Beruflich Dokumente

Kultur Dokumente

Boiler Drum Level Control in Thermal Power Plant 2016

Hochgeladen von

Ali AlmisbahCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Boiler Drum Level Control in Thermal Power Plant 2016

Hochgeladen von

Ali AlmisbahCopyright:

Verfügbare Formate

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

Boiler Drum Level Control In Thermal

Power Plant

Shiji S.R1, Anish .S 2, Swapna .M 3

PG Student, Department of EEE, Lourdes Matha College of Science and Technology, Kuttichal, Kerala, India 1

Engineer, Department of CIG, Centre for Development of Advanced Computing, Vellayambalam, Kerala, India 2

Associate Professor, Department of EEE, Lourdes Matha College of Science and Technology, Kuttichal , Kerala, India 3

Abstract: The boiler is a fundamental part of almost all industries. It varies in application from low pressure to high

pressure. The proper and safe control of the steam drum water level is the most crucial operation of the boiler. The

boiler may get damaged due to overheating, if the level is too low, and also, due to overflow of water, if the level is too

high. Therefore, there exists an optimum interface level between steam and water within the boiler drum. The steam

boiler drum level is characterized by a high extent of nonlinearity, uncertainty, disturbance and overshoot.. The

cascade-three parameters water level control system includes boiler drum water level, steam flow and water supply.

Boiler drum water level is controlled by using cascaded Proportional Integral Derivative(PID) controller technique and

then optimization is done by using Model Predictive Controller(MPC).Simulations are done in 210MW thermal power

plant. The comparative analysis shows the better result when an advanced controller such as MPC is used. MPC has a

comparatively less overshoot than PID controller and much faster settling occurs for an MPC , which shows the

superiority of MPC.

Keywords: PID Controller, MPC Controller, Process Variables (PV)

I. INTRODUCTION

The water level of boiler drum is one of the crucial control (b)Thermodynamics of pressure and temperature,

parameters for any process industries, which reflects the geometry of the steam drum, and equation of continuity

control of mainly boiler load and feed water indirectly. If are the parameters to define transmitter calibration.

the water level is critically high it results in low drum (c)The zero elevation and span against transmitter

pressure causing swelling and results in water carryover specifications must be checked to ensure proper

into the steam piping.. If the water is low then results in calibration of selected transmitter.

high drum pressure causing shrinkage which is severe

enough to trip the boiler. The feedwater control system is a Boiler operating conditions that alter the total volume of

three element type, designed to monitor changes in steam water in the boiler cannot be corrected by feed forward

flow, water flow and drum level. Steam flow is the rate of control strategy. For example, forced circulation boilers

steam leaving the boiler - the demand. Water flow is the may have steam generating sections that are placed out of

rate of feedwater flow into the boiler - the supply. service or in service intermittently. The level controller

itself must be correct for these unmeasured disturbances

Drum level reflects the amount of water in the boiler - the using the normal feedback control algorithm. Feedwater

inventory. With changes in boiler load (steam flow), steam flow and steam output flow transmitters are required to

and water flow become unbalanced and water level find out the difference between the two flows. A drum

consequently deviates from the normal position. In such an level transmitter reference is used to control the boiler feed

event, the level controller will adjust the boiler feed water water control valve.

valve position to restore the flow to its set point before the

boiler drum liquid level is even affected. The level II. TYPES OF BOILER FEED WATER CONTROL

controller is the primary controller, (sometimes referred to

as the master controller) in this cascade, adjusting the set There are different types of control techniques for a boiler

point of the flow controller, which is the secondary feed water control.

controller (sometimes identified as the slave controller).

For measurement of drum level following points must be A. Single Element Control

taken care of:- Single Element Drum Level Control is the simplest and

least effective method to regulate the water level. It is

(a)Elimination of errors which are attributed in mainly used for boilers with modest change requirement

measurement due to fluctuating water level or changing and start-up operation. The process variable coming out

rate of water inflow and steam outflow. from the drum level transmitter is compared to the set

Copyright to IARJSET DOI 10.17148/IARJSET 139

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

point and a deviation value is produced. This signal is fed III. PROBLEM FORMULATION

into the controller and make corrective action.

A boiler of a thermal power plant is taken and the drum

level control of the boiler is achieved using conventional

PID controller and compared with MPC. The comparison

of both the controller performance is analyzed

IV.MATHEMATICAL MODELLING OF BOILER

DRUM

Fig1: Single Element Control Mass and energy conservation equations are written for

the drum in its entirety. The entire contents of the drum

B. Two Element Control are assumed to be in the saturation state.

Two Element Drum Level Control includes steam flow as

a feed forward element Two element control system has A. Mass and Energy Balance

two variables, drum level and steam flow to manipulate

the feed water control valve. This strategy compensate the The boiler drum level ld responds in an integrating manner

imbalance between feed water mass flow and steam mass to the steam flow Fd and feed water flow Few . Basically,

flow out into the drum. It is adequate for load changes of the drum model describes the dynamics of drum water

moderate speed and magnitude. It has some drawbacks i.e. volume Vdw in terms of the mass and energy conversion

it can use on a single boiler with a single feed water pump equations. A separate relationship between Vdw and ld is

using a constant feed water pressure, it cannot adjust for derived then from the geometry of the drum and this

pressure or load disturbances in the feed water system and equation is solved using the Newton-Raphson method to

it cannot eliminate phasing interaction between various obtain ld. The mass and energy balance equations for the

portions of the process. boiler drum are derived as follows :

Mass Balance:

Rate of change of mass of steam and water in the drum

= Feed water flow to the drum – steam flow from the drum

d

V d V dw d V dw dw

F ew F d (1)

dt

Energy Balance:

Rate of change of energy of steam and water in the drum

Fig 2: Two Element Control = Total energy of steam and water mixture after leaving

the water walls - Energy of drum water - Energy of drum

C. Three Element Control steam

Three element control strategy is the commonly used

method to control the drum water level. This method is d

ideally suited for a boiler plant, which consists of multiple dt V d V dw d h d V dw dw h dw F D h w F D F ew h dw FD hd (2)

boilers with multiple feed water pumps. By using cascade

control mechanism, level element act as primary loop, The differential equations obtained are

flow element acts as the secondary loop and steam flow

acts as the feed forward controller. This strategy attempts d

d F ew dw F d X q F D dw (3)

1

d

to compensate the changes or disturbance in steam flow d

dt q 2 q 4 dw

and feed water flow.

1

dV 1

q 3 F ew q 3 F d X

dw

q

FD (4)

dt q4 dw

where Xq is the steam quality.

The drum level ld is computed using Newton-Raphson

Method. [3]

f l d k (5)

ld k 1 l d k

f ' l d k

Fig3: Three Element Control

Copyright to IARJSET DOI 10.17148/IARJSET 140

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

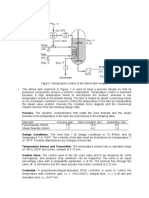

V. BOILER DRUM LEVEL MODEL WITH The level controller is the primary controller also known

CONVENTIONAL CONTROL SYSTEM as master controller in this cascade, adjusting the set point

of the flow controller, which is the secondary controller,

referred as slave controller.

The third element is the flow of steam leaving the steam

drum. The variation in demand from the steam header is

the most common disturbance to the boiler level control

system in an industrial steam system.

The boiler level control scheme do not feed the steam flow

signal directly. Instead, the difference between the outlet

steam flow and the inlet water flow is calculated. The

difference value is directly added to the set point signal to

the feed water flow controller. Therefore, if the steam flow

Fig4: Feed Water Flow Control System

out of the boiler is suddenly increased by the startup of a

Most of the medium and high pressure boilers today use a turbine, for example, the set point to the feed water flow

controller is increased by exactly the amount of the

“3-element” boiler control strategy. The term “3-element

measured steam flow increase.

control” refers to the three process variables(PV’s) that are

measured to effect control of the boiler feed water control

valve. These measured PVs are: VI. MODEL DEVELOPMENT AND SIMULATION

USING MATLAB / SIMULINK

-Liquid level in the boiler drum

The differential equations (3) and (4) are solved and

-Flow of feed water to the boiler drum

simulation studies are carried out with the help of the

-Flow of steam leaving the boiler drum

nominal values of the boiler drum variables and

Fig 4 shows a cascaded control for 3-element boiler drum

parameters collected from the 210 MW thermal power

level control.

plant boiler during the study. The data pertaining to these

The feed controller will immediately sense any variations drum variables and parameters are represented in Table1.

Open loop step response tests are conducted on the model

in the supply conditions which produce a change in feed

in order to determine its suitability to control application.

water flow. The flow controller will adjust the boiler feed

water valve position to restore the flow to its set point

before the boiler drum liquid level is even affected.

Table 1 Nominal values of Boiler Drum variables

Variables Description Value Unit

d Density of drum steam 8.221 x 10

5 Kg/cm3

dw Density of water in drum 63.097 x 10

5 Kg/sec

Few Feedwater flow 163.5023 Kcal/kg

hew Enthalpy of feedwater 131.97 Kg/sec

Fd Steam flow from drum 175.014 Kg/sec

ld Drum level 88.90 Cm

pd Steam pressure in the drum 176.8 Kg/cm2

Td Saturated steam temperature 354 o

C

Xq Steam quality 0.95 -

hd Gradient of drum steam enthalpy -657954.52 Kcal-cm3/Kg2

hdw Gradient of water enthalpy at drum Conditions 1128547.11 Kcal-cm3 /Kg2

Gradient of drum steam density -2.0132 -

dw

Vd Volume of drum 40185469.46 cm

3

Vdw Drum water volume 20092734.73 cm

3

l Length of drum 1500 cm

r Radius of drum 88.9 cm

Copyright to IARJSET DOI 10.17148/IARJSET 141

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

Input, output and state variables of the boiler drum model

is represented in Figure 5

Few BOILER DRUM ld

Few MODEL

Fd

Vdw pd

Fig 5: Block diagram of boiler drum model

screen and on a black-and-white hardcopy Fig 8: Regulation of boiler drum level using PID controller

Using the described controller design, boiler drum water

level control of boiler drum is implemented using

SIMULINK. We get the output response shown in fig 7,

and fig.8. From the response of PID Control, it is found

out that the settling time and overshoot is high. To

improve the response of PID controller, here we use an

advanced controller MPC.

Fig 6: Boiler Drum Model Simulink

VII. SIMULATION RESULTS

The Boiler Drum water level control system is modeled in

this paper, and is simulated with conventional PID

controller and an advanced control technique such as MPC

using MATLAB/SIMULINK environment. The Fig:9 Regulation of boiler drum drum water volume using

simulations are carried out with the nominal values of a MPC

210MW thermal power plant. In both cases feed water

flow and steam flow is considered and the corresponding

variations in drum level and drum water volume is

analyzed.

Fig:10 Regulation of boiler drum level using MPC

Above fig 9 and Fig 8 shows the simulation of boiler drum

level and volume using MPC. A better response is

Fig 7: Regulation of boiler drum water volume using PID obtained with reduced settling time and overshoot

controller compared to PID controller.

Copyright to IARJSET DOI 10.17148/IARJSET 142

ISSN (Online) 2393-8021

IARJSET ISSN (Print) 2394-1588

International Advanced Research Journal in Science, Engineering and Technology

National Conference on Emerging Trends in Engineering and Technology (NCETET’16)

Lourdes Matha College of Science & Technology, Thiruvananthapuram

Vol. 3, Special Issue 3, August 2016

VIII. CONCLUSION

In this paper, PID controller and MPC are designed for the

regulation of boiler drum level. This work basically

evaluate the performance of PID and MPC for boiler drum

level control system. The simulation result shows the

performance of proposed control system and the

comparison between both the control strategies are

studied. From Simulation response the performance of

MPC is more accurate and better than PID controller. With

MPC a faster settling time is obtained without any

overshoot.

REFERENCES

[1] Damian Flynn: Thermal Power Plant Simulation and control, The

Institution of Electrical Engineers (2003).

[2] Rominus Valsalam S: Modelling, simulation and adaptive optimal

control of a boiler, PhD thesis (2003)

[3] David, A. C: An introduction to genetic algorithms for scientists

and engineers, World Scientific Publishing Co. Pte. Ltd (1999).

[4] Wei, J. L. Wang, J. H. and Wu, Q. H.: Coal mill modelling using

evolutionary computation technique and its on-line implementation,

Control 2004,University of Bath U.K,ID-080 (2004).

[5] Astrom K.J and Bell R.D: Drum boiler Dynamics, Automatica,

No.36, pp. 363-378, (2000)

[6] Flymn ME and Malley M.J.O: A drum boiler model for long term

power system dynamic simulation, IEEE transactions on Power

Systems, Vol 14, No.1 (1999)

Copyright to IARJSET DOI 10.17148/IARJSET 143

Das könnte Ihnen auch gefallen

- 7800 Series Burner ControlDokument57 Seiten7800 Series Burner ControldanterpoNoch keine Bewertungen

- GE Versapro Programming ManualDokument291 SeitenGE Versapro Programming ManualLeo BurnsNoch keine Bewertungen

- E50001-G720-A143-X-4a00 WS Sicam TM 1703 Acp UsDokument6 SeitenE50001-G720-A143-X-4a00 WS Sicam TM 1703 Acp UsdannrangerNoch keine Bewertungen

- Sugar enDokument12 SeitenSugar enakhmad zaenudinNoch keine Bewertungen

- Col Step7 v5.6 TrialDokument1 SeiteCol Step7 v5.6 TrialfasgafdgsfdgsfdgafdNoch keine Bewertungen

- Controls & Instrumentation FOR 660 MW Supercritical Unit at TirodaDokument23 SeitenControls & Instrumentation FOR 660 MW Supercritical Unit at TirodaAakash kumar ShrivastavaNoch keine Bewertungen

- Boiler Control OverviewDokument4 SeitenBoiler Control OverviewMAS98Noch keine Bewertungen

- IfixDokument568 SeitenIfixFrancisco Simon Reyes ParancanNoch keine Bewertungen

- GFS-426B PACSystems ProgrammingDokument460 SeitenGFS-426B PACSystems ProgrammingElafanNoch keine Bewertungen

- Atv31 (E)Dokument220 SeitenAtv31 (E)Santos Zosimo Ocas GoicocheaNoch keine Bewertungen

- Packscan InfoDokument4 SeitenPackscan InfosathyasingNoch keine Bewertungen

- API 610 Vertical Turbine Pump VS6 (Can Type) VS1 (Sump Type)Dokument22 SeitenAPI 610 Vertical Turbine Pump VS6 (Can Type) VS1 (Sump Type)Magico NinoNoch keine Bewertungen

- High Concentration Slurry Density - Pem News LetterDokument4 SeitenHigh Concentration Slurry Density - Pem News LetterGirish BhagchandaniNoch keine Bewertungen

- Testing of Porcelain Enamel Powder PropertiesDokument4 SeitenTesting of Porcelain Enamel Powder PropertiesMiroslav LukačevićNoch keine Bewertungen

- CP SP 1372e 03 PDFDokument40 SeitenCP SP 1372e 03 PDFArribas Quilaton LeoNoch keine Bewertungen

- SRI SensorDokument7 SeitenSRI SensorArun GuptaNoch keine Bewertungen

- DCS PLC PC or PASDokument7 SeitenDCS PLC PC or PASSrikar Reddy GummadiNoch keine Bewertungen

- Atv 71Dokument2 SeitenAtv 71DedyNoch keine Bewertungen

- Jumag Gesamtkatalog enDokument24 SeitenJumag Gesamtkatalog enatisz333Noch keine Bewertungen

- Control ValveDokument2 SeitenControl ValveNadia KamaNoch keine Bewertungen

- Post ESP GuidelinesDokument26 SeitenPost ESP GuidelineschristiancribeiroNoch keine Bewertungen

- GFK1645L VersaMax Miano Users ManualDokument733 SeitenGFK1645L VersaMax Miano Users ManualAntonio ChoquevilcaNoch keine Bewertungen

- Electric Drives and Controls Pneumatics Service Linear Motion and Assembly Technologies HydraulicsDokument102 SeitenElectric Drives and Controls Pneumatics Service Linear Motion and Assembly Technologies HydraulicsAnderson ThiagoNoch keine Bewertungen

- GE Synch Check RelayDokument4 SeitenGE Synch Check RelayVikrantNoch keine Bewertungen

- PCS7 APL Styleguide en EN en-US PDFDokument130 SeitenPCS7 APL Styleguide en EN en-US PDFcc_bauNoch keine Bewertungen

- PCS7 Demoproject Edible Oil Docu enDokument54 SeitenPCS7 Demoproject Edible Oil Docu enDragoslav DzolicNoch keine Bewertungen

- Zenith H20H52DT - Service ManualDokument48 SeitenZenith H20H52DT - Service ManualrolaperezNoch keine Bewertungen

- Vortex FMDokument14 SeitenVortex FMtirutkkNoch keine Bewertungen

- Kinemax Gas or Oil Burners: Bulletin 4200Dokument26 SeitenKinemax Gas or Oil Burners: Bulletin 4200agua1829Noch keine Bewertungen

- Quick Start Guide To Using PID in Logix5000Dokument9 SeitenQuick Start Guide To Using PID in Logix5000vijaysatawNoch keine Bewertungen

- PID Controllers and Tuning (Prof. Cesar Prada) PDFDokument144 SeitenPID Controllers and Tuning (Prof. Cesar Prada) PDFYesika Alvarez OrtegaNoch keine Bewertungen

- S7 TIA Portal Programming With SCL: Online Instructor-Led TrainingDokument1 SeiteS7 TIA Portal Programming With SCL: Online Instructor-Led TrainingKhaled El-BeheryNoch keine Bewertungen

- Internship ReportDokument39 SeitenInternship ReportUtkarsh YadavNoch keine Bewertungen

- Introduction To Magnetic Flow MetersDokument11 SeitenIntroduction To Magnetic Flow MetersNïkĦïl ДkДvØØrNoch keine Bewertungen

- SPPA-T1000 System OverviewDokument14 SeitenSPPA-T1000 System OverviewNAYEEMNoch keine Bewertungen

- Hollias Macs v6.5.2 Functon BlockDokument1.079 SeitenHollias Macs v6.5.2 Functon BlockMovieGame Nime99Noch keine Bewertungen

- 7.21 TGOV1: Steam Turbine-GovernorDokument2 Seiten7.21 TGOV1: Steam Turbine-GovernorMuthukumar SNoch keine Bewertungen

- User ManualDokument32 SeitenUser ManualAljun LumbaoNoch keine Bewertungen

- Pressure & Temperature Switch RT SeriesDokument4 SeitenPressure & Temperature Switch RT SeriesVivek Vous AimeNoch keine Bewertungen

- Chapter 1Dokument24 SeitenChapter 1Anonymous tytJlPojNoch keine Bewertungen

- Recent Advances Turbine BypassDokument4 SeitenRecent Advances Turbine BypassretrogradesNoch keine Bewertungen

- Microcal Cat132Dokument2 SeitenMicrocal Cat132ajaysatpute100% (2)

- CM44PDokument52 SeitenCM44PSadot GutierrezNoch keine Bewertungen

- 4 - Operation Manual M&W Head Control - 00 - ENDokument5 Seiten4 - Operation Manual M&W Head Control - 00 - ENTaco PinhoNoch keine Bewertungen

- 23 09 13.33 - Control ValvesDokument25 Seiten23 09 13.33 - Control Valvesforevertay2000Noch keine Bewertungen

- TMR Vs QMR TMR Vs QMR TMR vs. QMR TMR vs. QMRDokument15 SeitenTMR Vs QMR TMR Vs QMR TMR vs. QMR TMR vs. QMRdijoz85Noch keine Bewertungen

- 750 193levelmasterDokument50 Seiten750 193levelmasterJesus CovarrubiasNoch keine Bewertungen

- Micrologix 1400Dokument2 SeitenMicrologix 1400Carlos RetanaNoch keine Bewertungen

- Rittal Assem Purge Type Z y 0000 0000Dokument16 SeitenRittal Assem Purge Type Z y 0000 0000Ashish GuptaNoch keine Bewertungen

- Process Control System A Complete Guide - 2020 EditionVon EverandProcess Control System A Complete Guide - 2020 EditionNoch keine Bewertungen

- 4d28aa63 Pawlak Performance Analysis ofDokument16 Seiten4d28aa63 Pawlak Performance Analysis ofAszenNoch keine Bewertungen

- Feedwater Level Control of Boiler Steam Drum Using Imc and Lead Lag Imc IJERTV4IS060680Dokument4 SeitenFeedwater Level Control of Boiler Steam Drum Using Imc and Lead Lag Imc IJERTV4IS060680Raj KumarNoch keine Bewertungen

- Boiler Instrumentation and ControlsDokument22 SeitenBoiler Instrumentation and ControlsPranav KevadiyaNoch keine Bewertungen

- Steam Boiler Drum Level Control Using DCS - One/Three Element MethodDokument7 SeitenSteam Boiler Drum Level Control Using DCS - One/Three Element Methodkonda reddyNoch keine Bewertungen

- Boiler Drum Level Control by Using WideDokument12 SeitenBoiler Drum Level Control by Using WideChristianaPrasetya100% (1)

- Boiler Drum Processing Through LabVIEWDokument9 SeitenBoiler Drum Processing Through LabVIEWShree Kumar MishraNoch keine Bewertungen

- Boiler Instrumentation and ControlsDokument23 SeitenBoiler Instrumentation and ControlsVora Vishal100% (2)

- Intelligence-Based Hybrid Control For Power Plant Boiler: Wei Wang, Han-Xiong Li, and Jingtao ZhangDokument8 SeitenIntelligence-Based Hybrid Control For Power Plant Boiler: Wei Wang, Han-Xiong Li, and Jingtao ZhangGanesh Kumar ArumugamNoch keine Bewertungen

- BUSTION MANAGEMENT - BOILER DRUM - SIEMENS - AD353-105r3 PDFDokument5 SeitenBUSTION MANAGEMENT - BOILER DRUM - SIEMENS - AD353-105r3 PDFGeorge MarkasNoch keine Bewertungen

- A Novel Wind Turbine Condition Monitoring Method Based On Cloud ComputingDokument9 SeitenA Novel Wind Turbine Condition Monitoring Method Based On Cloud ComputingAli AlmisbahNoch keine Bewertungen

- Comparison of Wavelet Family Performances in ECG Signal DenoisingDokument6 SeitenComparison of Wavelet Family Performances in ECG Signal DenoisingAli AlmisbahNoch keine Bewertungen

- Wind Turbine Simulator Fault Diagnosis Via Fuzzy Modelling and Identification TechniquesDokument8 SeitenWind Turbine Simulator Fault Diagnosis Via Fuzzy Modelling and Identification TechniquesAli AlmisbahNoch keine Bewertungen

- Maximization of Power Capture in Wind Turbines Using Robust Estimation and Lyapunov Extremum Seeking Control PDFDokument90 SeitenMaximization of Power Capture in Wind Turbines Using Robust Estimation and Lyapunov Extremum Seeking Control PDFAli AlmisbahNoch keine Bewertungen

- RECURSIVE IDENTIFICATION ALGORITHMS LIBRARY by NavratilDokument11 SeitenRECURSIVE IDENTIFICATION ALGORITHMS LIBRARY by NavratilAli AlmisbahNoch keine Bewertungen

- Ehanced Benchmark Challenge With NREL 5 MW FASTDokument6 SeitenEhanced Benchmark Challenge With NREL 5 MW FASTAli AlmisbahNoch keine Bewertungen

- Santibanez Strict Lyapunov Function and Chetaev Function For Stability Instability Analysis of The Pendulum PDFDokument5 SeitenSantibanez Strict Lyapunov Function and Chetaev Function For Stability Instability Analysis of The Pendulum PDFAli AlmisbahNoch keine Bewertungen

- Commande Matlab LMIDokument20 SeitenCommande Matlab LMIibovNoch keine Bewertungen

- Modeling Estimation Florian ZurbriggenDokument61 SeitenModeling Estimation Florian ZurbriggenAli AlmisbahNoch keine Bewertungen

- A First Course in Stochastic Processes PDFDokument573 SeitenA First Course in Stochastic Processes PDFAli Almisbah100% (1)

- 5Dokument18 Seiten5Yahya Ben WalidNoch keine Bewertungen

- 1271 PDFDokument74 Seiten1271 PDFAnonymous xGwQEOQiGzNoch keine Bewertungen

- Multivariable Optimal Control of An Industrial Nonlinear Boiler Turbine UnitDokument17 SeitenMultivariable Optimal Control of An Industrial Nonlinear Boiler Turbine UnitAliAlMisbahNoch keine Bewertungen

- Recursive Lecture PDFDokument33 SeitenRecursive Lecture PDFAli AlmisbahNoch keine Bewertungen

- Lect 14 PDFDokument22 SeitenLect 14 PDFRafael Sánchez CrespoNoch keine Bewertungen

- Design of Static and Dynamic DecouplerDokument6 SeitenDesign of Static and Dynamic DecouplerAli AlmisbahNoch keine Bewertungen

- A55 3 Thomas Model Based Power Plant Master ControlDokument11 SeitenA55 3 Thomas Model Based Power Plant Master ControlAli AlmisbahNoch keine Bewertungen

- Levinson Recursion PDFDokument28 SeitenLevinson Recursion PDFAli AlmisbahNoch keine Bewertungen

- Tutorial Model Predictive Control TechnologyDokument15 SeitenTutorial Model Predictive Control TechnologyYijia ZhuNoch keine Bewertungen

- The Application of Genetic Algorithms To Parameter Esitmation in Lead Acid Battery ModelsDokument137 SeitenThe Application of Genetic Algorithms To Parameter Esitmation in Lead Acid Battery ModelsAliAlMisbahNoch keine Bewertungen

- Drum-Boiler Control PerformanceDokument70 SeitenDrum-Boiler Control PerformanceAli Almisbah50% (2)

- Electric MachineryDokument12 SeitenElectric MachineryJohnatan A. RodriguesNoch keine Bewertungen

- Robust Path Following in The Present of Sliding Effect Based On LMIDokument6 SeitenRobust Path Following in The Present of Sliding Effect Based On LMIAli AlmisbahNoch keine Bewertungen

- Application of Multi-Objective Optimization Using TLBO of Optimal Power FlowDokument10 SeitenApplication of Multi-Objective Optimization Using TLBO of Optimal Power FlowAli AlmisbahNoch keine Bewertungen

- Drum-Boiler Control PerformanceDokument70 SeitenDrum-Boiler Control PerformanceAli Almisbah50% (2)

- An Adaptive Dynamic Matrix ControlDokument6 SeitenAn Adaptive Dynamic Matrix ControlAli AlmisbahNoch keine Bewertungen

- Efficiency Optimization of A Conventional Boost DC DC ConverterDokument7 SeitenEfficiency Optimization of A Conventional Boost DC DC ConverterAli AlmisbahNoch keine Bewertungen

- L01 Mini PDFDokument137 SeitenL01 Mini PDFAli AlmisbahNoch keine Bewertungen

- DIP Lecture 1&2 PDFDokument63 SeitenDIP Lecture 1&2 PDFAhmedNoch keine Bewertungen

- Chirimuuta. Outside ColorDokument262 SeitenChirimuuta. Outside Colorcrazijoe100% (2)

- Flotation Control and OptimisationDokument11 SeitenFlotation Control and OptimisationAmalia PănescuNoch keine Bewertungen

- Causality Bernhard SchölkopfDokument169 SeitenCausality Bernhard SchölkopfQingsong GuoNoch keine Bewertungen

- Pave RuttingDokument440 SeitenPave RuttingbloomdidoNoch keine Bewertungen

- Fluid Coupling in Belt Conveyor DrivesDokument12 SeitenFluid Coupling in Belt Conveyor Drivesnoelaroboi100% (2)

- 0i Connection Manual 64113EN1 PDFDokument1.224 Seiten0i Connection Manual 64113EN1 PDFAnkit SabhayaNoch keine Bewertungen

- Resummation and Renormalization in Eff Ective Theories of Particle PhysicsDokument229 SeitenResummation and Renormalization in Eff Ective Theories of Particle PhysicsDomenico Barillari100% (2)

- Making HEC-RAS Models Run FasterDokument27 SeitenMaking HEC-RAS Models Run FasterAaron NicholsNoch keine Bewertungen

- Phy1 11 - 12 Q1 0102 FDDokument31 SeitenPhy1 11 - 12 Q1 0102 FDKaye AquinoNoch keine Bewertungen

- Automation and Robotic Lec 2Dokument9 SeitenAutomation and Robotic Lec 2Josh Sam Rindai MhlangaNoch keine Bewertungen

- ACA 2010 Abstracts Manish Chandra PathakDokument602 SeitenACA 2010 Abstracts Manish Chandra Pathakpmcy2Noch keine Bewertungen

- Ahmed BodyDokument15 SeitenAhmed Bodyk sai krishnaNoch keine Bewertungen

- Heatcraft BN PDFDokument44 SeitenHeatcraft BN PDFDavid GironNoch keine Bewertungen

- 7900 Icp MsDokument5 Seiten7900 Icp MsKim Uyên VõNoch keine Bewertungen

- R5 - FCC Main Fractionator: Process DataDokument24 SeitenR5 - FCC Main Fractionator: Process Datanico123456789Noch keine Bewertungen

- Bearing Basics For Gas-Industry Screw CompressorsDokument5 SeitenBearing Basics For Gas-Industry Screw CompressorsDayo IdowuNoch keine Bewertungen

- Light NcertDokument55 SeitenLight NcertDani MathewNoch keine Bewertungen

- SilverThin Slewing Rings and Pinions CatalogDokument16 SeitenSilverThin Slewing Rings and Pinions CatalogGanesh LohakareNoch keine Bewertungen

- Musica Universalis First DraftDokument78 SeitenMusica Universalis First DraftWilliam1091Noch keine Bewertungen

- Astm d4945Dokument7 SeitenAstm d4945M.Malyadri ReddyNoch keine Bewertungen

- HW 3Dokument3 SeitenHW 3Siva RamNoch keine Bewertungen

- Martini L4 TemperatureControlDokument11 SeitenMartini L4 TemperatureControlJubaer JamiNoch keine Bewertungen

- Long-Life Asphalt Pavements - Technical2007Dokument24 SeitenLong-Life Asphalt Pavements - Technical2007Sen HuNoch keine Bewertungen

- Forces and Motion ActivityDokument5 SeitenForces and Motion Activityjanice alquizarNoch keine Bewertungen

- Olympic 2018 - Tien Giang 11Dokument17 SeitenOlympic 2018 - Tien Giang 11Trần Quốc ToảnNoch keine Bewertungen

- CSE 2261 Structural Analysis II: Course OutlineDokument38 SeitenCSE 2261 Structural Analysis II: Course OutlinezakheusNoch keine Bewertungen

- The Definite Integral and Its ApplicationsDokument13 SeitenThe Definite Integral and Its Applicationsapi-312673653100% (1)

- 2010 Aisc Steel ToolsDokument4 Seiten2010 Aisc Steel Toolsmuh2006Noch keine Bewertungen

- A Comparative Research On Corrosion Behavior of A Standard, Crack-Free and Duplex Hard Chromium CoatingsDokument6 SeitenA Comparative Research On Corrosion Behavior of A Standard, Crack-Free and Duplex Hard Chromium CoatingsKarthi SundarNoch keine Bewertungen