Beruflich Dokumente

Kultur Dokumente

When To Perform Pipe Stress Analysis

Hochgeladen von

zakir84md36390 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten1 SeiteOriginaltitel

When to Perform Pipe Stress Analysis.doc

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten1 SeiteWhen To Perform Pipe Stress Analysis

Hochgeladen von

zakir84md3639Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

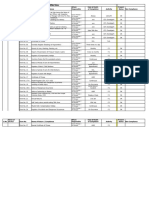

When to Perform Pipe Stress Analysis:

1. Lines that are 3 inch and larger that are:

a) connected to rotating equipment,

b) subject to differential settlement of connected equipment and/or supports,

c) with temperatures less than 20 F.

2. Lines connected to reciprocating equipment such as suction and discharge lines from reciprocating

compressors.

3. Lines 4 inches and larger connected to air coolers, steam generators or fired heater tube sections.

4. All size lines with temperatures of 600 F and higher.

5. Welded lines 6 inches and larger at a design temperature of 350 F or higher.

6. Lines 16 inches and larger (any temperature differential), because of large F=P*A thrust forces

7. High pressure lines (over 2000 psi), although pressures over 1500 psi are sometimes a problem,

particularly with restraint arrangements.

8. Lines subject to external pressure.

9. Thin-walled pipe or ducting of 18 inch diameter or larger, having an outside diameter over wall thickness

ratio of more than 90.

10. Lines requiring proprietary expansion devices, such as expansion joints or victaulic couplings.

11. Underground process lines. Pressures greater than 1000 psi in underground piping inevitably generates

high thrust forces, even at very low expansion temperature differentials. Attention is required on burial

techniques, changes in direction, ground entry/exit, or connection to equipment or tanks. Other examples

include pump/booster stations, terminals, meter stations and s****er traps.

12. Internally lined process piping & jacketed piping.

13. Lines in critical service.

14. Pressure relief systems. Also relief valve stacks with an inlet pressure greater than 150 psi.

15. Branch lines tie-ins or matched size, particularly relief systems tied together or large branch piping of

same size or close to piping being connected

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Check For Installation of Diesel Generator SetDokument2 SeitenCheck For Installation of Diesel Generator SetgpjegatheeshNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- SRU Training ModuleDokument161 SeitenSRU Training ModuleArun Kumar PNoch keine Bewertungen

- Piping Design ManualDokument155 SeitenPiping Design Manualnick10686100% (1)

- Huafengdongli 495 4100 Series Operationmanual PDFDokument73 SeitenHuafengdongli 495 4100 Series Operationmanual PDFSergio Ricardo IbañezNoch keine Bewertungen

- 210 MW BoilerDokument25 Seiten210 MW BoilerAhemadNoch keine Bewertungen

- Ventilation CalculationDokument148 SeitenVentilation CalculationFarid Sedeky100% (2)

- Richmond Stress NotesDokument110 SeitenRichmond Stress Notesmsaad2100% (2)

- Pid of A Piping SystemDokument4 SeitenPid of A Piping SystemBandaluppi VenkateshNoch keine Bewertungen

- Technology BoilerDokument26 SeitenTechnology Boilervery sihombing100% (1)

- P&IDDokument7 SeitenP&IDTagabo AliNoch keine Bewertungen

- OCW ACT BY KAK Tax PDFDokument57 SeitenOCW ACT BY KAK Tax PDFzakir84md3639Noch keine Bewertungen

- List of Staturoty ComplianceDokument12 SeitenList of Staturoty Compliancezakir84md3639Noch keine Bewertungen

- Form 17 - Health RegisterDokument2 SeitenForm 17 - Health Registerzakir84md3639Noch keine Bewertungen

- All Legal FormDokument13 SeitenAll Legal Formzakir84md3639Noch keine Bewertungen

- Bocw Formats MMSDokument6 SeitenBocw Formats MMSzakir84md3639Noch keine Bewertungen

- List of Staturoty ComplianceDokument12 SeitenList of Staturoty Compliancezakir84md3639Noch keine Bewertungen

- FD Fan Discharge DuctDokument5 SeitenFD Fan Discharge Ductzakir84md3639Noch keine Bewertungen

- BOCW ACT, 1996 Word DocuDokument38 SeitenBOCW ACT, 1996 Word Docuzakir84md3639Noch keine Bewertungen

- OCW ACT BY KAK Tax PDFDokument57 SeitenOCW ACT BY KAK Tax PDFzakir84md3639Noch keine Bewertungen

- Sexual Harassment Prevention - Legal Obligations of Employers PDFDokument7 SeitenSexual Harassment Prevention - Legal Obligations of Employers PDFzakir84md3639Noch keine Bewertungen

- BOCW LawsDokument9 SeitenBOCW LawsNoopur Kashyap100% (1)

- JapanDokument658 SeitenJapanzakir84md3639Noch keine Bewertungen

- Safety Audit Checklist Audited Section / Area: Audit Date: Auditor Name: Auditee NameDokument8 SeitenSafety Audit Checklist Audited Section / Area: Audit Date: Auditor Name: Auditee Namezakir84md3639Noch keine Bewertungen

- Meenaperfumery Shopping CartDokument4 SeitenMeenaperfumery Shopping Cartzakir84md3639Noch keine Bewertungen

- UsimpDokument954 SeitenUsimpzakir84md3639Noch keine Bewertungen

- Richmond Stress NotesDokument1 SeiteRichmond Stress Noteszakir84md3639Noch keine Bewertungen

- UsmetDokument459 SeitenUsmetzakir84md3639Noch keine Bewertungen

- Steel ChinaDokument263 SeitenSteel Chinazakir84md3639Noch keine Bewertungen

- DutchDokument1.107 SeitenDutchzakir84md3639Noch keine Bewertungen

- SaDokument203 SeitenSazakir84md3639Noch keine Bewertungen

- UkDokument807 SeitenUkzakir84md3639Noch keine Bewertungen

- KoreanDokument213 SeitenKoreanzakir84md3639Noch keine Bewertungen

- Branch Reinforcement - ASME 31.1Dokument8 SeitenBranch Reinforcement - ASME 31.1zakir84md3639Noch keine Bewertungen

- ThaiDokument55 SeitenThaizakir84md3639Noch keine Bewertungen

- AusDokument449 SeitenAuszakir84md3639Noch keine Bewertungen

- GermanDokument110 SeitenGermanzakir84md3639Noch keine Bewertungen

- AusDokument449 SeitenAuszakir84md3639Noch keine Bewertungen

- Need For Cooling System in IC EngineDokument19 SeitenNeed For Cooling System in IC EngineKINTUNoch keine Bewertungen

- From The Steam Table: Table 3 PT 1@ 540 C & 8mpa H 3496.7 KJ/KG & S 6.8481 PT 2 at 0.0035 Mpa & S S 6.8481 by InterpolationDokument5 SeitenFrom The Steam Table: Table 3 PT 1@ 540 C & 8mpa H 3496.7 KJ/KG & S 6.8481 PT 2 at 0.0035 Mpa & S S 6.8481 by InterpolationMark AgusNoch keine Bewertungen

- Alstom Editorial Guide Thailand To Showcase Latest Upgrade of Alstom S Gt26 in Combined Cycle - Whitepaperpdf.renderDokument4 SeitenAlstom Editorial Guide Thailand To Showcase Latest Upgrade of Alstom S Gt26 in Combined Cycle - Whitepaperpdf.renderEngr Jonathan O OkoronkwoNoch keine Bewertungen

- 02.lecture - 02 - Intro To IC EngineDokument112 Seiten02.lecture - 02 - Intro To IC Enginemahbububur rahmanNoch keine Bewertungen

- PumpsDokument4 SeitenPumpsLakshminarayanaNoch keine Bewertungen

- Cashback Model ListDokument79 SeitenCashback Model Listgixabat112Noch keine Bewertungen

- T4 Air Conditioning StudyDokument10 SeitenT4 Air Conditioning StudySzeQiLungNoch keine Bewertungen

- Wesman GBC GbsDokument4 SeitenWesman GBC GbsHardik PanchalNoch keine Bewertungen

- Aksesoris PumpDokument10 SeitenAksesoris PumpDido AlexanNoch keine Bewertungen

- Gas Turbine Trip System 2.2.5.3 Trip MatrixDokument1 SeiteGas Turbine Trip System 2.2.5.3 Trip MatrixMohammad Jahangir AlamNoch keine Bewertungen

- EX22CT (RHFE-559FTA2) : FeaturesDokument4 SeitenEX22CT (RHFE-559FTA2) : Featuresrafiullah353Noch keine Bewertungen

- Sheet 16 U-820 Sulfur Recovery Unit: Technical ServicesDokument1 SeiteSheet 16 U-820 Sulfur Recovery Unit: Technical ServicesAsad PatelNoch keine Bewertungen

- Vapor Power Cycles Lecture 1Dokument23 SeitenVapor Power Cycles Lecture 1Albert Shesman100% (1)

- Model 4WI 100 - 800 HP Boilers: 1.4 SubmittalsDokument4 SeitenModel 4WI 100 - 800 HP Boilers: 1.4 SubmittalssebaversaNoch keine Bewertungen

- Curva TE10D - 750GPM@165PSI - 2600RPMDokument2 SeitenCurva TE10D - 750GPM@165PSI - 2600RPMVictor Saldaña100% (1)

- Helical Coil SG Design CalculationDokument7 SeitenHelical Coil SG Design Calculationlram70Noch keine Bewertungen

- Liquid Metal Fast Breeder Reaction NotesDokument3 SeitenLiquid Metal Fast Breeder Reaction NotesM Qasim YousfiNoch keine Bewertungen

- Energy. Syllabus 2009 - Sem 2Dokument31 SeitenEnergy. Syllabus 2009 - Sem 2Suseel Jai KrishnanNoch keine Bewertungen

- Bir Berkin CPF Upgradation - TDE's ClarificationsDokument16 SeitenBir Berkin CPF Upgradation - TDE's ClarificationsMetidja BilalNoch keine Bewertungen

- Section 1.13 Hydraulic System Hand PumpsDokument4 SeitenSection 1.13 Hydraulic System Hand Pumpsaerogem618Noch keine Bewertungen

- Two-Way Threaded Globe Valve: FeaturesDokument4 SeitenTwo-Way Threaded Globe Valve: FeaturesTASDIKNoch keine Bewertungen

- Product Identification Number - IngersollrandDokument6 SeitenProduct Identification Number - Ingersollrandandy habibiNoch keine Bewertungen