M uf = φC f d − = 229.5 kN-m

2

Cf

As1 = = 1663.043 sq-mm

f sy

Again, the value for φ is 0.80 by default. Therefore, the balance of the

moment, M* to be carried by the web is:

M=

uw M * − Muf = 462 – 229.5 = 232.5

The web is a rectangular section of dimensions b w and d, for which the design

depth of the compression block is recalculated as:

2 M uw

a1 =−

d d2 − = 101.5118 mm

0.85 f ′c φ bw

If a 1 ≤ a max , the area of tension reinforcement is then given by:

M uw

As 2 = = 1688.186 sq-mm

a1

φ f sy d −

2

Ast = As1 + As 2 = 3351.23 sq-mm = 33.512 sq-cm

Shear Design

The shear force carried by the concrete, V uc , is calculated as:

13

A

Vuc = β1β 2 β3bw d o f 'cv st = 0 kN

bw d o

where,

f 'cv = ( f 'c ) = 3.107 N/mm2 ≤ 4MPa

1/3

EXAMPLE AS 3600-09 RC-BM-001 - 6

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

do

β1 = 1.11.6 − ≥ 1.1 =1.2925, β 2 = 1 and β 3 = 1

1000

The shear force is limited to a maximum of:

Vu . max = 0.2 f 'c bd o = 765 kN

Given V*, V uc , and V u.max , the required shear reinforcement is calculated as

follows, where, φ, the strength reduction factor, is 0.7.

If V * ≤ φVuc / 2,

Asv

= 0 , if D ≤ 750 mm, otherwise A sv.min shall be provided.

s

If φVu.min < V * ≤ φVu.max ,

Asv

=

(

V * − φVuc ) ,

s φ f sy. f d o cot θ v

and greater than A sv.min, defined as:

Asv. min b

= 0.22826 sq-mm/mm = 228.26 sq-mm/m

= 0.35 w

s f sy . f

θ v = the angle between the axis of the concrete compression strut and the

longitudinal axis of the member, which varies linearly from 30

degrees when V*=φV u.min to 45 degrees when V*=φ V u,max = 35.52

degrees

If V * > φVmax , a failure condition is declared.

For load combination, the N* and V* are calculated as follows:

N* = 1.2Nd + 1.5N1

V* = N*

(COMB130)

Nd = 30 kips

Nl = 130 kips

N* = 231 kN

EXAMPLE AS 3600-09 RC-BM-001 - 7

Software Verification

PROGRAM NAME: SAFE

REVISION NO.: 0

N* = 231 kN, ( φVu.min < V * ≤ φVu.max , )

Asv

=

( )

V * − φVuc

, = 1.205 sq-mm/mm or 12.05 sq-cm/m

s φ f sy. f do cot θ v

EXAMPLE AS 3600-09 RC-BM-001 - 8

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Basic Requirements in Swimming Pool Construction - The ConstructorDokument10 SeitenBasic Requirements in Swimming Pool Construction - The ConstructorBunkun15Noch keine Bewertungen

- Swimming Pool Details Structures SampleDokument1 SeiteSwimming Pool Details Structures SampleBunkun15100% (3)

- How To Construct A Concrete Swimming Pool - (PDF) - The ConstructorDokument13 SeitenHow To Construct A Concrete Swimming Pool - (PDF) - The ConstructorBunkun15Noch keine Bewertungen

- Intake Tower Existing DamDokument3 SeitenIntake Tower Existing DamBunkun15Noch keine Bewertungen

- Title - Section 6-1.29 - Swimming Pool Design Standards - New York Codes, Rules and RegulationsDokument24 SeitenTitle - Section 6-1.29 - Swimming Pool Design Standards - New York Codes, Rules and RegulationsBunkun15Noch keine Bewertungen

- Checklist ResPoolsDokument7 SeitenChecklist ResPoolsBunkun15Noch keine Bewertungen

- Swimming Pool Roofing OptionsDokument2 SeitenSwimming Pool Roofing OptionsBunkun15100% (1)

- Swimming Pool Sample LayoutsDokument1 SeiteSwimming Pool Sample LayoutsBunkun15Noch keine Bewertungen

- Swimming Pool Site PlanDokument1 SeiteSwimming Pool Site PlanBunkun15Noch keine Bewertungen

- Starting A Bookstore BusinessDokument11 SeitenStarting A Bookstore BusinessBunkun15Noch keine Bewertungen

- 4 Ways To Book PublishingDokument7 Seiten4 Ways To Book PublishingBunkun15Noch keine Bewertungen

- IRSE Green BookDokument2 SeitenIRSE Green BookBunkun150% (1)

- How To Start A Bookstore BusinessDokument5 SeitenHow To Start A Bookstore BusinessBunkun15Noch keine Bewertungen

- University OrganogramDokument1 SeiteUniversity OrganogramBunkun15Noch keine Bewertungen

- Imperial College of Business Studies Employment Application FormDokument3 SeitenImperial College of Business Studies Employment Application FormBunkun15Noch keine Bewertungen

- Basements For HousingDokument2 SeitenBasements For HousingBunkun15Noch keine Bewertungen

- Stable Sprayed ConcreteDokument2 SeitenStable Sprayed ConcreteBunkun15Noch keine Bewertungen

- Simple Beam Deflection - Uniform Load Partially Distributed at Left EndDokument1 SeiteSimple Beam Deflection - Uniform Load Partially Distributed at Left EndBunkun15Noch keine Bewertungen

- Imperial College: of Business StudiesDokument1 SeiteImperial College: of Business StudiesBunkun15Noch keine Bewertungen

- SAP2000 Command LineDokument2 SeitenSAP2000 Command LineBunkun15Noch keine Bewertungen

- Import - SAP2000 MS Excel Spreadsheet .Xls File: New ModelDokument1 SeiteImport - SAP2000 MS Excel Spreadsheet .Xls File: New ModelBunkun15Noch keine Bewertungen

- Live Load Distribution Factor CalculationsDokument5 SeitenLive Load Distribution Factor CalculationsBunkun15Noch keine Bewertungen

- ETABS Insertion PointDokument3 SeitenETABS Insertion PointBunkun15Noch keine Bewertungen

- SAP2000 Sign CoventionDokument5 SeitenSAP2000 Sign CoventionBunkun15Noch keine Bewertungen

- ETABS Property ModifierDokument1 SeiteETABS Property ModifierBunkun150% (1)

- ETABS End OffsetDokument2 SeitenETABS End OffsetBunkun1567% (3)

- ETABS Joint RestraintsDokument2 SeitenETABS Joint RestraintsBunkun15100% (3)

- ETABS Section PropDokument1 SeiteETABS Section PropBunkun15Noch keine Bewertungen

- ETABS Additional MassDokument2 SeitenETABS Additional MassBunkun15Noch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Chemistry /pi Eɪtʃ/ Hydrogen Power Acidity Basicity Aqueous Solution H AlkalineDokument22 SeitenChemistry /pi Eɪtʃ/ Hydrogen Power Acidity Basicity Aqueous Solution H AlkalineCHUKWU VICTORNoch keine Bewertungen

- Battery Room Ventilation CalculationDokument17 SeitenBattery Room Ventilation Calculationzicus2010100% (1)

- Particulate Processing of Metals and CeramicsDokument98 SeitenParticulate Processing of Metals and CeramicsDamy Manesi0% (2)

- 1 4571a316ti69Dokument2 Seiten1 4571a316ti69Admir TalicNoch keine Bewertungen

- Timetal 834 Timet Data SheetDokument2 SeitenTimetal 834 Timet Data SheetBonnie AttardNoch keine Bewertungen

- Visual Examination of Welds - Welds 3-14Dokument64 SeitenVisual Examination of Welds - Welds 3-14carlos100% (1)

- MEBERC PhyChemDokument122 SeitenMEBERC PhyChemJames Ivan Palanas RotorNoch keine Bewertungen

- Wingwall StabilityDokument2 SeitenWingwall Stability98675Noch keine Bewertungen

- Fenner Drive Coupling Tire CouplingDokument5 SeitenFenner Drive Coupling Tire Couplinganandha kumara swamyNoch keine Bewertungen

- TraversingDokument14 SeitenTraversingZaff CarrickNoch keine Bewertungen

- Reductor SHB50-FDokument28 SeitenReductor SHB50-FJaime Casas-corderoNoch keine Bewertungen

- O Level Notes On Mass, Weight and DensityDokument8 SeitenO Level Notes On Mass, Weight and DensityRavi MothoorNoch keine Bewertungen

- MeteorologyPart1 196 QDokument193 SeitenMeteorologyPart1 196 QBharat HarmilapiNoch keine Bewertungen

- Purchase Item ListDokument6 SeitenPurchase Item ListSumit PandeyNoch keine Bewertungen

- Mechanical Properties of Matter IITJEEDokument14 SeitenMechanical Properties of Matter IITJEESiddharth AcharyaNoch keine Bewertungen

- Ultrasound Beam FormingDokument48 SeitenUltrasound Beam FormingSri Nivas ChandrasekaranNoch keine Bewertungen

- 6 MaxwelleqDokument7 Seiten6 MaxwelleqChristopher Jordan EvoniukNoch keine Bewertungen

- Stefan-Boltzmann Law: 2 H C Exp 1Dokument16 SeitenStefan-Boltzmann Law: 2 H C Exp 1RonyVargasNoch keine Bewertungen

- Sifat Listrik & MagnetDokument43 SeitenSifat Listrik & MagnetirmaNoch keine Bewertungen

- Is 8147Dokument170 SeitenIs 8147Asha JatalNoch keine Bewertungen

- BIOLS102-UOB-Chapter 2Dokument4 SeitenBIOLS102-UOB-Chapter 2Noor JanahiNoch keine Bewertungen

- 11th Chemistry Centum Coaching Team Question Paper English MediumDokument5 Seiten11th Chemistry Centum Coaching Team Question Paper English MediumpradeepvcpNoch keine Bewertungen

- Strenfth of Material, Mechanical DesignDokument194 SeitenStrenfth of Material, Mechanical Designabhishek anandNoch keine Bewertungen

- Internal Energy and The Ideal GasDokument9 SeitenInternal Energy and The Ideal GasfagroupandahmadsonsNoch keine Bewertungen

- Design Procedure For Steel Frame Structures According To Bs 5950Dokument46 SeitenDesign Procedure For Steel Frame Structures According To Bs 5950Chong Chee Yen100% (2)

- Thermo Reflection ScriptDokument2 SeitenThermo Reflection ScriptKhairul AznizamNoch keine Bewertungen

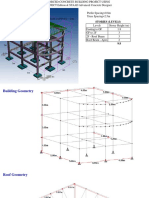

- 2 Storeys BuildingDokument30 Seiten2 Storeys BuildinglavyNoch keine Bewertungen

- Forces On Curved Surfaces 1Dokument13 SeitenForces On Curved Surfaces 1Yours PamoreNoch keine Bewertungen

- Tmp1a33 TMPDokument12 SeitenTmp1a33 TMPFrontiersNoch keine Bewertungen

- ME255-mod 2Dokument30 SeitenME255-mod 2Owusu Gyamera Justice DanielNoch keine Bewertungen