Beruflich Dokumente

Kultur Dokumente

Formulation and Evaluation of Lamotrizine Orodispensible Tablets

Hochgeladen von

Baru Chandrasekhar RaoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Formulation and Evaluation of Lamotrizine Orodispensible Tablets

Hochgeladen von

Baru Chandrasekhar RaoCopyright:

Verfügbare Formate

IAJPS 2018, 05 (01), 769-778 K.

Ramanji Reddy et al ISSN 2349-7750

CODEN [USA]: IAJPBB ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

http://doi.org/10.5281/zenodo.1174207

Available online at: http://www.iajps.com Research Article

FORMULATION AND EVALUATION OF LAMOTRIZINE

ORODISPENSIBLE TABLETS

K. Ramanji Reddy*1, Dr. S. Jaya 2, R.Srikanth 2, Dr. Chandaka Madhu1

1

Scientist, Startech Labs Pvt. Ltd., Madinaguda, Hyderabad,TS-5000050

2

Anurag Pharmacy College, Ananthagiri (V), Kodad (M), Nalgonda,TS-508206

Abstract:

The aim of the present study was to develop and optimize oral disintegrating tablets of model drug (Lamotrizine) to

give quick onset of action by rapidly disintegrating in a few seconds without the need of water with better patient

compliance. In such cases, bioavailability of drug is significantly greater and adverse event is reduced than those

observed from conventional tablet dosage form. By performing compatibility studies by IR spectrophotometry, no

interaction was confirmed. Oral disintegrating tablets were formulated by direct compression method and evaluated

by UV-Visibile spectrophotometer. Standard calibration curve prepared to determine the drug content in the

prepared tablets. Prior to compression, the blend of drug and excipients were evaluated for flow properties such as

Angle of repose, Bulk density, Tapped density, % Compressibility, and Hausner ratio. All the formulation showed

excellentproperties. Oral disintegrating tablets were prepared by direct compression technique using CADMACH

16 station tablet punching machine, equipped with round flat punches of 8 mm diameter. Post compression

evaluation of prepared oral disintegrating tablets were carried out with the help of different pharmacopoeial and

non-pharmacopoeial (industry specified) tests. The shape and color of all the formulations were found to be circular

and white in color. The thickness was found to be uniform in specific formulations. The hardness and friability are

also within the permitted limits. Dissolution of tablets was carried out. The crospovidone used formulation gave the

more dissolution profile compared to other superdisintegrants.

Keywords: Lamotrizine, UV-Visibile spectrophotometer , superdisintegrants, crospovidone

Corresponding author:

K. Ramanji Reddy, M.Sc, M.Phil., (Ph.D). QR code

Sr. Scientist in Startech Labs Pvt. Ltd.

Madinaguda, Hyderabad, India

ramanjibiotech@gmail.com

Mobile No: 9700971895

Please cite this article in press as K. Ramanji Reddy et al., Formulation and Evaluation of Lamotrizine

Orodispensible Tablets , Indo Am. J. P. Sci, 2018; 05(01).

www.iajps.com Page 769

IAJPS 2018, 05 (01), 769-778 K. Ramanji Reddy et al ISSN 2349-7750

INTRODUCTION:

Recent advances in novel drug delivery systems API Characterization

(NDDS) aim to enhance safety and efficacy of drug A. Organoleptic evaluation

molecules by formulating a convenient dosage form Organoleptic characters like color, odor, and taste of

for administration and to achieve better patient drug were observed and recorded using descriptive

compliance [1]. One such approach was oral terminology.

dispersible tablets which has gained acceptance and

popularity in the recent time. Oro - dispersible tablet B. Analytical evaluation

provides a convenient means of administrating drugs, Calibration Curve of Lamotrizine in 0.1N Hcl5

particularly to pediatrics and geriatric patients, more

importantly they can be taken without water for oral Preparation of Stock solution

drug administration. Several pharmaceutical Stock I: 100mg of the drug was accurately weighed

industries prepared oro - dispersible tablets by direct and transferred into the 100 ml volumetric flask. It was

compression technique by selecting suitable dissolved in sufficient quantity of buffer and volume

superdisintegrants. Direct compression technique was made up to the mark with 6.8 Phosphate buffer to

offers important advantages such as increased output, get a 1000 µg/ml solution. This was the standard stock

reduced cost, less machinery and improved drug solution containing 1 mg/ml of model drug. (Stock I).

stability when compared to the wet granulation

method [2]. Stock 2: From above stock 1 solution 10ml was taken

and make up with 6.8 Phosphate buffer to 100ml and

Lamotrigine is an anticonvulsant medication used to this was 100 ppm concentration solution.

treat epilepsy and bipolar disorder. In bipolar, it is

used to treat acute episodes of depression, rapid Preparation of the calibration curve

cycling in bipolar type II, and prevent recurrence in From the stock II solution proper dilutions were

bipolar type I3. Common side effects include made to 10 ml volumetric flasks and were diluted

sleepiness, headache, vomiting, trouble with with 6.8 Phosphate buffer up to the mark to obtain

coordination, and rash. Serious side effects include concentration of 1, 2, 3, 4 and 5µg/ml respectively.

lack of red blood cells, suicide, Stevens-Johnson Absorbance of each solution was measured at 243

syndrome, and allergic reactions. There are concerns nm. The Standard curve preparation was performed.

that use during pregnancy or breastfeeding may result The absorbances on x-axis were plotted against the

in harm. Lamotrigine is a phenyltriazine, making it concentrations on y-axis and r 2 value was obtained.

chemically different from other anticonvulsants. It

appears to increase the action of gamma- Pre-Formulation Studies

aminobutyric acid (GABA), the main inhibitory I. FT-1R Studies [6]

neurotransmitter in the central nervous system and The IR absorption spectra of the Lamotrizine drug and

decrease voltage-sensitive sodium channels [4]. with different superdisintegrants, natural gums and

excipients were taken in the range of 4000-450 cm-1

using KBr disc method, 1-2 mg of the substance to be

The present research work has been carried out with examined was triturated with 300-400 mg, specified

an aim to formulate Lamotrizine orally disintegrating quantity, of finely powdered and dried potassium

tablets with superdisintegrants like crospovidone, bromide .These quantities are usually sufficient to give

croscaramellose sodium and sodium starch glycolate a disc of 10-15mm diameter and pellet of suitable

in different concentrations intensity by a hydraulic press. The scans were

evaluated for presence of principle peaks of drug,

MATERIALS AND METHOD: shifting and masking of drug peaks due presence super

Chemicals Required: disintegrants and excipients.

Cefuroxime axetil, Mannitol, Microcrystalline

cellulose, crospovidone, Magnesium stearate, Sodium Formulation Planning

starch glycolate. Oro dispersible tablets containing 6.25mg of

Lamotrizine were prepared with a total tablet weight

Apparatus Required: of 150mg. By conducting the thorough literature

Balance, sieves, tapped density tester, mixer survey, the excipients were selected and an attempt

granulator, mechanical stirrer, dryer, compression was made to produce Oro dispersible tablets.

meachine, vernier calipers, hardness tester,

disintegration apparatus, stability chambers, phmeter

and dissolution

www.iajps.com Page 770

IAJPS 2018, 05 (01), 769-778 K. Ramanji Reddy et al ISSN 2349-7750

General formula glidant and lubricant were incorporated, magnesium

Different superdisintegrants croscarmellose sodium, stearate also decreases the hardness of tablets without

crospovidone, Sodium starch glycollate in the affecting the disintegration time.

concentration range of 3- 7.5%.. Microcrystalline

cellulose (Avicel PH102) was selected as the filler or Formulation of different batches

diluent, owing to its multiple functionalities as binder, The main aim of the present study was to formulate

disintegrant, compressibility and flowability. Out of different batches using three various

the various grades available, the granular form - superdisintegrants and other ingredients in varying

Avicel PH102 was selected for direct compression concentrations. So, different batches of formulations

purpose, because it had been already reported to were planned accordingly. According to that F1, F2,

provide lower crushing strengths and shorter F3 (with Crospovidone-3%, 5%, 7.5%), F4, F5, F6

disintegration times. To improve flow property of the (with Crosscaramellose-3%, 5%, 7.5%), F7, F8, F9

blend magnesium stearate (1.5%) and aerosil (1%) as (with Sodium starch glycollate-3%, 5%, 7.5%).

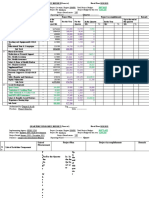

Table 1: Formulations of Different Batches (F1-F9)

Formulations Code

Ingredients (mg) F1 F2 F3 F4 F5 F6 F7 F8 F9

6.25 6.25 6.25 6.25 6.25 6.25 6.25 6.25

Lamotrizine 6.25

Crospovidone 4.5 7.5 11.25 ------ ------ ------- ------ ------ -----

Croscarmellose

------ ------ ------ 4.5 7.5 11.25 ------ ------ -----

sod.

SSG ------ ----- ---- ------- ------ ----- 4.5 7.5 11.25

qs Qs qs Qs qs qs qs qs Qs

MCC 102

0.75 0.75 0.75 0.75 0.75 0.75 0.75 0.75

Vanillin 0.75

30 30 30 30 30 30 30 30

Mannitol 30

Magnesium

2.25 2.25 2.25 2.25 2.25 2.25 2.25 2.25 2.25

stearate

1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5 1.5

Aerosil

Evaluation of Tablet Blends:

Pre-compression parameters:

1. Angle of repose [7] volume was measured directly from the graduation

A funnel with 10 mm inner diameter of stem was marks on the cylinder as ml. The volume measure

fixed at a height of 2 cm. over the platform. About 10 was called as the bulk volume and the bulk density

gm of sample was slowly passed along the wall of the was calculated by following formula.

funnel till the tip of the pile formed and touches the

Tapped densities the drug was determined by pouring

steam of the funnel. A rough circle was drawn around

gently 25 gm of sample through a glass funnel into a

the pile base and the radius of the powder cone was

100 ml graduated cylinder. The cylinder was tapped

measured.

from height of 2 inches until a constant volume was

2. Bulk density and tapped density [8] obtained. In USP TAP DENSITY TESTER, Tap

Apparent Bulk density (gm/ml) of the drug was density is measured in 500taps, 750 taps & 1250taps

determined by pouring (preseived 40-mesh) gently 25 with drop/time-299-302. Volume occupied by the

gm of sample through a glass funnel into a 100 ml sample after tapping were recorded and tapped

graduated cylinder. Then after pouring the powder density was calculated.

bed was made uniform without disturbing. Then the

www.iajps.com Page 771

IAJPS 2018, 05 (01), 769-778 K. Ramanji Reddy et al ISSN 2349-7750

3. Measures of Powder Compressibility (Carr’s threaded bolt until the tablet fractures. As the spring is

compressibility index) [9] compressed, a pointer rides along a gauge on the barrel

Compressibility is the ability of powder to decrease to indicate the force. The force of fracture is recorded

in volume under pressure. Compressibility is a and the zero force reading is deducted from it.

measure that is obtained from density determinations. Generally, a minimum hardness of 5 - 7 kg/cm2 is

It is also one of the simple methods to evaluate flow considered acceptable for uncoated tablets.

property of powder by comparing the bulk density

and tapped density. High density powders tend to 4. Weight Variation Test [13]

possess free flowing properties. A useful empirical Twenty tablets from each batch were weighed with

guide is given by the Carr’s index or compressibility electronic digital balance and average weight was

index calculated from bulk density and tapped determined. Then individual tablets were weighted and

density. individual weight was compared with the average

weight. The percentage deviation was calculated and

4. Hausner ratio [10] checked for weight variation. Standard deviation was

Hausner’s ratio provides an indication of the degree calculated. Using this procedure weight variation

of densification which could result form vibration of range of all the batches were determined and recorded.

the feed hopper. A lower value of indicates better

flow and vice versa. 5. Friability [14]

The friability of tablets was determined by using

Method of Formulation [11]: Roche Friabilator. It is expressed in percentage (%).

Direct compression method. Thirty three tablets (6.600gms.) were initially weighed

The model drug (Lamotrizine) is thoroughly mixed (Winitial) and transferred into friabilator. The friabilator

with the super disintegrants and then other excipients was operated at 25 rpm for 4 minutes or run up to 100

are added to the mixer and passed through the sieve revolutions. The tablets were weighed again (Wfinal).

(sieve no. 40). Collected the powder mixer, blended The percentage friability was then calculated by,

with magnesium stearate (pre sieved through sieve no.

60), the powder blend is subjected to drying for 𝐋𝐨𝐬𝐬 𝐢𝐧 𝐰𝐞𝐢𝐠𝐡𝐭

% 𝐅𝐫𝐢𝐚𝐛𝐢𝐥𝐢𝐭𝐲 = × 𝟏𝟎𝟎

removal of moisture content and then subjected the 𝐈𝐧𝐢𝐭𝐢𝐚𝐥 𝐰𝐞𝐢𝐠𝐡𝐭

blend for tablet compression by using Round and flat

faced punches in CADMACH 16 punches tablet Where,

punching machine. Punches of 8 mm diameter were

used for compression. Tablet of 150 mg was prepared W1 = Initial weight of the 33 tablets before testing.

by adjusting hardness and volume screw of

W2 = Final weight of the 33 tablets after testing.

compression machine properly.

Friability values below 1% are generally acceptable.

Post compression tests:

1. Organoleptic properties of tablets % Friability of tablets less than 1% is considered

Organoleptic properties such as taste, color, odour, acceptable. Thus, it is necessary that this parameter

were evaluated. Ten tablets from each batch were should be evaluated and the results are within bound

randomly selected and tested for taste, color, odour limits (0.1 - 0.9%).

and physical appearance.

6. In vitro Disintegration time [15]

2. Uniformity of Thickness [12] The process of breakdown of a tablet into smaller

The thickness of individual tablets of 6 numbers were particles is called as disintegration. The in-vitro

measured with vernier calipers, it permits accurate disintegration time of a tablet was determined using

measurements and provides information of the disintegration apparatus as per I.P. specifications.

variation between tablets. Tablet thickness should be

controlled within ± 5% variation of standard value. I.P. Specifications: Place one tablet in each of the 6

tubes of the basket. Add a disc to each tube and run

3. Hardness [13]: The tablet hardness of different the apparatus using 0.1N Hcl as dissolution medium

formulations was measured using the Monsanto maintained at 370±2C as the immersion liquid. The

hardness tester for 6 tablets. The tester consists of a assembly should be raised and lowered between 30

barrel containing a compressible spring held between cycles per minute in the 0.1N Hcl maintained at

two plungers. The lower plunger was placed in contact 37±2c. The time in seconds taken for complete

with the tablet, and a zero was taken. The upper disintegration of the tablet with no palpable mass

plunger was then forced against the spring by turning a

www.iajps.com Page 772

IAJPS 2018, 05 (01), 769-778 K. Ramanji Reddy et al ISSN 2349-7750

remaining in the apparatus was measured and paddles at 50 rpm. As per the official recommendation

recorded. of IP 500ml of 0.1N Hcl used as dissolution medium

and the temperature of the medium was set at 37 ± 0.5

7. Drug Content Uniformity [16, 17] 0

C. 5 ml of sample was withdrawn at predetermined

Assay time interval of 5min., 10min., 15min., 20min, 30min,

Twenty tablets were selected randomly and powdered. 45mins and 60mins. And same volume of fresh

A quantity of this powder corresponding to one tablet medium was replaced. The withdrawn samples were

was dissolved in 100 ml of 0.1N Hcl, stirred for 15 analyzed by an UV-visible spectrophotometer at 243

min and filtered. 1 ml of the filtrate was diluted to 100 nm using 0.1N Hcl solution as blank solution.

ml with 0.1N Hcl. Absorbance of this solution was

measured at 243nm using 0.1N Hcl as blank and The drug content was calculated using the equation

content of drug was estimated. generated from standard calibration curve. The %

8. In vitro Dissolution studies [18]: cumulative drug release was calculated.

Dissolution of the tablet of each batch was carried out

using USP type II apparatus (ELECTRO LAB) using

Table 2: Summary of general dissolution conditions

Sl. No. Parameter Specifications

1. Dissolution medium 6.8 pH Phosphate buffer

2. Temperature 37±0.5oc

3. Rotation speed 50 rpm

4. USP Type II Paddle

5. Volume withdrawn 5 ml

6. λmax 243 nm

RESULTS AND DISCUSSION:

RESULTS

Table 3: Organoleptic characteristics of the drug

Characteristics Results

Colour White to off white powder

Table 4: Calibration Curve of Lamotrizine with 6.8 Ph Phosphate Buffer

Concentration Absorbance

0 0

1 0.084

2 0.165

3 0.249

4 0.330

5 0.445

0.5

0.4 y = 0.0871x - 0.0055

R² = 0.9963

Absorbance

0.3

0.2

0.1

0

-0.1 0 1 2 3 4 5 6

Concentration

Fig .1: Calibration Curve of Lamotrizine with 6.8 Ph Phosphate Buffer

www.iajps.com Page 773

IAJPS 2018, 05 (01), 769-778 K. Ramanji Reddy et al ISSN 2349-7750

Drug-excipients Compatibility studies

Fig .2: FT-IR spectra of Lamotrizine

Fig .3: FT-IR spectra of Lamotrizine final formulation

Table 5: Evaluation of tablet blend for formulations (F1 – F9)

Bulk Angle

Density Tapped Hausner Compressibility of

Formulation (g/cc) Density(g/cc) ratio index (%) repose

F1 0.42 0.48 1.14 12.50 26.09

F2 0.39 0.45 1.15 13.33 27.16

F3 0.35 0.41 1.17 14.63 25.57

F4 0.44 0.50 1.14 12.00 26.38

F5 0.42 0.47 1.12 10.64 28.94

F6 0.45 0.51 1.13 11.76 24.64

F7 0.38 0.43 1.13 11.63 29.10

F8 0.40 0.45 1.13 11.11 27.69

F9 0.46 0.52 1.13 11.54 25.18

www.iajps.com Page 774

IAJPS 2018, 05 (01), 769-778 K. Ramanji Reddy et al ISSN 2349-7750

Table 6: Evaluation of Immediate Release Tablets for formulations (F1 – F9)

Formulation Hardness(kg/cm2) Friability(%) Weight (mg) Thickness(mm)

F1 3.2 0.35 151 2.20

F2 3.0 0.32 148 2.21

F3 3.4 0.36 150 2.16

F4 3.6 0.34 151 2.11

F5 3.2 0.38 150 2.19

F6 3.5 0.40 148 2.13

F7 3.0 0.37 152 2.20

F8 3.3 0.32 151 2.18

F9 3.5 0.41 149 2.14

Table 7: Evaluation of Immediate Release Tablets for formulations (F1 – F9)

Formulation Disintegration time(sec) Drug content (%)

F1 17 97.80

F2 14 99.05

F3 10 98.12

F4 5 99.10

F5 4 99.48

F6 2 98.16

F7 32 97.45

F8 24 98.16

F9 20 99.09

0.5

0.4

% Friability

0.3

0.2 Friability(%)

0.1

0

F1 F2 F3 F4 F5 F6 F7 F8 F9

Formulations

Fig .4: Bar graph comparison friability for formulations (F1- F9)

40 Disintegration time(sec)

Disintegration

30

time(sec)

20

10

0

F1 F2 F3 F4Formulations

F5 F6 F7 F8 F9

Fig .5: Bar graph comparison between Disintegration time for formulations (F1- F9)

www.iajps.com Page 775

IAJPS 2018, 05 (01), 769-778 K. Ramanji Reddy et al ISSN 2349-7750

Table 8: Cumulative % drug release for formulations (F1 – F9)

Time in

min F1 F2 F3 F4 F5 F6 F7 F8 F9

0 0 0 0 0 0 0 0 0 0

5 19 21 13 21 33 69 28 29 28

10 32 34 22 45 64 99 40 43 45

15 40 45 52 52 83 99 62 67 60

30 51 53 76 63 98 98 74 81 78

45 67 70 99 85 98 98 83 89 82

60 80 94 99 98 98 98 89 98 99

120

Cumulative % drug

100

80

release

F1

60

F2

40

F3

20

0

0

40 20

60 80

Time in min

Fig .6: Linear graph comparison between cumulative % drug release for formulations (F1- F3)

150

100

%CDR

F4

50

F5

0 F6

0 10 20 30 40 50 60 70

time in Mins

Fig .7: Linear graph comparison between cumulative % drug release for formulations (F4 - F6)

120

100 Dissolution profile

80

%CDR

60 F7

40 F8

20

0 F9

0 10 20 30 40 50 60 70

Time in mins

Fig .8: Linear graph comparison between cumulative % drug release for formulations (F7- F9)

www.iajps.com Page 776

IAJPS 2018, 05 (01), 769-778 K. Ramanji Reddy et al ISSN 2349-7750

Table 9: Stability studies of optimized formulation at room temperature

Cumulative % drug release

Time Colour Drug content ± St.D.

± St.D.

First day White 96.20± 0.91 96.20±0.55

30 days White 95.84 ± 0.23 96.01±0.72

60 days White 99. 06 ± 0.62 95.62±0.65

90 days White 98. 92 ± 0.31 95.20±0.98

Stability Studies of Lamotrizine Optimized The bulk density and tapped density for all

Formulation: formulation (F1 – F9) varied from 0.35 - 0.46

The optimized formulation of Lamotrizine (F6) were gm/cm3 and 0.41 - 0.52 gm/cm3 respectively. The

subjected to short-term stability testing by storing the results of carr’s consolidate index or %

microspheres at room temperature 25°C/60%RH. compressibility index and hausner’s ratio for the

entire formulation (F1 – F9) blend range from 11.11-

Results from stability studies indicate that the 14.63 and 1.12-1.17 respectively, shows fair flow

formulated ODT are stable for a period of 3 months properties. The results are shown in the (Table.).

under room temperature i.e., 30˚C temp and 65±5%

RH. There were no remarkable changes were POST COMPRESSION PARAMETERS

observed during the period of storage.The optimized 1. Organoleptic properties

formulation of Lamotrizine (F6) were subjected to All the tablets show similar color, odour, taste and

accelerated stability testing by storing the microspheres physical appearance. There is no impact of

at accelerated temperature 40°C/70%RH. superdisintegrants in their organoleptic properties. 2.

DISCUSSIONS Hardness test

I. API Characterization By using the superdisintegrants, the hardness values

i. Organoleptic properties ranged from 3.0-3.5 kg/cm2 for formulations (F1-F9)

An organoleptic property such as color was evaluated

and the results are within the standards, shown in 3. Weight variation test

(Table.). The entire tablet passes weight variation test, as the

average % weight variation was within the

ii. Analytical evaluation (Determination of λ max) Pharmacopeial limit - 7.5%. It was found to be

The absorption wavelength maximum was found 148mg -152 mg. The weight of all the tablets was

to be at 243 nm. found to be uniform with less deviation.

Pre-Formulation Studies 4. Friability test

FTIR spectral data The friability values were found to be within the limit

The FT-IR represents the peaks of the Lamotrizine 0.32-0.41 (0.5 - 1%). The above evaluation parameter

functional groups. These peaks were not affected, showed no significant difference between F1-F9

they were prominently observed in IR-spectra of formulations.

Lamotrizine along with super disintegrants, simple

disintegrants and other excipients. The spectral 5. In-vitro Disintegration test

details of the drug and the excipients are shown in Disintegration test carried out in modified dissolution

(Figure.). There was no difference in the position of apparatus, Results shows the formulations with 3%,

the absorption bands, hence providing evidence for 5%, 7.5% of SSG having high disintegrating time as

the absence of any chemical incompatibility between 32, 24, 20 sec. The disintegration time of F1, F2, F3

pure drug with the excipients. with 3%, 5%, 7.5% CP formulations is 17, 14, 10 sec

respectively and is almost better than F4, F5, F6, F7,

Pre- Compression Parameters F8, F9 formulations and comparative profile

1. Angle of repose

All the formulations prepared by direct compression 6. Drug content uniformity

method showed the angle of repose less than 25, The concentration of the drug in all the formulations

which reveals excellent flow property. with superdisintegrants was found to be 97.45 –

99.48%. It was within the IP limits. The results of

2. Bulk density, Tapped density, Hausner ratio, drug content of all batches are shown in

Compressibility index

www.iajps.com Page 777

IAJPS 2018, 05 (01), 769-778 K. Ramanji Reddy et al ISSN 2349-7750

7. In-vitro Dissolution studies of migraine: a double-blind, placebo-controlled,

Dissolution is carried out in USP apparatus type-2 dose-range finding study. Neurology. 1996

apparatus at 50rpm in 900ml dissolution media (0.1N Feb;46(2):522-6.

HCL) for 60 minutes. At the end of 30 minutes 1. 7.Kumaresan C. Orally Disintegrating Tablet-Rapid

almost total amount of the drug is released (i.e. 98%), Disintegration, Sweet Taste, And target Release

from the formulation prepared by the direct Profile.2008 Sep;6(5):435-8.

compression method with 7.5% croscaramellose 2. 8Biradar SS, Bhagavati ST. and Kuppasad IJ. Fast

sodium. Dissolving Drug Delivery Systems. The Internet

journal of pharmacology.2006;4(2):567-9.

CONCLUSION: 3. 9.Kumar R, Patil MB, Patil SR, Paschapur MS.

The above results suggest that the formulated oral Development and Characterization Of Melt-In-

disintegrating tablets of Lamotrizine exhibited good Mouth Tablets Of Haloperidol By Sublimation

physical parameters and rapidly disintegrating Technique. International journal of pharmacy and

without affecting the release profile and is very Pharmaceutical sciences. 2009 July-Sep;1(1):65-73.

effective in case of elderly and pediatric patients. The 4. 10.Radke RS, Jadhav JK, Chajeed MR. Formulation

overall results indicated that formulation F6 with And Evaluation of Orodispersible Tablets Of

croscarmellose sodium (7.5%) had a higher edge Baclofan. International Journal of ChemTech

compared to other formulations containing Research. 2009 July-Sept; l(3): 517-21

superdisintegrants. They satisfy all the criteria for 5. 11.Yourong Fu, Segno HJ, Kinam P. Fast-melting

oral disintegrating tablets. This direct compression tablets based on highly

process is simple, reproducible and robust to prepare plastic granules. Journal of Controlled Release.

orally disintegrating tablets of Lamotrizine. 2005; 109 (2005): 203-10.

6. 12.Ranch KM , Koli AR, Vyas BA, Parikh RK,

REFERENCES Vyas RB. Formulation, Design and Optimization of

1.Pranzatelli M R. Innovations in drug delivery to Orodispersible Tablets of Atenolol. International

the central nervous system. Drugs Today. 1999; Journal of PharmTech Research. 2009 Oct;

35(6):435. 1(4):1559-68.

2.Ivares P. Formulation and evaluation of 7. 13.Swamy PV, Shirsand SB, Hiremath S, Younus

zolmitriptan fast disintegrated tablets prepared by A. Orodispersible Tablets of Carbamazepine

direct compression. Norbotten:Lulea University of Prepared by Direct Compression Method Using Full

Technology; 2009 (cited 2012 jun 2). Factorial Design. J. Pharm.2008 June; 7(1): 1-5.

3.Rapoport AM, Ramadan AM, Adelman JU et al. 8. 14.Khalid KA, Ahmed AH, Mowafaq MG, and

Optimizing the dose of zolmitriptan for the acute Alaa AA. Formulation and Optimization of

treatment of migraine. Neurology.1997 Orodispersible Tablets of Diazepam. AAPS

Nov;49(5):1210-8. PharmSciTech. 2010 March; 11(1):356-61.

4.Danavena R , Bhoomaiah B, Phani.R.S.CH, K 9. 15.Nagaraju R, Sujatha B, Vidyadhara S and

Balamurali krishna. Validated RP – HPLC method Sasidhar RLC. Design and evaluation of fast

for the estimation of zolmitriptan in formulation. dissolving films containing nizatidine. Ind J Pharm

Pharmacophore.2011; 2(2):150-5. Edu Res 2012; 46(4): 318-22.

5.Soloman GD, Cady RK, Klapper JA, Earl NL, 10. 16. Sultana F, Arafat M, Pathan SI. Preparation and

Saper JR, Ramadan NM. Clinical efficacy and evaluation of fast dissolving oral thin film of

tolerability of 2.5 mg zolmitriptan for the acute caffeine. Int J Pharm Bio Sci 2013; 3(1): 153-61.

1 11. 17.Prasanna D, Manoranjan S. Formulation and

treatment of migraine. evaluation of fast dissolving films of Zolmitriptan.

Int Res J Pham 2012; 3(5): 373-76.

Neurology. 1997 Nov;49(5):1219-

12. 18.Renuka S, Parikh RK, Gohel MC, Soniwala MM.

56.

Development of taste masked films of Valdecoxib

6.Visser WH, Klein KB, Cox RC, jones D. Ferrari

for oral use. Ind J Pharm Sci 2007; 69(2): 320-23.

MD. 311C90 a new central and peripherally acting

5-HT1D receptor agonist in the acute oral treatment

www.iajps.com Page 778

Das könnte Ihnen auch gefallen

- Analytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationDokument8 SeitenAnalytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationBaru Chandrasekhar RaoNoch keine Bewertungen

- Gastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsDokument7 SeitenGastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsBaru Chandrasekhar RaoNoch keine Bewertungen

- Development and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormDokument11 SeitenDevelopment and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormBaru Chandrasekhar RaoNoch keine Bewertungen

- A Brief Review On YawsDokument7 SeitenA Brief Review On YawsBaru Chandrasekhar RaoNoch keine Bewertungen

- Knowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyDokument8 SeitenKnowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyBaru Chandrasekhar RaoNoch keine Bewertungen

- Assessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaDokument7 SeitenAssessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaBaru Chandrasekhar RaoNoch keine Bewertungen

- Review On: Inventory ManagementDokument8 SeitenReview On: Inventory ManagementBaru Chandrasekhar RaoNoch keine Bewertungen

- Descriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreDokument4 SeitenDescriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreBaru Chandrasekhar RaoNoch keine Bewertungen

- Pharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoDokument7 SeitenPharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoBaru Chandrasekhar RaoNoch keine Bewertungen

- Relationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityDokument4 SeitenRelationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityBaru Chandrasekhar RaoNoch keine Bewertungen

- The Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalDokument11 SeitenThe Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalBaru Chandrasekhar RaoNoch keine Bewertungen

- An Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentDokument6 SeitenAn Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentBaru Chandrasekhar RaoNoch keine Bewertungen

- STUDIES ON QUALITATIVE PHYTOCHEMICAL ANALYSIS AND ANTIBACTERIAL ACTIVITY OF Piper NigrumDokument7 SeitenSTUDIES ON QUALITATIVE PHYTOCHEMICAL ANALYSIS AND ANTIBACTERIAL ACTIVITY OF Piper NigrumBaru Chandrasekhar RaoNoch keine Bewertungen

- RP-HPLC Method Development and Validation of Alogliptin Bulk and Tablet Dosage FormDokument8 SeitenRP-HPLC Method Development and Validation of Alogliptin Bulk and Tablet Dosage FormBaru Chandrasekhar RaoNoch keine Bewertungen

- DISTINCTIVE PHARMACOLOGICAL ACTIVITIES OF Eclipta Alba AND IT'S COUMESTAN WEDELOLACTONEDokument7 SeitenDISTINCTIVE PHARMACOLOGICAL ACTIVITIES OF Eclipta Alba AND IT'S COUMESTAN WEDELOLACTONEBaru Chandrasekhar RaoNoch keine Bewertungen

- Pharmacological and Phytochemical Evidence of Scutia Genus Plants - A ReviewDokument7 SeitenPharmacological and Phytochemical Evidence of Scutia Genus Plants - A ReviewBaru Chandrasekhar RaoNoch keine Bewertungen

- Determination of Bioactive Compounds From Piper Nigrum L by Using Ft-Ir Spectroscopic AnalysisDokument3 SeitenDetermination of Bioactive Compounds From Piper Nigrum L by Using Ft-Ir Spectroscopic AnalysisBaru Chandrasekhar RaoNoch keine Bewertungen

- Determination of Bioactive Compounds From Piper Longum L. by Using HP-LC AnalysisDokument4 SeitenDetermination of Bioactive Compounds From Piper Longum L. by Using HP-LC AnalysisBaru Chandrasekhar RaoNoch keine Bewertungen

- DETERMINATION OF BIOACTIVE COMPOUNDS FROM Piper Nigrum. L BY USING HPLC ANALYSISDokument3 SeitenDETERMINATION OF BIOACTIVE COMPOUNDS FROM Piper Nigrum. L BY USING HPLC ANALYSISBaru Chandrasekhar RaoNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Qualification of Analytical Instruments For Use in Pharmaceutical Industry-A Scientific ApproachDokument23 SeitenQualification of Analytical Instruments For Use in Pharmaceutical Industry-A Scientific Approachmicrobioasturias100% (4)

- AppendicitisDokument7 SeitenAppendicitisTim LuoNoch keine Bewertungen

- OpenStax - Psychology - CH15 PSYCHOLOGICAL DISORDERSDokument42 SeitenOpenStax - Psychology - CH15 PSYCHOLOGICAL DISORDERSAngelaNoch keine Bewertungen

- February 2019Dokument4 SeitenFebruary 2019sagar manghwaniNoch keine Bewertungen

- Kebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IDokument5 SeitenKebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IRiska AyuNoch keine Bewertungen

- Mbs KatalogDokument68 SeitenMbs KatalogDobroslav SoskicNoch keine Bewertungen

- Manual Chiller Parafuso DaikinDokument76 SeitenManual Chiller Parafuso Daiking3qwsf100% (1)

- 5L ReductionsDokument20 Seiten5L ReductionsCarlos Javier Orellana OrtizNoch keine Bewertungen

- Pengaruh Penambahan Lateks Pada Campuran Asphalt Concrete Binder Course (AC-BC)Dokument10 SeitenPengaruh Penambahan Lateks Pada Campuran Asphalt Concrete Binder Course (AC-BC)Haris FirdausNoch keine Bewertungen

- SUPERHERO Suspension Training ManualDokument11 SeitenSUPERHERO Suspension Training ManualCaleb Leadingham100% (5)

- US Army Medical Course MD0722-100 - Microbiology For The Veterinary SpecialistDokument114 SeitenUS Army Medical Course MD0722-100 - Microbiology For The Veterinary SpecialistGeorges100% (2)

- Hippocrates OathDokument6 SeitenHippocrates OathSundary FlhorenzaNoch keine Bewertungen

- TDS Shell Spirax s6 Gxme 75w-80Dokument2 SeitenTDS Shell Spirax s6 Gxme 75w-80rstec pyNoch keine Bewertungen

- Bulk-Fill Composite RestorationsDokument9 SeitenBulk-Fill Composite RestorationssusethNoch keine Bewertungen

- 348 - Ct-Tol Toluene TdsDokument1 Seite348 - Ct-Tol Toluene Tdsonejako12Noch keine Bewertungen

- Dam Lecture 14 - Design Criteria Earth DamsDokument4 SeitenDam Lecture 14 - Design Criteria Earth DamsCarolineMwitaMoseregaNoch keine Bewertungen

- Perioperative Care For CABG PatientsDokument32 SeitenPerioperative Care For CABG PatientsAya EyadNoch keine Bewertungen

- Medical Representative Healthcare Sales in Fort Myers FL Resume Greg HejlikDokument2 SeitenMedical Representative Healthcare Sales in Fort Myers FL Resume Greg HejlikGregHejlikNoch keine Bewertungen

- Ineffective Breastfeeding - NCPDokument10 SeitenIneffective Breastfeeding - NCPJullian PloyaNoch keine Bewertungen

- As 2419.1-2005 Fire Hydrant Installations System Design Installation and CommissioningDokument9 SeitenAs 2419.1-2005 Fire Hydrant Installations System Design Installation and CommissioningSAI Global - APAC14% (7)

- Quarterly Progress Report FormatDokument7 SeitenQuarterly Progress Report FormatDegnesh AssefaNoch keine Bewertungen

- Toaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRDokument17 SeitenToaz - Info Fermentation of Carrot Juice Wheat Flour Gram Flour Etc PRBhumika SahuNoch keine Bewertungen

- 45096Dokument12 Seiten45096Halusan MaybeNoch keine Bewertungen

- Distribución Del Mercurio Total en Pescados y Mariscos Del Mar ArgentinoDokument15 SeitenDistribución Del Mercurio Total en Pescados y Mariscos Del Mar ArgentinoaldiNoch keine Bewertungen

- Weekly Meal Prep GuideDokument7 SeitenWeekly Meal Prep Guideandrew.johnson3112Noch keine Bewertungen

- 1 Nitanshi Singh Full WorkDokument9 Seiten1 Nitanshi Singh Full WorkNitanshi SinghNoch keine Bewertungen

- Senographe Crystal: The Choice Is Crystal ClearDokument7 SeitenSenographe Crystal: The Choice Is Crystal ClearmuhammadyassirNoch keine Bewertungen

- 13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaDokument9 Seiten13 Lombe Mumba Ramson 2017 Knowledge Attitude and Practice of Breast Self Examination For Early Detectoin of Breast Cancer Among Women in Roan Constituency in Luanshya Copperbelt Province ZambiaArick Frendi AndriyanNoch keine Bewertungen

- Mobil Delvac 1 ESP 5W-40Dokument3 SeitenMobil Delvac 1 ESP 5W-40RachitNoch keine Bewertungen

- CH 13 RNA and Protein SynthesisDokument12 SeitenCH 13 RNA and Protein SynthesisHannah50% (2)