Beruflich Dokumente

Kultur Dokumente

Heat Transfer Through Pipe and Insulation

Hochgeladen von

ballisnothingCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Heat Transfer Through Pipe and Insulation

Hochgeladen von

ballisnothingCopyright:

Verfügbare Formate

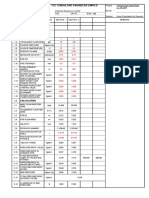

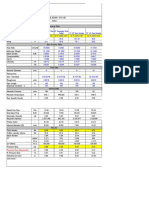

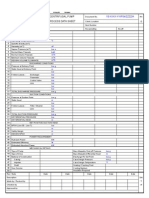

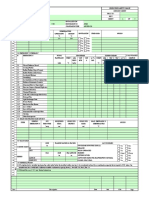

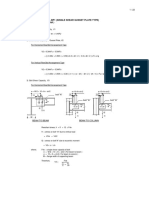

Pipe 58"-9.

52mm with 212mm refactory

Refractory: Low Thermal Mass (Ceramic Fibre) Heat Transfer through Pipe Calculation

Thermal Conductivity 0.3 W/m.K Horizntal cylinder in natural convection to be considered. for Outside Surface Temperature Approximation

For air around 30 deg.C (approx.)

Pipe OD 1.4732 m

Pipe Thk 0.00952 m Ta 292 K Ta = 19 deg.C

Refac. Thk 0.212 m g 9.81 m/s2

Ins. Thk 0 m β 0.003 1/K

ΔT 113 K assumed To = 132 deg.C

D 1.4732 m (iterate until To at output is close to To input)

Ti = 750 deg.C ν 0.00001475 m2/s

α 0.00002078 m2/s

ri 0.515 m k 0.02544 W/m.K

rp 0.727 m

rc 0.737 m RaD 3.96E+10

ro 0.737 m Pr 0.704

kr 0.3 W/m.K

kp 45 W/m.K

ki 0.065 W/m.K

NuD 374.2174

ΔT ΔT

Q= =( )

h 6.4622 W/m2.K

∑R R n

Q

3378.66

Ti Rf Tp

refac. Rf 1.83E-01 K/m.W 750 1.83E-01 132

pipe Rp 4.60E-05 K/m.W

ins. Rc 0.00E+00 K/m.W Q

air conv. Ra 3.34E-02 K/m.W 3378.66

Tp Rp Tc

ΣR 2.16E-01 K/m.W 132 4.60E-05 132

ΔT 731 K

Q

Q 3378.66 W/m (per 1 unit length) 3378.66

Tc Rc To

132 0.00E+00 132 <<< PIPE SKIN TEMPERATURE (°C)

02/05/2018 Heat transfer through pipe with refactory and insulation Pipe Stress Engineering

Das könnte Ihnen auch gefallen

- Line Sizing LiqDokument12 SeitenLine Sizing LiqDana GuerreroNoch keine Bewertungen

- Strainer Drop PressureDokument2 SeitenStrainer Drop PressureJose Manuel Cervantes0% (1)

- TBE Inlet Separator V 2100 FLNG2Dokument6 SeitenTBE Inlet Separator V 2100 FLNG2halipzramlyzNoch keine Bewertungen

- Binoy's Engg DatasDokument29 SeitenBinoy's Engg DatasSreejith GNoch keine Bewertungen

- Pump (English) TemplateDokument1 SeitePump (English) TemplateMichael HaiseNoch keine Bewertungen

- Steam Pressure DropDokument8 SeitenSteam Pressure DropDavid Muñoz CastroNoch keine Bewertungen

- Basket Filter CalcDokument17 SeitenBasket Filter CalcRajesh NareNoch keine Bewertungen

- Calculation Cover Sheet: ClientDokument9 SeitenCalculation Cover Sheet: Clientanamaria ursuNoch keine Bewertungen

- Input Data: Tce Consulting Engineers LimitedDokument2 SeitenInput Data: Tce Consulting Engineers Limitedsaptarshi samantaNoch keine Bewertungen

- 302 - Nozzle Design Tool Ver E4.01Dokument2 Seiten302 - Nozzle Design Tool Ver E4.01Honey TiwariNoch keine Bewertungen

- Trunnion CalculationDokument92 SeitenTrunnion CalculationkarunaNoch keine Bewertungen

- Calculation Cover SheetDokument6 SeitenCalculation Cover SheetAnonymous a4Jwz14WNoch keine Bewertungen

- Calculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesDokument5 SeitenCalculation Tool Heat Flux Through A Single Pipe KNOWING Skin TemperaturesselisenNoch keine Bewertungen

- Pressure DropDokument19 SeitenPressure DropGigis Kintan MyarthalunaNoch keine Bewertungen

- Heat Loss Insulated PipeDokument32 SeitenHeat Loss Insulated PipeDougMooreNoch keine Bewertungen

- Heat Loss From A Buried Oil PipeDokument20 SeitenHeat Loss From A Buried Oil PipeJuan Pablo ApazaNoch keine Bewertungen

- Cavitation-Pump-Pipe-Skid CalcDokument56 SeitenCavitation-Pump-Pipe-Skid CalcOltun KAYANoch keine Bewertungen

- Nozzle Check Top Head: Input ParametersDokument2 SeitenNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- Maz - Design - Separator Capacity EvaluationDokument5 SeitenMaz - Design - Separator Capacity EvaluationNaeem HussainNoch keine Bewertungen

- Condensate Line SizingDokument2 SeitenCondensate Line SizingAnonymous oVRvsdWzfBNoch keine Bewertungen

- Shell & Dish ThicknessDokument3 SeitenShell & Dish Thicknesskirandas_mullasseryNoch keine Bewertungen

- Steam Tracing Excel 2007Dokument74 SeitenSteam Tracing Excel 2007cybermineNoch keine Bewertungen

- Gas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, TeesDokument4 SeitenGas Line Sizing by API 14E Method Revision #: ??: Pressure Drop (Fittings Etc) Elbows, Tees Elbows, Tees Elbows, Teesusaid saifullahNoch keine Bewertungen

- Gas Line Sizing - Api 14E Input Description Unit: General DataDokument13 SeitenGas Line Sizing - Api 14E Input Description Unit: General DataSamuel Onyewuenyi100% (1)

- CPF-010 Process Line Sizing Attachment - 0Dokument38 SeitenCPF-010 Process Line Sizing Attachment - 0goodspeed_ph100% (1)

- Flange Loading CheckDokument48 SeitenFlange Loading CheckrefuzerNoch keine Bewertungen

- Volume Calculation For Pressure Vessel TankDokument2 SeitenVolume Calculation For Pressure Vessel Tanksai srikarNoch keine Bewertungen

- Top Pipe MomentDokument2 SeitenTop Pipe MomentrsubramaniNoch keine Bewertungen

- Vdocuments - MX Rectangular Tank CalculationDokument34 SeitenVdocuments - MX Rectangular Tank CalculationAtilla TekinNoch keine Bewertungen

- Valve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016Dokument4 SeitenValve Sizing Calculation Sheet: Version: V3.1.0 Date: 20/01/2016JOSE MARTIN MORA RIVEROSNoch keine Bewertungen

- Pipe Wall THK Calc For External PressureDokument2 SeitenPipe Wall THK Calc For External PressurektejankarNoch keine Bewertungen

- Heat Exchanger CalcDokument34 SeitenHeat Exchanger Calcميثة الغيثيةNoch keine Bewertungen

- Line Losses (Fittings) ΔP (ft) ΔP (ft)Dokument3 SeitenLine Losses (Fittings) ΔP (ft) ΔP (ft)ahmadlieNoch keine Bewertungen

- Pressure Drop CalculatorDokument12 SeitenPressure Drop CalculatorKevin PratyatamaNoch keine Bewertungen

- CN5191 - L2 - A1-Centrifugal Pump Process Data SheetDokument1 SeiteCN5191 - L2 - A1-Centrifugal Pump Process Data SheetMochi CumilinaNoch keine Bewertungen

- Vertical Separator SizingDokument4 SeitenVertical Separator SizingnemprrNoch keine Bewertungen

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDokument4 SeitenWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- Pt. Bahana Karya Mandiri: Data SheetDokument8 SeitenPt. Bahana Karya Mandiri: Data SheetBowo Edhi WibowoNoch keine Bewertungen

- Find Eq - Length (M) :: Manual Pressure Drop CalculationDokument7 SeitenFind Eq - Length (M) :: Manual Pressure Drop Calculationcryptic postNoch keine Bewertungen

- 2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Dokument20 Seiten2654 - Pipe Wall Thickness Calculation As Per ASME B31.3Sridhar Vijayan100% (3)

- Pressure Loss / Source Pressure Calculator - For Fighting System PipesDokument4 SeitenPressure Loss / Source Pressure Calculator - For Fighting System PipesRn KisNoch keine Bewertungen

- CPF-010 Utility Line Sizing Attachment - 0Dokument31 SeitenCPF-010 Utility Line Sizing Attachment - 0goodspeed_phNoch keine Bewertungen

- Ppgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Dokument10 SeitenPpgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Tifano KhristiyantoNoch keine Bewertungen

- Dps-3-1206-013-E1782-A4-2 (Final)Dokument449 SeitenDps-3-1206-013-E1782-A4-2 (Final)Siva baalanNoch keine Bewertungen

- Calculation AgitatorDokument3 SeitenCalculation AgitatorKrishnaAgarwalNoch keine Bewertungen

- Line Stop Welded To Shoe CalculationDokument16 SeitenLine Stop Welded To Shoe CalculationmohdnazirNoch keine Bewertungen

- No Yes No Yes No Yes No Yes No Yes No YesDokument8 SeitenNo Yes No Yes No Yes No Yes No Yes No YesEkundayo JohnNoch keine Bewertungen

- Separator All Oil and Gas SpreadsheetDokument22 SeitenSeparator All Oil and Gas SpreadsheetSatria 'igin' Girindra Nugraha100% (1)

- Super CalculationsDokument9 SeitenSuper CalculationsNoé MarínNoch keine Bewertungen

- PY SEW Do P T: Pipe Wall Thickness Calculation SheetDokument1 SeitePY SEW Do P T: Pipe Wall Thickness Calculation Sheetanon_714194540Noch keine Bewertungen

- Trunnion Calculation - MasterDokument92 SeitenTrunnion Calculation - MasterSrisaran Srinivas ArasavelliNoch keine Bewertungen

- Sp-210-E-103 Rev 0Dokument7 SeitenSp-210-E-103 Rev 0Natarajan RavisankarNoch keine Bewertungen

- Skirt Support TrialDokument11 SeitenSkirt Support TrialAbhishek Nag0% (1)

- Chapter 3 SolutionsDokument6 SeitenChapter 3 SolutionsAnonymous GjWVoVAnWYNoch keine Bewertungen

- HT Rate Calculations - Helical CoilsDokument4 SeitenHT Rate Calculations - Helical CoilssandeshNoch keine Bewertungen

- Solutions To Home Work # 1: 3-14C Convection Heat Transfer Through The Wall Is Expressed AsDokument6 SeitenSolutions To Home Work # 1: 3-14C Convection Heat Transfer Through The Wall Is Expressed Aspriyadarshini212007Noch keine Bewertungen

- Calculo Radiación TérmicaDokument9 SeitenCalculo Radiación TérmicamarcmanichNoch keine Bewertungen

- Pipeline Pressurisation & de Pressurisation CalculationDokument4 SeitenPipeline Pressurisation & de Pressurisation Calculationhatakerobot50% (2)

- CondenserDokument5 SeitenCondensersandeshNoch keine Bewertungen

- Staff Quarter Type-H DBR For Upper Veda WTP 28-12-2023Dokument25 SeitenStaff Quarter Type-H DBR For Upper Veda WTP 28-12-2023PramodNoch keine Bewertungen

- Limestone Processing HandbookDokument24 SeitenLimestone Processing HandbookballisnothingNoch keine Bewertungen

- Use Case Diagram: Bunny HostelDokument2 SeitenUse Case Diagram: Bunny HostelballisnothingNoch keine Bewertungen

- Codeware, Inc.: Houston, TX, USADokument45 SeitenCodeware, Inc.: Houston, TX, USAballisnothingNoch keine Bewertungen

- BiomassGasification 2010 PDFDokument64 SeitenBiomassGasification 2010 PDFballisnothingNoch keine Bewertungen

- Mathematics and AlgorithmsDokument468 SeitenMathematics and Algorithmsandeh100% (1)

- Biomass GasificationDokument21 SeitenBiomass GasificationLê Đức PhúNoch keine Bewertungen

- Understanding FFTs and WindowingDokument15 SeitenUnderstanding FFTs and WindowingSamruddha ThakurNoch keine Bewertungen

- 06 Practical Design ApproachDokument10 Seiten06 Practical Design ApproachballisnothingNoch keine Bewertungen

- Ten Steps To An Effective Bin Design - AIChEDokument8 SeitenTen Steps To An Effective Bin Design - AIChEhwang2Noch keine Bewertungen

- 1.8 3D Coupled CFD FEM Code Strategy - Hannink - 20081007Dokument13 Seiten1.8 3D Coupled CFD FEM Code Strategy - Hannink - 20081007ballisnothingNoch keine Bewertungen

- 3D Data ModelDokument58 Seiten3D Data ModelballisnothingNoch keine Bewertungen

- 02 Stress Analysis of Piping System and Code Requirements ASME B31.3Dokument40 Seiten02 Stress Analysis of Piping System and Code Requirements ASME B31.3ballisnothing100% (2)

- SmartSketch Drawing Editor Document BasicsDokument51 SeitenSmartSketch Drawing Editor Document Basicsballisnothing100% (3)

- 06 Triangle Fluid Control Leakage Behavior of Gaskets in Flanged ConnectionsDokument24 Seiten06 Triangle Fluid Control Leakage Behavior of Gaskets in Flanged ConnectionsballisnothingNoch keine Bewertungen

- 03 Pipe Supports and Pipe RestraintsDokument19 Seiten03 Pipe Supports and Pipe RestraintsballisnothingNoch keine Bewertungen

- Caesar Ii: Project Execution and Project Setup Files/FoldersDokument18 SeitenCaesar Ii: Project Execution and Project Setup Files/FoldersballisnothingNoch keine Bewertungen

- 05 Basic CII OperationDokument17 Seiten05 Basic CII OperationballisnothingNoch keine Bewertungen

- 30-09 Oko FinallDokument6 Seiten30-09 Oko FinallZoebairNoch keine Bewertungen

- Hopper DesigningDokument34 SeitenHopper DesigningZaeem Uddin Ali100% (2)

- Anchor Bolt: Table J3.2 AISC ASD Table J3.2 AISC ASDDokument15 SeitenAnchor Bolt: Table J3.2 AISC ASD Table J3.2 AISC ASDballisnothingNoch keine Bewertungen

- Solids Flow Bins Hoppers Feeders Marinelli PDFDokument10 SeitenSolids Flow Bins Hoppers Feeders Marinelli PDFJakesNoch keine Bewertungen

- Structural Design of Steel Bins and SilosDokument36 SeitenStructural Design of Steel Bins and Silosyoussefayay92% (12)

- BP1 Bolt Connection CapacityDokument22 SeitenBP1 Bolt Connection CapacityballisnothingNoch keine Bewertungen

- Flange and Gasket Detail PDFDokument74 SeitenFlange and Gasket Detail PDFumar_hazrad8219Noch keine Bewertungen

- Standard Shoe Verification Rev - ADokument19 SeitenStandard Shoe Verification Rev - AballisnothingNoch keine Bewertungen

- Refrigeration & Freezing of FoodsDokument60 SeitenRefrigeration & Freezing of Foodsorenchladee100% (3)

- CORR A SEAL Handbook PDFDokument60 SeitenCORR A SEAL Handbook PDFballisnothingNoch keine Bewertungen

- 3D Data ModelDokument58 Seiten3D Data ModelballisnothingNoch keine Bewertungen

- UKOOA GRP 1994 IncompletedDokument161 SeitenUKOOA GRP 1994 IncompletedballisnothingNoch keine Bewertungen

- Ebook Ebook PDF Principles of Physics A Calculus Based Text Hybrid 5th Edition PDFDokument38 SeitenEbook Ebook PDF Principles of Physics A Calculus Based Text Hybrid 5th Edition PDFpatrick.weber681100% (28)

- Unit 1Dokument2 SeitenUnit 1kick singhNoch keine Bewertungen

- Exam 010601Dokument3 SeitenExam 010601alialavi2Noch keine Bewertungen

- ME212 Dynamics - CHPT 15Dokument63 SeitenME212 Dynamics - CHPT 15FAHAD STARNoch keine Bewertungen

- Microprocessor Heat SinkDokument7 SeitenMicroprocessor Heat SinkSteven BiascaNoch keine Bewertungen

- Topic 4.5 Formative Answer KeyDokument1 SeiteTopic 4.5 Formative Answer Key이수연Noch keine Bewertungen

- Electromagnetic Waves Solutions Manual - InanDokument156 SeitenElectromagnetic Waves Solutions Manual - Inansurajvidhata55% (11)

- SHM Test SheetDokument8 SeitenSHM Test SheetMohammad UmairNoch keine Bewertungen

- Special Relativity ExamplesDokument10 SeitenSpecial Relativity ExamplesMaryam Taba100% (1)

- Fiber Optic CommunicationDokument181 SeitenFiber Optic CommunicationECE HoD PSNCET100% (1)

- Fundamentals of Fluid Mechanics 8th Edition Solution ManualDokument14 SeitenFundamentals of Fluid Mechanics 8th Edition Solution ManualS Trooper29Noch keine Bewertungen

- Physics One Shot For NEET 2024Dokument4 SeitenPhysics One Shot For NEET 2024Vaishnavi Srivastava 11BNoch keine Bewertungen

- Chapter OneDokument59 SeitenChapter OneAbenezer MarkNoch keine Bewertungen

- Basics of Rotating Machines: Energy TransferDokument11 SeitenBasics of Rotating Machines: Energy Transfernico NicoNoch keine Bewertungen

- Ultrasonic Waves Are Waves Above 20000Hz Infrasonic Waves Most Bat and Dog Communication Is Ultrasonic While Elephants and Whales Are InfrasonicDokument4 SeitenUltrasonic Waves Are Waves Above 20000Hz Infrasonic Waves Most Bat and Dog Communication Is Ultrasonic While Elephants and Whales Are InfrasonicSyamira ZakariaNoch keine Bewertungen

- Physics Principles With Applications 7th Edition Giancoli Solutions ManualDokument31 SeitenPhysics Principles With Applications 7th Edition Giancoli Solutions ManualNatalieWilsonkmgaf100% (10)

- Uniformly Accelerated MotionDokument20 SeitenUniformly Accelerated MotionSilver RitzNoch keine Bewertungen

- Importance of Dimensionless Numbers in Mass TransferDokument27 SeitenImportance of Dimensionless Numbers in Mass TransferAli AmmarNoch keine Bewertungen

- Stars N GalaxiesDokument56 SeitenStars N Galaxiesnozel77Noch keine Bewertungen

- 8 01 Fall 1999 Assign7Dokument2 Seiten8 01 Fall 1999 Assign7Sarvesh KanaujiaNoch keine Bewertungen

- Physics Midterm Practice TestDokument4 SeitenPhysics Midterm Practice TestSebastianPosadaNoch keine Bewertungen

- DCC MicroprojectDokument25 SeitenDCC MicroprojectSaniya PuchalwarNoch keine Bewertungen

- Nicol PrismDokument2 SeitenNicol PrismPushpendra KumarNoch keine Bewertungen

- Acoustics The Science of SoundDokument132 SeitenAcoustics The Science of SoundDelaniaD100% (4)

- Chapter 15 PDFDokument6 SeitenChapter 15 PDFabdullah adNoch keine Bewertungen

- Problem 12-26Dokument2 SeitenProblem 12-26Amelia SantosNoch keine Bewertungen

- Heat Transfer - Chap5 - Natural ConvectionDokument43 SeitenHeat Transfer - Chap5 - Natural ConvectionNelNoch keine Bewertungen

- 3.7.2.4 Orbits of Planets and SatellitesDokument55 Seiten3.7.2.4 Orbits of Planets and SatellitesRutba SafdarNoch keine Bewertungen

- Phy Chapter Wise P1 P3Dokument277 SeitenPhy Chapter Wise P1 P3sidharthNoch keine Bewertungen

- Handout For Science Odl - Level Auto-HerDokument77 SeitenHandout For Science Odl - Level Auto-HerKennedy MulengaNoch keine Bewertungen