Beruflich Dokumente

Kultur Dokumente

Factory Acceptance Test Checklist for Low Voltage Electrical Boards

Hochgeladen von

Balamurugan ArumugamOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Factory Acceptance Test Checklist for Low Voltage Electrical Boards

Hochgeladen von

Balamurugan ArumugamCopyright:

Verfügbare Formate

CKE.ITP.01.35.(00).

2012

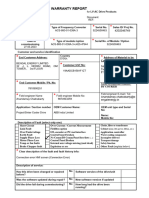

FACTORY ACCEPTANCE TEST Date Issued : 16th January 2012

CHECKLIST FOR VISUAL INSPECTION OF LOW Revision : -

VOLTAGE ELECTRICAL BOARDS Revision Date : -

Page : 1/5

PROJECT NAME :

MANUFACTURER NAME :

Notes:

1. This form is to be used as a checklist for visual inspection acceptance only. Other acceptance criteria such as dielectric

properties test, insulation resistance test and functional test shall use the forms provided by the manufacturer. S.O Rep is

advised to begin the FAT with the visual inspection test ahead.

2. Prior departure to the factory, SO Representatives (SORs) are recommended to bring together:

Documents : Approved Shop Drawing of Switchboard, BQ & Material List as per contract

Tools : Digital Caliper, Measuring Tape, Torchlight, Digital Camera

3. Upon arrival and prior of any testing, SO Representatives are required to check/ensure:

a. Date of calibration status of the instruments to be used for testing. (Calibration validity: 2 years)

b. Certificate of the manufacturer’s competent person who will in charge for the testing. (Min. AO)

c. Brand & Model of the material installed had been approved during construction stage as referred to

material approval list (comply to J-MAL and material list as per contract).

d. Inspect thoroughly compliance of the manufactured switchboard with the approved shop drawing

particularly on the following criteria:

Rating, Number of Poles & Arrangement of EACH Switchgear and terminals

SPECIFICATION/JKR COMPLIANCE

NO. DESCRIPTION [√: Yes, X : No, - : Not REMARKS

REQUIREMENT Applicable]

Board Name:

Also applicable to PFC

A) Self-Contained Floor Mounted Cubicle Switchboard Board and GSC Board

1 Form of Separation Form 2B Minimum Requirement.

2 Frame Thickness Switchboard ≥ 2.5 mm

3 Panels, Covers & Doors ≥ 2.0 mm

Thickness

4 Panel (Top & Sides) Removable

5 Panels, Covers & Front Cylindrical knurled head (chromed type)

Doors c/w retaining clip

6 Serrated Star Washer At front cover

7 Material for Frame Rolled Steel

8 Anti Rust Treatment Epoxy dry powder

9 Color Enamel Grey (Exterior)

Matt White (Interior)

10 Base Cover Plates Provided

11 Door Espagnolette/cremone bolt, locking

device & satin chrome lever handle at the

center fixing

12 Rear Door Hinged removable & double-leaf type

12.1 Width of Each Leaf < 450 mm

13 Louvers with filter Sides & back

14 Withdrawable switchgear Own compartment with rear connected

busbars

15 Height of indicating ≤ 2000 mm (above the base)

instrument

16 Building automation Separately housed in a compartment

devices, transducers, relays

17 SPD Separate compartment at immediate

lower subsection & totally

compartmentalize

18 Tool Compartment Located at the lowest subsection c/w

lockable with key

19 All secondary wiring Neat Properly labelled with number

sleeves

Cawangan Kejuruteraan Elektrik, JKR Malaysia.

CKE.ITP.01.35.(00).2012

FACTORY ACCEPTANCE TEST Date Issued : 16th January 2012

CHECKLIST FOR VISUAL INSPECTION OF LOW Revision : -

VOLTAGE ELECTRICAL BOARDS Revision Date : -

Page : 2/5

SPECIFICATION/JKR COMPLIANCE

NO. DESCRIPTION [√: Yes, X : No, - : Not REMARKS

REQUIREMENT Applicable]

B) Wall Mounted Switchboard

1 Material Sheet steel

2 Thickness ≥ 2.0 mm

3 Portion of the Front Cover Fibre type

(cut-out & meter)

3.1 Thickness ≥ 5.0 mm

4 Louvers with filter Both sides

5 Serrated Star Washer At front cover

6 Anti Rust Treatment Epoxy dry powder

7 Color Enamel Grey

8 Panels, Covers & Front Cylindrical knurled head (chromed type)

Doors c/w retaining clip

9 All secondary wiring Properly labelled with number sleeves

C) Busbars

1 Mounting Non-hygroscopic insulator

2 Busbar Tinned hard drawn high conductivity

copper

3 Horizontal Busbar & Drawing requirement: Horizontal & Vertical

Compliance:

Vertical Busbar Size (at Tender (mm) Working (mm) Busbar Size (at main

incoming supply) should be

main incoming supply) Size R the same.

Y Size as installed is similar

B or more than as in the

N approved shop drawing.

4 Distrubution Busbar Size Drawing requirement:

Compliance:

similar as approved shop Tender (mm) Working (mm) Size at each Distribution

drawing (Vertical at each R Busbar shall be less than or

equal to the maximum size

outgoing) Y of outgoing circuit breakers

B connected to it.

N

5 Multiple Parallel Busbars Separated by tinned copper spacers (at Spacing=busbar thickness

spacing equal to the busbar thickness)

6 Main Busbar Arrangement R-Y-B-N (from back to front) Front Back

R - Y - B - N

7 Phase Indication/ Painted with colour at appropriate points

Identification to denote the phase

8 Switchboard Earthing Bar Tinned copper

8.1 Size 50 mm x 6 mm Or else otherwise

specified

9 Earthing Bar Identification Painted with green at appropriate points

D) Conductors

1 Sizes As per approved drawing

2 Cabling Neat and tighten

3 Coloured Cable For < 25mm2 cable: shall be colour coded

to identify the phase &neutral conductors

4 Cable End Termination Coloured cable sleeve to identify the

phase and neutral conductors

E) Others

1 Indicating Lamps Easily be replaced from the front of the

panel. LED type

2 Anti Condensation Heater Installed for every 2 sections, excluding

busbar compartment. Heater c/w

enclosure

2.1 Heater c/w automatic thermostat control, ON-

OFF switch & indicating lamp.

3 Labels Engraved with white lettering,black

background & fastened or riveted

Cawangan Kejuruteraan Elektrik, JKR Malaysia.

CKE.ITP.01.35.(00).2012

FACTORY ACCEPTANCE TEST Date Issued : 16th January 2012

CHECKLIST FOR VISUAL INSPECTION OF LOW Revision : -

VOLTAGE ELECTRICAL BOARDS Revision Date : -

Page : 3/5

SPECIFICATION/JKR COMPLIANCE

NO. DESCRIPTION [√: Yes, X : No, - : Not REMARKS

REQUIREMENT Applicable]

F) Switchgears

1 Switchgears Current rating are accordance with

drawing and/or BQ

2 ACBs Withdrawable metal clad,

flush mounted & horizontal drawout

isolation, c/w shutter

2.1 No. of poles 3 or 4

2.2 Icw Minimum 50 kA at 415V for 1 sec. or

otherwise specified

2.3 Copper tape/bar from Tinned copper

frame (metal) of ACB

to SEB

2.4 Used as Bus-coupler 4 pole

3 MCCBs No. of poles are accordance with drawing

and/or BQ

3.1 Icu Minimum 50 kA at 415V for 1 sec. or

otherwise specified

3.2 Incoming Feeder Provided with panel mounting external If required

Circuit Breaker ≥ 400A operating handle with padlocking

facilities and door interlocking facilities

G) Current Transformers

1 Secondary Rating 5A

2 Rating ≥ 15 VA

3 Accuracy (for measuring & Class 1.0 or otherwise specified

metering)

4 Accuracy (for protection) Class 10P10 or otherwise specified

H) Surge Protection Device

1 Connecting Leads as short as possible Preferably not exceeding

0.5m for the total length.

2 2.1 Isolation of SPD : 4 pole MCCB or fuses or otherwise

MCCB / Fuse specified

2.2 Isolation of SPD : Separate compartment for SPD

Compartment

3 Transparent Window for At front cover of the SPD’s compartment

viewing the SPD indicator for viewing the SPD indicator

4 Label “Amaran” at SPD Sentences as in L-S1 with red lettering on

compartment a white background

I ) Distribution Board

1 Material Sheet steel

2 Thickness 1.2mm to 1.5 mm

3 Serrated Star Washer At front cover

4 Anti Rust Treatment Epoxy dry powder

5 Color Enamel Grey

6 Panels, Covers & Front Cylindrical knurled head (chromed type)

Doors c/w retaining clip

7 Comb / Fork Busbar Insulated type

Cawangan Kejuruteraan Elektrik, JKR Malaysia.

CKE.ITP.01.35.(00).2012

FACTORY ACCEPTANCE TEST Date Issued : 16th January 2012

CHECKLIST FOR VISUAL INSPECTION OF LOW Revision : -

VOLTAGE ELECTRICAL BOARDS Revision Date : -

Page : 4/5

SPECIFICATION/JKR COMPLIANCE

NO. DESCRIPTION [√: Yes, X : No, - : Not REMARKS

REQUIREMENT Applicable]

Note : For item J, K & L, the compliance of specification & JKR requirement for item Self-Contained Floor Mounted Cubicle Switchboard

and item Busbar are similar as LV Switchboard above. i.e: Thickness, size, material, etc.

J) Power Factor Correction Board (PFCB)

1 Enclosure Not form part of the switchboard it is

connected to (independent) but match the

height and depth.

1.1 Icu of MCCB / ACB Minimum 50 kA at 415V for 1 sec. or Icu:

otherwise specified Ics:

1.2 Access Front & rear

2 Capacitor

2.1 Category C (min. 40oC)

2.2 Rated Voltage 525V, 50Hz

2.3 Housing/Container Heavy metal sheet steel

2.4 Separation between Min. 80mm

capacitors

3 Reactor Installed in separate compartment of

PFCB c/w rubber pad to reduce noise due

to vibration etc.

3.1 Class H

3.2 kVAR Rating Min. 6%

(Reactance)

3.3 Rated Voltage 440V

4 MCCB

4.1 Icu of MCCB / ACB Minimum 50 kA at 415V for 1 sec. or Icu:

otherwise specified. Ics:

Ics = 100% Icu

4.2 Minimum Continuous Min. 155% of rated capacitor currents

Current Ratings

5 Switching Contactor

5.1 Utilization Category AC-6B

5.2 Minimum Continuous Min. 135% of rated capacitors currents

Current Rating

5.3 Ventilation Van Heavy duty type* c/w filter and *Air Exchange :

automatic shutter Min.200 cubic meter

perhour

6 All secondary wiring Properly labelled with number sleeves

K) Generator Set Switchboard [Essential Board]

1 Enclosure Not form part of the switchboard it is

connected to (independent) but match the

height and depth.

2 Automatic Transfer Transparent protection screen of full

Switching Equipment compartment size shall be provided in front

(ATSE) of automatic changeover contactors / ATSE

2.1 Contactor Utilization AC-33B

Category

2.2 MCCB / ACB type 4 pole

3 Tinned Copper Earthing 25mm x 6mm

Bar

4 All secondary wiring Properly labelled with number sleeves

L) Generator Set Control Board (GSCB) [AMF Board]

1 Enclosure Not form part of the switchboard it is

connected to (independent) but match the

height and depth.

2 Emergency Stop Push- Provided and c/w self-latching mushroom

Button head type

3 Alarm Bell Min.250mm diameter

4 All secondary wiring Properly labelled with number sleeves

Cawangan Kejuruteraan Elektrik, JKR Malaysia.

CKE.ITP.01.35.(00).2012

FACTORY ACCEPTANCE TEST Date Issued : 16th January 2012

CHECKLIST FOR VISUAL INSPECTION OF LOW Revision : -

VOLTAGE ELECTRICAL BOARDS Revision Date : -

Page : 5/5

COMMENTS (IF ANY)

CHECKED BY [S.O. Representative)

Signature : Position :

Name : Date :

(CAPITALS)

On behalf of :

WITNESSED BY [JKR] *if applicable

Signature : Position :

Name : Date :

(CAPITALS)

On behalf of :

ELECTRICAL CONTRACTOR

Signature : Position :

Name : Date :

(CAPITALS)

On behalf of :

MANUFACTURER

Signature : Position :

Name : Date :

(CAPITALS)

On behalf of :

Cawangan Kejuruteraan Elektrik, JKR Malaysia.

Das könnte Ihnen auch gefallen

- Auto Synchronizing 3 DG SetsDokument9 SeitenAuto Synchronizing 3 DG Setssunilmvgr5Noch keine Bewertungen

- Design of Pile FoundationDokument16 SeitenDesign of Pile FoundationD SRINIVASNoch keine Bewertungen

- HT Panel Test ReportDokument4 SeitenHT Panel Test ReportItx Adi0% (1)

- Is 3043 Earthing PDFDokument108 SeitenIs 3043 Earthing PDFPuspesh Giri100% (6)

- Is 3043 Earthing PDFDokument108 SeitenIs 3043 Earthing PDFPuspesh Giri100% (6)

- Schematic Diagram For 22kV Switchgear PDFDokument101 SeitenSchematic Diagram For 22kV Switchgear PDFAn Trần TuấnNoch keine Bewertungen

- Earthing Resistance Calculations Is 3043Dokument14 SeitenEarthing Resistance Calculations Is 3043haris100% (1)

- 43-SDMS-02 - Specs MV Step Voltage PDFDokument17 Seiten43-SDMS-02 - Specs MV Step Voltage PDFfabiano_projetoNoch keine Bewertungen

- Cable ScheduleDokument12 SeitenCable ScheduleamilasriNoch keine Bewertungen

- Install, Operate and Maintain Low Voltage PanelDokument72 SeitenInstall, Operate and Maintain Low Voltage Panelgiau richkyNoch keine Bewertungen

- LS - 2 Power FactorDokument33 SeitenLS - 2 Power FactorsugunavengadasonNoch keine Bewertungen

- HT Cable Sizing CalculationDokument3 SeitenHT Cable Sizing CalculationBalamurugan Arumugam100% (1)

- HT Cable Sizing CalculationDokument3 SeitenHT Cable Sizing CalculationBalamurugan Arumugam100% (1)

- Hume Pipe & Cable Trench Sizing Calculation 25.07.20Dokument4 SeitenHume Pipe & Cable Trench Sizing Calculation 25.07.20PremBhushanNoch keine Bewertungen

- MV Cables Data Sheet - SampleDokument5 SeitenMV Cables Data Sheet - SampleAvoor KhanNoch keine Bewertungen

- Precommissioning Procedures of Testing Commissioning PDFDokument96 SeitenPrecommissioning Procedures of Testing Commissioning PDFRatheesh Kumar100% (1)

- Check List For Cable Glanding & TerminationDokument1 SeiteCheck List For Cable Glanding & TerminationImran Khan100% (4)

- Inspection Checklist For LV Electrical WorksDokument40 SeitenInspection Checklist For LV Electrical WorksMOHAMMED EJAS83% (6)

- Checking of Electrical PanelDokument7 SeitenChecking of Electrical PanelReneboy LambarteNoch keine Bewertungen

- 32-Sdms-09 (Gas Insulated Metal Clad MV Switchgear)Dokument50 Seiten32-Sdms-09 (Gas Insulated Metal Clad MV Switchgear)Haytham BafoNoch keine Bewertungen

- Technical Submittal - 3 WAY & 4 WAY - RMUDokument149 SeitenTechnical Submittal - 3 WAY & 4 WAY - RMUفارس معتوقNoch keine Bewertungen

- NGR Routine Test ProcedureDokument6 SeitenNGR Routine Test Procedurezaheer ahamedNoch keine Bewertungen

- Specification For Public Address (P.a) SystemDokument45 SeitenSpecification For Public Address (P.a) SystemKhairul AshrafNoch keine Bewertungen

- MV SWGR & CGR - Inspn & Test Procedure IECDokument9 SeitenMV SWGR & CGR - Inspn & Test Procedure IECMohammed Madi100% (2)

- Check List LT PanelDokument1 SeiteCheck List LT PanelAnil PatelNoch keine Bewertungen

- Malaysian Standard: Electric Cable and Wire: 600/1 000 (Um 1 200) V MULTI CORE PVC Insulated Cable - ArmouredDokument19 SeitenMalaysian Standard: Electric Cable and Wire: 600/1 000 (Um 1 200) V MULTI CORE PVC Insulated Cable - ArmouredAli Akbar100% (1)

- Power Systems For AIX III - Advanced Administration and Problem DeterminationDokument946 SeitenPower Systems For AIX III - Advanced Administration and Problem DeterminationgsgheneaNoch keine Bewertungen

- Esah 3.1Dokument34 SeitenEsah 3.1maurice86100% (1)

- Annex A Diesel Generators TORDokument37 SeitenAnnex A Diesel Generators TORnachiNoch keine Bewertungen

- Annex A Diesel Generators TORDokument37 SeitenAnnex A Diesel Generators TORnachiNoch keine Bewertungen

- 36KV Outdoor Ring Main Unit Technical SpecificationDokument9 Seiten36KV Outdoor Ring Main Unit Technical SpecificationBADRI VENKATESHNoch keine Bewertungen

- Guidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFDokument89 SeitenGuidelines 11 KV 33KV OUTDOOR TRANSFORMERS PDFSwaroop Biswas100% (1)

- 7.7.20 Electrical Installation PDFDokument35 Seiten7.7.20 Electrical Installation PDFtanishq13Noch keine Bewertungen

- Specification For MV MCCDokument39 SeitenSpecification For MV MCCamhosny2010Noch keine Bewertungen

- BQ 13 Street Lighting and Traffic PDFDokument11 SeitenBQ 13 Street Lighting and Traffic PDFNurly SafNoch keine Bewertungen

- Rmu Visual Inspection ChecklistDokument1 SeiteRmu Visual Inspection ChecklistJoe_Average100% (2)

- JKR 11kV Transformer TestDokument29 SeitenJKR 11kV Transformer TestSeanChanNoch keine Bewertungen

- EPE 12kV SwitchgearDokument48 SeitenEPE 12kV Switchgearaimiza100% (1)

- L s3 Low Voltage Underground CableDokument20 SeitenL s3 Low Voltage Underground CableAsith Savinda100% (4)

- Market Survey FlooringDokument12 SeitenMarket Survey FlooringJhanviNoch keine Bewertungen

- Trane Rtaa 322 - 3151Dokument32 SeitenTrane Rtaa 322 - 3151trutleptNoch keine Bewertungen

- DPS 03rev02Dokument67 SeitenDPS 03rev02siso hegoNoch keine Bewertungen

- LV Planning Guidelines SummaryDokument100 SeitenLV Planning Guidelines SummaryDwayne Dennis100% (3)

- TG-NET-SST-018 Secondary Distribution Substations - Particular Requirements For Outdoor Substation and Enclosures - PETE OWEN 1Dokument37 SeitenTG-NET-SST-018 Secondary Distribution Substations - Particular Requirements For Outdoor Substation and Enclosures - PETE OWEN 1Foaad Ahmad100% (1)

- Sun Power Engineering (PVT) LTD: No 74/12, Dikwella Road, Beliatta, SrilankaDokument4 SeitenSun Power Engineering (PVT) LTD: No 74/12, Dikwella Road, Beliatta, SrilankasameeraNoch keine Bewertungen

- JKR Specs L-S1 Specification For Low Internal Electrical Installation May-2011 Rev.2Dokument114 SeitenJKR Specs L-S1 Specification For Low Internal Electrical Installation May-2011 Rev.2Leong Km86% (7)

- Check List For Installation of Earthing System: Contractor: Sub-ContractorDokument4 SeitenCheck List For Installation of Earthing System: Contractor: Sub-ContractorRyn RcioNoch keine Bewertungen

- MS2015-Building Installation ElectricalDokument44 SeitenMS2015-Building Installation ElectricalScalperNoch keine Bewertungen

- 050 Vacuum Pump Systems 2021Dokument190 Seiten050 Vacuum Pump Systems 2021Balamurugan ArumugamNoch keine Bewertungen

- 050 Vacuum Pump Systems 2021Dokument190 Seiten050 Vacuum Pump Systems 2021Balamurugan ArumugamNoch keine Bewertungen

- MALAYSIAN STANDARDS FOR ELECTRICAL ENGINEERING AND ELECTRONICSDokument46 SeitenMALAYSIAN STANDARDS FOR ELECTRICAL ENGINEERING AND ELECTRONICSrwaz3535100% (2)

- CQRS Documents by Greg YoungDokument56 SeitenCQRS Documents by Greg YoungAndrey ChasovskikhNoch keine Bewertungen

- Ee03100 Low Voltage SwitchboardDokument25 SeitenEe03100 Low Voltage SwitchboardDeepak Verma100% (1)

- Medium Voltage Application Guide en IECDokument224 SeitenMedium Voltage Application Guide en IECJag Jagdish0% (1)

- Method Statement of ELECTRICAL WORKS REV NOV 2020Dokument15 SeitenMethod Statement of ELECTRICAL WORKS REV NOV 2020Faiz Bukhari100% (6)

- Big CPU Big DataDokument424 SeitenBig CPU Big DataKountNoch keine Bewertungen

- Battery Ups EarthingDokument36 SeitenBattery Ups EarthingkishansaiNoch keine Bewertungen

- The Ghost of Thomas KempeDokument160 SeitenThe Ghost of Thomas KempeDa Ny57% (7)

- Raychem Catalogue - APKT - 7.2kV To 36kVDokument2 SeitenRaychem Catalogue - APKT - 7.2kV To 36kVdes1982100% (2)

- 11kV Dist Xfmr SpecDokument33 Seiten11kV Dist Xfmr SpecKarthikNoch keine Bewertungen

- Technical Data Sheet (33-11kV Substation Construction) - Rev.0Dokument109 SeitenTechnical Data Sheet (33-11kV Substation Construction) - Rev.0elsayedNoch keine Bewertungen

- Technical DataDokument50 SeitenTechnical DataYuzaly Salleh0% (2)

- SIRIM - PS045003 - IEC60502-1 Power Cables With Extruded Solid Insulation (27-8-20) PDFDokument3 SeitenSIRIM - PS045003 - IEC60502-1 Power Cables With Extruded Solid Insulation (27-8-20) PDFanas Bie100% (2)

- Cold Test Report 3Dokument1 SeiteCold Test Report 3Venkitesh PG100% (1)

- Cable Slab TNBDokument20 SeitenCable Slab TNBPoi 3647Noch keine Bewertungen

- 4 - Electrical SpecificationsNIT39 PDFDokument69 Seiten4 - Electrical SpecificationsNIT39 PDFDileep ChintalapatiNoch keine Bewertungen

- L-s1 Specification For Low Voltage Internal Electrical InstallationDokument154 SeitenL-s1 Specification For Low Voltage Internal Electrical InstallationKW LeeNoch keine Bewertungen

- Distribution Board Schedule Db-L&P-Work Shop 1-4 TPN 10: 10A 10A 10A 10A 10A 10A 10A 10A 10A 10A 20A 20ADokument9 SeitenDistribution Board Schedule Db-L&P-Work Shop 1-4 TPN 10: 10A 10A 10A 10A 10A 10A 10A 10A 10A 10A 20A 20ANiveeth ChattergyNoch keine Bewertungen

- Ibvsi RJ Sangrah Ee Relay GTP 12 - Rev 01Dokument6 SeitenIbvsi RJ Sangrah Ee Relay GTP 12 - Rev 01Om SaxenaNoch keine Bewertungen

- 06 - FEWA-EL-PROT-TD-0132, Rev 1, 2016Dokument34 Seiten06 - FEWA-EL-PROT-TD-0132, Rev 1, 2016MuraryspottyNoch keine Bewertungen

- AMBPL Busduct SpecsDokument5 SeitenAMBPL Busduct SpecsPrasadNoch keine Bewertungen

- INSTALLATION SPECIFICATION FOR LO PEKANBARU OFFICEDokument7 SeitenINSTALLATION SPECIFICATION FOR LO PEKANBARU OFFICEMuhamad IqbalNoch keine Bewertungen

- MVCC-Tech SpecDokument3 SeitenMVCC-Tech Specvishnu ojhaNoch keine Bewertungen

- Avx Flexiterm MLCC DSDokument5 SeitenAvx Flexiterm MLCC DSguest guestNoch keine Bewertungen

- Model Warranty FormDokument3 SeitenModel Warranty FormTrisna KaranNoch keine Bewertungen

- Specification of Solar Tube Well Fodder SargodhaDokument3 SeitenSpecification of Solar Tube Well Fodder SargodhaAbdul RashidNoch keine Bewertungen

- INSULATOR SILICON 11kV PIN TYPE COMPLETE WITH LARGE HEAD SPINDLEDokument2 SeitenINSULATOR SILICON 11kV PIN TYPE COMPLETE WITH LARGE HEAD SPINDLELeo PaulNoch keine Bewertungen

- Work Progress ReportDokument6 SeitenWork Progress ReportBalamurugan ArumugamNoch keine Bewertungen

- Ball Mill Panel SLDDokument1 SeiteBall Mill Panel SLDBalamurugan ArumugamNoch keine Bewertungen

- Calculus Report6031 20210702 055202Dokument25 SeitenCalculus Report6031 20210702 055202Balamurugan ArumugamNoch keine Bewertungen

- Ain Shams Engineering Journal - Optimal Load Shedding Using BSADokument12 SeitenAin Shams Engineering Journal - Optimal Load Shedding Using BSABalamurugan ArumugamNoch keine Bewertungen

- 04-Industry-1540386707 WiproDokument20 Seiten04-Industry-1540386707 WiprocmashtamoorthyNoch keine Bewertungen

- Lightning Protection Risk Analysis-62305 Part-21Dokument105 SeitenLightning Protection Risk Analysis-62305 Part-21Balamurugan ArumugamNoch keine Bewertungen

- Ceiling mounting rails and accessories dimensions technical specsDokument1 SeiteCeiling mounting rails and accessories dimensions technical specsBalamurugan ArumugamNoch keine Bewertungen

- Modelado de Un Transformador en Delta AbiertoDokument2 SeitenModelado de Un Transformador en Delta AbiertoyradyhNoch keine Bewertungen

- Test Report: Patient ID 0100007634 Sid NoDokument2 SeitenTest Report: Patient ID 0100007634 Sid NoBalamurugan ArumugamNoch keine Bewertungen

- Electrical Load List of Luminous DT 26.03.2021 R1Dokument11 SeitenElectrical Load List of Luminous DT 26.03.2021 R1Balamurugan ArumugamNoch keine Bewertungen

- Timesheet - Week 23 - 2021-DKDokument1 SeiteTimesheet - Week 23 - 2021-DKBalamurugan ArumugamNoch keine Bewertungen

- EB Guidelines For Haridwar 33kV HT SupplyDokument1 SeiteEB Guidelines For Haridwar 33kV HT SupplyBalamurugan ArumugamNoch keine Bewertungen

- Tps-Sch-Bd-Me-Ge-El-0001-A - Cable ScheduleDokument5 SeitenTps-Sch-Bd-Me-Ge-El-0001-A - Cable ScheduleBalamurugan ArumugamNoch keine Bewertungen

- Lightning Protection Risk Analysis-62305 Part-21Dokument105 SeitenLightning Protection Risk Analysis-62305 Part-21Balamurugan ArumugamNoch keine Bewertungen

- Distribution Transformer Calculations: Developed By: Mahmoud SalamaDokument1 SeiteDistribution Transformer Calculations: Developed By: Mahmoud SalamaBalamurugan ArumugamNoch keine Bewertungen

- Selection of Main CB and Branch CB 22-8-12Dokument25 SeitenSelection of Main CB and Branch CB 22-8-12Balamurugan ArumugamNoch keine Bewertungen

- 4th Floor Panel List Busduct Elements DiscussionDokument1 Seite4th Floor Panel List Busduct Elements DiscussionBalamurugan ArumugamNoch keine Bewertungen

- Timesheet - Week 22 - 2021-PGDokument1 SeiteTimesheet - Week 22 - 2021-PGBalamurugan ArumugamNoch keine Bewertungen

- Comprehensive Insurance Policy DetailsDokument4 SeitenComprehensive Insurance Policy DetailsBalamurugan ArumugamNoch keine Bewertungen

- Selection of Main CB and Branch CB 22-8-12Dokument25 SeitenSelection of Main CB and Branch CB 22-8-12Balamurugan ArumugamNoch keine Bewertungen

- CH2SMDokument32 SeitenCH2SMxavierlthNoch keine Bewertungen

- The The: Evolution of Warren, or Triangular, TrussDokument1 SeiteThe The: Evolution of Warren, or Triangular, TrussMr. DreamNoch keine Bewertungen

- IT2006 Industry ReportDokument13 SeitenIT2006 Industry Reportapi-3819238Noch keine Bewertungen

- "The Future of The Past", Sibyl Moholi-NagyDokument7 Seiten"The Future of The Past", Sibyl Moholi-NagyJosep PascualNoch keine Bewertungen

- Manuale PlayStation 2Dokument88 SeitenManuale PlayStation 2Davide MaffettoniNoch keine Bewertungen

- Instruction: Answer All Question: Assignment 1 Analysis of Prestress and Bending Stress BFS 40303Dokument4 SeitenInstruction: Answer All Question: Assignment 1 Analysis of Prestress and Bending Stress BFS 40303tashadzureenNoch keine Bewertungen

- All Products BrochureDokument16 SeitenAll Products BrochureArmandoMiquilenaNoch keine Bewertungen

- TEYSSOT 2016 - Key Points.. Between Figure and GroundDokument40 SeitenTEYSSOT 2016 - Key Points.. Between Figure and GroundEvandro Smarieri SoaresNoch keine Bewertungen

- Global Engineering Consultancy ProfileDokument6 SeitenGlobal Engineering Consultancy ProfileOladunni AfolabiNoch keine Bewertungen

- Active Directory: The Brain of a Windows Server NetworkDokument25 SeitenActive Directory: The Brain of a Windows Server NetworkWilkin Felisilda Simo0% (1)

- Solaris Cluster Changing Public IP Addresses or Logical Host IP in Cluster Doc ID 1003630 PDFDokument3 SeitenSolaris Cluster Changing Public IP Addresses or Logical Host IP in Cluster Doc ID 1003630 PDFKuswahyudi UtomoNoch keine Bewertungen

- Interpreter of MaladiesDokument50 SeitenInterpreter of MaladiesmahakNoch keine Bewertungen

- Array Processors: SIMD Computer OrganizationDokument45 SeitenArray Processors: SIMD Computer OrganizationArshad Matin100% (1)

- Ad 630Dokument13 SeitenAd 630Antonio PerezNoch keine Bewertungen

- Gardtec Eurosec CP8L LCD Engineer ManDokument24 SeitenGardtec Eurosec CP8L LCD Engineer ManChrisNoch keine Bewertungen

- OpenSSH ServerDokument2 SeitenOpenSSH ServerSingha RakyongNoch keine Bewertungen

- Brosur Deltagrout CG - REV - 20100725MTDokument2 SeitenBrosur Deltagrout CG - REV - 20100725MTjimdabrondNoch keine Bewertungen

- IDM International Diploma in ICT COMPUTING Combined Assesment: Computer Platforms (2014)Dokument135 SeitenIDM International Diploma in ICT COMPUTING Combined Assesment: Computer Platforms (2014)Hashan Thilakarathna0% (1)

- ESET Mail Security For Microsoft Exchange ServerDokument195 SeitenESET Mail Security For Microsoft Exchange ServerAnonymous J0VjSbNoch keine Bewertungen

- Catalog AccuscoreDokument8 SeitenCatalog AccuscoreAsif ShahNoch keine Bewertungen

- Suspended Structures PDFDokument18 SeitenSuspended Structures PDFtilak mehraNoch keine Bewertungen

- BBMP fever clinics contact detailsDokument11 SeitenBBMP fever clinics contact detailsnavchakraNoch keine Bewertungen

- Launcher LogDokument4 SeitenLauncher LogNickazaz1Noch keine Bewertungen