Beruflich Dokumente

Kultur Dokumente

Safe Work Method Statement - Formwork and Concreting

Hochgeladen von

Anonymous gmNTrHsOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Safe Work Method Statement - Formwork and Concreting

Hochgeladen von

Anonymous gmNTrHsCopyright:

Verfügbare Formate

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

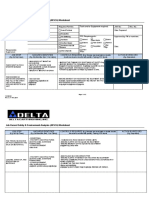

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

Possible Safety or

Task Breakdown RB Task Breakdown RA Task Breakdown

Environment hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented

Design Personal Injury F Designers must L Engineer

Specifications - Crushing - Fully describe all features of design

- Falls - Provide SWMS for installation and stripping

- Being struck by falling - Define load cases

object - Define Acceptance criteria

- Provide for field adjustment

- Describe location of weep, vibrator and clean out

holes and inspection openings

- Detail sequence of concrete placement, including

any slopes, direction of pore and time between pores

- Describe strength stability and stiffness of system

- Detail foundation materials

- Details of surface type (filling, compaction, drainage)

- Allow for loads during construction (such as workers

materials, wind, false decks, rain, water runoff) reduce

fall risks where pracricable

Certification of design must be provided by a competent

Person

All formwork materials ( timber/plywood, prefab modules, aluminum,

steel or plastic) must meet quality design testing criteria as defined in

codes or standard practices

All exposed rebars must contain end caps

- Correct size for rebar

- Fitted correctly

- Regular inspections are undertaken to check conditions of

endcaps and to ensure no caps are missing

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

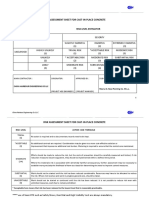

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

Possible Safety or

Task Breakdown RB Task Breakdown RA Task Breakdown

Environment hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented

Preparation Personal Injury F Project documentation must be available on site and include at least L Engineer Site

- Crushing - design specifications Supervisor

- Falls - drawings

- Being struck by falling - loading calculations

object - plans/Elevations

Collapse of structure - general arrangements

- maximum point loadings

- component types and spacings

- methods of securing structure and components

- formply size

- minimum stripping times

- edge protection

- back propping where required

- any variation from design and subsequent certification of

variations

- safe load bearings

- time frames between pour and pour rates

Personal Personal Injury F Competency based training L Site Supervisor

Requirements - Crushing - site induction

- Falls - nature of hazards and emergency plan

- Being struck by falling - requirements from HSE Plan

object - operation of heavy equipments as required

Collapse of structure - PPE (use, maintanence, storage)

- specific SWMS

Risk Control Personal Injury F consider: L Site Supervisor

- Crushing - edge protection and netting to prevent falling objects

- Falls - fit for purpose work platforms/scaffolding

- Being struck by falling - traffic management, mechanical lifting, adequate lighting

object - PPE and house keeping

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

Possible Safety or

Task Breakdown RB Task Breakdown RA Task Breakdown

Environment hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented

Formwork erection Personal Injury F all framing must be carried out so that it complies with on site design L All

- Crushing documentation and any manufacturers' requirements

- Falls inspect all formwork components to ensure acceptable conditions

- Being struck by falling as per

object Traditional

Collapse of structure Foundation:

- ensure stable base

- ensure base plates are provided under props and standards

- ensure suitable sole boards are provided

Note: Base plates and sole boards may not be required if

competent persons deems them unnecessary

Note: If Lapped planks are used, they must be secured against

uplifting and slipping

Pre pour inspection Personal Injury F Inspection must be undertaken by qualified person to ensure L Site Supervisor

- Crushing - safe work practices were followed

- Falls - system complies with requirement of design and project

- Being struck by falling documentation

object - is adequately braced

Collapse of structure - is strippable

- has adequate connections

- correct spacing of frames, props and timbers

- correct joists and bearer sizes

- accectable jack extensions

- adequate bracing to ensure stability

The engineer should suppliy an inspection certificate to verify the

structural integrity of the support structure and formwork system

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

Possible Safety or

Task Breakdown RB Task Breakdown RA Task Breakdown

Environment hazards

NOTE: RB = Risk Rating before controls implemented - RA = Risk Rating after controls are implemented

During Concrete Personal Injury F Ensure L All

Pour - Crushing - continuous supervision of the formwork assembly and

- Falls concrete placement

- Being struck by falling - Communication between supervising personnel and

object the placing crews

Collapse of structure - Monitor indicators if installed

- if any failure, undue settlement or distortion of the

formwork develops, work should cease and

- the affected formwork assembly or component

strengthened or replaced

- Concrete is placed and compacted in a matter that

ensures specified quality of surface finish

Dismantling Personal Injury F Concrete should be inspected prior to dismantle L Site Supervisor

formwork - Crushing Check for unacceptable:

(Stripping) - Falls - warping

- Being struck by falling - twisting

object - cracks

Collapse of structure - blowholes

- deviations as per

Emergency Plan Personal Injury M Must include at least M All

- Crushing - rescue procedures

- Falls - evacuation points

- Being struck by falling - roles/responsibilities

object - communication procedures

Collapse of structure - first aid

- use and location of fire protection equipments

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

SAFE WORK METHOD STATEMENT - part 2

Training in the following safe work procedures/

Formal training, Licenses required for workers

Duties of workers undertaking this task: SWMS/ training modules is required:

undertaking this task:

All workers to be trained in relevant procedures

- License to perform high risk work (heavy Name Operator Site specific Inductions

equipments like Crane, forklift, Man lift) Name Rigger Training in SWMS

- TUV certificate for Equipment and Name Supervisor Nature of hazards/risks

operator Emergency procedures

Duties of regulatory permits/licenses,

Details of Supervisory Agreements for workers

Engineering details/Certificates/Work Cover Relevant Codes of Practice

undertaking this tasks:

Approvals

- Competent supervisors for job - Local council permits

- Direct on site-supervision - Building Approvals

- Remote site - communication systems/ - EPA approvals/ Permits

schedule - 3rd party attestation

- Audits - PPE to comply with standards

- Spot checks, etc

- Reporting systems

Tools/ Equipments Maintanence details for tools/ equipments used on job

Example

- Electric jack Hammer As per manufacture recommendation, Electrical tested/ Tagged every 3 months

-

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

SAFE WORK METHOD STATEMENT FOR CONCRETE FORMWORK

Part 3 - SIGN OFF

This SWMS has been developed in consultation and cooperation with the workers and relevant persons from the prestigious Organization. I have read the above

SWMS and understand its contents. I confirm that I have skills and training, including relevant certifications to conduct the task as described. I agree to comply

safety requirements within this SWMS including safe work instructions and Personal Protective Equipments described

Name Qualification Signature Date Time Organization

Review No. 1 2 3 4 5 6 7

Name and initials

Date

Document No. 007 Activity : Concrete Formwork Review No. 000 Date: 19th December 2017

Prepared by: Muhammed Shabin

Project Engineer 12/19/2017

Das könnte Ihnen auch gefallen

- SWMS DemolitionDokument18 SeitenSWMS Demolitionalee0007100% (1)

- Safe Work Method StatementDokument11 SeitenSafe Work Method StatementJNoch keine Bewertungen

- Instructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsDokument21 SeitenInstructions For Use: Hse-Pro-006A Asbestos Management - Minor Works SwmsWinstone AudiNoch keine Bewertungen

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDokument12 SeitenIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpNoch keine Bewertungen

- Plumbing Sewerage - Drainage Swms 10Dokument26 SeitenPlumbing Sewerage - Drainage Swms 10Shahrin KamaruzamanNoch keine Bewertungen

- FRM-00413 Corporate Safety - Excavation and Trenching Permit FormDokument3 SeitenFRM-00413 Corporate Safety - Excavation and Trenching Permit FormAhmad Hafidz Mahendra100% (1)

- Safe Work Method Statement WorksheetDokument7 SeitenSafe Work Method Statement WorksheetianllagasNoch keine Bewertungen

- SWMS - PlumberDokument7 SeitenSWMS - PlumberSiddiqueShaikhNoch keine Bewertungen

- JHEA Loading and Offloading FENCEDokument13 SeitenJHEA Loading and Offloading FENCEStansilous Tatenda NyagomoNoch keine Bewertungen

- Safe Work Method StatementDokument19 SeitenSafe Work Method StatementParas100% (2)

- Master Builders SA - Safe Work Method Statement - Roof Metal InstallationDokument7 SeitenMaster Builders SA - Safe Work Method Statement - Roof Metal InstallationvictorNoch keine Bewertungen

- Index of OP Project HIRA Activities ID No. Activities Remarks Format NoDokument7 SeitenIndex of OP Project HIRA Activities ID No. Activities Remarks Format NoSameer JogasNoch keine Bewertungen

- Job Hazard Analysis (Jha) WorksheetDokument4 SeitenJob Hazard Analysis (Jha) WorksheetSamer AlsumaryNoch keine Bewertungen

- Safe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201Dokument18 SeitenSafe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201mkash028100% (1)

- 45 - Method Statements For Erection of Steel PDFDokument1 Seite45 - Method Statements For Erection of Steel PDFAbdul RahmanNoch keine Bewertungen

- Risk Assessment For Precast Sewerage House Connection Chamber ConstructionDokument3 SeitenRisk Assessment For Precast Sewerage House Connection Chamber ConstructionBig ZaddyNoch keine Bewertungen

- Safety Method StatementDokument14 SeitenSafety Method StatementnayakyaNoch keine Bewertungen

- Concrete Formwork Work Method Statement (SWMS) V8Dokument5 SeitenConcrete Formwork Work Method Statement (SWMS) V8pparreraNoch keine Bewertungen

- SWMS Mobilisation of Blocks For MLT TEST RKDokument14 SeitenSWMS Mobilisation of Blocks For MLT TEST RKrakeshkhanna78100% (1)

- Safe Work Method Statement - PlumbingDokument4 SeitenSafe Work Method Statement - PlumbingJohn KurongNoch keine Bewertungen

- Buildsafe AustraliaDokument12 SeitenBuildsafe AustraliaRahmat HariNoch keine Bewertungen

- CEMP Audit ChecklistDokument6 SeitenCEMP Audit ChecklistNash C. UsopNoch keine Bewertungen

- Roof Fall Hazard AssessmentDokument3 SeitenRoof Fall Hazard AssessmentBilal HussainNoch keine Bewertungen

- Carefour RA-For Block Works and Plastering WorksDokument17 SeitenCarefour RA-For Block Works and Plastering Worksfaizan khanNoch keine Bewertungen

- Job Hazard Safety & Environment Analysis (JHSEA) Worksheet: Operation/QYPXDokument2 SeitenJob Hazard Safety & Environment Analysis (JHSEA) Worksheet: Operation/QYPXJb TiscubNoch keine Bewertungen

- Subcontractors EHS Audit TemplateDokument7 SeitenSubcontractors EHS Audit TemplateDeepakNoch keine Bewertungen

- Safe Work Method Statement WorksheetDokument5 SeitenSafe Work Method Statement Worksheetgoodspeed_phNoch keine Bewertungen

- Risk Assessment Erection of Precast Concrete ElementsDokument2 SeitenRisk Assessment Erection of Precast Concrete ElementsBunyamin Selimoglu100% (1)

- SWMS 2 Fixing CarpenterDokument3 SeitenSWMS 2 Fixing CarpenterJonasNoch keine Bewertungen

- JSA Formet New Structural Steel FabricationDokument7 SeitenJSA Formet New Structural Steel Fabricationsakthi venkatNoch keine Bewertungen

- JSARA - Fire Detection System InstallationDokument13 SeitenJSARA - Fire Detection System InstallationUtku Can KılıçNoch keine Bewertungen

- Safe Work Method Statement: Excavation, Trenching and Underground ServicesDokument5 SeitenSafe Work Method Statement: Excavation, Trenching and Underground ServicesMorhne RufinNoch keine Bewertungen

- Safe Work Method Statement (SWMS) : DemolitionDokument11 SeitenSafe Work Method Statement (SWMS) : DemolitionSafety HaveLockNoch keine Bewertungen

- Ref: Section / Dept: Civil Activity: Risk Assessment For False CeilingDokument1 SeiteRef: Section / Dept: Civil Activity: Risk Assessment For False CeilingJack P100% (2)

- Painting (General Safety) SWMS 10183-4 - SAMPLEDokument6 SeitenPainting (General Safety) SWMS 10183-4 - SAMPLEKunal PanchalNoch keine Bewertungen

- Jsa Fueling Equipment On DeckDokument2 SeitenJsa Fueling Equipment On DeckIlya BordonosovNoch keine Bewertungen

- Safe Work Method StatementDokument4 SeitenSafe Work Method StatementShahed Facebook100% (1)

- Excavation of RoadDokument7 SeitenExcavation of RoadCharles LambNoch keine Bewertungen

- Blasting and Painting - BUHPDokument6 SeitenBlasting and Painting - BUHPMuhammed yahiyaNoch keine Bewertungen

- Construction HSE Management Plan Final PDFDokument43 SeitenConstruction HSE Management Plan Final PDFSayed DarwishNoch keine Bewertungen

- JSA NO 2 Piling WorkDokument6 SeitenJSA NO 2 Piling WorkfadliNoch keine Bewertungen

- Precast Erection JSWDokument6 SeitenPrecast Erection JSWPrabhakaran GurunathanNoch keine Bewertungen

- HSE-F-314 Passenger-Material Hoist Monthly ChecklistDokument1 SeiteHSE-F-314 Passenger-Material Hoist Monthly ChecklistAhmad RazaNoch keine Bewertungen

- Job Safety Analysis WorksheetDokument7 SeitenJob Safety Analysis WorksheetMohamedSaidNoch keine Bewertungen

- Cast-In Place Concrete - Risk Assessment SheetDokument3 SeitenCast-In Place Concrete - Risk Assessment SheetYash SharmaNoch keine Bewertungen

- Excavation & Trenching PlanDokument37 SeitenExcavation & Trenching PlanBogdan RaduNoch keine Bewertungen

- Ladders, Hop Ups Risk AssessmentDokument8 SeitenLadders, Hop Ups Risk AssessmentRebecca Winter100% (1)

- HIRADC Asphalt RoadDokument1 SeiteHIRADC Asphalt RoadAshadi Amir100% (1)

- JSA Erection of Gathering TentDokument12 SeitenJSA Erection of Gathering TentMuhammad Tariq100% (2)

- Brazing (Oxygen and Acetylene)Dokument6 SeitenBrazing (Oxygen and Acetylene)My Zain100% (1)

- SWMSDokument11 SeitenSWMSSathika Godawatta100% (1)

- Office Safety PlanDokument12 SeitenOffice Safety PlanberatcansuNoch keine Bewertungen

- Excavation Trenching and HorizontalDokument5 SeitenExcavation Trenching and HorizontalRaed Naim Khammash100% (1)

- WMS Structural Steel Structual Steel ErectionDokument7 SeitenWMS Structural Steel Structual Steel ErectionconcretemadNoch keine Bewertungen

- JGS SHES JHRA 001 13 Grating Installation and RemovalDokument2 SeitenJGS SHES JHRA 001 13 Grating Installation and Removalarnel sungkip100% (2)

- SWMS 3 Moving Plant On Construction SitesDokument7 SeitenSWMS 3 Moving Plant On Construction SitesSyazli EimranNoch keine Bewertungen

- Part-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykeDokument4 SeitenPart-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykevivekaramanaNoch keine Bewertungen

- HSE-RA-018 Use of An Angle Grinder - Rev 0Dokument15 SeitenHSE-RA-018 Use of An Angle Grinder - Rev 0عمروNoch keine Bewertungen

- Safe System Of Work A Complete Guide - 2020 EditionVon EverandSafe System Of Work A Complete Guide - 2020 EditionNoch keine Bewertungen

- Sample SWMS SP003 - Margate Parade Boardwalk Concrete WorkDokument10 SeitenSample SWMS SP003 - Margate Parade Boardwalk Concrete WorkHaytham S. AtiaNoch keine Bewertungen

- Hume PipesDokument3 SeitenHume PipesSathish100% (1)

- Shear Strength of SlabDokument3 SeitenShear Strength of Slabaleena4Noch keine Bewertungen

- Presentation DCC10012 Sesi 220222023Dokument3 SeitenPresentation DCC10012 Sesi 220222023Putry JazmeenNoch keine Bewertungen

- Exp 1 Introduction UTMDokument6 SeitenExp 1 Introduction UTMSusmit AloneNoch keine Bewertungen

- API Standards WhitepaperDokument6 SeitenAPI Standards WhitepaperISHUNoch keine Bewertungen

- Voltage FlickerDokument7 SeitenVoltage FlickerAnonymous xaeuoo4Noch keine Bewertungen

- Puzzle Cube Technical DrawingsDokument7 SeitenPuzzle Cube Technical Drawingsapi-371576090Noch keine Bewertungen

- Steel Building DesignDokument12 SeitenSteel Building DesignĄlmost ĄwhisperNoch keine Bewertungen

- Ey ThesisDokument5 SeitenEy Thesisafjrooeyv100% (1)

- SmartPlant SpoolgenDokument2 SeitenSmartPlant SpoolgenLuis MiñoNoch keine Bewertungen

- Guru Prasadh Recommendation - Panneer SirDokument1 SeiteGuru Prasadh Recommendation - Panneer SirkrishnaNoch keine Bewertungen

- Conexões IPEXDokument66 SeitenConexões IPEXBrian RobertsNoch keine Bewertungen

- 7SJ80 7SK80 PA enDokument2 Seiten7SJ80 7SK80 PA enzaheer ahamedNoch keine Bewertungen

- Senior Electrical Engineer 1571155865Dokument2 SeitenSenior Electrical Engineer 1571155865Fariyad AnsariNoch keine Bewertungen

- D-Statcom With PI Controller For Voltage Stability: A. Sherly G. SusithraDokument3 SeitenD-Statcom With PI Controller For Voltage Stability: A. Sherly G. Susithraely nzukiNoch keine Bewertungen

- FreyssinetDokument17 SeitenFreyssinetJuan CastilloNoch keine Bewertungen

- Agile Software Development A Case Study of Web ApplicationDokument7 SeitenAgile Software Development A Case Study of Web ApplicationsleshiNoch keine Bewertungen

- Concrete Wall in Tropical ClimateDokument11 SeitenConcrete Wall in Tropical ClimateSuryasis DasguptaNoch keine Bewertungen

- Development of Recycled PET Fiber and Its Application As Concrete-Reinforcing FiberDokument8 SeitenDevelopment of Recycled PET Fiber and Its Application As Concrete-Reinforcing FiberJunaid Ahmad100% (1)

- Deepwater Landing String DesignDokument6 SeitenDeepwater Landing String Designrdos14Noch keine Bewertungen

- Sample Career Episode CDR Writing PDFDokument4 SeitenSample Career Episode CDR Writing PDFMark Peter100% (3)

- Profibus OverviewDokument41 SeitenProfibus OverviewVarun Kumar100% (3)

- Wildlife Crossing Design Based On AASHTO-17th & ACI 318-14Dokument1 SeiteWildlife Crossing Design Based On AASHTO-17th & ACI 318-14Bilal Ahmed BarbhuiyaNoch keine Bewertungen

- Euroweld: European Certification For Welding PersonnelDokument21 SeitenEuroweld: European Certification For Welding PersonnelScott TrainorNoch keine Bewertungen

- Multi Instrument Mi-1 and Mi-2Dokument4 SeitenMulti Instrument Mi-1 and Mi-2hassan karimiNoch keine Bewertungen

- Engineering STD DWGDokument6 SeitenEngineering STD DWGvyroreiNoch keine Bewertungen

- Trailer Mounted Concrete Pump Catalog - Taian Sinotep Machinery Co.,Ltd - Concrete Pump Manufacturer in ChinaDokument25 SeitenTrailer Mounted Concrete Pump Catalog - Taian Sinotep Machinery Co.,Ltd - Concrete Pump Manufacturer in ChinasinotepconcretepumpNoch keine Bewertungen

- 77385Dokument342 Seiten77385WajahatNoch keine Bewertungen

- Effects of Column CreepDokument11 SeitenEffects of Column CreephemalcmistryNoch keine Bewertungen

- Robert B. Walford - Business Process Implementation For It Professionals and Managers (1999, Artech House)Dokument322 SeitenRobert B. Walford - Business Process Implementation For It Professionals and Managers (1999, Artech House)hamzaNoch keine Bewertungen