Beruflich Dokumente

Kultur Dokumente

DECIPHER Hydraulic Disk Brakes Bleeding Manual

Hochgeladen von

iridiusOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DECIPHER Hydraulic Disk Brakes Bleeding Manual

Hochgeladen von

iridiusCopyright:

Verfügbare Formate

PROMAX DSK -913 HYDRAULIC DISC BRAKE MAINTENANCE

1 2 3 MANUAL

7 9

12

4) Slightly pull upright the plunger of M5 injector to suck all the air inside lever bracket and hose. Then

continuing pressing the plunger to add brake fluid. Repeat press - pull loop several times until there is no

REPAIR AND MAINTENANCE

“PROMAX“ hydraulic disc brake uses DOT.4 brake fluid. It is compatible with other brands of DOT.4. bubble coming out. <Photo 7,8>

(But don’t mixed use with different brands) NOTICE:

PRECAUTION: a. Make sure that the injector is fully locked into fluid-filling hole and sealed. If there are continuous

1) Never use the brake fluid other than DOT.4 Series or add any mineral oil to “PROMAX” hydraulic disc brake. air bubbles coming up while pulling the plunger of the injector, lock the injector tighter (or use an

Otherwise, the rubber parts in the hydraulic system will be damaged and braking function may be lost. 8mm open wrench).

2) After a certain period of application, the temperature resistance of the brake fluid will be decreased. b. When installing injector, turn the steel screw. Do not turn the plastic part of the injector or the

For safety, it is recommended to change the brake fluid periodically about every 1 year. plastic joint may be broken.

3) DO NOT try to disassemble or modify the hydraulic disc brake in any way. Service on this product c. Hold the outer body of injector and actuate the plunger of injector to prevent plastic part breaking

MUST be performed ONLY by qualified professional mechanics that are familiar with and understand during pressing and pulling injector. <Photo 7,8>

the technical details of how this product works. 5) Before removing the injector, press slightly the plunger to make the reservoir is under positive pressure.

1. Brake hose cut-short process Then remove the injector. If the screw hole is not full of fluid, you may need to repeat step 4.

Tools and Accessories Required: 6) Tighten the fluid-filling bolt. (locking torque 20~30 kg-cm) Clean lever bracket with wet tissue paper.

Clip ring x 1 Hose connector x 1 Hose bolt x 1

7) Depress brake lever several times. If the brake feeling is stiff, it means the brake is ready for service.

Hose cutter Hose Wrench:8mm Tape Measure

Adjust lever bracket to preferred angle. If not, there must be some air inside the brake system. Redo

Tissue Paper

step 3 to 6.

※ Use PROMAX DC913 designated brake hose.

3. Brake fluid replacement

1) Place the bike in a steady standing position. Tools and Accessories Required:

2) Loosen hose bolt completely with an 8mm hose wrench. Pull hose away from the lever bracket. Shake 2 empty cans for fresh & used fluid Fresh DOT.4 brake fluid, 25 cc

hose to make it easier to pull out if necessary. Take care to avoid the residual fluid leaking. Wipe and Torx wrench, T10 Allen wrench 3, 4, 5mm Minus screw driver

make it clean if the brake fluid leaks. <Photo 1> 20cc injector, M5 x 2 Spacer, 10.5mm thick

3) Measure the hose length needed according to the size of front fork/frame with tape measure. Cut brake

hose with hose cutter. <Photo 2> 1) Place the bike in a steady standing position.

NOTICE: 2) Loosen lever bracket with a 4mm Allen wrench. Turn the lever bracket till the fluid-filling hole beside the

a. Please reconfirm again that hose length is enough before cutting. The hose cannot be longer oil reservoir is upright and tighten the lever bracket.

after cut-short. 3) Remove the caliper from the fork/frame, leaving the adapter on the fork/frame.

b. The cut end should be clean, flat and perpendicular to the hose itself. 4) Insert a “minus screw driver” into the gap of brake pads, push brake pads back to the end. Remove

c. Do not depress the lever during the whole hose cutting process because it will let the brake fluid brake pads and pad spring. (See the instruction for “Pad Removal”) Clean pad recess of caliper.

flow out or spurt. 5) Insert 10.8mm spacer into pad recess and lock it with a rubber band. <Photo 9>

4) Slide hose bolt over the hose first and clip ring second. <Photo 3> 6) Remove the drain bolt on the caliper with T10 Torx wrench. Lock empty M5 injector into the drain hole.

5) Hold hose tight; push hose connector into the end of the hose. <Photo 10,11> (Check the o-ring on the bolt is still good or not. If it is damaged, change a new one)

NOTICE: Hose connector must be fully pressed into brake hose without gap or fluid leakage may occur 7) Remove the fluid-filling bolt on lever bracket with a 3mm Allen wrench. Suck fresh brake fluid fully into

and lead to the brake system failure. another M5 injector (about 25C.C.) and exhaust the air inside. Lock into fluid-filling hole by hand.

6) Insert brake hose completely into the screw hole of lever bracket or caliper. Let clip ring slip into the 8) Push the plunger of injector on lever bracket side to add fresh brake fluid into the brake system till there

screw hole. While pushing the brake hose, tighten the hose bolt. (locking torque 110~120 kg-cm) is only a little brake fluid left in the injector. (About 5C.C.) Do not let the air inside injector get into the

<Photo 4> brake system. Simultaneously, the used fluid will come out from caliper and get into another injector.

7) Add brake fluid according to the procedure of “Adding brake fluid”. 9) Move caliper to about the same height position as lever bracket and remove caliper side injector.

WARNING : The “hose bolt”, “clip ring” and “hose connector” must be tightened enough. Or it will cause <Photo 12> Tighten the drain bolt back. (locking torque 20~30 kg-cm)

hose loose and fluid bleeding, which will lead to brake system failure and rider injury. Dispose of the used brake fluid in injector properly.

10)Bleeding the air per “Adding brake fluid” Step 4 to 7.

2. Adding brake fluid / Air bubbles removal 11)Remove 10.8mm spacer from caliper. Clean caliper and brake hose with wet tissue paper. Reassemble

Tools and Accessories Required: brake pads and pad spring. (See the instruction for “Pad Removal”)

Empty can for fresh fluid Fresh DOT.4 brake fluid, 10 cc

12)Reassemble caliper back to the fork/frame and adjust lever bracket to preferred angle.

Allen wrench: 3 mm&4mm 20cc injector M5 Tissue Paper

WARNING:

a. Every bolt should be fastened to the correct torque during the operation. Strongly recommend

1) Place the bike in a steady standing position.

using a torque wrench to assemble all parts.

2) Loosen lever bracket with a 4mm Allen wrench. Turn the lever bracket till the fluid-filling hole beside the

b. DOT.4 brake fluid will corrode the painting. If the brake fluid gets on the lever bracket or caliper,

oil reservoir is upright and tighten the lever bracket.

clean it with wet tissue paper immediately.

3) Remove the fluid-filling bolt with a 3mm Allen wrench. Suck about 10cc fresh brake fluid into M5 injector

c. DOT.4 brake fluid is harmful to your skin and eyes. Do wear appropriate work clothes, glove and

and exhaust the air inside. Lock into fluid-filling hole by hand. <Photo 5,6>

goggles during working.

(Check the o-ring on the bolt is still good or not. If it is damaged, change a new one)

Das könnte Ihnen auch gefallen

- ISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsDokument4 SeitenISO 8750 DIN 7343 420-545 HV: Spiral Spring PinsViswanathan SrkNoch keine Bewertungen

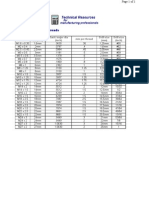

- Tap Chart - Metric ThreadsDokument1 SeiteTap Chart - Metric ThreadssonytechoNoch keine Bewertungen

- Anschutz 64 Match BoltDokument1 SeiteAnschutz 64 Match BoltAnonymous cCQKlG0RqNoch keine Bewertungen

- Cylinder Block - Repair ProcedurDokument34 SeitenCylinder Block - Repair Procedurfebri yulianto100% (1)

- MT-II LabDokument7 SeitenMT-II LabAjay Vikram0% (1)

- 2430 & TB2448 ComarisionDokument6 Seiten2430 & TB2448 ComarisionpiyushNoch keine Bewertungen

- FastenersDokument56 SeitenFastenersAnonymous Dp4DdscGSNoch keine Bewertungen

- Technical Data TB2448 Ver March 9, 2012Dokument13 SeitenTechnical Data TB2448 Ver March 9, 2012anhthoNoch keine Bewertungen

- Operator'S Manual Manuel de L'Utilisateur Manual Del OperadorDokument25 SeitenOperator'S Manual Manuel de L'Utilisateur Manual Del OperadorSergio LopezNoch keine Bewertungen

- Ssi .308DPMS Ur V3.3Dokument2 SeitenSsi .308DPMS Ur V3.3Ashley MolomoNoch keine Bewertungen

- JIS B.0203.e.1982Dokument14 SeitenJIS B.0203.e.1982Angel Alvarez CarrilloNoch keine Bewertungen

- Rolamentos e Retentores - Falk-Type-YB,-YBTDokument5 SeitenRolamentos e Retentores - Falk-Type-YB,-YBTVendedorNoch keine Bewertungen

- Superflush SF-400CDokument25 SeitenSuperflush SF-400CmgiovannozziNoch keine Bewertungen

- Hilti TE 804 and 905avr PartsDokument13 SeitenHilti TE 804 and 905avr PartsAqui Solo100% (1)

- Snap PDFDokument2 SeitenSnap PDFZoebairNoch keine Bewertungen

- Metric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityDokument5 SeitenMetric DIN 6921 Hexagon Flange Bolts: Visit Our For Product AvailabilityJaganNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument21 SeitenDisclosure To Promote The Right To InformationBrijeshNoch keine Bewertungen

- Mav 2005 InstalationDokument1 SeiteMav 2005 InstalationCamilo Andrés Nope FajardoNoch keine Bewertungen

- BZ 8002953Dokument15 SeitenBZ 8002953uuur35Noch keine Bewertungen

- DIN 128 A - Split Spring Washers, Curved, Form ADokument6 SeitenDIN 128 A - Split Spring Washers, Curved, Form ASantosh100% (1)

- Piulite Hexagonale-DIN934, IsO4032Dokument2 SeitenPiulite Hexagonale-DIN934, IsO4032butca1Noch keine Bewertungen

- Rr212403 Automobile Engineering DrawingDokument4 SeitenRr212403 Automobile Engineering DrawingSrinivasa Rao GNoch keine Bewertungen

- Contents 22844Dokument5 SeitenContents 22844Hidayat TofikNoch keine Bewertungen

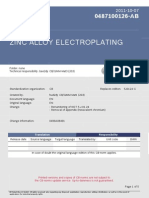

- Plating Standard - NOR - 0487100126 - 00 - 20111212 - 0AB - Dy - DMDokument5 SeitenPlating Standard - NOR - 0487100126 - 00 - 20111212 - 0AB - Dy - DMParag AdwankarNoch keine Bewertungen

- European Standard Norme Europeenne Europaische Norm: Ultrasonic Testing of $teel BarsDokument13 SeitenEuropean Standard Norme Europeenne Europaische Norm: Ultrasonic Testing of $teel BarspraveenNoch keine Bewertungen

- PALM SQUEEZERS and Other Unique HandgunsDokument10 SeitenPALM SQUEEZERS and Other Unique Handgunsblowmeasshole1911Noch keine Bewertungen

- TEKTRO HDC300 Installation InstructionDokument2 SeitenTEKTRO HDC300 Installation Instructiontm5u2rNoch keine Bewertungen

- Poseidon Pegasus Seals Deluxe (Forw) Installation and Maintenance Manual...Dokument10 SeitenPoseidon Pegasus Seals Deluxe (Forw) Installation and Maintenance Manual...Marlon Alejandro Arboleda TapiaNoch keine Bewertungen

- Mirage g4 Gls at ModelDokument3 SeitenMirage g4 Gls at ModelSol S.Noch keine Bewertungen

- SM Tm3989 Knott A4Dokument1 SeiteSM Tm3989 Knott A4Marc GlebNoch keine Bewertungen

- Group 4 Auxiliary Pump: 1. FunctionDokument6 SeitenGroup 4 Auxiliary Pump: 1. FunctionTaha RdmanNoch keine Bewertungen

- Saunders HC4 Diaphragm Valves Installation and Maintenance Instructions Manual ValvesDokument6 SeitenSaunders HC4 Diaphragm Valves Installation and Maintenance Instructions Manual ValvesJose Gregorio FerrerNoch keine Bewertungen

- Removal: Disassembly Service PointDokument5 SeitenRemoval: Disassembly Service PointBaggerkingNoch keine Bewertungen

- MIN - 549410 - Poseidon Pegasus Seals (Aft) Installation & Maintenance ...Dokument9 SeitenMIN - 549410 - Poseidon Pegasus Seals (Aft) Installation & Maintenance ...Marlon Alejandro Arboleda TapiaNoch keine Bewertungen

- Catálogo Bomba BanjoDokument8 SeitenCatálogo Bomba BanjoVitchenzo Zimmer DezordiNoch keine Bewertungen

- 12 Frenos Suzuki IntruderDokument32 Seiten12 Frenos Suzuki Intruderbenjapana100% (2)

- Power Steering Pump Service and Repair, 1999 Toyota Truck 4 Runner 2WDDokument8 SeitenPower Steering Pump Service and Repair, 1999 Toyota Truck 4 Runner 2WDCarlos VillaltaNoch keine Bewertungen

- Rammer 1655 Service 2015Dokument52 SeitenRammer 1655 Service 2015SerkanAlNoch keine Bewertungen

- Rear SealDokument9 SeitenRear SealHammad Uddin JamilyNoch keine Bewertungen

- Manual 1008-1010Dokument12 SeitenManual 1008-1010Edgar Eduardo Tellez RuizNoch keine Bewertungen

- GT7638Dokument8 SeitenGT7638LorenzoNoch keine Bewertungen

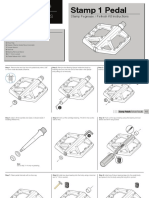

- Stamp 1 OverhaulDokument3 SeitenStamp 1 OverhaulsecamachoiNoch keine Bewertungen

- FIS113eng Hi Temp BellowsDokument8 SeitenFIS113eng Hi Temp Bellowsmahesh_eilNoch keine Bewertungen

- Ford Ranger Mazda BT50 Pre-Oil Filter Fitting InstructionsDokument1 SeiteFord Ranger Mazda BT50 Pre-Oil Filter Fitting InstructionsMaster XeotoNoch keine Bewertungen

- 2010-2015 DHX RC4 - RC2 Rebuild - Bike Help Center - FOXDokument34 Seiten2010-2015 DHX RC4 - RC2 Rebuild - Bike Help Center - FOXYadi RomaNoch keine Bewertungen

- 500sm Sani Bomba MoynoDokument4 Seiten500sm Sani Bomba MoynoRonaldo JanglinNoch keine Bewertungen

- Mezzer Pro Expert Service GuideDokument43 SeitenMezzer Pro Expert Service GuideMatteo QuerellaNoch keine Bewertungen

- QHD 1 BrakesDokument5 SeitenQHD 1 BrakesjoesantaneNoch keine Bewertungen

- Contitech: Installation Tips - Changing Timing Belts: Press ReleaseDokument6 SeitenContitech: Installation Tips - Changing Timing Belts: Press Releasecabral_bhNoch keine Bewertungen

- MM01001 enDokument32 SeitenMM01001 enmahmoud yarahmadiNoch keine Bewertungen

- Ford C-4 Trans-Brake Installation Instructions Reversed Pattern Manual (PRN123) #72021Dokument2 SeitenFord C-4 Trans-Brake Installation Instructions Reversed Pattern Manual (PRN123) #72021G Ramon SPNoch keine Bewertungen

- 5mL Pipettor Cleaning-CareDokument1 Seite5mL Pipettor Cleaning-CareNavi MoralesNoch keine Bewertungen

- Air Bleeding From Brake LineDokument10 SeitenAir Bleeding From Brake LineKoyfoNoch keine Bewertungen

- 57-0346 InstDokument1 Seite57-0346 InstIdham ZawawiNoch keine Bewertungen

- MSA5TCD97L3692Dokument3 SeitenMSA5TCD97L3692Mudflap CalizayaNoch keine Bewertungen

- 66 TSF Series Service InstructionsDokument4 Seiten66 TSF Series Service InstructionsCodinsa SAS Ingeniero MantenimientoNoch keine Bewertungen

- Brake Booster Check: Chapter 1 Tune-Up and Routine MaintenanceDokument2 SeitenBrake Booster Check: Chapter 1 Tune-Up and Routine MaintenanceHilario Gayosso CruzNoch keine Bewertungen

- SERVICE ALERT #387 Automatic Drain Wear KitDokument5 SeitenSERVICE ALERT #387 Automatic Drain Wear KitvaleryNoch keine Bewertungen

- Bucyrus: Technical ManualDokument7 SeitenBucyrus: Technical ManualJohn GrayNoch keine Bewertungen

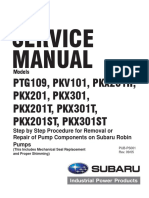

- Subaru Pumps Pkv101 Pkx201h Pkx201 Pkx301 Pkx201st Pkx301st Pkx201t Pkx301t ServiceDokument88 SeitenSubaru Pumps Pkv101 Pkx201h Pkx201 Pkx301 Pkx201st Pkx301st Pkx201t Pkx301t ServiceEdgardo M. Diolola100% (1)

- 070-251 SM - 2007 - 01 Service Manual TDSH & GDSHDokument12 Seiten070-251 SM - 2007 - 01 Service Manual TDSH & GDSHAlexNoch keine Bewertungen

- Catalog1 - Completo-11-20Dokument3 SeitenCatalog1 - Completo-11-20Walter FormigoniNoch keine Bewertungen

- Audi A4 B5 Wiring DiagramDokument21 SeitenAudi A4 B5 Wiring DiagramRoyTristan Molina Cudilla71% (7)

- Equipo KOBA Noble Lift PTE15N Partes PDFDokument33 SeitenEquipo KOBA Noble Lift PTE15N Partes PDFMario AguirreNoch keine Bewertungen

- M-4026-FA FiestaST Quaife Differential Installation KitDokument11 SeitenM-4026-FA FiestaST Quaife Differential Installation Kitjoecosta77Noch keine Bewertungen

- ASTRA J Bulb Reference ListDokument2 SeitenASTRA J Bulb Reference ListSlobodan NocajNoch keine Bewertungen

- Chapter 62 - Main Rotor: BHT-412-CR&O-3Dokument194 SeitenChapter 62 - Main Rotor: BHT-412-CR&O-3252nd PAS100% (1)

- Hot Mix Plant Apollo ANP1500 & 2000Dokument165 SeitenHot Mix Plant Apollo ANP1500 & 2000Niten Gupta88% (16)

- BREMBO EUROCAR Catalogo EmailDokument32 SeitenBREMBO EUROCAR Catalogo EmailСветлана ГайдайNoch keine Bewertungen

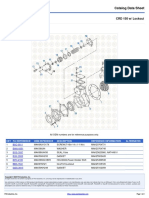

- Pai - Catalog - Sheet - 1204 CRD150 LOCKOUTDokument2 SeitenPai - Catalog - Sheet - 1204 CRD150 LOCKOUTjon fredyNoch keine Bewertungen

- 2 1.2 Ordering Spare Parts 2 1.3 Working Conditions and Tools 3 1.4 Service Work 3Dokument31 Seiten2 1.2 Ordering Spare Parts 2 1.3 Working Conditions and Tools 3 1.4 Service Work 3Sales Aydinkaya100% (1)

- Massey Ferguson MF 154 TRACTOR Service Parts Catalogue ManualDokument14 SeitenMassey Ferguson MF 154 TRACTOR Service Parts Catalogue Manualbvk2980022100% (1)

- 426 Sup MatDokument209 Seiten426 Sup MatZEUS ARMYNoch keine Bewertungen

- 35.HF Deluxe I3s (Jan, 2020)Dokument139 Seiten35.HF Deluxe I3s (Jan, 2020)Raj Auto Agency Mandvi100% (1)

- 112LHa200WB60EHRF (GT60M)Dokument16 Seiten112LHa200WB60EHRF (GT60M)rolandNoch keine Bewertungen

- Catalogo Productos CodriseDokument89 SeitenCatalogo Productos CodriseJPVYcG4xas100% (1)

- Demolition Hammer: GSH 11 E - 3 611 C16 8K0Dokument8 SeitenDemolition Hammer: GSH 11 E - 3 611 C16 8K0sanjoy PaulNoch keine Bewertungen

- Cub Cadet Parts Manual For Model 2518 48 TractorDokument9 SeitenCub Cadet Parts Manual For Model 2518 48 Tractorlaura100% (49)

- Flosser Product CatalogDokument189 SeitenFlosser Product CatalogJavierNoch keine Bewertungen

- Workshop Manual Transporter 2016 28-29Dokument331 SeitenWorkshop Manual Transporter 2016 28-29samueleNoch keine Bewertungen

- CouplingDokument2 SeitenCouplingAdam MuhammadNoch keine Bewertungen

- Gabel WPDokument50 SeitenGabel WPLordHandNoch keine Bewertungen

- Nsiw em CatalogueDokument68 SeitenNsiw em Cataloguejavier06.678061Noch keine Bewertungen

- AT 402 - IPM 5 Power - Plant - 01 20 PDFDokument19 SeitenAT 402 - IPM 5 Power - Plant - 01 20 PDFJef Avionica LtdaNoch keine Bewertungen

- MODEL 1433FH Fixed Head Power Meat Saw Operating and Service ManualDokument40 SeitenMODEL 1433FH Fixed Head Power Meat Saw Operating and Service ManualJivan KaprielianNoch keine Bewertungen

- Chapter 64 - Tail Rotor: BHT-412-CR&O-4Dokument60 SeitenChapter 64 - Tail Rotor: BHT-412-CR&O-4252nd PAS100% (2)

- Manual YBDokument65 SeitenManual YBGiancarloNoch keine Bewertungen

- WAF30 GU Part ListDokument5 SeitenWAF30 GU Part ListChia PeterNoch keine Bewertungen

- MX 10 PartsDokument3 SeitenMX 10 PartsneelotpalnayakNoch keine Bewertungen

- Electronic Parts Catalog - Option Detail Option Group Graphic Film Card DateDokument2 SeitenElectronic Parts Catalog - Option Detail Option Group Graphic Film Card DatenurdinzaiNoch keine Bewertungen