Beruflich Dokumente

Kultur Dokumente

Standard Commissioning Procedure For Building Exhaust Fans: General Notes

Hochgeladen von

Abdul Mohid SheikhOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Standard Commissioning Procedure For Building Exhaust Fans: General Notes

Hochgeladen von

Abdul Mohid SheikhCopyright:

Verfügbare Formate

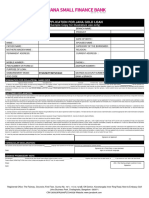

BUILDING EXHAUST FAN STANDARD COMMISSIONING PROCEDURE

PRO-________

STANDARD COMMISSIONING PROCEDURE FOR

BUILDING EXHAUST FANS

Building Name ____________________________________

PRO-______ EXHAUST FAN #’s____________________________

Associated Procedures: __________________________________________________

NAME & FIRM OF PERSON(S) DOING TEST:

DATE(S) OF TEST:

General Notes:

1. The Standard Commissioning Procedure for Air Handling Units should be used for building exhaust fans that are

integrated with supply air systems. It is not necessary to repeat commissioning documentation for such fans in

this form.

2. This is a set of generic test procedures for building exhaust fans. It addresses exhaust fan installation and

performance. If the complexity, configuration, or other aspects of a specific project require substitute tests or

additional tests, explain on the comments sheets, and attach the additional test procedures and field data.

Attach all relevant functional performance verification sheets, and always attach the final signed and dated

procedure certification page.

3. In all test sections, circle or otherwise highlight any responses that indicate deficiencies (i.e. responses that don’t

meet the criteria for acceptance). Acceptance requires correction and retest of all deficiencies, as defined in

each test section under “Criteria for Acceptance” or “Acceptance”. Attach all retest data sheets. Complete the

Deficiency Report Form for all deficiencies.

4. This Commissioning Procedure does not comprehensively address fire and life safety or basic equipment safety

controls.

5. To ensure that these Commissioning Procedures will not damage any equipment or affect any equipment

warranties, have the equipment manufacturers’ representatives review all test procedures prior to execution, as

relevant.

1. Approvals

I certify that the data and test results as recorded herein are accurate.

Signature, Commissioning Agent Date

Firm Name (Area Code) Phone Number

Notes:

File: 378004224.doc, Release 1.0, 9/97 Page 1

Building Name

BUILDING EXHAUST FAN STANDARD COMMISSIONING PROCEDURE

PRO-________

2. Operator Interview (Existing Buildings Only):

Determine from a discussion with the building operator whether the exhaust fans are operating properly to the best of

their knowledge. Note any known problems, and possible solutions.

3. Documentation on site or at Facilities (this section to be completed by CA)

Check if Okay. Enter comment or note number if deficient.

Check Equip Tag->

Equipment manufacturer’s submittals, inc. performance data, fan

curves, dimensional data, etc.

Installation and startup manual

Startup documentation (inc. VFD programming if applicable)

Test and Balance report

Sequences and control strategies

O&M manuals

· Documentation complete as per contract documents.................................___ YES ___ NO

Notes:

File: 378004224.doc, Release 1.0, 9/97 Page 2

Building Name

BUILDING EXHAUST FAN STANDARD COMMISSIONING PROCEDURE

PRO-________

4. Model verification (this section to be completed by CA)

1 = as specified, 2 = as submitted, 3 = as installed. Enter requested data. Check if Okay. Enter note number if

deficient.

Equip Tag-->

Service

(elevator room,

stairway, etc.)

1

Manuf. 2

3

1

Model 2

3

Serial # 3

1

Volts/Ph/A 2

3

1

CFM 2

3

1

S.P. 2

3

1

Motor Hp 2

3

1

RPM 2

3

1

Motor Effic 2

3

VFD Mfctr& 1 / / / / /

Model # 2 / / / / /

if applicable 3 / / / / /

· The equipment installed matches the specifications...................................___ YES ___ NO

Notes:

File: 378004224.doc, Release 1.0, 9/97 Page 3

Building Name

BUILDING EXHAUST FAN STANDARD COMMISSIONING PROCEDURE

PRO-________

5. Installation Checks

This section is to be completed by the Commissioning Agent (CA), Mechanical Contractor (MC), Electrical

Contractor (EC), or Control Contractor (CC), as noted in final column. Person checking off each item shall initial in

final column. Check if Okay. Enter comment or note number if deficient.

Check Equip Tag-> Contr. /

Initials

General Installation

General appearance good, no apparent damage CA/

TAB report section for unit reviewed & acceptable CA/

(Acceptance: design ±10%)

Controls point calibration report reviewed, as CA/

relevant?

Casing condition: dents, cracks, etc.? CA/

Shipping restraints removed? CA/

Vibration isolation devices installed & released from CA/

shipping restraints?

Seismic restraints installed per spec? CA/

Adequate maintenance access to all components? CA/

(inc. space & access doors)

Access doors close tightly? CA/

Discharge air damper moves freely / closes tightly? CA/

Equipment tags attached? CA/

Electrical

Electrical connections tight? CA/

Power disconnects properly labeled? CA/

Motor contactors in good condition? EC/

Motor overload heaters properly sized? EC/

Fan motor volts, rated CA/

Fan motor volts into motor. Acceptance: ±10% of CA/

rating, all phases

Fan motor FLA, rated CA/

Fan motor full speed Amps (record only for motors > CA/

2hp)

Fan motor measured Amps < Rated FLA? CA/

Notes:

File: 378004224.doc, Release 1.0, 9/97 Page 4

Building Name

BUILDING EXHAUST FAN STANDARD COMMISSIONING PROCEDURE

PRO-________

Check Equip Tag-> Contr. /

Initials

Fan:

Fan belt tension & condition okay? CA/

Fan rotation correct? CA/

Fan blades clean? CA/

Fan full speed RPM CA/

Fan VFD, if relevant:

Drive location not subject to excessive temperature, CA/

moisture, dirt

Drive size matches motor size CA/

Fan motor volts into drive. Acceptance: ±10% of CA/

rating, all phases

Voltage Imbalance into drive, % Acceptance: < 2% CA/

VFD maximum speed setting. Acceptance: 100% or CA/

60 Hz

VFD minimum speed setting. CA/

VFD motor full load speed setting. Acceptance: Equal CA/

to motor rating.

VFD motor frequency setting. Acceptance: same as CA/

rated motor freq.

VFD motor line voltage setting. Acceptance: same CA/

as rated motor voltage, usually 460 volts.

(VFD) Programmed accel./decel. time. Acceptance: CA/

10-60 seconds, or per mfctr.

No disconnects installed between VFD & motor EC/

without shutdown interlock to VFD?

Shutdown interlocks between VFD & motor verified to CA/

be operational?

Separate conduit for VFD incoming power and EC/

outgoing motor leads?

No power correction capacitors connected to motor? EC/

Motor rotation correct in bypass? CA/

VFD bypass mode verified? CA/

Notes:

File: 378004224.doc, Release 1.0, 9/97 Page 5

Building Name

BUILDING EXHAUST FAN STANDARD COMMISSIONING PROCEDURE

PRO-________

Check Equip Tag-> Contr. /

Initials

General Run Test:

Run Test: Observe unit under normal operation &

load 2 times in an 8 hour period, at least 3 hours

apart. Verify that there is no unusual noise, vibration,

or other problems

Observation #1: Time of Day / Acceptable? CA/

Observation #2: Time of Day / Acceptable? CA/

Notes:

File: 378004224.doc, Release 1.0, 9/97 Page 6

Building Name

BUILDING EXHAUST FAN STANDARD COMMISSIONING PROCEDURE

PRO-________

6. Functional Performance Verification:

The following sections are a series of field tests that are intended to verify that the exhaust fans, as installed, operate

as intended by the designer. Duplicate this page as required. Complete the tests under the control type relevant to

each fan.

Since there are many possible controls sequences for exhaust fans, it is impossible to write generic tests that cover all

such sequences. If the standard test procedures are not applicable or adequate, modify or replace the standard

procedures. Document the sequences, tests, and results at a level of rigor equal to or greater than that of the standard

test procedures. First describe in detail the approved control sequence. Next describe in detail what tests you plan to

do to verify each control sequence, along with any required test conditions. Finally, describe your test results and

conclusions, including any deficiencies found. Add sheets as necessary. It is not necessary to repeat any tests that

were documented in other standard commissioning procedures, but refer to those documents where relevant.

Attach to this form all relevant field data, monitored data, graphs, trend logs, and so forth. Annotate any data and

graphs so that it is clear what the data are proving. EMS trend logs of EMS outputs, program print-outs, or schedule

and setpoint print-outs are not acceptable as proof of operation, unless the information is first verified to be accurate

and documentation is attached. Trend logs of sensor inputs to the EMS are acceptable. If you were not able to

complete a test, explain in a comment.

Check Equip Tag-->

Control Type: T=temperature, M=manual,

TOD=time of day, INT=interlocked,

O=other (describe; e.g. CO, CO2, smoke)

For Temperature Controlled Fans:

1. Record temperature setpoint prior to

test changes

2. Is temp. setpoint reasonable?

3. Is sensor or stat location okay?

4. Measure & record temperature at

sensor or thermostat

5. Lower setpoint to 5 F deg below

measured temp & record new

setpoint

6. Does fan start?

7. Raise setpoint to 5 F deg above

measured temp & record new

setpoint

8. Does fan stop?

9. Reset setpoint to starting value &

record

10. Sequence verified?

Notes:

File: 378004224.doc, Release 1.0, 9/97 Page 7

Building Name

BUILDING EXHAUST FAN STANDARD COMMISSIONING PROCEDURE

PRO-________

Check Equip Tag-->

For Manually Controlled Fans:

11. Is manual switch properly located?

12. Switch fan off at switch. Does fan

stop?

13. Switch fan on at switch. Does fan

start?

14. Sequence verified?

For Time-of-Day Controlled Fans:

15. Record programmed start & stop

times (by day of week if S/S times

vary)

16. Is the start/stop schedule reasonable?

17. Observe or trend fan status during

scheduled ON time. Is fan on?

18. Observe or trend fan status during

scheduled OFF time. Is fan off?

19. Sequence verified?

For Interlocked Fans:

20. ID of controlling equipment

21. With controlling equipment ON, should

exhaust fan be ON or OFF?

22. Start test with exhaust fan on. Switch / / / / / /

status of controlling equipment &

note initial & final status.

23. Does exhaust fan stop?

24. Again switch status of controlling

equipment & note final status.

25. Does exhaust fan start?

26. Sequence verified?

Notes:

File: 378004224.doc, Release 1.0, 9/97 Page 8

Building Name

BUILDING EXHAUST FAN STANDARD COMMISSIONING PROCEDURE

PRO-________

Check Equip Tag-->

For Fans Controlled by Other

Means:

27. Describe control sequence as

designed.

28. Fill in test procedures and results in

spaces below

29.

30.

31.

32.

33.

34.

35.

36.

· The functional performance tests are all successfully completed.............................___ YES ___ NO

Notes:

File: 378004224.doc, Release 1.0, 9/97 Page 9

Building Name

Das könnte Ihnen auch gefallen

- PC - Packaged DX Air Conditioning or Heat Pump, IdDokument7 SeitenPC - Packaged DX Air Conditioning or Heat Pump, Idsushilalway4uNoch keine Bewertungen

- Electrical ChecklistDokument12 SeitenElectrical ChecklistAdhyartha KerafNoch keine Bewertungen

- Cooling Tower Construction ChecklistDokument6 SeitenCooling Tower Construction ChecklistGopinath GopiNoch keine Bewertungen

- Standard Commissioning Procedure For Evaporative Cooling SystemsDokument10 SeitenStandard Commissioning Procedure For Evaporative Cooling Systemsbedilu77Noch keine Bewertungen

- Chauvin Arnoux F05 PDFDokument36 SeitenChauvin Arnoux F05 PDFluis2006041380Noch keine Bewertungen

- Commissioning Procedure EngrDokument11 SeitenCommissioning Procedure EngrkumarNoch keine Bewertungen

- Pre - Functional Checklist Documentation 9Dokument5 SeitenPre - Functional Checklist Documentation 9renjithv_4Noch keine Bewertungen

- MC PartsDokument14 SeitenMC PartsManoj MariappanNoch keine Bewertungen

- Rmprtbiddoc PREFUNCTIONALCHECKLISTSDokument37 SeitenRmprtbiddoc PREFUNCTIONALCHECKLISTSDani HambalinaNoch keine Bewertungen

- Test Sample FormatsDokument13 SeitenTest Sample FormatsMohamed AshrafNoch keine Bewertungen

- 2.6.1.1 AHU - Construction.checklistDokument5 Seiten2.6.1.1 AHU - Construction.checklistHiếu Nguyễn100% (1)

- BMS T&C Manual PDFDokument25 SeitenBMS T&C Manual PDFSultan SikandarNoch keine Bewertungen

- ACU PM Checklist ADokument1 SeiteACU PM Checklist Aamdesilva125100% (1)

- PC - EXHAUST FANS ID #'SDokument3 SeitenPC - EXHAUST FANS ID #'SAbdul Mohid SheikhNoch keine Bewertungen

- Aucommissioningmaster - Part 5Dokument10 SeitenAucommissioningmaster - Part 5YapKJNoch keine Bewertungen

- Generic Test & Acceptance ChecklistDokument24 SeitenGeneric Test & Acceptance ChecklistM Kashif JunaidNoch keine Bewertungen

- Tooo': oOO OO.Dokument28 SeitenTooo': oOO OO.ediasianagriNoch keine Bewertungen

- SECTION 01813 Prefunctional ChecklistsDokument36 SeitenSECTION 01813 Prefunctional ChecklistsBalasuperamaniam RamanNoch keine Bewertungen

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListDokument17 SeitenSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListnadeemNoch keine Bewertungen

- gb4000c Opman 6164.1007.02 03Dokument48 Seitengb4000c Opman 6164.1007.02 03P Plaza MolinaNoch keine Bewertungen

- GE E4879 Certified Component Verification BSDDokument12 SeitenGE E4879 Certified Component Verification BSDEduardo RibasNoch keine Bewertungen

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDokument2 SeitenObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNoch keine Bewertungen

- Reply - Technical Bid Clarification - GEDokument18 SeitenReply - Technical Bid Clarification - GEhasanNoch keine Bewertungen

- York Comissioning FormDokument6 SeitenYork Comissioning Formfopoku2k2Noch keine Bewertungen

- Test - Comm.. For Gen. - ATS PanelDokument8 SeitenTest - Comm.. For Gen. - ATS PanelAhmedNoch keine Bewertungen

- Air Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationDokument6 SeitenAir Handling Unit Construction Checklist: Project: Date: AHU Tag: Building: LocationGopinath GopiNoch keine Bewertungen

- Observations & Comments Sheet (OCS) : Qatar Olympic CommitteeDokument2 SeitenObservations & Comments Sheet (OCS) : Qatar Olympic CommitteeIbrahim SirpiNoch keine Bewertungen

- Safe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsDokument9 SeitenSafe Work Method of Statement For Testing and Commissioning of Diesel GeneratorsHumaid ShaikhNoch keine Bewertungen

- 001 Gas Turbine Generator Commissioning ProcedureDokument62 Seiten001 Gas Turbine Generator Commissioning Proceduremghogha88% (8)

- Emm Task 05 20 00 95 210 801 G100372359 - 1641564260467Dokument7 SeitenEmm Task 05 20 00 95 210 801 G100372359 - 1641564260467marioNoch keine Bewertungen

- Check ListDokument6 SeitenCheck Listiman2222Noch keine Bewertungen

- SECTION 11 12 00 Parking Control EquipmentDokument10 SeitenSECTION 11 12 00 Parking Control EquipmentRima Baz FadousNoch keine Bewertungen

- (Temp) Checklist For Inspection & Functional Acceptance Tests in Factory and Pre-Commissioning Test On Site (Green V 3.0)Dokument12 Seiten(Temp) Checklist For Inspection & Functional Acceptance Tests in Factory and Pre-Commissioning Test On Site (Green V 3.0)pdrichNoch keine Bewertungen

- Iso Work InstructionsDokument115 SeitenIso Work InstructionsEkondroNoch keine Bewertungen

- TIC Information 12 Dec 2023Dokument43 SeitenTIC Information 12 Dec 2023Sayan KeawponwongNoch keine Bewertungen

- Ammeter, Voltmeter Testing Not Applicable For This PanelDokument3 SeitenAmmeter, Voltmeter Testing Not Applicable For This Paneleswaran005Noch keine Bewertungen

- 18.review Performance Test Procedure Rev 2Dokument6 Seiten18.review Performance Test Procedure Rev 2Akhmad SyukrieNoch keine Bewertungen

- BDokument1 SeiteBsyed jeelani ahmedNoch keine Bewertungen

- High Efficiency MotorsDokument3 SeitenHigh Efficiency MotorsDeclan4Noch keine Bewertungen

- Nternet Protocol Based CCTV CameraDokument1 SeiteNternet Protocol Based CCTV CameraJason SalazarNoch keine Bewertungen

- Auxiliary Relay Test Report: Sheet 1 of 1Dokument1 SeiteAuxiliary Relay Test Report: Sheet 1 of 1TariqMalikNoch keine Bewertungen

- 1.mechanical - Electrical Completion Inspection Checklist - E20812Dokument3 Seiten1.mechanical - Electrical Completion Inspection Checklist - E20812Lulu ChaniagoNoch keine Bewertungen

- SECTION 16208 Engine GeneratorsDokument38 SeitenSECTION 16208 Engine Generatorsno nameNoch keine Bewertungen

- EZM-9930 en MDokument48 SeitenEZM-9930 en MFawzi AlzubairyNoch keine Bewertungen

- Bac A4 Hazardous Area Power Supplies v6Dokument6 SeitenBac A4 Hazardous Area Power Supplies v6Taiwo AdenipekunNoch keine Bewertungen

- TD Commissioning Protocol Rev07 07gbDokument10 SeitenTD Commissioning Protocol Rev07 07gbPanupan ThakongNoch keine Bewertungen

- Check List For MCC and Capacitor Bank InstallationDokument2 SeitenCheck List For MCC and Capacitor Bank InstallationNaing Win TunNoch keine Bewertungen

- Delta Manual Control UG - V02Dokument24 SeitenDelta Manual Control UG - V02Adrián Darío Nieves LeyvaNoch keine Bewertungen

- Commissioning: Commissioning High Voltage EquipmentDokument14 SeitenCommissioning: Commissioning High Voltage Equipment2091979Noch keine Bewertungen

- 3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommDokument10 Seiten3 - VP-SP2021-ON-MA-0700-0029-0200 - 1 - Startup CommNishit KhuntNoch keine Bewertungen

- Tab Nebb PPT by Aipath 2010 PDFDokument80 SeitenTab Nebb PPT by Aipath 2010 PDFdiningkoNoch keine Bewertungen

- 2.6.3.1 Water - Cooled.chiller - Construction.checklistDokument4 Seiten2.6.3.1 Water - Cooled.chiller - Construction.checklistdana setiawanNoch keine Bewertungen

- ARIVU QAQC ENG Curriculum VitaeDokument3 SeitenARIVU QAQC ENG Curriculum Vitaearivazhaganverger2018Noch keine Bewertungen

- PRES-E-04 Electrical Equipment - Oil & TransformerDokument2 SeitenPRES-E-04 Electrical Equipment - Oil & TransformersalamlinNoch keine Bewertungen

- Eaton Guidespec Substation Tranformer Dry Type 26 12 16Dokument9 SeitenEaton Guidespec Substation Tranformer Dry Type 26 12 16Homero BasalduaNoch keine Bewertungen

- Transmission A40F Functional CheckDokument2 SeitenTransmission A40F Functional CheckMrAlbert2009100% (1)

- F5 Transmission Control: To IndexDokument77 SeitenF5 Transmission Control: To IndexKwun Hok ChongNoch keine Bewertungen

- Ach550 Pnpt02u en - RevfDokument5 SeitenAch550 Pnpt02u en - Revfahmed HOSNYNoch keine Bewertungen

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusVon EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNoch keine Bewertungen

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Tips & TricksDokument17 SeitenTips & TricksSatish KumarNoch keine Bewertungen

- Testing of Earth Leakage RelayDokument1 SeiteTesting of Earth Leakage RelayAbdul Mohid SheikhNoch keine Bewertungen

- Air Change CFM CalculatorDokument1 SeiteAir Change CFM CalculatorAbdul Mohid SheikhNoch keine Bewertungen

- Data Centers Cooling SystemsDokument3 SeitenData Centers Cooling SystemsAbdul Mohid SheikhNoch keine Bewertungen

- Air Conditioner BTU CalculatorDokument1 SeiteAir Conditioner BTU CalculatorAbdul Mohid SheikhNoch keine Bewertungen

- Purpose of Contact Resistance TestDokument1 SeitePurpose of Contact Resistance TestAbdul Mohid SheikhNoch keine Bewertungen

- Ground Testing in Difficult InstallationsDokument3 SeitenGround Testing in Difficult InstallationsAbdul Mohid SheikhNoch keine Bewertungen

- Rundown Tank Purpose and Working - Chemical Engineering WorldDokument2 SeitenRundown Tank Purpose and Working - Chemical Engineering WorldAbdul Mohid SheikhNoch keine Bewertungen

- Automation FAQDokument16 SeitenAutomation FAQtarunmgNoch keine Bewertungen

- Ball Valve Types and PartsDokument2 SeitenBall Valve Types and PartsAbdul Mohid SheikhNoch keine Bewertungen

- Pre RemovalDokument8 SeitenPre RemovalAbdul Mohid SheikhNoch keine Bewertungen

- Connections and Composition of LV, MV, HV Capacitor BanksDokument7 SeitenConnections and Composition of LV, MV, HV Capacitor BanksAbdul Mohid SheikhNoch keine Bewertungen

- Advances in SW Desal Voutchkov PDFDokument7 SeitenAdvances in SW Desal Voutchkov PDFAhmed AnsariNoch keine Bewertungen

- 4 Important Methods of Ground Resistance TestingDokument5 Seiten4 Important Methods of Ground Resistance TestingAbdul Mohid SheikhNoch keine Bewertungen

- Honeywell - APT4000 Series 4-Wire PH AnalyzersDokument8 SeitenHoneywell - APT4000 Series 4-Wire PH AnalyzersAbdul Mohid SheikhNoch keine Bewertungen

- The Most Common Methods of Measuring The Resistance of An Earth Electrode - EEP-001Dokument7 SeitenThe Most Common Methods of Measuring The Resistance of An Earth Electrode - EEP-001Abdul Mohid SheikhNoch keine Bewertungen

- The Most Common Methods of Measuring The Resistance of An Earth Electrode - EEP-001Dokument7 SeitenThe Most Common Methods of Measuring The Resistance of An Earth Electrode - EEP-001Abdul Mohid SheikhNoch keine Bewertungen

- Current Differential Line Protection Setting ConsiderationsDokument28 SeitenCurrent Differential Line Protection Setting ConsiderationskankokwahNoch keine Bewertungen

- Four Very Important Precautions For The Installation of Cables and Busbar Trunking SystemsDokument11 SeitenFour Very Important Precautions For The Installation of Cables and Busbar Trunking SystemsAbdul Mohid SheikhNoch keine Bewertungen

- Method of Statement For Fire Fighting Works (Part-1)Dokument5 SeitenMethod of Statement For Fire Fighting Works (Part-1)Abdul Mohid Sheikh100% (1)

- O&m Activities in SubstationDokument159 SeitenO&m Activities in SubstationDevidas KulkarniNoch keine Bewertungen

- General SpecificationDokument327 SeitenGeneral SpecificationmaymanyassinNoch keine Bewertungen

- PLC Implementation of Beverage Routing Control AlgorithmDokument67 SeitenPLC Implementation of Beverage Routing Control AlgorithmBesim BytyqiNoch keine Bewertungen

- Soiling Rates of PV Modules vs. Thermopile PyranometersDokument3 SeitenSoiling Rates of PV Modules vs. Thermopile PyranometersAbdul Mohid SheikhNoch keine Bewertungen

- Earthing System Calculation For Steel Factory Substation 132 11kV 40MVADokument29 SeitenEarthing System Calculation For Steel Factory Substation 132 11kV 40MVAsahli medNoch keine Bewertungen

- Honeywell - APT4000 Series 4-Wire PH AnalyzersDokument8 SeitenHoneywell - APT4000 Series 4-Wire PH AnalyzersAbdul Mohid SheikhNoch keine Bewertungen

- Gas Insulated Substation Definitions and BasicsDokument36 SeitenGas Insulated Substation Definitions and Basicsmani_208eeNoch keine Bewertungen

- Ring Main Unit (RMU) As An Important Part of Secondary Distribution SubstationsDokument4 SeitenRing Main Unit (RMU) As An Important Part of Secondary Distribution SubstationsAbdul Mohid SheikhNoch keine Bewertungen

- IEC 61439: The Mystery of The Temperature Rise Limits: An Alert To Low-Voltage Switchgear BuyersDokument3 SeitenIEC 61439: The Mystery of The Temperature Rise Limits: An Alert To Low-Voltage Switchgear BuyersAbdul Mohid SheikhNoch keine Bewertungen

- PTL Whats New v3 80 EnuDokument6 SeitenPTL Whats New v3 80 EnuNababan Muhammad Saleh MangatasNoch keine Bewertungen

- Handout Waste Catch BasinDokument2 SeitenHandout Waste Catch BasinJonniel De GuzmanNoch keine Bewertungen

- Iso 22301 2019 en PDFDokument11 SeitenIso 22301 2019 en PDFImam Saleh100% (3)

- Action Plan in T.L.E Project Title Objectives Activities Person-In-Charge Time Frame Success IndicatorDokument1 SeiteAction Plan in T.L.E Project Title Objectives Activities Person-In-Charge Time Frame Success IndicatorEdelmar BenosaNoch keine Bewertungen

- 12 Logarithm Approximate FloatingDokument6 Seiten12 Logarithm Approximate FloatingPhilippe Englert VelhaNoch keine Bewertungen

- High Speed Power TransferDokument33 SeitenHigh Speed Power TransferJAYKUMAR SINGHNoch keine Bewertungen

- Bassoon (FAGOT) : See AlsoDokument36 SeitenBassoon (FAGOT) : See Alsocarlos tarancón0% (1)

- 00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentDokument4 Seiten00022443the Application of A Continuous Leak Detection System To Pipelines and Associated EquipmentFaizal AbdullahNoch keine Bewertungen

- Ortho TechnologyDokument196 SeitenOrtho Technologyr3doc3Noch keine Bewertungen

- Lecture BouffonDokument1 SeiteLecture BouffonCarlos Enrique GuerraNoch keine Bewertungen

- MC4 CoCU 6 - Welding Records and Report DocumentationDokument8 SeitenMC4 CoCU 6 - Welding Records and Report Documentationnizam1372100% (1)

- Adolescents' Gender and Their Social Adjustment The Role of The Counsellor in NigeriaDokument20 SeitenAdolescents' Gender and Their Social Adjustment The Role of The Counsellor in NigeriaEfosaNoch keine Bewertungen

- Gold Loan Application FormDokument7 SeitenGold Loan Application FormMahesh PittalaNoch keine Bewertungen

- Banin Cawu 1: Panitia Ujian Perguruan Islam Mathali'Ul FalahDokument4 SeitenBanin Cawu 1: Panitia Ujian Perguruan Islam Mathali'Ul FalahKajen PatiNoch keine Bewertungen

- Level I 2018 2019 Program Changes PDFDokument2 SeitenLevel I 2018 2019 Program Changes PDFMuhammad BurairNoch keine Bewertungen

- Monster Hunter: World - Canteen IngredientsDokument5 SeitenMonster Hunter: World - Canteen IngredientsSong HoeNoch keine Bewertungen

- Oracle SOA Suite Oracle Containers For J2EE Feature Overview OC4JDokument10 SeitenOracle SOA Suite Oracle Containers For J2EE Feature Overview OC4JLuis YañezNoch keine Bewertungen

- Passage Planning: Dr. Arwa HusseinDokument15 SeitenPassage Planning: Dr. Arwa HusseinArwa Hussein100% (3)

- Evan Lagueux - H Argument EssayDokument7 SeitenEvan Lagueux - H Argument Essayapi-692561087Noch keine Bewertungen

- Full Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full ChapterDokument13 SeitenFull Download University Physics With Modern Physics 14th Edition Young Test Bank PDF Full Chapterpoetrycloudyzjm12q100% (19)

- Linux and The Unix PhilosophyDokument182 SeitenLinux and The Unix PhilosophyTran Nam100% (1)

- CryptogrophyDokument37 SeitenCryptogrophyFarah EssidNoch keine Bewertungen

- Speaking RubricDokument1 SeiteSpeaking RubricxespejoNoch keine Bewertungen

- Week 3 Alds 2202Dokument13 SeitenWeek 3 Alds 2202lauren michaelsNoch keine Bewertungen

- FIGMADokument22 SeitenFIGMACessNoch keine Bewertungen

- Ims DB DCDokument90 SeitenIms DB DCpvnkraju100% (1)

- Details Philippine Qualifications FrameworkDokument6 SeitenDetails Philippine Qualifications FrameworkCeline Pascual-RamosNoch keine Bewertungen

- ManualDokument24 SeitenManualCristian ValenciaNoch keine Bewertungen

- Lesson 1 Concepts About Educational TechnologyDokument17 SeitenLesson 1 Concepts About Educational TechnologyMarvin ContigaNoch keine Bewertungen

- 835 (Health Care Claim PaymentAdvice) - HIPAA TR3 GuideDokument306 Seiten835 (Health Care Claim PaymentAdvice) - HIPAA TR3 Guideअरूण शर्माNoch keine Bewertungen

- S3 U4 MiniTestDokument3 SeitenS3 U4 MiniTestĐinh Thị Thu HàNoch keine Bewertungen