Beruflich Dokumente

Kultur Dokumente

California Plumbing Code - Matrix Adoption Table Chapter 3 - General Regulations

Hochgeladen von

Anonymous PCsoNCt0mFOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

California Plumbing Code - Matrix Adoption Table Chapter 3 - General Regulations

Hochgeladen von

Anonymous PCsoNCt0mFCopyright:

Verfügbare Formate

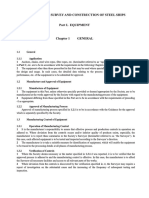

CALIFORNIA PLUMBING CODE – MATRIX ADOPTION TABLE

CHAPTER 3 - GENERAL REGULATIONS

Adopting Agency BSC SFM HCD DSA OSHPD CSA DPH AGR DWR CA

Adopt Entire Chapter X X

1 2 1/AC AC SS SS/CC 1 2 3 4

Adopt Entire Chapter as

amended (amended sections X X X X X X X X

listed below)

Adopt only those sections

that are listed below

Chapter/Section

301.2 X X

301.2.1 † †

301.2.1.1 † †

301.2.1.2 † †

301.5 X X

303.0 Exception X

304.0 Exception X

311.9 X X X X

311.10 X X X

311.11 X

311.12 X X X

316.1.6 X X

316.1.8 X X XX

316.1.9 X X XX

316.2.4 X X X X XX

320.0 X X XX

The state agency does not adopt sections identified by the following symbol: †

2010 CALIFORNIA PLUMBING CODE 39

40 2010 CALIFORNIA PLUMBING CODE

CHAPTER 3

GENERAL REGULATIONS

301.0 Materials – Standards and Alternates. 301.2 Alternate Materials and Methods of Construction

301.1 Minimum Standards. Equivalency. Nothing in this code is intended to prevent the

use of systems, methods, or devices of equivalent or superior

301.1.1 Approvals. All pipe, pipe fittings, traps, fixtures,

quality, strength, fire resistance, effectiveness, durability, and

material, and devices used in a plumbing system shall be

safety over those prescribed by this code. Technical docu-

listed or labeled (third-party certified) by a listing agency

mentation shall be submitted to the Authority Having Juris-

(accredited conformity assessment body) and shall con-

diction to demonstrate equivalency. The Authority Having

form to approved applicable recognized standards refer-

Jurisdiction shall have the authority to approve or disapprove

enced in this code, and shall be free from defects. Unless

otherwise provided for in this code, all materials, fix- the system, method or device for the intended purpose. [HCD

tures, or devices used or entering into the construction of 1 & HCD 2] (See Section 1.8.7).

plumbing systems, or parts thereof, shall be submitted to However, the exercise of this discretionary approval by

the Authority Having Jurisdiction for approval. the Authority Having Jurisdiction shall have no effect beyond

301.1.2 Marking. Each length of pipe and each pipe fit- the jurisdictional boundaries of said Authority Having Juris-

ting, trap, fixture, material, and device used in a plumb- diction. Any alternate material or method of construction so

ing system shall have cast, stamped, or indelibly marked approved shall not be considered as conforming to the re-

on it the manufacturer's mark or name, which shall read- quirements and/or intent of this code for any purpose other

ily identify the manufacturer to the end user of the prod- than that granted by the Authority Having Jurisdiction when

uct. When required by the approved standard that applies, the submitted data does not prove equivalency.

the product shall be marked with the weight and the qual- 301.2.1 Testing. The Authority Having Jurisdiction shall

ity of the product. Materials and devices used or entering have the authority to require tests, as proof of equiva-

into the construction of plumbing and drainage systems, lency.

or parts thereof, shall be marked and identified in a man- 301.2.1.1 Tests shall be made in accordance with ap-

ner satisfactory to the Authority Having Jurisdiction. proved or applicable standards, by an approved test-

Such marking shall be done by the manufacturer. Field ing agency at the expense of the applicant. In the

markings shall not be acceptable. absence of such standards, the Authority Having Ju-

301.1.3 Standards. Standards listed or referred to in this risdiction shall have the authority to specify the test

chapter or other chapters cover materials that will con- procedure.

form to the requirements of this code, when used in ac- 301.2.1.2 The Authority Having Jurisdiction shall

cordance with the limitations imposed in this or other have the authority to require tests to be made or re-

chapters thereof and their listing. Where a standard cov- peated if, at any time, there is reason to believe that

ers materials of various grades, weights, quality, or con- any material or device no longer conforms to the re-

figurations, there may be only a portion of the listed quirements on which its approval was based.

standard that is applicable. Design and materials for spe-

301.3 Flood Hazard Resistance.

cial conditions or materials not provided for herein shall

be permitted to be used only by special permission of the 301.3.1 General. Plumbing systems shall be located

Authority Having Jurisdiction after the Authority Hav- above the design flood elevation.

ing Jurisdiction has been satisfied as to their adequacy. A Exception: Plumbing systems are permitted to be located

list of accepted plumbing materials standards is included below the design flood elevation provided that the sys-

in Table 14-1. IAPMO Installation Standards are in- tems are designed and installed to prevent water from en-

cluded in Appendix I for the convenience of the users of tering or accumulating within their components and the

this code. They are not considered as a part of this code systems are constructed to resist hydrostatic and hydro-

unless formally adopted as such by the Authority Having dynamic loads and stresses, including the effects of buoy-

Jurisdiction. ancy, during the occurrence of flooding to the design

301.1.4 Existing Buildings. In existing buildings or flood elevation.

premises in which plumbing installations are to be al- 301.3.2 Flood Hazard Areas Subject to High- Velocity

tered, repaired, or renovated, the Authority Having Ju- Wave Action. Plumbing systems in buildings located in

risdiction has discretionary powers to permit deviation flood hazard areas subject to high-velocity wave action

from the provisions of this code, provided that such pro- shall meet the requirements of Section 301.3.1, and plumb-

posal to deviate is first submitted for proper determina- ing systems, pipes, and fixtures shall not be mounted on or

tion in order that health and safety requirements, as they penetrate through walls that are intended to breakaway

pertain to plumbing, shall be observed. under flood loads as required by the Building Code.

2010 CALIFORNIA PLUMBING CODE 41

GENERAL REGULATIONS

301.4 Alternative Engineered Design. 302.0 Iron Pipe Size (IPS) Pipe.

301.4.1 Design Criteria. An alternative engineered de- Iron, steel, brass, and copper pipe shall be standard- weight

sign shall conform to the intent of the provisions of this iron pipe size (IPS) pipe.

code and shall provide an equivalent level of quality,

strength, effectiveness, fire resistance, durability, and

303.0 Disposal of Liquid Waste.

safety. Material, equipment, or components shall be de-

signed and installed in accordance with the manufac- It shall be unlawful for any person to cause, suffer, or permit

turer’s installation instructions. the disposal of sewage, human excrement, or other liquid

wastes, in any place or manner, except through and by means

301.4.2 Permit Application. The registered professional

of an approved drainage system, installed and maintained in

engineer shall indicate on the design documents that the

accordance with the provisions of this code.

plumbing system, or parts thereof, is an alternative engi-

neered design so that it is noted on the construction per- Exception: [HCD 1] Limited-density owner-built rural

mit application. The permit and permanent permit dwellings. A water closet shall not be required when an al-

records shall indicate that an alternative engineered de- ternate system is provided and has been approved by the local

sign was part of the approved installation. health official. Where an alternative to the water closet is in-

stalled, a system for the disposal or treatment of graywater

301.4.3 Technical Data. The registered professional en- shall be provided to the dwelling. Graywater systems shall be

gineer shall submit sufficient technical data to substanti- designed according to water availability, use and discharge.

ate the proposed alternative engineered design and to The design, use and maintenance standards of such systems

prove that the performance meets the intent of this code. shall be the prerogative of the local health official.

301.4.4 Design Documents. The registered professional

engineer shall provide two (2) complete sets of signed

and sealed design documents for the alternative engi- 304.0 Connections to Plumbing System Required.

neered design for submittal to the Authority Having Ju- Plumbing fixtures, drains, appurtenances, and appliances,

risdiction. The design documents shall include floor used to receive or discharge liquid wastes or sewage, shall be

plans and a riser diagram of the work. Where appropri- connected properly to the drainage system of the building or

ate, the design documents shall indicate the direction of premises, in accordance with the requirements of this code.

flow, pipe sizes, grade of horizontal piping, loading, and Exception: [HCD 1] Limited-density owner-built rural

location of fixtures and appliances. dwellings. Where conventional plumbing, in all or in part, is

301.4.5 Design Approval. Any approval of an alterna- installed within the structure, it shall be installed in accor-

tive engineered design shall be at the discretion of the dance with the provisions of this code. Alternative materials

Authority Having Jurisdiction. The exercise of this dis- and methods shall be permitted provided that the design com-

cretionary approval by the Authority Having Jurisdiction plies with the intent of the code, and that such alternatives

shall have no effect beyond the jurisdictional boundaries shall perform to protect health and safety for the intended

of said Authority Having Jurisdiction. Any alternative purpose.

engineered design so approved shall not be considered

as conforming to the requirements and/or intent of this 305.0 Sewers Required.

code for any purpose other than that granted by the Au-

thority Having Jurisdiction. 305.1 Every building in which plumbing fixtures are installed

shall have a connection to a public or private sewer except as

301.4.6 Design Review. The Authority Having Jurisdic- provided in Section 305.2.

tion shall have the authority to require testing of the al-

ternative engineered design in accordance to Section 305.2 When a public sewer is not available for use, drainage

301.2.1, including the authority to require an independ- piping from buildings and premises shall be connected to an

ent review of the design documents by a registered pro- approved private sewage disposal system.

fessional engineer selected by the Authority Having 305.3 In cities and/or counties where the installation of build-

Jurisdiction and at the expense of the applicant. ing sewers is under the jurisdiction of a department other than

301.4.7 Inspection and Testing. The alternative engi- the Authority Having Jurisdiction, the provisions of this code

neered design shall be tested and inspected in accordance relating to building sewers need not apply.

with the submitted testing and inspection plan and the re-

quirements of this code. 306.0 Damage to Drainage System or Public Sewer.

301.5 One- and Two-Family Dwellings. [HCD 1 & HCD 2] 306.1 It shall be unlawful for any person to deposit, by any

The provisions contained in this code shall not apply to one means whatsoever, into any plumbing fixture, floor drain, in-

and two-family dwelling private sewage disposal systems and terceptor, sump, receptor, or device, which is connected to

minimum plumbing facilities when alternate facilities or in- any drainage system, public sewer, private sewer, septic tank,

stallations have been approved by the local health authority, or cesspool, any ashes; cinders; solids; rags; inflammable,

provided that such alternative facilities or installations pro- poisonous, or explosive liquids or gases; oils; grease; or any

vide substantially equivalent or greater protection to health other thing whatsoever that would, or could, cause damage

and safety. to the drainage system or public sewer.

42 2010 CALIFORNIA PLUMBING CODE

GENERAL REGULATIONS

306.2 Roofs, inner courts, vent shafts, light wells, or similar except that a double hub sanitary tapped tee shall be permit-

areas having rainwater drain, shall discharge to the outside of ted to be used on a vertical line as a fixture connection.

the building or to the gutter and shall not be connected to the 311.2 No drainage or vent piping shall be drilled and tapped

sanitary drainage system unless first approved by the Au- for the purpose of making connections thereto, and no cast-

thority Having Jurisdiction. iron soil pipe shall be threaded.

311.3 No waste connection shall be made to a closet bend or

307.0 Industrial Wastes. stub of a water closet or similar fixture.

307.1 Wastes detrimental to the public sewer system or detri- 311.4 Except as hereinafter provided in Sections 908.0, 909.0,

mental to the functioning of the sewage treatment plant shall and 910.0, no vent pipe shall be used as a soil or waste pipe,

be treated and disposed of as found necessary and directed nor shall any soil or waste pipe be used as a vent. Also, sin-

by the Authority Having Jurisdiction. gle-stack drainage and venting systems with unvented branch

307.2 Sewage or other waste from a plumbing system that lines are prohibited.

may be deleterious to surface or subsurface waters shall not 311.5 No fitting, fixture and piping connection, appliance, de-

be discharged into the ground or into any waterway unless it vice, or method of installation that obstructs or retards the

has first been rendered safe by some acceptable form of treat- flow of water, wastes, sewage, or air in the drainage or vent-

ment as required by the Authority Having Jurisdiction. ing systems, in an amount exceeding the normal frictional re-

sistance to flow, shall be used unless it is indicated as

acceptable in this code or is approved per Section 301.1 of

308.0 Location. this code. The enlargement of a three (3) inch (80 mm) closet

308.1 Except as otherwise provided in this code, no plumb- bend or stub to four (4) inches (100 mm) shall not be consid-

ing system, drainage system, building sewer, private sewage ered an obstruction.

disposal system, or parts thereof shall be located in any lot 311.6 Except for necessary valves, where inter-membering or

other than the lot that is the site of the building, structure, or mixing of dissimilar metals occurs, the point of connection

premises served by such facilities. shall be confined to exposed or accessible locations.

308.2 No subdivision, sale, or transfer of ownership of exist- 311.7 Valves, pipes, and fittings shall be installed in correct

ing property shall be made in such manner that the area, clear- relationship to the direction of flow.

ance, and access requirements of this code are decreased. 311.8 Screwed Fittings. Screwed fittings shall be ABS, cast-

iron, copper, copper alloy, malleable iron, PVC, steel, or other

309.0 Improper Location. approved materials. Threads shall be tapped out of solid metal

or molded in solid ABS or PVC.

Piping, fixtures, or equipment shall not be so located as to in-

terfere with the normal use thereof or with the normal opera- 311.9 [OSHPD 1, 2, 3 & 4] Drainage piping over operating

tion and use of windows, doors, or other required facilities. and delivery rooms, nurseries, food preparation centers,

food-serving facilities, food storage areas, and other sensi-

tive areas shall be kept to a minimum and shall not be ex-

310.0 Workmanship. posed. Special precautions shall be taken to protect these

310.1 Design, construction, and workmanship shall be in con- areas from possible leakage from necessary overhead

formity with accepted engineering practices and shall be of drainage piping systems. Piping over switchboards, panel

such character as to secure the results sought to be obtained boards, and motor control centers are subject to restrictions

by this code. of the California Electrical Code where applicable.

310.2 It is unlawful to conceal cracks, holes, or other imper- 311.10 [OSHPD 1, 3 & 4] Floor drains shall not be installed

fections in materials by welding, brazing, or soldering or by in operating and delivery rooms. Floor drains with self-prim-

using therein or thereon any paint, wax, tar, solvent cement, ing traps may be installed in cystoscopic rooms.

other leak-sealing or repair agent. 311.11 [SFM] For applications listed in Section 1.11.0 reg-

310.3 Burred ends of pipe and tubing shall be reamed to the ulated by the Office of the State Fire Marshal, plastic piping

full bore of the pipe or tube, and chips shall be removed. shall not be exposed as a portion of the interior room finish

310.4 Installation Practices. Plumbing systems shall be in- in a building or structure if the piping has a flame-spread rat-

stalled in a manner conforming to this code, applicable stan- ing exceeding 75 when tested in accordance with ASTM E 84-

dards, and the manufacturer’s installation instructions. In 77a, “Test for Surface Burning Characteristics of Building

Materials.”

instances where the code, applicable standards, or the manu-

facturer’s instructions conflict, the more stringent provisions 311.12 [OSHPD 1, 2 & 4] Services/Systems and Utilities.

shall prevail. Refer to Section 1224.4.1, California Building Code.

311.0 Prohibited Fittings and Practices. 312.0 Independent Systems.

311.1 No double hub fitting, single or double tee branch, sin- The drainage system of each new building and of new work

gle or double tapped tee branch, side inlet quarter bend, run- installed in any existing building shall be separate and inde-

ning thread, band, or saddle shall be used as a drainage fitting, pendent from that of any other building, and, when available,

2010 CALIFORNIA PLUMBING CODE 43

GENERAL REGULATIONS

every building shall have an independent connection with a plate shall extend along the framing member not less than one

public or private sewer. and one-half (11⁄2) inches (38 mm) beyond the outside diam-

Exception: Where one (1) building stands in the rear of an- eter of the pipe or tubing.

other building on an interior lot, and no private sewer is avail- Exception: See Section 1211.3.4.

able or can be constructed to the rear building through an 313.10 Sleeves.

adjoining court, yard, or driveway, the building drain from 313.10.1 Sleeves shall be provided to protect piping

the front building shall be permitted to be extended to the rear through concrete and masonry walls and concrete floors.

building.

Exception: Sleeves shall not be required where open-

ings are drilled or bored.

313.0 Protection of Piping, Materials, and Structures. 313.10.2 Piping through concrete or masonry walls shall

313.1 Piping passing under or through walls shall be pro- not be subject to any load from building construction.

tected from breakage. Piping passing through or under cin- 313.10.3 In exterior walls, annular space between sleeves

ders or other corrosive materials shall be protected from and pipes shall be sealed and made water-tight, as ap-

external corrosion in an approved manner. Approved provi- proved by the Authority Having Jurisdiction. Any pene-

sions shall be made for expansion of hot water piping. Voids tration through fire-resistive construction shall be in

around piping passing through concrete floors on the ground accordance with Section 313.7.

shall be appropriately sealed.

313.10.4 Any pipe sleeve through a firewall shall have

313.2 Piping in connection with a plumbing system shall be the space around the pipe completely sealed with an ap-

so installed that piping or connections will not be subject to proved fire-resistive material in accordance with other

undue strains or stresses, and provisions shall be made for ex- codes.

pansion, contraction, and structural settlement. No plumbing 313.11 Any structural member weakened or impaired by cut-

piping shall be directly embedded in concrete or masonry. No ting, notching, or otherwise shall be reinforced, repaired, or

structural member shall be seriously weakened or impaired replaced so as to be left in a safe structural condition in ac-

by cutting, notching, or otherwise, as defined in the Building cordance with the requirements of the Building Code.

Code.

313.12 Ratproofing.

313.3 No building sewer or other drainage piping or part

thereof, constructed of materials other than those approved 313.12.1 Strainer plates on drain inlets shall be designed

for use under or within a building, shall be installed under or and installed so that no opening is exceeding one-half

(1⁄2) inch (12.7 mm) in the least dimension.

within two (2) feet (610 mm) of any building or structure, or

less than one (1) foot (305 mm) below the surface of the 313.12.2 Meter boxes shall be constructed in such a man-

ground. ner that rats cannot enter a building by following the

service pipes from the box into the building.

313.4 Piping subject to corrosion, erosion, or mechanical

damage shall be protected in an approved manner. 313.12.3 In or on buildings where openings have been

made in walls, floors, or ceilings for the passage of pipes,

313.5 Protectively Coated Pipe. Protectively coated pipe

such openings shall be closed and protected by the in-

shall be inspected and tested, and any visible void, damage,

stallation of approved metal collars securely fastened to

or imperfection to the pipe coating shall be repaired to com-

the adjoining structure.

ply with Section 313.0.

313.12.4 Tub waste openings in framed construction to

313.6 No water, soil, or waste pipe shall be installed or per-

crawl spaces at or below the first floor shall be protected

mitted outside of a building or in an exterior wall unless,

by the installation of approved metal collars or metal

where necessary, adequate provision is made to protect such

screen securely fastened to the adjoining structure with

pipe from freezing.

no opening exceeding one-half (1⁄2) inch (12.7 mm) in the

313.7 Piping penetrations of fire-resistance-rated walls, par- least dimension.

titions, floors, floor/ceiling assemblies, roof/ceiling assem-

blies, or shaft enclosures shall be protected in accordance with

the requirements of the Building Code. 314.0 Hangers and Supports.

313.8 Waterproofing of Openings. Joints at the roof around 314.1 Suspended piping shall be supported at intervals not to

pipes, ducts, or other appurtenances shall be made water-tight exceed those shown in Table 3-2.

by the use of lead, copper, galvanized iron, or other approved 314.2 Piping shall be supported in such a manner as to main-

flashings or flashing material. Exterior wall openings shall be tain its alignment and prevent sagging.

made water-tight. Counterflashing shall not restrict the re- 314.3 Piping in the ground shall be laid on a firm bed for its

quired internal cross-sectional area of the vent. entire length; where other support is otherwise provided, it

313.9 Plastic and copper piping penetrating a framing mem- shall be approved per Section 301.0 of this code.

bers to within one (1) inch (25.4 mm) of the exposed framing 314.4 Hangers and anchors shall be of sufficient strength to

shall be protected by steel nail plates not less than No. 18 support the weight of the pipe and its contents. Piping shall be

gauge (0.0478 inches) (1.2 mm) in thickness. The steel nail isolated from incompatible materials.

44 2010 CALIFORNIA PLUMBING CODE

GENERAL REGULATIONS

314.5 Piping, fixtures, appliances, and appurtenances shall be on plastic pipe shall be factory cut or molded. Threaded

adequately supported in accordance with this code, the man- plastic pipe shall be Schedule 80 minimum wall thick-

ufacturer’s installation instructions, and as required by the ness. Tubing threads shall conform to fine tubing thread

Authority Having Jurisdiction. standards. When a pipe joint material is used, it shall be

314.6 Hanger rod sizes shall be no smaller than those shown applied only on male threads, and such materials shall be

in Table 3-1. approved types, insoluble in water and nontoxic.

314.7 Gas piping shall be supported by metal straps or hooks Cleanout plugs and caps shall be lubricated with water-

at intervals not to exceed those shown in Table 12-3. insoluble, nonhardening material or tape. Thread tape or

thread lubricants and sealants specifically intended for

use with plastics shall be used on plastic threads. Con-

TABLE 3-1 ventional pipe thread compounds, putty, linseed-oil-

HANGER ROD SIZES based products, and unknown lubricants and sealants

PIPE AND TUBE SIZE ROD SIZE

shall not be used on plastic threads.

(inches) mm (inches) mm

⁄2 – 4

1

15 – 100 3

⁄8 9.5 316.1.2 Wiped Joints. Joints in lead pipe or fittings or

5–8 125 – 200 1

⁄2 12.7 between lead pipe or fittings and brass or copper pipe,

10 – 12 250 – 300 5

⁄8 15.9 ferrules, solder nipples, or traps shall be full-wiped

joints. Wiped joints shall have an exposed surface on

each side of a joint not less than three-fourths (3⁄4) inch

315.0 Trenching, Excavation, and Backfill. (19.1 mm) and not less than as thick as the material being

315.1 Trenches deeper than the footing of any building or joined. Wall or floor flange lead-wiped joints shall be

structure and paralleling the same shall be not less than 45 made by using a lead ring or flange placed behind the

degrees (0.79 rad) therefrom, or as approved per Section joint at the wall or floor. Joints between lead pipe and

301.0 of this code. cast-iron, steel, or wrought iron shall be made by means

315.2 Tunneling and driving shall be permitted to be done in of a caulking ferrule or soldering nipple.

yards, courts, or driveways of any building site. Where suffi- 316.1.3 Soldered Joints. Joints in copper tubing shall be

cient depth is available to permit, tunnels shall be permitted made by the appropriate use of approved copper or cop-

to be used between open-cut trenches. Tunnels shall have a per alloy fittings. Surfaces to be joined by soldering shall

clear height of two (2) feet (610 mm) above the pipe and shall be cleaned bright by manual or mechanical means.

be limited in length to one-half (1⁄2) the depth of the trench,

with a maximum length of eight (8) feet (2438 mm). When The joints shall be properly fluxed with an approved-

pipes are driven, the drive pipe shall be not less than one (1) type flux and made up with approved solder. Solder and

size larger than the pipe to be laid. fluxes shall be manufactured to approved standards. Sol-

ders and fluxes with a lead content that exceeds two-tenths

315.3 Open Trenches. Excavations required to be made for

(0.2) of one (1) percent shall be prohibited in piping sys-

the installation of a building drainage system or any part

tems used to convey potable water.

thereof, within the walls of a building, shall be open trench

work and shall be kept open until the piping has been in- 316.1.4 Flared Joints. Flared joints for soft copper tubing

spected, tested, and accepted. shall be made with fittings meeting approved standards.

315.4 Excavations shall be completely backfilled as soon The tubing shall be reamed to the full inside diameter, re-

after inspection as practicable. Adequate precaution shall be sized to round, and expanded with a proper flaring tool.

taken to ensure proper compactness of backfill around piping 316.1.5 Flexible Compression Factory-Fabricated

without damage to such piping. Trenches shall be backfilled Joints. Where pipe is joined by means of flexible com-

in thin layers to twelve (12) inches (305 mm) above the top pression joints, such joints shall conform to approved

of the piping with clean earth, which shall not contain stones, standards and shall not be considered as slip joints.

boulders, cinderfill, frozen earth, construction debris, or other

316.1.6 Solvent Cement Plastic Pipe Joints. Plastic pipe

materials that would damage or break the piping or cause cor-

rosive action. Mechanical devices such as bulldozers, graders, and fittings designed to be joined by solvent cementing shall

etc., shall be permitted to then be used to complete backfill to comply with applicable standards referenced in Table 14-1.

grade. Fill shall be properly compacted. Suitable precautions ABS pipe and fittings shall be cleaned and then

shall be taken to ensure permanent stability for pipe laid in joined with solvent cement(s).

filled or made ground. CPVC pipe and fittings shall be cleaned and then

joined with listed primer(s) and solvent cement(s).

316.0 Joints and Connections. Exceptions:

316.1 Types of Joints. (1) Listed solvent cements that do not require the use of

316.1.1 Threaded Joints. Threads on iron pipe size primer shall be permitted for use with CPVC pipe

(IPS) pipe and fittings shall be standard taper pipe and fittings, manufactured in accordance with

threads in accordance with standards listed in Table 14- ASTM D2846, one-half (1⁄2) inch (15 mm) through

1. Threads on tubing shall be approved types. Threads two (2) inches (50 mm) in diameter.

2010 CALIFORNIA PLUMBING CODE 45

GENERAL REGULATIONS

(2) [HCD 1 & HCD 2] Low VOC One-Step Cement that Section 316.1.7. Flared joints shall conform to the require-

does not require the use of primer shall be utilized ments of Section 316.1.4. Pressed joints shall conform to

with CPVC pipe and fittings, manufactured in ac- the requirements of 316.1.9.

cordance with ASTM D 2846, Standard for Chlori- 316.2.2 Unions. Approved unions shall be permitted to

nated Poly Plastic Hot- and Cold-Water Distribution be used in drainage piping when accessibly located in the

Systems, 1⁄2 inch through 2 inches in diameter. trap seal or between a fixture and its trap in the vent sys-

PVC pipe and fittings shall be cleaned and joined tem, except underground or in wet vents, at any point in

with primer(s) and solvent cement(s). the water supply system, and in gas piping as permitted

A solvent cement transition joint between ABS and by Section 1211.3.2(4).

PVC building drain and building sewer shall be made 316.2.3 Plastic Pipe to Other Materials. When con-

using a listed transition solvent cement. necting plastic pipe to other types of piping, only ap-

[HCD 1 & HCD 2] Plastic pipe and fittings joined with proved types of fittings and adapters designed for the

solvent cement shall utilize Low VOC primer(s), if a primer specific transition intended shall be used.

is required, and Low VOC solvent cement(s) as defined in 316.2.4 Dielectric Unions. [HCD 1 & HCD 2, OSHPD

Section 214. 1, 2, 3 & 4] Dielectric unions shall be used at all points

316.1.7 Brazing and Welding. Brazing and welding of connection where there is a dissimilarity of metals.

shall conform to the applicable standard(s) in Table 14- 316.3 Flanged Fixture Connections.

1. Only brazing alloys having a liquid temperature above 316.3.1 Fixture connections between drainage pipes and

1000˚F (538˚C) shall be used. Brazing on medical gas water closets, floor outlet service sinks and urinals shall

systems shall be performed by certified installers meet- be made by means of approved brass, hard lead, ABS,

ing the requirements of ASME Boiler and Pressure Ves- PVC, or iron flanges caulked, soldered, solvent ce-

sel Code, Section IX, Welding and Brazing mented; rubber compression gaskets; or screwed to the

Qualifications, or AWS B2.2, Standard for Brazing Pro- drainage pipe. The connection shall be bolted with an ap-

cedure and Performance Qualifications. proved gasket, washer, or setting compound between the

316.1.8 [Not permitted for OSHPD 1, 2, 3 & 4] Pres- fixture and the connection. The bottom of the flange shall

sure-Lock-Type Connection. This is a mechanical con- be set on an approved firm base.

nection that depends on an internal retention device to 316.3.2 Closet bends or stubs shall be cut off so as to

prevent pipe or tubing separation. Connection is made present a smooth surface even with the top of the closet

by inserting the pipe or tubing into the fitting to a pre- ring before rough inspection is called.

scribed depth.

316.3.3 Wall-mounted water closet fixtures shall be se-

316.1.9 [Not permitted for OSHPD 1, 2, 3 & 4] Pressed curely bolted to an approved carrier fitting. The con-

Fitting. This is a mechanical connection for joining cop- necting pipe between the carrier fitting and the fixture

per tubing that uses a crimping tool to affix the O-ring shall be an approved material and designed to accom-

seal copper or copper alloy fitting to the tubing. The tub- modate an adequately sized gasket. Gasket material shall

ing shall be inserted into the fitting, and the crimp shall be neoprene, felt, or similar approved types.

be made using the tool recommended by the manufac-

turer. 316.4 Prohibited Joints and Connections.

316.1.10 Push-fit Fitting. A mechanical fitting where 316.4.1 Drainage System. Any fitting or connection that

the connection is assembled by pushing the tube or pipe has an enlargement, chamber, or recess with a ledge,

into the fitting and is sealed with an “O” ring. shoulder, or reduction of pipe area that offers an ob-

struction to flow through the drain shall be prohibited.

316.1.11 Heat Fusion Weld Joints. This type of joint is

used in some thermoplastic systems to connect pipe to 316.4.2 No fitting or connection that offers abnormal ob-

fittings or pipe lengths directly to one another (butt-fu- struction to flow shall be used. The enlargement of a

sion). This method of joining pipe to fittings includes three (3) inch (80 mm) closet bend or stub to four (4)

socket-fusion, electro-fusion, and saddle-fusion. This inches (100 mm) shall not be considered an obstruction.

method of welding involves the application of heat and

pressure to the components, allowing them to fuse to- 317.0 Increasers and Reducers.

gether forming a bond between the pipe and fitting.

Where different sizes of pipes and fittings are to be connected,

316.2 Special Joints. the proper size increasers or reducers or reducing fittings shall

316.2.1 Copper Tubing to Screw Pipe Joints. Joints from be used between the two sizes. Brass or cast-iron body

copper tubing to threaded pipe shall be made by the use of cleanouts shall not be used as a reducer or adapter from cast-

brass adapter fittings. The joint between the copper tubing iron drainage pipe to iron pipe size (IPS) pipe.

and the fitting shall be a soldered brazed flared, or pressed

joint and the connection between the threaded pipe and the

318.0 Food-Handling Establishments.

fitting shall be made with a standard pipe size screw joint.

Solder shall conform to the requirements of Section Food or drink shall not be stored, prepared, or displayed be-

316.1.3. Brazed joints shall conform to the requirements of neath soil or drain pipes, unless those areas are protected

46 2010 CALIFORNIA PLUMBING CODE

GENERAL REGULATIONS

against leakage or condensation from such pipes reaching the

food or drink as described below. Where building design re-

quires that soil or drain pipes be located over such areas, the

installation shall be made with the least possible number of

joints and shall be installed so as to connect to the nearest ad-

equately sized vertical stack with the provisions as follows:

318.1 Openings through floors over such areas shall be sealed

water-tight to the floor construction.

318.2 Floor and shower drains installed above such areas

shall be equipped with integral seepage pans.

318.3 Soil or drain pipes shall be of an approved material as

listed in Table 14-1 and Section 701.0. Materials shall con-

form to established standards. Cleanouts shall be extended

through the floor construction above.

318.4 Piping subject to operation at temperatures that will

form condensation on the exterior of the pipe shall be ther-

mally insulated.

318.5 Where pipes are installed in ceilings above such areas,

the ceiling shall be of the removable type, or shall be pro-

vided with access panels in order to form a ready access for

inspection of piping.

319.0 Test Gauges.

Tests required by this code, which are performed utilizing dial

gauges, shall be limited to gauges having the following pres-

sure graduations or incrementations.

319.1 Required pressure tests of ten (10) psi (69 kPa) or less

shall be performed with gauges of one-tenth of a pound (0.10)

(0.7 kPa) incrementation or less.

319.2 Required pressure tests exceeding ten (10) pounds (69

kPa) but less than or equal to one-hundred (100) psi (689 kPa)

shall be performed with gauges of one (1) psi (6.9 kPa) in-

crementation or less.

319.3 Required pressure tests exceeding one-hundred (100)

psi (689 kPa) shall be performed with gauges incremented for

two (2) percent or less of the required test pressure.

319.4 Test gauges shall have a pressure range not exceeding

twice the test pressure applied.

320.0 [Not permitted for OSHPD 1, 2, 3 & 4] Medical Gas

and Vacuum Systems.

Such piping shall be installed, tested, and verified in compli-

ance with the applicable standards referenced in Table 14-1

and the requirements of Chapter 13. The Authority Having

Jurisdiction shall require evidence of the competency of the

installers and verifiers.

2010 CALIFORNIA PLUMBING CODE 47

GENERAL REGULATIONS

TABLE 3-2

HANGERS AND SUPPORT

Cast Lead and Oakum 5 feet (1524 mm), except 10 feet (3048 Base and each floor not to exceed

MATERIALS TYPES OF JOINTS HORIZONTAL VERTICAL

mm) where 10 foot lengths (3048 mm) 15 feet (4572 mm)

are installed1,2,3

Compression Gasket Every other joint, unless over 4 feet Base and each floor a maximum of

(1219 mm), then support each joint1,2,3 15 feet (4572 mm)

Cast-Iron Hubless Shielded Coupling Every other joint, unless over 4 feet Base and each floor a maximum of

(1219 mm), then support each joint1,2,3,4 15 feet (4572 mm)

Copper Tube and Pipe Soldered or Brazed 11⁄2 inches (40 mm) and smaller, 6 feet Each floor, a maximum of 10 feet

(1829 mm), 2 inches (50 mm) and (3048 mm)5

larger, 10 feet (3048 mm)

Steel and Brass Pipe for Water or Threaded or Welded 3

⁄4 inch (20 mm) and smaller, 10 feet Every other floor, a maximum of 25

DWV (3048 mm), 1 inch (25 mm) and larger, feet (7620 mm)5

12 feet (3658 mm)

Steel, Brass, and Tinned Copper Threaded or Welded 1

⁄2 inch (15 mm), 6 feet (1829 mm), 3⁄4 ⁄2 inch (15 mm), 6 feet (1829 mm),

1

Pipe for Gas inch (20 mm) and 1 inch (25 mm), 8 ⁄4 inch (20 mm) and 1 inch (25

3

feet (2438 mm), 11⁄4 inch (32 mm) and mm), 8 feet (2438 mm), 11⁄4 (32

larger, 10 feet (3048 mm) mm) every floor level

Schedule 40 PVC and ABS Solvent Cemented All sizes, 4 feet (1219 mm). Allow for Base and each floor. Provide mid-

DWV expansion every 30 feet (9144 mm).3,6 story guides. Provide for expansion

every 30 feet (9144 mm).6

CPVC Solvent Cemented 1 inch (25 mm) and smaller, 3 feet Base and each floor. Provide mid-

(914 mm), 11⁄4 inch (32 mm) and story guides.6

larger, 4 feet (1219 mm)

Lead Wiped or Burned Continuous Support A maximum of 4 feet (1219 mm)

Copper Mechanical In accordance with standards acceptable to the Authority Having Jurisdiction

Steel and Brass Mechanical In accordance with standards acceptable to the Authority Having Jurisdiction

}

PEX Metal Insert and Metal 32 inches (813 mm) Base and each floor.

Compression Provide mid-story guides.

PEX-AL-PEX Metal Insert and Metal ⁄2 inch (15 mm) All sizes Base and each floor.

}

1

Compression ⁄4 inch (20 mm)

3

98 inches Provide mid-story guides.

1 inch (25 mm) (2489 mm)

PE-AL-PE Metal Insert and Metal 1

⁄2 inch (15 mm) All sizes Base and each floor.

Compression 3

⁄4 inch (20 mm) 98 inches Provide mid-story guides.

1 inch (25 mm) (2489 mm)

Polypropylene (PP) Fusion weld (socket, butt, 1 inch (25 mm) and smaller, 32 inches Base and each floor.

saddle, electrofusion), (813 mm); 11⁄4 inches (32 mm) and Provide mid-story guides.

threaded (metal threads larger, 4 feet (1219 mm)

only), or mechanical

1 Support adjacent to joint, a maximum of eighteen (18) inches (457 mm).

2 Brace at a maximum of forty (40) feet (12 192 mm) intervals to prevent horizontal movement.

3 Support at each horizontal branch connection.

4 Hangers shall not be placed on the coupling.

5 Vertical water lines shall be permitted to be supported in accordance with recognized engineering principles with regard to expansion and contraction,

when first approved by the Authority Having Jurisdiction.

6 See the appropriate IAPMO Installation Standard for expansion and other special requirements.

48 2010 CALIFORNIA PLUMBING CODE

Das könnte Ihnen auch gefallen

- Methodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsVon EverandMethodologies for Seismic Safety Evaluation of Existing Nuclear InstallationsNoch keine Bewertungen

- 2015 SMCChapter 3Dokument12 Seiten2015 SMCChapter 3safiamukadam248Noch keine Bewertungen

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsVon EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNoch keine Bewertungen

- Quality Assurance: 2.1 GeneralDokument8 SeitenQuality Assurance: 2.1 GeneralEnrique AbayNoch keine Bewertungen

- Asme Viii - Div.1Dokument2 SeitenAsme Viii - Div.1cwkimNoch keine Bewertungen

- Chapter 6 Duct Systems California Mechanical Code - Matrix Adoption Table Chapter 6 - Duct Systems (Matrix Adoption Tables Are Non-Regulatory, Intended Only As An Aid To The Code User. SeeDokument16 SeitenChapter 6 Duct Systems California Mechanical Code - Matrix Adoption Table Chapter 6 - Duct Systems (Matrix Adoption Tables Are Non-Regulatory, Intended Only As An Aid To The Code User. SeeAnonymous yniiLtiNoch keine Bewertungen

- Nfpa 5000-18 480Dokument1 SeiteNfpa 5000-18 480sundarNoch keine Bewertungen

- Standard Separator Design Piping Guidelines by SBLDokument15 SeitenStandard Separator Design Piping Guidelines by SBLMuddassar SultanNoch keine Bewertungen

- 1000 38 AdminCodeDokument59 Seiten1000 38 AdminCodegeorgadam1983Noch keine Bewertungen

- Sans 347.2010Dokument47 SeitenSans 347.2010madodandembe100% (1)

- Michigan FL-CL RulesDokument59 SeitenMichigan FL-CL RulesDawsonite100% (1)

- Section 2 Ele. RevisedDokument10 SeitenSection 2 Ele. RevisedfiraolNoch keine Bewertungen

- Doe Standard Specification For Hepa Filters Used by Doe ContractorsDokument32 SeitenDoe Standard Specification For Hepa Filters Used by Doe Contractorsalmary_gNoch keine Bewertungen

- F2164Dokument5 SeitenF2164Hernando Andrés Ramírez Gil100% (1)

- Section 10 - Stray Current Corrosion ControlDokument31 SeitenSection 10 - Stray Current Corrosion ControlNabil RamehNoch keine Bewertungen

- E329-14a Standard Specification For Agencies Engaged in Construction Inspection, Testing, or Special InspectionDokument11 SeitenE329-14a Standard Specification For Agencies Engaged in Construction Inspection, Testing, or Special InspectionFahad RedaNoch keine Bewertungen

- Caso Codigo 2541 - Asme VDokument1 SeiteCaso Codigo 2541 - Asme VMiguel Angel Aguilar MenaNoch keine Bewertungen

- Astm E1001Dokument10 SeitenAstm E1001Jon DownNoch keine Bewertungen

- National Board Pressure Relief Device Certification Administrative RequirementsDokument3 SeitenNational Board Pressure Relief Device Certification Administrative RequirementsHaroltAlexisLeonTripulNoch keine Bewertungen

- Sast4302 01Dokument2 SeitenSast4302 01GiasuddinNoch keine Bewertungen

- CR 0063 PDFDokument39 SeitenCR 0063 PDFنبيل عبد المجيدNoch keine Bewertungen

- UT AstmDokument14 SeitenUT Astmaun.muhd2Noch keine Bewertungen

- TAS 201-94 - Impact Test ProceduresDokument7 SeitenTAS 201-94 - Impact Test ProceduresAndrea Nicola TurcatoNoch keine Bewertungen

- ATC Substation Eqpt Ratings CR-0063Dokument39 SeitenATC Substation Eqpt Ratings CR-0063kcirrenwod100% (1)

- Nureg 0800 3.6.1 Plant Design For Protection Against Postulated Piping Failures in Fluid Systems Outside ContainmentDokument12 SeitenNureg 0800 3.6.1 Plant Design For Protection Against Postulated Piping Failures in Fluid Systems Outside ContainmentFernando DiezNoch keine Bewertungen

- QM 333Dokument50 SeitenQM 333saily_india60% (5)

- MECHdhiyworldDokument2 SeitenMECHdhiyworldgicofNoch keine Bewertungen

- Part L EQUIPMENT 430 - Erstl - L - Egstl - L-CV - 2013Dokument63 SeitenPart L EQUIPMENT 430 - Erstl - L - Egstl - L-CV - 2013Dave DumontNoch keine Bewertungen

- Testing Application Standard (TAS) 201-94 Impact Test ProceduresDokument6 SeitenTesting Application Standard (TAS) 201-94 Impact Test ProceduresKarolan PoloNoch keine Bewertungen

- C 390 - 79 R00 QZM5MC0WMGDokument3 SeitenC 390 - 79 R00 QZM5MC0WMGM RNoch keine Bewertungen

- Part K MATERIALS 430 - Erstl - K - Egstl - K-CV - 2013Dokument209 SeitenPart K MATERIALS 430 - Erstl - K - Egstl - K-CV - 2013Dave DumontNoch keine Bewertungen

- Astm B 594Dokument9 SeitenAstm B 594Dinesh Gupta100% (1)

- Wika LMB Eng Ik CCB Hvac 01Dokument22 SeitenWika LMB Eng Ik CCB Hvac 01riyadigeng19gmailcomNoch keine Bewertungen

- Nuclear Facility Decommissioning Plans: Standard Guide ForDokument6 SeitenNuclear Facility Decommissioning Plans: Standard Guide ForNik MazrolNoch keine Bewertungen

- Astm E2192-13Dokument23 SeitenAstm E2192-13Stephen LewellenNoch keine Bewertungen

- Nfpa 3 - 2024Dokument110 SeitenNfpa 3 - 2024henrique.hs18Noch keine Bewertungen

- E2192-13 Guía Estándar para Dimensionamiento de Altura Plana de Defectos Por UltrasonidosDokument23 SeitenE2192-13 Guía Estándar para Dimensionamiento de Altura Plana de Defectos Por Ultrasonidosfredy lopezNoch keine Bewertungen

- Standard Practice For Operation and Maintenance of Integrated Natural Gas Pipelines and Optical Fiber SystemsDokument5 SeitenStandard Practice For Operation and Maintenance of Integrated Natural Gas Pipelines and Optical Fiber Systemssebastian novoaNoch keine Bewertungen

- Lightning Protection SpecificationsDokument10 SeitenLightning Protection SpecificationsJose Manuel Miras LopezNoch keine Bewertungen

- Silver-Tungsten Electrical Contact Materials: Standard Specification ForDokument4 SeitenSilver-Tungsten Electrical Contact Materials: Standard Specification ForsamehNoch keine Bewertungen

- Uniform Mechanical Code - 2009 Chapter 1Dokument10 SeitenUniform Mechanical Code - 2009 Chapter 1memosplumbingNoch keine Bewertungen

- Rules For Classification of Diving Systems and Submersibles 2018Dokument131 SeitenRules For Classification of Diving Systems and Submersibles 2018Halassi Hoàng100% (1)

- Chapter 1 AdministrationDokument5 SeitenChapter 1 Administrationapi-131679190Noch keine Bewertungen

- 06 Modu rcn4Dokument22 Seiten06 Modu rcn4djodje1Noch keine Bewertungen

- Doe STD 3020 2005 Hepa StandartiDokument23 SeitenDoe STD 3020 2005 Hepa StandartiFuriaServaNoch keine Bewertungen

- Section 20 08 16 - Hvac/ Plumbing/Fire Supression Systems Functional Performance TestsDokument19 SeitenSection 20 08 16 - Hvac/ Plumbing/Fire Supression Systems Functional Performance TestsSaber ElkassasNoch keine Bewertungen

- Works Masterspec 230594Dokument5 SeitenWorks Masterspec 230594Joshua FernandezNoch keine Bewertungen

- Appendix 3 Definitions: Licensed by Information Handling Services Licensed by Information Handling ServicesDokument3 SeitenAppendix 3 Definitions: Licensed by Information Handling Services Licensed by Information Handling ServicesIsrael Orta SánchezNoch keine Bewertungen

- 2006 NC Fuel Gas Code AmendmentsDokument20 Seiten2006 NC Fuel Gas Code AmendmentsjameyconnorNoch keine Bewertungen

- Guidelines For Certification of Drilling Plants, 2006Dokument57 SeitenGuidelines For Certification of Drilling Plants, 2006majdi jerbiNoch keine Bewertungen

- E570-97 Flux Leakage Ferro TubularDokument6 SeitenE570-97 Flux Leakage Ferro TubularAsif HameedNoch keine Bewertungen

- DhiqworldDokument2 SeitenDhiqworldgicofNoch keine Bewertungen

- 26 05 30 APAC Vibration and Seismic Control For Electrical Systems M0Dokument10 Seiten26 05 30 APAC Vibration and Seismic Control For Electrical Systems M0OnieChicaritoNoch keine Bewertungen

- MECHdhiqworldDokument2 SeitenMECHdhiqworldgicofNoch keine Bewertungen

- California Building Code MOTEMS 2014Dokument85 SeitenCalifornia Building Code MOTEMS 2014Søren MørchNoch keine Bewertungen

- Rev. B English 04 / 2011: ProcedureDokument12 SeitenRev. B English 04 / 2011: ProceduremarceloNoch keine Bewertungen

- 03 Pre-Commissioning and Commissioning 26 08 00 09022022011343Dokument13 Seiten03 Pre-Commissioning and Commissioning 26 08 00 09022022011343ibrahimsirpiNoch keine Bewertungen

- TST-08 - Insulator HardwareDokument8 SeitenTST-08 - Insulator HardwarerinaldiafriyantoNoch keine Bewertungen

- Section 26 08 16 - Electrical Systems Functional Performance TestsDokument14 SeitenSection 26 08 16 - Electrical Systems Functional Performance TestsdexterNoch keine Bewertungen

- Engineering DataDokument40 SeitenEngineering DataAnonymous PCsoNCt0mFNoch keine Bewertungen

- Civil Plans PDFDokument8 SeitenCivil Plans PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- IFPA SFPE NFPA 20 2016 and Beyond PDFDokument50 SeitenIFPA SFPE NFPA 20 2016 and Beyond PDFzattie89Noch keine Bewertungen

- Hot Water Return PipingDokument44 SeitenHot Water Return PipingAnonymous PCsoNCt0mFNoch keine Bewertungen

- Hot Water Return PipingDokument44 SeitenHot Water Return PipingAnonymous PCsoNCt0mFNoch keine Bewertungen

- E20s HAP50 - Manual HAP PDFDokument144 SeitenE20s HAP50 - Manual HAP PDFAnonymous XhkjXCxxsT100% (1)

- Cast Iron Pipe Fittings Eng PDFDokument124 SeitenCast Iron Pipe Fittings Eng PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- InsulationDokument75 SeitenInsulationengr_atulNoch keine Bewertungen

- Teh 1096aDokument47 SeitenTeh 1096aAnonymous dq9CohrNoch keine Bewertungen

- Fire Flow Calculator WooksheetDokument4 SeitenFire Flow Calculator WooksheetYosses Sang NahkodaNoch keine Bewertungen

- EN - 420, 420PC Data Sheet PDFDokument4 SeitenEN - 420, 420PC Data Sheet PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- NH PDFDokument48 SeitenNH PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- K-3609 Spec PDFDokument2 SeitenK-3609 Spec PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- Es WD BV 240 Usa PDFDokument1 SeiteEs WD BV 240 Usa PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- Pages From Gov - Ca.bsc.2016.05 PDFDokument1 SeitePages From Gov - Ca.bsc.2016.05 PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- Lynn Allen's AutoCAD 2014 Tips and TricksDokument17 SeitenLynn Allen's AutoCAD 2014 Tips and TricksZoltán NémethNoch keine Bewertungen

- W 750 IS Specification Sheet PDFDokument2 SeitenW 750 IS Specification Sheet PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- t275 PDFDokument1 Seitet275 PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- 2163C NH PDFDokument4 Seiten2163C NH PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- Munchkin Installation Images PDFDokument17 SeitenMunchkin Installation Images PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- Aoscg10210series300 PDFDokument6 SeitenAoscg10210series300 PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- Aoscg61040 PDFDokument1 SeiteAoscg61040 PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- Cec 140 2012 002 PDFDokument597 SeitenCec 140 2012 002 PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- SupMat01 PDFDokument5 SeitenSupMat01 PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- Codensate Removal Pump PDFDokument2 SeitenCodensate Removal Pump PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- SupMat01 PDFDokument5 SeitenSupMat01 PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- Sizing Guide For Water HeaterDokument4 SeitenSizing Guide For Water Heatersakhrs2000Noch keine Bewertungen

- Storage Tank 335 Gallons PDFDokument1 SeiteStorage Tank 335 Gallons PDFAnonymous PCsoNCt0mFNoch keine Bewertungen

- System No. F-A-1008: F Ratings - 2 and 3 HR (See Item 3B) T Rating - 0 HRDokument2 SeitenSystem No. F-A-1008: F Ratings - 2 and 3 HR (See Item 3B) T Rating - 0 HRAnonymous PCsoNCt0mFNoch keine Bewertungen

- Sewer Design HandbookDokument16 SeitenSewer Design HandbookVhuso Mwafuka MaringeNoch keine Bewertungen

- BUILDING PLUMBING SYSTEM Part 2Dokument10 SeitenBUILDING PLUMBING SYSTEM Part 2Nyein Aye MyatNoch keine Bewertungen

- Project Report On Thermal PlantDokument58 SeitenProject Report On Thermal Plantmenyu198964% (11)

- FSSC Check List PRPDokument26 SeitenFSSC Check List PRPAneel100% (2)

- Fes TBT Housekeeping PDFDokument1 SeiteFes TBT Housekeeping PDFsalem enwaijiNoch keine Bewertungen

- Toward A New Conception of The Enviroment - CompetitivenessDokument222 SeitenToward A New Conception of The Enviroment - CompetitivenessLuis Alberto Nemojón PuentesNoch keine Bewertungen

- Climate Change EssayDokument2 SeitenClimate Change EssayGeorlNoch keine Bewertungen

- Application For New Sewerage Connection Domestic - CommercialDokument2 SeitenApplication For New Sewerage Connection Domestic - CommercialvijayNoch keine Bewertungen

- Jet Grouting Guide SpecificationDokument26 SeitenJet Grouting Guide Specificationshachen2014100% (1)

- AIR DATS SYS DPS-450-User-ManualDokument124 SeitenAIR DATS SYS DPS-450-User-Manualdiako lopezNoch keine Bewertungen

- MMDA vs. Concerned Citizens (2011) ResolutionDokument22 SeitenMMDA vs. Concerned Citizens (2011) ResolutionErika Cristel DiazNoch keine Bewertungen

- Palm Oil BiomassDokument7 SeitenPalm Oil Biomassnhalieza1067Noch keine Bewertungen

- Urine Color Chart To Indicate DehydrationDokument2 SeitenUrine Color Chart To Indicate DehydrationSoon Siew LeeNoch keine Bewertungen

- Pumper: E-T A EDokument13 SeitenPumper: E-T A EPumper TraderNoch keine Bewertungen

- Electrolux LFV619K Cooker HoodDokument188 SeitenElectrolux LFV619K Cooker HoodGiorgianaNoch keine Bewertungen

- 3 Ways To Make Your Cell Phone Battery Last Longer - WikiHowDokument12 Seiten3 Ways To Make Your Cell Phone Battery Last Longer - WikiHowHari Krishna.MNoch keine Bewertungen

- Pentel 2020 21 CatalogueDokument39 SeitenPentel 2020 21 Cataloguetoàn lêNoch keine Bewertungen

- Environmental Inspection For Crane Barge Check ListDokument1 SeiteEnvironmental Inspection For Crane Barge Check ListMuhammad Ali WafaNoch keine Bewertungen

- The Use of Recycle Material in ManufacturingDokument26 SeitenThe Use of Recycle Material in ManufacturingKasidis NaktupNoch keine Bewertungen

- Lab Visit ReportDokument7 SeitenLab Visit ReportEzad juferi100% (1)

- IELTS Task 1 SamplesDokument15 SeitenIELTS Task 1 SamplesAkun StreamNoch keine Bewertungen

- GMP Plus B2 RequirementsDokument49 SeitenGMP Plus B2 RequirementsSameer NaikNoch keine Bewertungen

- Turnning Waste: Into EnergyDokument23 SeitenTurnning Waste: Into EnergyGreen MyanmarNoch keine Bewertungen

- Methane MSDSDokument4 SeitenMethane MSDSSalma FarooqNoch keine Bewertungen

- CHEM 181: An Introduction To Environmental ChemistryDokument21 SeitenCHEM 181: An Introduction To Environmental ChemistrymArv131994Noch keine Bewertungen

- Environmental Stress (521 KB) PDFDokument11 SeitenEnvironmental Stress (521 KB) PDFbluefloroNoch keine Bewertungen

- Sample Brgy DTPDokument43 SeitenSample Brgy DTPohm silvaNoch keine Bewertungen

- Household Knowledge and Practices in Solid Waste Segregation and RecyclingDokument10 SeitenHousehold Knowledge and Practices in Solid Waste Segregation and RecyclingMichaela CruzNoch keine Bewertungen

- Jayaram Nagar, Chellangkuppam, Cuddalore-607003.: C K College of Engineering and TechnologyDokument6 SeitenJayaram Nagar, Chellangkuppam, Cuddalore-607003.: C K College of Engineering and TechnologyPradeepkumarNoch keine Bewertungen

- Denim CycleDokument47 SeitenDenim CycleHaleema ManzoorNoch keine Bewertungen