Beruflich Dokumente

Kultur Dokumente

Inv04a-Lhc Detection en

Hochgeladen von

musewejamesoumaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Inv04a-Lhc Detection en

Hochgeladen von

musewejamesoumaCopyright:

Verfügbare Formate

DEPOT INVARIANTS FICHE-INV-04A

Version : 1

Date : 30/09/2015

Vapour and liquid hydrocarbons

MS/AMO/LA/LOG

Page 1 / 2

MS/AMO/HSEQ-DD

1) EQUIPMENTS AIM :

To detect the presence of combustible gas in the air or the presence of layers of liquid hydrocarbons.

2) STANDARDS OF INSTALLATION :

GS-AMO-SL-029 and STD-AMO-SL-354.

3) CONCERNED INSTALLATIONS :

All liquid hydrocarbon tanks with a storage temperature higher than the flash-point and with

3

operational capacity up to 100 m .

All liquid hydrocarbon tanks with a storage temperature lower than the flash-point and with operational

3

capacity up to than 5.000 m .

All separators of liquid hydrocarbon depots whatever are their capacities.

4) TIMELINE OF EQUIPMENT INSTALLATION:

Mandatory for new depots.

All existing depots must be equipped before the end of 2017.

5) DESCRIPTION OF THE EQUIPMENT:

Vapour HC optic detector « HCV » with

infrared absorption (type OLDHAM OLCT IR

Version E)

Liquid HC detector « HCL » consists of 1

sensor connected to a float. It uses the

density difference between water and

hydrocarbons for detection (LARCO HK1H

type) – 2 sensors for separator (LARCO

HK2H type)

Sensors are failsafe connected: in case of failure they have to indicate the defect (loss of current,

break in the cable…). Information acquisition could be managed by automate or by a dedicated

station. The minimal action will be audible and visual alarm activation. This equipment will be protected

with an uninterruptible power supply (UPS).

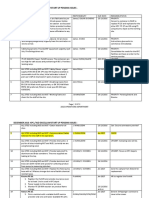

Bund compartment Pump house

Stored products (at the lowest point) (at the lowest point)

Separator

Product with T°C of storage 1 HCL (HK2H type)

1 HCV 1 HCV Into the second last

higher than the flash-point

Product with T°C of storage separator compartment

1 HCL 1 HCL (concrete)

lower than the flash-point

Or into the last separator

Mixed 1 HCV + 1HCL 1 HCV + 1HCL compartment

(prefabricated)

6) VISUAL OF THE EQUIPMENT AND BUDGET ESTIMATION :

Installed on a support at about 40 cm from the ground level.

Liquid HC Estimative cost: 3 k€ per detector

detector Vapour HC Add:

detector - preparatory costs (works, cables)

- installation costs and

commissioning

AME’s contract with purchasing

department.

DEPOT INVARIANTS FICHE-INV-04A

Version : 1

Date : 30/09/2015

Vapour and liquid hydrocarbons

MS/AMO/LA/LOG

Page 2 / 2

MS/AMO/HSEQ-DD

7) MAINTENANCE OF THE EQUIPMENT :

HCL DETECTOR – LARCO type

Frequency Control Actor

Check the cleanness of the pit where the detector is installed –

Daily Depot collaborator

clean it if needed.

Check if the float slides without constraints on its rail.

Test the operation of the detector by immersing it in water to

Quarterly check the transmission of the visual and sound alarm to the Depot collaborator

control panel and the linked actions.

Clean the detector.

HCV DETECTOR – OLDHAM type

Monthly Check if the detector is in good condition. Depot collaborator

Calibrate the detector with a standard gas (be careful: the

standard gas cylinders have a best before date) and realize a

Quarterly functional test. Depot collaborator

Check the transmission of the alarm to the detection system

(visual and sound).

After each vapour Check the good functioning of the detector and the absence of

Depot collaborator

detection drift.

HC DETECTION SYSTEM – CONTROL PANEL

Check the absence of detection and alarm and that all LED of

Daily Depot collaborator

detectors are green.

Use the TEST button to check the good functioning of the LED

Weekly Depot collaborator

and buzzer (sound alarm).

Every intervention has to be recorded on the life-sheet of the equipment.

8) DOWNGRADED SITUATION :

HCL DETECTION

Problem on the detector or on the

Increase frequency of rounds – replacement by a HCL detector in stock if

connection between the HCL detector and

available.

the electrical office

The power supply of the HCL detectors has to be automatically secured by a

Failure of site general power supply

generator or UPS (electronic cards have to be protected).

Increase frequency of rounds – replacement by a HCL detector in stock if

Defect of a HCL detector

available.

HCV DETECTION

Problem on the detector or on the

Increase frequency of rounds and implementation of a mobile detector (reload

connection between the HCV detector and

it regularly and alternate with another mobile detector).

the electrical office

The power supply of the HCV detectors has to be automatically secured by a

Failure of site general power supply

generator or an inverter (electronic cards have to be protected).

Increase frequency of rounds and implementation of a mobile detector (reload

Defect of a HCV detector it regularly and alternate with another mobile detector). Replacement if

possible with another HCV detector.

Das könnte Ihnen auch gefallen

- Novec Hazard Room CalcDokument8 SeitenNovec Hazard Room Calckarim3samirNoch keine Bewertungen

- Nfs2-8 Instal Manual WebDokument0 SeitenNfs2-8 Instal Manual WebDota NgNoch keine Bewertungen

- Guideline For FM200 Systems Rev18Dokument17 SeitenGuideline For FM200 Systems Rev18Salman YahyaNoch keine Bewertungen

- Guideline For TSP Sapphire SystemsDokument15 SeitenGuideline For TSP Sapphire SystemsCK ChioNoch keine Bewertungen

- Fire Alarm System Operating InstructionsDokument32 SeitenFire Alarm System Operating InstructionsJun Rey DasigNoch keine Bewertungen

- EST EST2 v3.5 Serial Number Log Book PDFDokument22 SeitenEST EST2 v3.5 Serial Number Log Book PDFAhamed KyanaNoch keine Bewertungen

- Parking Garage Ventlation1Dokument2 SeitenParking Garage Ventlation1MOHAMED ELKHASHABNoch keine Bewertungen

- Tyco Water Curtain NozzleDokument2 SeitenTyco Water Curtain NozzlejonejackrousseauNoch keine Bewertungen

- Drainage Lect - 1 BAUDokument68 SeitenDrainage Lect - 1 BAUAbed BaayounNoch keine Bewertungen

- English Book A4 Final UpdateDokument221 SeitenEnglish Book A4 Final UpdateVinay PallivalppilNoch keine Bewertungen

- 848 - 2017 Decree of The Ministry of The Environment On Fire Safety of BuildingsDokument25 Seiten848 - 2017 Decree of The Ministry of The Environment On Fire Safety of BuildingsPatrik AlfredssonNoch keine Bewertungen

- Product Manual DCP Trolley Mounted 25-50-75 KGDokument6 SeitenProduct Manual DCP Trolley Mounted 25-50-75 KGm4l4ysiaNoch keine Bewertungen

- TYCO Sprinkler Application Chart PDFDokument1 SeiteTYCO Sprinkler Application Chart PDFRomyrNoch keine Bewertungen

- Asd 640Dokument2 SeitenAsd 640RICHI100% (1)

- 49.22 2007 ASHRAE Handbook-HVAC Applications (SI) : Swimming Pools/Health Clubs. The Desirable Temperature ForDokument2 Seiten49.22 2007 ASHRAE Handbook-HVAC Applications (SI) : Swimming Pools/Health Clubs. The Desirable Temperature ForAhmed Mohamed GadoNoch keine Bewertungen

- Shield Pipes Fittings PDFDokument36 SeitenShield Pipes Fittings PDFilieoniciuc50% (2)

- VRF Additonal Refrigerant Charge CalculationDokument5 SeitenVRF Additonal Refrigerant Charge CalculationtowiwaNoch keine Bewertungen

- SEVO Systems Pocket BrochureDokument8 SeitenSEVO Systems Pocket BrochureNikhil RajanNoch keine Bewertungen

- Construction V2-0 Sept 10 - ACC - WE - DB1000Dokument34 SeitenConstruction V2-0 Sept 10 - ACC - WE - DB1000vin ssNoch keine Bewertungen

- 2 FM200 ComponentsDokument40 Seiten2 FM200 ComponentsJose Antonio Lara0% (1)

- Specification For Sprinkler LPC - FSD Circular 2006 - 03Dokument46 SeitenSpecification For Sprinkler LPC - FSD Circular 2006 - 03James Li100% (1)

- PMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Dokument1 SeitePMG-EnG-O-DSH-U00-001-W Rev 3 Fire Fighting & Safety Equipment Datasheet - Part11Aditya PranotoNoch keine Bewertungen

- Viking Residential Sprinkler Installation GuideDokument18 SeitenViking Residential Sprinkler Installation Guidesina_84Noch keine Bewertungen

- Cla-Val: Fire Protection Pressure Relief ValveDokument2 SeitenCla-Val: Fire Protection Pressure Relief ValveShoaib AhmedNoch keine Bewertungen

- Pyro Sim ManualDokument180 SeitenPyro Sim Manualcrow250Noch keine Bewertungen

- Mechanical Plan Review GuideDokument11 SeitenMechanical Plan Review GuideEngelbert CasanovaNoch keine Bewertungen

- GW SprinklersDokument18 SeitenGW SprinklersmajdirossrossNoch keine Bewertungen

- 800024-004 Diom Manual, Ihp Co2Dokument47 Seiten800024-004 Diom Manual, Ihp Co2rulo zamora mendez100% (1)

- RF Spacing High CeilingsDokument73 SeitenRF Spacing High CeilingsmkpNoch keine Bewertungen

- Fire Sprinkler System Design GuidelinesDokument11 SeitenFire Sprinkler System Design GuidelinesMarck Gheson InacayNoch keine Bewertungen

- FM200 SpecDokument14 SeitenFM200 SpecDak Serik100% (1)

- Calculation of Invert LevelsDokument15 SeitenCalculation of Invert LevelsUsama ChatthaNoch keine Bewertungen

- MvwsDokument1 SeiteMvwsparthasutradharNoch keine Bewertungen

- MECH QCDD Exam Questions KIC by Amr SaadDokument4 SeitenMECH QCDD Exam Questions KIC by Amr SaadSHERIF KHATTABNoch keine Bewertungen

- Fire SuppresionDokument1 SeiteFire Suppresionʞǝǝs Uǝ ƎpıɥNoch keine Bewertungen

- Fire ProDokument104 SeitenFire ProMaiger100% (2)

- Selection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of PracticeDokument21 SeitenSelection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of Practiceabhirami91Noch keine Bewertungen

- Flow-Switch-RapidropDokument4 SeitenFlow-Switch-RapidropNOMANNoch keine Bewertungen

- CHECKLSITDokument2 SeitenCHECKLSITaboobacker siddiqueNoch keine Bewertungen

- HydraulicDokument8 SeitenHydraulicOsama OmayerNoch keine Bewertungen

- PN 441880Dokument4 SeitenPN 441880JhojanCeleitaNoch keine Bewertungen

- Tuto Pyrosim Hvac Room PDFDokument14 SeitenTuto Pyrosim Hvac Room PDFgilles arzulNoch keine Bewertungen

- Kidde ECS and ECS-500 Part Number List For Nozzle Used With Novec 1230 K-45-2165 AADokument14 SeitenKidde ECS and ECS-500 Part Number List For Nozzle Used With Novec 1230 K-45-2165 AAelias rangelNoch keine Bewertungen

- Fts034 Hi-Fog 2000 Us Light Hazard (FM)Dokument3 SeitenFts034 Hi-Fog 2000 Us Light Hazard (FM)Wissam Jarmak100% (1)

- MANUAL IOMFES-iflow REV01 PDFDokument139 SeitenMANUAL IOMFES-iflow REV01 PDFambition1340cnNoch keine Bewertungen

- Tyco General Products CatalogoDokument96 SeitenTyco General Products Catalogojoana ramirezNoch keine Bewertungen

- Guideline For Inert Gas Systems Rev5.PDF-1Dokument21 SeitenGuideline For Inert Gas Systems Rev5.PDF-1nicholas.ny95Noch keine Bewertungen

- Left Elevation: AroomDokument4 SeitenLeft Elevation: AroomMUBASHIRNoch keine Bewertungen

- Fire HydrantDokument31 SeitenFire HydrantVikas YamagarNoch keine Bewertungen

- FM Global Property Loss Prevention Data Sheets: 1.0 SCOPEDokument38 SeitenFM Global Property Loss Prevention Data Sheets: 1.0 SCOPEhhNoch keine Bewertungen

- Key Maintenance SwitchDokument4 SeitenKey Maintenance SwitchkuraimundNoch keine Bewertungen

- Fans in Fire SafetyDokument58 SeitenFans in Fire SafetyMohammed Majeed Ali100% (1)

- CyberCat 2015 FULL PrintoutDokument430 SeitenCyberCat 2015 FULL PrintoutKrishna Kumar100% (1)

- FirePro Xtinguish V1.03Dokument99 SeitenFirePro Xtinguish V1.03احمد الجزار2007100% (1)

- TCVN 4513-1988 - Internal Water Supply Design StandardDokument30 SeitenTCVN 4513-1988 - Internal Water Supply Design StandardgiangNoch keine Bewertungen

- Grundfos Pumping Station Model-A95922154P11138 RehabilitationDokument3 SeitenGrundfos Pumping Station Model-A95922154P11138 RehabilitationMotasem AlnajjarNoch keine Bewertungen

- As ISO 14520.2-2009 Gaseous Fire-Extinguishing Systems - Physical Properties and System Design CF3I ExtinguisDokument6 SeitenAs ISO 14520.2-2009 Gaseous Fire-Extinguishing Systems - Physical Properties and System Design CF3I ExtinguisSAI Global - APACNoch keine Bewertungen

- Hi-Fog For Buildings: Technical IntroductionDokument16 SeitenHi-Fog For Buildings: Technical IntroductionEsther TapiaNoch keine Bewertungen

- Marine Sewage and Hygiene Test Kits Help Ships ComplyDokument5 SeitenMarine Sewage and Hygiene Test Kits Help Ships ComplyPhan Cao An TruongNoch keine Bewertungen

- CLX-Brochure 영문Dokument4 SeitenCLX-Brochure 영문Elias Dalens CastroNoch keine Bewertungen

- Burhani Contract - Rev 1-16.11.8Dokument27 SeitenBurhani Contract - Rev 1-16.11.8musewejamesoumaNoch keine Bewertungen

- As Built Valuation For Fire Drill Ramp Works - 1.11.18Dokument1 SeiteAs Built Valuation For Fire Drill Ramp Works - 1.11.18musewejamesoumaNoch keine Bewertungen

- 00569420181106140644Dokument1 Seite00569420181106140644musewejamesoumaNoch keine Bewertungen

- Access Controls Cost Estimates - A1-3d37dDokument5 SeitenAccess Controls Cost Estimates - A1-3d37dmusewejamesoumaNoch keine Bewertungen

- Gapco Terminal InspectionDokument18 SeitenGapco Terminal InspectionmusewejamesoumaNoch keine Bewertungen

- Air CompressorsDokument8 SeitenAir CompressorsmusewejamesoumaNoch keine Bewertungen

- Car and General Contract Servicing of Generators 2016 2019Dokument20 SeitenCar and General Contract Servicing of Generators 2016 2019musewejamesoumaNoch keine Bewertungen

- Diploma HseDokument1 SeiteDiploma HsemusewejamesoumaNoch keine Bewertungen

- Nesvax Email CorrespondenceDokument1 SeiteNesvax Email CorrespondencemusewejamesoumaNoch keine Bewertungen

- List of Critical Safety Barriers: NO.s Code LocationsDokument2 SeitenList of Critical Safety Barriers: NO.s Code LocationsmusewejamesoumaNoch keine Bewertungen

- Chain Link Fencing at Nrs - FinancialDokument1 SeiteChain Link Fencing at Nrs - FinancialmusewejamesoumaNoch keine Bewertungen

- Boarding Pass 2Dokument1 SeiteBoarding Pass 2musewejamesoumaNoch keine Bewertungen

- Euler FlowDokument9 SeitenEuler FlowmusewejamesoumaNoch keine Bewertungen

- List of Critical Safety Barriers: NO.s Code LocationsDokument2 SeitenList of Critical Safety Barriers: NO.s Code LocationsmusewejamesoumaNoch keine Bewertungen

- ContainmentDokument1 SeiteContainmentmusewejamesoumaNoch keine Bewertungen

- Par - Changamwe LPG PlantDokument2 SeitenPar - Changamwe LPG PlantmusewejamesoumaNoch keine Bewertungen

- Analysis+ DMA 35 EX PetroDokument2 SeitenAnalysis+ DMA 35 EX PetromusewejamesoumaNoch keine Bewertungen

- Changamwe LPG HLA Recalibration of Tanks - Status 29.08.17Dokument1 SeiteChangamwe LPG HLA Recalibration of Tanks - Status 29.08.17musewejamesoumaNoch keine Bewertungen

- LAPESADokument16 SeitenLAPESAmusewejamesoumaNoch keine Bewertungen

- 05148Dokument1 Seite05148musewejamesoumaNoch keine Bewertungen

- Boarding Pass: Ouma / James MRDokument1 SeiteBoarding Pass: Ouma / James MRmusewejamesoumaNoch keine Bewertungen

- KPC NJD EXCELLIUM START UP ISSUESDokument3 SeitenKPC NJD EXCELLIUM START UP ISSUESmusewejamesoumaNoch keine Bewertungen

- 03 Fluid Flow Rev PRN (Compatibility Mode)Dokument38 Seiten03 Fluid Flow Rev PRN (Compatibility Mode)musewejamesoumaNoch keine Bewertungen

- Electricmotors 1Dokument101 SeitenElectricmotors 1musewejamesoumaNoch keine Bewertungen

- Analysis Final Revised List of Sites Weighing Scales Final ListDokument1 SeiteAnalysis Final Revised List of Sites Weighing Scales Final ListmusewejamesoumaNoch keine Bewertungen

- MSC Building Services EngineeringDokument7 SeitenMSC Building Services EngineeringmusewejamesoumaNoch keine Bewertungen

- This Was One of FrancoDokument10 SeitenThis Was One of FrancomusewejamesoumaNoch keine Bewertungen

- Excellium Project - Standby Pump and Stainless Steel Tanks - NJDDokument4 SeitenExcellium Project - Standby Pump and Stainless Steel Tanks - NJDmusewejamesoumaNoch keine Bewertungen

- Edoc Corrective Action Plan 2016Dokument2 SeitenEdoc Corrective Action Plan 2016musewejamesoumaNoch keine Bewertungen

- Bomba 750 GPM 110 PSIDokument1 SeiteBomba 750 GPM 110 PSIEDWIN HUMBERTO QUICENO CANONoch keine Bewertungen

- Chemsheets As 1138 Free Radical Substitution 2 ANS Bns28Dokument2 SeitenChemsheets As 1138 Free Radical Substitution 2 ANS Bns28charlesma12350% (4)

- 3 BrochureDokument32 Seiten3 Brochureali1984marNoch keine Bewertungen

- PINOYBIX SATELLITE COMMUNICATION QuestionDokument47 SeitenPINOYBIX SATELLITE COMMUNICATION QuestionCamille VeaNoch keine Bewertungen

- How To Size Pump Suction PipingDokument2 SeitenHow To Size Pump Suction PipingShebnemNoch keine Bewertungen

- 04.integration of 2D Analog and 3D High Resolution Seismic Data For Regional Shallow Overburden Description in Tangguh Field, IndonesiaDokument17 Seiten04.integration of 2D Analog and 3D High Resolution Seismic Data For Regional Shallow Overburden Description in Tangguh Field, IndonesiaHerry SuhartomoNoch keine Bewertungen

- Tle/Epas: Quarter 1 - Module 1Dokument28 SeitenTle/Epas: Quarter 1 - Module 1Doone Heart Santander CabuguasNoch keine Bewertungen

- Reflection Numericals TestDokument15 SeitenReflection Numericals Testshalu malaniNoch keine Bewertungen

- DP27, DP27E, DP27R and DP27Y Pilot Operated Pressure Reducing ValvesDokument36 SeitenDP27, DP27E, DP27R and DP27Y Pilot Operated Pressure Reducing ValvesAntonio FedatoNoch keine Bewertungen

- Freezing Point of Aqueous Engine Coolants: Standard Test Method ForDokument3 SeitenFreezing Point of Aqueous Engine Coolants: Standard Test Method ForMaxNoch keine Bewertungen

- Full Download Discovering The Universe 10th Edition Comins Solutions ManualDokument12 SeitenFull Download Discovering The Universe 10th Edition Comins Solutions Manualpetrorichelle501100% (38)

- Bitumen 50-70 Pen EcDokument1 SeiteBitumen 50-70 Pen Ecaegean227Noch keine Bewertungen

- Penetapan Kadar Zink Pada Sediaan Farmasi Dengan Metode Kompleksometri Dan Spektrofotometri Serapan AtomDokument9 SeitenPenetapan Kadar Zink Pada Sediaan Farmasi Dengan Metode Kompleksometri Dan Spektrofotometri Serapan AtomKikiNoch keine Bewertungen

- Differential Geometry Theorem and ApplicationsDokument92 SeitenDifferential Geometry Theorem and ApplicationsJuan David MesaNoch keine Bewertungen

- Lecture Remote Sensing 008 ThermalDokument29 SeitenLecture Remote Sensing 008 Thermalcurious aimNoch keine Bewertungen

- DS Wear Creusabro Superten 2020 1Dokument3 SeitenDS Wear Creusabro Superten 2020 1Erdinc BayatNoch keine Bewertungen

- Mastery Test in Physical Science - Gr.11Dokument3 SeitenMastery Test in Physical Science - Gr.11kert mendozaNoch keine Bewertungen

- ModelingandControlofX ShapeQuadcopterDokument13 SeitenModelingandControlofX ShapeQuadcopterዮናስNoch keine Bewertungen

- Varistor Tutorial: Register To Download Premium Content!Dokument10 SeitenVaristor Tutorial: Register To Download Premium Content!a_calabreseNoch keine Bewertungen

- Light Sensor To Switch On A Light or Any Device LDR: December 2018Dokument14 SeitenLight Sensor To Switch On A Light or Any Device LDR: December 2018michael kogoNoch keine Bewertungen

- EM-214 Bifilar and Trifler Suspension ApparatusDokument2 SeitenEM-214 Bifilar and Trifler Suspension ApparatusMUHAMMAD NAUMANNoch keine Bewertungen

- MITIGATING TRANSIENT RECOVERY VOLTAGES USING SUPERCAPACITORSDokument6 SeitenMITIGATING TRANSIENT RECOVERY VOLTAGES USING SUPERCAPACITORSLuis ÁtilaNoch keine Bewertungen

- ASTM D5454-11e1Dokument3 SeitenASTM D5454-11e1Angel MurilloNoch keine Bewertungen

- XENOY™ Resin 1760E - AmericasDokument4 SeitenXENOY™ Resin 1760E - AmericasWellington C. de AraujoNoch keine Bewertungen

- Electricity Distribution Systems ExplainedDokument2 SeitenElectricity Distribution Systems ExplainedMichael SharpeNoch keine Bewertungen

- Physics For Scientists and Engineers, 6e Chapter 11 - Angular MomentumDokument15 SeitenPhysics For Scientists and Engineers, 6e Chapter 11 - Angular MomentumHoàng HàNoch keine Bewertungen

- Performance CurvesDokument1 SeitePerformance CurveskapsarcNoch keine Bewertungen

- A Gas Expands at Constant Temperature From An Init...Dokument2 SeitenA Gas Expands at Constant Temperature From An Init...Mahboob AliNoch keine Bewertungen

- 2018 Grade 10 Physics Notes PDFDokument136 Seiten2018 Grade 10 Physics Notes PDFSalifyanji100% (3)

- QuST Sponsored MTechDokument1 SeiteQuST Sponsored MTechRahul RoushanNoch keine Bewertungen