Beruflich Dokumente

Kultur Dokumente

Use of A Radiochromic Film Dosimetry System: Standard Practice For

Hochgeladen von

Partth VachhaniOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Use of A Radiochromic Film Dosimetry System: Standard Practice For

Hochgeladen von

Partth VachhaniCopyright:

Verfügbare Formate

ISO/ASTM 51275:2004(E)

Standard Practice for

Use of a Radiochromic Film Dosimetry System1

This standard is issued under the fixed designation ISO/ASTM 51275; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision.

1. Scope 51261 Guide for Selection and Calibration of Dosimetry

1.1 This practice covers the procedures for handling, test- Systems for Radiation Processing4

ing, and using a radiochromic film dosimetry system to 51400 Practice for Characterization and Performance of a

measure absorbed dose in materials irradiated by photons or High-Dose Radiation Dosimetry Calibration Laboratory4

electrons in terms of absorbed dose in water. 51707 Guide for Estimating Uncertainties in Dosimetry for

1.2 This practice applies to radiochromic film dosimeters Radiation Processing4

that can be used within part or all of the specified ranges as 2.3 International Commission on Radiation Units and

follows: Measurements (ICRU) Reports:5

1.2.1 The absorbed dose range is 1 Gy to 100 kGy. ICRU Report 14 Radiation Dosimetry: X–Rays and Gamma

1.2.2 The absorbed dose rate is 1 3 10–2 to 1 3 1013 Gy/s Rays with Maximum Photon Energies Between 0.6 and 50

(1-4).2 MeV

1.2.3 The radiation energy range for both photons and ICRU Report 17 Radiation Dosimetry: X–Rays Generated

electrons is 0.1 to 50 MeV. at Potentials of 5 to 150 kV

1.2.4 The irradiation temperature range is –78 to +60°C. ICRU Report 34 The Dosimetry of Pulsed Radiation

1.3 This practice applies to radiochromic films of various ICRU Report 35 Radiation Dosimetry: Electron Beams with

formats, including small pieces used to measure a single dose Energies Between 1 and 50 MeV

value, strips used for one-dimensional dose-mapping, and ICRU Report 60 Fundamental Quantities and Units for

sheets used for two-dimensional dose-mapping. Three- Ionizing Radiation

dimensional dose-mapping may be achieved by proper place-

3. Terminology

ment of any of these formats.

1.4 This standard does not purport to address all of the 3.1 Definitions:

safety concerns, if any, associated with its use. It is the 3.1.1 analysis wavelength—wavelength used in a spectro-

responsibility of the user of this standard to establish appro- photometric instrument for the measurement of optical absor-

priate safety and health practices and determine the applica- bance or reflectance.

bility of regulatory limitations prior to use. 3.1.2 calibration curve—graphical representation of the

dosimetry system’s response function.

2. Referenced documents 3.1.3 dosimeter batch—quantity of dosimeters made from a

2.1 ASTM Standards: 3 specific mass of material with uniform composition, fabricated

E 170 Terminology Relating to Radiation Measurements in a single production run under controlled, consistent condi-

and Dosimetry tions and having a unique identification code.

E 668 Practice for Application of Thermoluminescence- 3.1.4 dosimetry system—system used for determining ab-

Dosimetry (TLD) Systems for Determining Absorbed Dose sorbed dose, consisting of dosimeters, measurement instru-

in Radiation-Hardness Testing of Electronic Devices ments and their associated reference standards, and procedures

2.2 ISO/ASTM Standards: for the system’s use.

3.1.5 measurement quality assurance plan—documented

program for the measurement process that ensures on a

1

continuing basis that the overall uncertainty meets the require-

This guide is under the jurisdiction of ASTM Committee E10 on Nuclear

Technology and Applications and is the direct responsibility of Subcommittee

ments of the specific application. This plan requires traceability

E10.01 on Dosimetry for Radiation Processing, and is also under the jurisdiction of to, and consistency with, nationally or internationally recog-

ISO/TC 85/WG 3. nized standards.

Current edition approved April 5, 2004. Published June 15, 2004. Originally 3.1.6 net absorbance, DA—change in measured optical

published as ASTM E 1275–88. Last previous ASTM edition E 1275–98e1. ASTM

E 1275–93 was adopted by ISO in 1998 with the intermediate designation ISO absorbance at a selected wavelength determined as the absolute

15557:1998(E). The present International Standard ISO/ASTM 51275:2004(E) difference between the pre-irradiation absorbance, A0, and the

replaces ISO 15557 and is a minor revision of the last previous edition ISO/ASTM post-irradiation absorbance, A, as follows:

51275:2002(E).

2

The boldface numbers in parentheses refer to the bibliography at the end of this DA 5?A 2 A0?. (1)

practice.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Annual Book of ASTM Standards, Vol 12.02.

5

Standards volume information, refer to the standard’s Document Summary page on Available from the International Commission on Radiation Units and Measure-

the ASTM website. ments, 7910 Woodmont Ave., Suite 800, Bethesda, MD 20814, USA.

© ISO/ASTM International 2004 – All rights reserved 1

ISO/ASTM 51275:2004(E)

3.1.6.1 Discussion—In practice, an average pre-irradiation 5.1.4 Thickness Gage, with a precision of 62 % of the film

absorbance may be used to determine net absorbance. thickness (at a 95 % confidence level), if the film’s thickness is

3.1.7 radiochromic film-dosimeter—specially prepared film to be measured.

containing ingredients that undergo change in optical absor- NOTE 2—Documentation provided by the manufacturer of the radio-

bance under ionizing radiation. This change in optical absor- chromic film dosimeter with regard to the film thickness and its variability

bance can be related to absorbed dose in water. may be substituted for direct measurement of thickness by the user. This

3.1.8 response function—mathematical representation of information may be verified by the user by analyzing a representative

the relationship between dosimeter response and absorbed dose sample of films.

for a given dosimetry system. NOTE 3—Some radiochromic film dosimeters contain a substrate which

is not radiochromic. With such dosimeters the thickness is not measured;

3.1.9 specific net absorbance (Dk)—Net absorbance, DA, at

instead use the manufacturer’s documentation of the thickness and/or

a selected wavelength divided by the optical pathlength, d, variability of the film’s radiation-sensitive layer.

through the dosimeter material as follows:

Dk 5 DA/d. (2)

5.1.5 Packaging materials for radiochromic films, where

applicable, such as pouches or envelopes to protect from light

3.2 Definitions of other terms used in this standard that or humidity variations.

pertain to radiation measurement and dosimetry may be found

in ASTM Terminology Standard E 170. Definitions in ASTM 6. Performance check of instrumentation

E 170 are compatible with ICRU 60; that document, therefore,

6.1 The performance of the photometer or spectrophotom-

may be used as an alternative reference.

eter shall be checked as specified in Section 7.4, and docu-

mented. Use reference standards traceable to national or

4. Significance and use

international standards.

4.1 The radiochromic film dosimetry system provides a 6.1.1 When using a spectrophotometer, check and document

means of determining absorbed dose in materials. Under the the accuracy of the wavelength scale and absorbance scale at or

influence of ionizing radiation, chemical reactions take place in near the analysis wavelength(s) at intervals not to exceed one

the radiochromic film creating or enhancing, or both, optical month during periods of use and as specified by the end-user’s

absorption bands. Absorbance is determined within these internal procedures.

radiation-induced absorption bands using a spectrophotometer 6.1.2 When using a photometer, check and document the

or photometer (See 5.1.2). accuracy of the absorbance scale at intervals not to exceed one

4.2 In the application of a specific dosimetry system, month during periods of use and as specified by the end-user’s

absorbed dose is determined by use of a calibration curve internal procedures.

traceable to national or international standards. 6.1.3 Compare the information obtained in 6.1.1 or 6.1.2

4.3 The absorbed dose determined is usually specified in with the original instrument specifications to ensure adequate

water. Absorbed dose in other materials may be determined by performance.

applying conversion factors. This is discussed in ISO/ASTM 6.2 Check the thickness gage prior to first use and periodi-

Guide 51261. cally thereafter to ensure reproducibility and lack of zero drift.

Check and document the calibration of the gage at intervals not

NOTE 1—For comprehensive discussion of various dosimetry methods

applicable to the radiation types and energies discussed in this practice, to exceed six months. Use gage blocks, traceable to national or

see ICRU Reports 14, 17, 34, and 35. international standards for this purpose.

4.4 Radiochromic film dosimetry systems are commonly 7. Calibration of the dosimetry system

applied in the industrial radiation processing of a variety of

products, for example, sterilization of medical devices and 7.1 Prior to use, the dosimetry system (consisting of a

processing of foods. specific batch of dosimeters and specific measurement instru-

ments) shall be calibrated in accordance with the user’s

5. Dosimetry system documented procedure that specifies details of the calibration

process and quality assurance requirements. This calibration

5.1 Components of the Dosimetry System—The following process shall be repeated at regular intervals to ensure that the

shall be used to determine absorbed dose with radiochromic accuracy of the absorbed dose measurement is maintained

film dosimetry systems: within required limits. Calibration methods are described in

5.1.1 Radiochromic Film Dosimeters ISO/ASTM Guide 51261.

5.1.2 Spectrophotometer or Photometer, having documen- 7.2 Calibration Irradiation of Dosimeters—Irradiation is a

tation covering analysis wavelength range, accuracy of wave- critical component of the calibration of the dosimetry system.

length selection, absorbance determination, spectral band- Calibration shall be performed in one of three ways by

width, and stray light rejection. Examples of appropriate irradiating the dosimeters at:

wavelengths for analysis for specific dosimetry systems are 7.2.1 an accredited calibration laboratory that provides an

provided by the manufacturer and in Refs (3-14, 15). absorbed dose (or an absorbed-dose rate) having measurement

5.1.3 Holder, to position the dosimeter reproducibly in and traceability to nationally or internationally recognized stan-

perpendicular to the analysis light beam. dards, or

2 © ISO/ASTM International 2004 – All rights reserved

ISO/ASTM 51275:2004(E)

7.2.2 an in-house calibration facility that provides an ab- 8.3 Analysis Procedure:

sorbed dose (or an absorbed-dose rate) having measurement 8.3.1 Avoid any exposure to ultraviolet radiation that may

traceability to nationally or internationally recognized stan- induce coloration of the dosimeter (see 8.1.1).

dards, or 8.3.2 Determine the post-irradiation absorbance, A, at the

7.2.3 a production or research irradiation facility together selected analysis wavelength(s).

with reference or transfer standard dosimeters that have mea- 8.3.3 If appropriate for the dosimeter being used, measure

surement traceability to nationally or internationally recog- the thickness of each dosimeter, or use the average thickness

nized standards. and document the uncertainty of the measurement.

7.3 When the radiochromic film dosimeter is used as a

transfer standard dosimeter, the calibration irradiation may be NOTE 6—Certain films may be too thin to allow the accurate determi-

performed only as stated in 7.2.1, or in 7.2.2 at a facility that nation of thickness using conventional gage technology. In such cases,

meets the requirements in ISO/ASTM 51400. statistical methods may be employed in order to provide the uncertainty

values discussed in Section 12.

7.4 Measurement Instrument Calibration and Performance

Verification—For the calibration of the instruments, and for the 8.3.4 Calculate the absorbed dose based on the pre- and

verification of instrument performance between calibrations, post-irradiation absorbances, the thickness, if appropriate, and

see ISO/ASTM Guide 51261 and/or instrument-specific oper- the calibration curve or response function.

ating manuals.

NOTE 7—Examples of radiochromic film dosimeter applications that

employ reflectance techniques or alternative methods for determining net

8. Procedure and specific net absorbance appear in the literature. The user may choose

8.1 Examination and Storage Procedure: to refer to these techniques (16, 17).

8.1.1 Ultraviolet radiation may cause the film to change

color. Perform tests to ensure that the handling/reading envi- 9. Characterization of each batch of dosimeters

ronment does not cause measurable color development. If 9.1 Repeatability of Specific Net Absorbance:

needed, place ultraviolet filters over fluorescent lights or 9.1.1 For each batch of dosimeters, the repeatability of

windows to reduce color development (see also 9.3.1). specific net absorbance should be obtained by analyzing the

8.1.2 Handle dosimeters according to manufacturer’s in- data from the sets of dosimeters irradiated during the calibra-

structions. Avoid handling dosimeter surfaces with bare fin- tion at each dose value.

gers. 9.1.2 Use the sample standard deviation (Sn-1 ) determined

8.1.3 Visually inspect the films for imperfections. Gently during calibration to calculate coefficients of variation (CV )

clean the dosimeters if necessary, for example with a soft brush for each absorbed dose value as follows:

or with air. Discard any dosimeters that show imperfections

such as scratches that could give rise to erroneous readings. Sn21

CV 5 3 100 ~%! (3)

8.1.4 Identify the dosimeters. Dk̄

8.1.5 Store the dosimeters according to the manufacturer’s 9.1.3 Document these coefficients of variation and note any

written recommendations. that are unusually large.

8.2 Irradiation Procedure:

8.2.1 Determine the pre-irradiation absorbance, A0, for each NOTE 8—In general, if the coefficients of variation values are greater

dosimeter at the selected analysis wavelength. Alternatively, than 2 %, then a redetermination of the data should be considered.

use an average (Ā0), determined by reading several dosimeters. 9.2 Post-Irradiation Characterization:

NOTE 4—If the orientation of the dosimeter has an effect on the 9.2.1 Some types of dosimeters may fade or may continue

absorbance reading, keep track of the dosimeter orientation (for example, color development after irradiation. This effect may depend on

by marking a corner or edge of the dosimeter). post-irradiation storage conditions such as temperature, humid-

8.2.2 If necessary, package the dosimeters to provide con- ity, or atmosphere. In order to determine if this is significant in

trolled environmental conditions during irradiation (see 9.3.1). a given application, measure the absorbance at the selected

8.2.3 Mark the packaged dosimeters appropriately for iden- wavelength(s) over the period of anticipated analysis and over

tification. the range of expected storage conditions (7, 8, 14, 16, 18).

8.2.4 Irradiate the dosimeters. 9.2.2 If absorbances measured in 9.2.1 are found to vary

significantly with post-irradiation storage time, then apply

NOTE 5—The dosimeters may be irradiated in the product undergoing

processing or in a medium of similar composition, or water, of appropriate

correction factors for such time-dependent variations, taking

dimensions so as to approximate electron equilibrium conditions. Such into account the calibration curve for that batch of dosimeters,

equilibrium conditions may not exist within dosimeters placed throughout in order to minimize dosimetric errors during routine applica-

the product under actual processing conditions. This particularly is the tion. Alternatively, control the post-irradiation storage and

case near interfaces of different materials. Irradiation under nonequilib- analysis so that correction factors are not needed..

rium conditions, such as on the surface of a product package, is often used 9.2.3 For a given set of irradiation conditions, this proce-

to monitor the absorbed dose delivered to the product and may be related

to absorbed dose within the product by correction factors under certain

dure needs to be performed only once for a given batch of

conditions. For a detailed discussion of this subject, see ISO/ASTM Guide dosimeters.

51261. 9.3 Other Factors:

© ISO/ASTM International 2004 – All rights reserved 3

ISO/ASTM 51275:2004(E)

9.3.1 The effects of temperature, humidity, absorbed dose 11.7 Record or reference the measurement quality assurance

rate, incident energy spectrum, electron equilibrium and back- plan used for the dosimetry system application.

ground ultraviolet radiation shall be taken into account. See

Refs (2-6) and (11-14, 16 and 19) for examples of the types and 12. Measurement uncertainty

magnitudes of the effects. Appropriate documented informa- 12.1 To be meaningful, a measurement of absorbed dose

tion regarding the magnitude and effect(s) upon the measure- shall be accompanied by an estimate of uncertainty.

ment made by the dosimetry system may be obtained from the

12.2 Components of uncertainty shall be identified as be-

scientific literature, dosimeter manufacturer, distributor, irra-

longing to one of two categories:

diation facility operator, or a qualified testing organization.

12.2.1 Type (A)—those evaluated by statistical methods, or

Some effects may be reduced or eliminated with proper

packaging. 12.2.2 Type (B)—those evaluated by other means.

12.3 Other ways of categorizing uncertainty have been

10. Application of dosimetry system widely used and may be useful for reporting uncertainty. For

10.1 The number of dosimeters required for the measure- example, the terms precision and bias or random and system-

ment of absorbed dose at a location on or within a material is atic (non-random) are used to describe different categories of

determined by the precision of the dosimetry system and the uncertainty.

required precision associated with the application. Appendix 12.4 If this practice is followed, the estimate of the ex-

X3 of Practice E 668 describes a statistical method for deter- panded uncertainty of an absorbed dose determined by this

mining this number. dosimetry system should be less than 6 % for a coverage factor

10.2 For irradiating and analyzing the dosimeters, follow k=2 (which corresponds approximately to a 95 % level of

the procedures in accordance with 8.2 and 8.3. confidence for normally distributed data.

10.3 Determine the absorbed dose from the mean specific

NOTE 9—The identification of Type A and Type B uncertainties is based

net absorbance values and the system calibration curve that on the methodology for estimating uncertainties published in 1995 by the

results from following the procedures in accordance with International Organization for Standardization (ISO) in the Guide to the

Section 7. Expression of Uncertainty in Measurement (20). The purpose of this type

10.4 Record the calculated absorbed dose and all other of characterization is to promote an understanding of how uncertainty

relevant data as outlined in Section 11. statements are developed and to provide a basis for the international

comparison of measurement results.

11. Minimum documentation requirements NOTE 10—ISO/ASTM Guide 51707 defines possible sources of uncer-

11.1 Record the dosimeter manufacturer, type, and batch tainty in dosimetry performed in radiation processing facilities and offers

identification (code). procedures for estimating the magnitude of the resulting uncertainties in

the measurement of absorbed dose using a dosimetry system. The

11.2 Record or reference the date of calibration, calibration

document defines and discusses basic concepts of measurement, including

source, and associated instruments used. estimation of the measured value of a quantity, “true” value, error and

11.3 Record or reference the irradiation environmental con- uncertainty. Components of uncertainty are discussed and methods are

ditions for the dosimeters, including temperature, pressure (if provided for estimating their values. Methods are also provided for

other than atmospheric), relative humidity, and composition of calculating the combined standard uncertainty and estimating expanded

the surrounding atmosphere (if other than air). (overall) uncertainty.

11.4 Record the date of irradiation and the dates on which

the non-irradiated and irradiated dosimeters are analyzed. 13. Keywords

11.5 Record the absorbance and thickness data, if appropri- 13.1 absorbed dose; dose measurement; dosimeter; dosim-

ate, and the resulting absorbed dose values. etry; electron beam; gamma radiation; ionizing radiation;

11.6 Record or reference the uncertainty in the value of the quality control; radiation processing; radiochromic dosimetry;

absorbed dose. radiochromic film; ICS 17.240

4 © ISO/ASTM International 2004 – All rights reserved

ISO/ASTM 51275:2004(E)

Bibliography

(1) Chappell, S. E. and Humphreys, J. C. “The Dose Response of a etry Systems Utilized in Radiation Processing of Medical Devices,”

Dye-Polychlorostyrene Film Dosimeter,” Transactions of Nuclear Radiation Physics and Chemistry, Vol 31, 1988, pp. 497–504.

Science, Vol 19, 1972, pp. 175–180. (12) Miller, A., Batsberg, W., and Karman, W., “A New Radiochromic

(2) Gehringer, P., Eschweiler, H., and Proksch, E., “Dose and Humidity Thin-Film Dosimeter System,” Radiation Physics and Chemistry, Vol

Effects on the Radiation Response of Nylon-Based Radiochromic Film 31, 1988, pp. 491–496.

Dosimeters,” International Journal of Applied Radiation and Isotopes, (13) McLaughlin, W. L., Humphreys, J. C., Hocken, D., and Chappas, W.

Vol 31, No. 10, 1980, pp. 595–605. J., “Radiochromic Dosimetry for Validation and Commissioning of

(3) McLaughlin, W. L., Humphreys, J. C., Levine, H., Miller, A., Radak, Industrial Radiation Processes,” Radiation Physics and Chemistry,

B. B., and Rativanich, N., “The Gamma-Ray response of Radiochro- Vol 31, 1988, pp. 505–514.

mic Dye Films at Different Absorbed Doses,” Radiation Physics and (14) Saylor, M. C., Tamargo, T. T., McLaughlin, W. L., Kahn, H. M.,

Chemistry, Vol 18, 1981, pp. 987–999. Lewis, D. F., and Schenfele, R. D., “A Thin Film Recording Medium

(4) McLaughlin, W. L., Humphreys, J.C., Radak, B. B., Miller, A., and for Use in Food Irradiation,” Radiation Physics and Chemistry, Vol

Olejnik, T. A., “The Response of Plastic Dosimeters to Gamma Rays 31, 1988, pp. 529–536.

and Electrons at High Dose Rates,” Radiation Physics and Chemistry,

(15) McLaughlin, W. L., Chen, Y. D., Soares, C. G., Miller, A., Vay Dyk,

Vol 14, 1979, pp. 535–550.

G. and Lewis, D. F., “Sensitometry of the Response of a New

(5) Levine, H., McLaughlin, W. L., and Miller, A., “Temperature and

Radiochromic Film Dosimeter to Gamma Radiation and Electron

Humidity Effects on the Gamma-Ray Response and Stability of Plastic

Beams,” Nucl. Instrum. Methods Phys. Res. A302, 1991, pp. 165–176

and Dyed Plastic Dosimeters,” Radiation Physics and Chemistry, Vol

(16) Prusik, T., and Montesalvo, M., and Wallace, T., “Use of Polydiacety-

14, 1979, pp. 551–574.

lenes in an Automated Label Dosimetry System,” Radiation Physics

(6) McLaughlin, W. L., Miller, A., Uribe, R. M., Kronenburg, S., and

and Chemistry, Vol 31, Second Edition, 1997, pp. 441–447.

Siebentritt, C. R., “Energy Dependence of Radiochromic Dosimeter

Response to X and Gamma Rays,” High Dose Dosimetry, Proceedings (17) “Absorbed Dose Determination in Photon and Electron Beams,”

of the International Symposium, Vienna, 1985, pp. 397–424. IAEA Technical Report Series No. 277, Vienna, Second Edition,

(7) Danchenko, V. and Griffin, G. F., “Delayed Darkening of Radiation- 1997.

Exposed Radiochromic Dye Dosimeters,” Transactions of Nuclear (18) McLaughlin, W. L., Puhl, J. M., Al-Sheikhly, M., Christou, C. A.

Science, Vol NS-25, No. 6, December 1981, pp. 4156–4160. Miller, A., Kovacs A., Wojnarovits, L., and Lewis, D F., “Novel.

(8) Chappas, W. J., “Accelerated Color Development Irradiated Radio- Radiochromic Films for Clinical Dosimetry,” Radiation Protection

chromic Dye Films,” Transactions of Nuclear Science, Vol NS-28, No. Dosimetry, Vol. 66, Nos. 1–4, 1996, pp. 263–268.

2, April 1981, pp. 1784–1785. (19) Janovsky, I. and Mehta, K., “The Effects of Humidity on the

(9) Patel, G. N., “Diacetylenes as Radiation Dosage Indicators,” Radiation Response of Radiochromic Film Dosimeters FWT-60–00 and

Physics and Chemistry, Vol 18, 1981, pp. 913–925. Gafchromic-DM-1260,” Radiat. Phys. Chem., 43, 1994, pp. 407–409.

(10) McLaughlin, W. L., Wei-Zhen, B., and Chappas, W. J., “Cellulose (20) “Guide to the Expression of Uncertainty in Measurement,” Interna-

Diacetate Film Dosimeters,” Radiation Physics and Chemistry, Vol tional Organization for Standardization, 1995, ISBN 92-67-10188-9.

31, 1988, pp. 481–490. (Available from International Organization for Standardization, 1 rue

(11) Schaffer, H. L., and Garcia, R. D., “Practical Application of Dosim- de Varembé, Case Postale 56, CH-1211, Geneva 20, Switzerland.)

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ISO, Case postale 56, CH-1211, Geneva 20, Switzerland, and ASTM International, 100 Barr Harbor

Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States. Individual reprints (single or multiple copies) of this

standard may be obtained by contacting ASTM at the above address or at 610-832-9585 (phone), 610-832-9555 (fax), or

service@astm.org (e-mail); or through the ASTM website (www.astm.org).

© ISO/ASTM International 2004 – All rights reserved 5

Das könnte Ihnen auch gefallen

- Iso Astm 51275-13Dokument6 SeitenIso Astm 51275-13Dmitry_ucpNoch keine Bewertungen

- Iso Astm 51026-15Dokument9 SeitenIso Astm 51026-15TertulianoPintoNoch keine Bewertungen

- Iso Astm 51818-13Dokument13 SeitenIso Astm 51818-13jose floresNoch keine Bewertungen

- Iso Astm 51401-13Dokument6 SeitenIso Astm 51401-13Oh No PotatoNoch keine Bewertungen

- Iso Astm 51205-17Dokument11 SeitenIso Astm 51205-17Oh No PotatoNoch keine Bewertungen

- Astm Iso-51631 (2020)Dokument9 SeitenAstm Iso-51631 (2020)AHMED SAMIR ALEMDARNoch keine Bewertungen

- Iso Astm 51276-12Dokument6 SeitenIso Astm 51276-12Pavan KumarNoch keine Bewertungen

- Iso Astm 51956-13Dokument8 SeitenIso Astm 51956-13Oh No PotatoNoch keine Bewertungen

- Iso Astm 51650-13Dokument6 SeitenIso Astm 51650-13Dmitry_ucpNoch keine Bewertungen

- Iso Astm 52701-13 PDFDokument10 SeitenIso Astm 52701-13 PDFAhmed LabibNoch keine Bewertungen

- E 1026 - 95 - RtewmjytotuDokument7 SeitenE 1026 - 95 - RtewmjytotuPrakash MakadiaNoch keine Bewertungen

- Characterization and Performance of A High-Dose Radiation Dosimetry Calibration LaboratoryDokument5 SeitenCharacterization and Performance of A High-Dose Radiation Dosimetry Calibration LaboratoryPartth VachhaniNoch keine Bewertungen

- Selecting Dosimetry Systems For Application in Pulsed X-Ray SourcesDokument19 SeitenSelecting Dosimetry Systems For Application in Pulsed X-Ray SourcesEric GozzerNoch keine Bewertungen

- Astm E0169 16Dokument6 SeitenAstm E0169 16archanaNoch keine Bewertungen

- Determining Relative Spectral Correction Factors For Emission Signal of Fluorescence SpectrometersDokument5 SeitenDetermining Relative Spectral Correction Factors For Emission Signal of Fluorescence Spectrometersmohammed karasnehNoch keine Bewertungen

- Iso Astm 51900-09Dokument12 SeitenIso Astm 51900-09Oh No PotatoNoch keine Bewertungen

- E 169 - 04 (2014) PDFDokument6 SeitenE 169 - 04 (2014) PDFruben carcamoNoch keine Bewertungen

- Iso Astm 51539-05 (2013)Dokument3 SeitenIso Astm 51539-05 (2013)Dmitry_ucpNoch keine Bewertungen

- E 1026 - 03 - RtewmjytukveDokument10 SeitenE 1026 - 03 - RtewmjytukvePrakash MakadiaNoch keine Bewertungen

- Dosimetry in An Electron Beam Facility For Radiation Processing at Energies Between 80 and 300 KevDokument8 SeitenDosimetry in An Electron Beam Facility For Radiation Processing at Energies Between 80 and 300 KevPartth VachhaniNoch keine Bewertungen

- ASTM Standard Practice For DosimetryDokument35 SeitenASTM Standard Practice For DosimetryachaudhuriNoch keine Bewertungen

- Analysis of Metals, Ores, and Related Materials by SpectrophotometryDokument8 SeitenAnalysis of Metals, Ores, and Related Materials by SpectrophotometryShehrije BejtaNoch keine Bewertungen

- ISOASTM51204Dokument10 SeitenISOASTM51204Partth VachhaniNoch keine Bewertungen

- Astm E1933 - 14 (2018)Dokument3 SeitenAstm E1933 - 14 (2018)Santiago AriasNoch keine Bewertungen

- Standard Practice For General Techniques For Obtaining InfraredDokument13 SeitenStandard Practice For General Techniques For Obtaining InfraredSree Microlab TestingNoch keine Bewertungen

- E 925 - 83 R94 - Rtkyns04m1i5neux PDFDokument6 SeitenE 925 - 83 R94 - Rtkyns04m1i5neux PDFpechugonisNoch keine Bewertungen

- Astm E925 09 2022Dokument4 SeitenAstm E925 09 2022Mohit KumarNoch keine Bewertungen

- Astm Iso 51818 (2020)Dokument13 SeitenAstm Iso 51818 (2020)AHMED SAMIR ALEMDARNoch keine Bewertungen

- Measurement of Computed Tomography (CT) System Performance: Standard Test Method ForDokument13 SeitenMeasurement of Computed Tomography (CT) System Performance: Standard Test Method ForLayth MyasarNoch keine Bewertungen

- Obtaining Bispectral Photometric Data For Evaluation of Fluorescent ColorDokument10 SeitenObtaining Bispectral Photometric Data For Evaluation of Fluorescent ColorRajat TiwariNoch keine Bewertungen

- Iso Astm 51631-13Dokument9 SeitenIso Astm 51631-13Dmitry_ucpNoch keine Bewertungen

- Astm E334 01 2021Dokument7 SeitenAstm E334 01 2021Şəbnəm SeyidovaNoch keine Bewertungen

- Iso Astm 51707 - 2015Dokument11 SeitenIso Astm 51707 - 2015Tamara Silvana CárcamoNoch keine Bewertungen

- E 666 - 97 - Rty2ni05nwDokument9 SeitenE 666 - 97 - Rty2ni05nwPrakash MakadiaNoch keine Bewertungen

- ASTM E2847 21 InfrarrojosDokument17 SeitenASTM E2847 21 InfrarrojosEver Daniel Castro Rodriguez100% (1)

- Iso Astm 51707-15Dokument11 SeitenIso Astm 51707-15Pavan Kumar100% (1)

- D3124-98 (Reapproved 2011)Dokument4 SeitenD3124-98 (Reapproved 2011)Deepak AryaNoch keine Bewertungen

- E2903-13 Standard Test Method For Measurement of The Effective Focal Spot Size of Mini and Micro Focus X-Ray TubesDokument5 SeitenE2903-13 Standard Test Method For Measurement of The Effective Focal Spot Size of Mini and Micro Focus X-Ray TubesDurga Jagan PuppalaNoch keine Bewertungen

- E 334 - 01 (2013)Dokument12 SeitenE 334 - 01 (2013)ruben carcamoNoch keine Bewertungen

- Qualification and Long-Term Stability of Computed Radiology SystemsDokument9 SeitenQualification and Long-Term Stability of Computed Radiology SystemsclaudiaNoch keine Bewertungen

- D 3124 - 98 - Rdmxmjqtotg - PDFDokument4 SeitenD 3124 - 98 - Rdmxmjqtotg - PDFsusanaNoch keine Bewertungen

- E592 1801061-1Dokument5 SeitenE592 1801061-1himaw20393Noch keine Bewertungen

- Astm G 138 2006 PDFDokument8 SeitenAstm G 138 2006 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- D7220-06 MEDXRF Sulfur AutomotiveDokument6 SeitenD7220-06 MEDXRF Sulfur AutomotiveVladimir KrzalicNoch keine Bewertungen

- Astm E1050.7243Dokument12 SeitenAstm E1050.7243wangxl2012100% (1)

- E1252 PDFDokument13 SeitenE1252 PDFrajlaxmi joshiNoch keine Bewertungen

- E 932 - 89 R02 - RTKZMGDokument6 SeitenE 932 - 89 R02 - RTKZMGpechugonisNoch keine Bewertungen

- E986-04 (Reapproved 2017)Dokument3 SeitenE986-04 (Reapproved 2017)Miguel BazalduaNoch keine Bewertungen

- E 181 - 10 PDFDokument21 SeitenE 181 - 10 PDFruben carcamoNoch keine Bewertungen

- Astm E275-2008 (2013)Dokument3 SeitenAstm E275-2008 (2013)AmarNoch keine Bewertungen

- Astm D 2008 - 12Dokument7 SeitenAstm D 2008 - 12alexander guerraNoch keine Bewertungen

- E1311-99 Thermal Imaging Minimum Temp DiffDokument3 SeitenE1311-99 Thermal Imaging Minimum Temp DiffsanthakumarNoch keine Bewertungen

- Alternate Actinide Calibration For Inductively Coupled Plasma-Mass SpectrometryDokument6 SeitenAlternate Actinide Calibration For Inductively Coupled Plasma-Mass SpectrometryTamara Silvana CárcamoNoch keine Bewertungen

- E 2446 - 16Dokument14 SeitenE 2446 - 16Enrique Antonio100% (2)

- Measuring and Compensating For Transmittance of An Attenuating Medium Using Infrared Imaging RadiometersDokument3 SeitenMeasuring and Compensating For Transmittance of An Attenuating Medium Using Infrared Imaging RadiometersEric GozzerNoch keine Bewertungen

- E 1255 - 96 RteyntutotyDokument13 SeitenE 1255 - 96 RteyntutotyNorman ricardo RojoNoch keine Bewertungen

- Methyl (Comonomer) Content in Polyethylene by Infrared SpectrophotometryDokument4 SeitenMethyl (Comonomer) Content in Polyethylene by Infrared Spectrophotometrymohammed karasnehNoch keine Bewertungen

- Astm E1897-1997 (2010) - 4375Dokument3 SeitenAstm E1897-1997 (2010) - 4375Ahmad ZakyNoch keine Bewertungen

- F 526 - 97 - Rjuyni05nwDokument11 SeitenF 526 - 97 - Rjuyni05nwYayan RnsNoch keine Bewertungen

- Dosimetry in Brachytherapy – An International Code of Practice for Secondary Standards Dosimetry Laboratories and HospitalsVon EverandDosimetry in Brachytherapy – An International Code of Practice for Secondary Standards Dosimetry Laboratories and HospitalsNoch keine Bewertungen

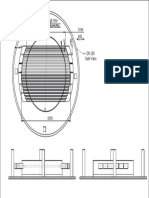

- Hearth Cooling PDFDokument1 SeiteHearth Cooling PDFPartth VachhaniNoch keine Bewertungen

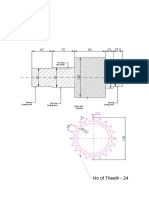

- Gearbox Pinion PDFDokument1 SeiteGearbox Pinion PDFPartth VachhaniNoch keine Bewertungen

- 5358 5185 400 DN 200 Gate Valve: Furnace Shell Outer DiameterDokument1 Seite5358 5185 400 DN 200 Gate Valve: Furnace Shell Outer DiameterPartth VachhaniNoch keine Bewertungen

- Design Validations of 450 T Eot Crane With Fea ApproachDokument73 SeitenDesign Validations of 450 T Eot Crane With Fea ApproachPartth VachhaniNoch keine Bewertungen

- 1.1 Background: Chapter 1 - IntroductionDokument12 Seiten1.1 Background: Chapter 1 - IntroductionPartth VachhaniNoch keine Bewertungen

- Fixed Bolted JointDokument16 SeitenFixed Bolted JointPartth VachhaniNoch keine Bewertungen

- Astm E2592-07Dokument4 SeitenAstm E2592-07Partth VachhaniNoch keine Bewertungen

- ISOASTM51204Dokument10 SeitenISOASTM51204Partth VachhaniNoch keine Bewertungen

- Corrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 680°F (360°C) or in Steam at 750°F (400°C)Dokument8 SeitenCorrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 680°F (360°C) or in Steam at 750°F (400°C)Partth VachhaniNoch keine Bewertungen

- Characterization and Performance of A High-Dose Radiation Dosimetry Calibration LaboratoryDokument5 SeitenCharacterization and Performance of A High-Dose Radiation Dosimetry Calibration LaboratoryPartth VachhaniNoch keine Bewertungen

- Astm G15Dokument5 SeitenAstm G15Partth VachhaniNoch keine Bewertungen

- Dosimetry in An Electron Beam Facility For Radiation Processing at Energies Between 80 and 300 KevDokument8 SeitenDosimetry in An Electron Beam Facility For Radiation Processing at Energies Between 80 and 300 KevPartth VachhaniNoch keine Bewertungen

- Design and Fabrication of DIE For Comp Action of Metal Powder in Powder MetallurgyDokument69 SeitenDesign and Fabrication of DIE For Comp Action of Metal Powder in Powder MetallurgyPartth VachhaniNoch keine Bewertungen

- Genetic Algorithm: Artificial Neural Networks (Anns)Dokument10 SeitenGenetic Algorithm: Artificial Neural Networks (Anns)Partth VachhaniNoch keine Bewertungen

- WORK INSTRUCTION For TrimosDokument10 SeitenWORK INSTRUCTION For TrimosPartth VachhaniNoch keine Bewertungen

- Operating Instruction of CMMDokument18 SeitenOperating Instruction of CMMPartth VachhaniNoch keine Bewertungen

- Metal Joining Process: Prepaed By: Vachhani Parth KDokument23 SeitenMetal Joining Process: Prepaed By: Vachhani Parth KPartth VachhaniNoch keine Bewertungen

- EFF's Guide To The Internet, V. 3.21 - Adam Gaffin - December 11, 1996 - (Minor Edit, June 13, 1999) - (Electronic Frontier Foundation)Dokument157 SeitenEFF's Guide To The Internet, V. 3.21 - Adam Gaffin - December 11, 1996 - (Minor Edit, June 13, 1999) - (Electronic Frontier Foundation)QuantDev-MNoch keine Bewertungen

- Information SecurityDokument22 SeitenInformation Securitydebleena mondalNoch keine Bewertungen

- Rectang & Circ Low Press Drop SiDokument2 SeitenRectang & Circ Low Press Drop SiLuis Gabriel BautistaNoch keine Bewertungen

- RS Signal and PDSCH RE Power CalculationDokument15 SeitenRS Signal and PDSCH RE Power Calculationshashank.prajapati9389Noch keine Bewertungen

- G95.desprendimiento CatodicoDokument4 SeitenG95.desprendimiento Catodicofernando magneNoch keine Bewertungen

- Zed-3 Se150 QSG LenDokument6 SeitenZed-3 Se150 QSG LenClaudia TituañaNoch keine Bewertungen

- Salt WasheryDokument7 SeitenSalt WasheryANoch keine Bewertungen

- Schneider ATV930 ATV950 Installation Manual PDFDokument143 SeitenSchneider ATV930 ATV950 Installation Manual PDFRodrigo VidalNoch keine Bewertungen

- Deep WebDokument12 SeitenDeep WebVir K Kharwar0% (1)

- XY200GY-6 Onwers ManualDokument33 SeitenXY200GY-6 Onwers ManualJonathanAndresGuerreroBarqueroNoch keine Bewertungen

- Manchester Encoding Using RS232Dokument4 SeitenManchester Encoding Using RS232Izhar Rosli100% (1)

- Environmental Stress Crack Resistance (ESCR) of Plastic Tighthead Drums Not Exceeding 60 Gal (227 L) in Rated CapacityDokument4 SeitenEnvironmental Stress Crack Resistance (ESCR) of Plastic Tighthead Drums Not Exceeding 60 Gal (227 L) in Rated CapacityAlevj DbNoch keine Bewertungen

- 516 - P2 - Sec 1 - 2018Dokument16 Seiten516 - P2 - Sec 1 - 2018jitendraNoch keine Bewertungen

- Sony Bravia KDLDokument36 SeitenSony Bravia KDLjafarrazaNoch keine Bewertungen

- Using Equotip Hardness Test BlocksDokument5 SeitenUsing Equotip Hardness Test Blocksanilbabu4Noch keine Bewertungen

- Challenging Baseline Inspection Paradigms For Oil Gas Upstream EquipmentDokument16 SeitenChallenging Baseline Inspection Paradigms For Oil Gas Upstream EquipmentSergey KichenkoNoch keine Bewertungen

- Manual MN-026 Champion 700 Series Motor Grader Series III Operators Manual L-4014-01!5!1991Dokument306 SeitenManual MN-026 Champion 700 Series Motor Grader Series III Operators Manual L-4014-01!5!1991estefaniacs100% (22)

- DTA Manual UsuarioDokument12 SeitenDTA Manual Usuario99lea99Noch keine Bewertungen

- SAE Seat Design OverviewDokument16 SeitenSAE Seat Design OverviewGuilherme PfeilstickerNoch keine Bewertungen

- Sedna Reporting FeaturesDokument13 SeitenSedna Reporting Featuressorin1970Noch keine Bewertungen

- Fastener TrainingDokument20 SeitenFastener TrainingJesus Barragán Ramos100% (2)

- TCP Congestion ControlDokument20 SeitenTCP Congestion ControlErik XuNoch keine Bewertungen

- Care Your HornDokument8 SeitenCare Your HornAlvaro Suarez VazquezNoch keine Bewertungen

- Kraken AKDokument12 SeitenKraken AKRomica Sibisan100% (1)

- Skirt and Dust Control BrochureDokument8 SeitenSkirt and Dust Control BrochureJacob MelendezNoch keine Bewertungen

- MVH S215BT Owners ManualDokument56 SeitenMVH S215BT Owners ManualCyberian100% (3)

- Jetty Pile Loading Test-rev-ADokument15 SeitenJetty Pile Loading Test-rev-AMochammad ShokehNoch keine Bewertungen

- Indian Ergonomics Standards - Existing and Needs: Production and General Engineering DepartmentDokument2 SeitenIndian Ergonomics Standards - Existing and Needs: Production and General Engineering Departmentnarendar.1Noch keine Bewertungen

- Electrical SMDB Check ListDokument2 SeitenElectrical SMDB Check ListBabu100% (2)

- MS 1837 - 2018 - FullpdfDokument48 SeitenMS 1837 - 2018 - FullpdfMay Ong100% (2)