Beruflich Dokumente

Kultur Dokumente

Te 049044

Hochgeladen von

salman1111aOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Te 049044

Hochgeladen von

salman1111aCopyright:

Verfügbare Formate

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

TBD

ENGG CERT

IAD

MSA

ISSUED FOR REVIEW

DESCRIPTION

NORTHERN AREA OIL OPERATION

CAPITAL PROGRAM MANAGEMENT

BI-10-09111

JO/EWO

10-01978

01/14/18

DATE

DEBOTTLENECK TANAJIB WATER HANDLING FACILITY

NO.

REV

DISCIPLINE

ENGINEER

01/14/18

MSA

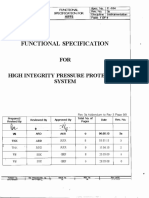

SIL ASSIGNMENT STUDY REPORT

DATE:

PROJECT

ENGINEER

IAD

01/14/18

DATE:

CERTIFIED

TBD

04104/13

01/14/18

DATE:

CONSTRUCTION

AGENCY

TBD

01/14/18

DATE:

OPERATIONS

TBD

Prepared By:

01/14/18

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

JAN 2018

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

(DCC) NO. _____________________

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 1

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

TBD

TABLE OF CONTENTS

ENGG CERT

IAD

1 INTRODUCTION ................................................................................................................. 3

MSA

2 SCOPE ................................................................................................................................ 3

3 OBJECTIVES ...................................................................................................................... 3

4 SIL STUDY TEAM ............................................................................................................... 4

5 DEFINITIONS & ABBREVIATIONS .................................................................................... 5

ISSUED FOR REVIEW

6 APPLICABLE DOCUMENTS .............................................................................................. 8

DESCRIPTION

6.1 PROJECT SPECIFIC DOCUMENTS............................................................................. 8

6.2 GENERAL REFERENCE DOCUMENTS....................................................................... 8

7 Project Description ............................................................................................................ 9

7.1 General .......................................................................................................................... 9

7.2 PROCESS DESCRIPTION ............................................................................................ 9

7.3 Produced Water Handling System ................................................................................. 9

7.4 Dehydrators Level Control Valves.................................................................................. 9

JO/EWO

10-01978

7.5 Recovered Oil Pump ...................................................................................................... 9

8 SIL Assignment Methodology......................................................................................... 10

01/14/18

DATE

9 SIL ASSIGNMENT: ........................................................................................................... 10

NO.

REV

10 LOPA Workshop Assumptions & Conventions ............................................................. 13

DISCIPLINE

ENGINEER

MSA

11 Results & Findings .......................................................................................................... 14

DATE:

01/14/18 11.1 WORKSHEET .............................................................................................................. 14

PROJECT

ENGINEER 11.2 LOPA SUMMARY ........................................................................................................ 14

IAD

01/14/18

12 Recommendations & ACTIONS ...................................................................................... 14

DATE:

CERTIFIED 13 .Conclusions .................................................................................................................... 15

TBD

DATE:

04104/13

01/14/18 14 Appendices ...................................................................................................................... 15

CONSTRUCTION

AGENCY

TBD

01/14/18

DATE:

OPERATIONS

TBD

01/14/18

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

(DCC) NO. _____________________

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 2

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

1 INTRODUCTION

TBD

SIL study session was conducted related to Project BI- BI-10-09111 “DEBOTTLENECK

ENGG CERT

IAD

TANAJIB WATER HANDLING FACILITY”

MSA

The SIL was facilitated by SNC Lavalin Fayez Engineering and attended by engineers

from Saudi Aramco and SLFE.

The SIL assessment session was conducted at SLFE office in Al-Khobar on 3rd Jan 2018.

ISSUED FOR REVIEW

The purpose of the SIL review within this study is to assign safety integrity levels to each

DESCRIPTION

Safety Instrumented Function (SIF) in accordance with Saudi Aramco standards (SAEP-

250) in order to demonstrate that the Safety Instrumented Functions (SIFs) proposed

provide adequate levels of risk reduction and meets the Risk Target Frequencies identified

by Layer of Protection Analysis (LOPA).

Findings from the study session were recorded in LOPA worksheets (provided by Saudi

Aramco P&CSD) as per Saudi Aramco standards.

JO/EWO

10-01978

2 SCOPE

01/14/18

DATE

The scope of SIL assessment consists of facilitating and chairing SIL workshop,

performing SIL assessment using Layer of Protection Analysis (LOPA) methodology in

NO.

REV

DISCIPLINE accordance with the guidelines provided in the Saudi Aramco Engineering Procedure,

ENGINEER

MSA

SAEP-250 (4 Dec. 2012) & IEC-61511.

01/14/18

DATE:

PROJECT

ENGINEER The purpose of this study is to access the Safety Instrumented Functions (SIFs) so that

IAD

01/14/18

the Design of Safety Integrated Systems is adequate to protect personnel, environment

DATE:

CERTIFIED and assets against potentially hazardous situation. The SIL assignment study included all

TBD

DATE:

04104/13

01/14/18 high-risk areas, which were developed during the HAZOP study undertaken on original

CONSTRUCTION

AGENCY design basis.

TBD

01/14/18

DATE: The team identified 02 SIF loops within the scope of the project. SIL Study was conducted

OPERATIONS

TBD for risk scenarios (identified during HAZOP) and recommended SIFs (identified in HAZOP

01/14/18

DATE: & listed in C&E) were evaluated for SIL Assignment.

CONTROL NUMBER

VERIFICATION

3 OBJECTIVES

EDSD

The objective of this SIL study is to systematically identify SIF required to prevent or

DATE:

BY:

mitigate a hazardous event and to determine its Safety Integrity Level (SIL) required for

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

the intended SIF.

BA

(DCC) NO. _____________________

10-01091-0001-001

The SIL determination study covers all the Safety Instrumented Functions (SIFs) as

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 3

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

identified in the referenced C&E diagrams.

TBD

Safety Integrity Level determination study is the part of overall safety studies, which

ENGG CERT

IAD

concentrates on risks associated with hazardous event and identification of independent

MSA

protection layers to mitigate that specific hazardous event. Establishing the necessary risk

reduction requirement and the corresponding SIL of SIFs is the purpose of SIL

assessment.

SIL assessment/determination is the phase 2 activity of the overall Safety Lifecycle (SLC)

ISSUED FOR REVIEW

DESCRIPTION

of the SIS (Figure 8 of IEC 61511-1:2003). This Phase 2 activity in IEC 61511- 1:2003 is

referred as “Allocation of the Safety Functions to Protection Layers”.

Safety Life Cycle Phase 1, i.e.” Hazard & Risk Assessment”, is required to be undertaken

before the commencement of Phase 2. Results of Phase 1 are required to be available

before the start of Phase 2.

4 SIL STUDY TEAM

JO/EWO

10-01978

The team performing the SIL analysis comprised of

01/14/18

DATE

• SIL Facilitator

• SLFE Instrumentation Engineer

NO.

REV

DISCIPLINE

• SLFE Process Engineer

ENGINEER

MSA • SLFE Project Management

01/14/18

DATE:

PROJECT

• Saudi Aramco Loss Prevention Department

ENGINEER

IAD • Saudi Aramco Proponent/ operations representative(s)

01/14/18

DATE:

CERTIFIED

• Saudi Aramco Project Management team

TBD

04104/13

01/14/18 Refer to Appendix A of this report for list of attendees.

DATE:

CONSTRUCTION

AGENCY

TBD

01/14/18

DATE:

OPERATIONS

TBD

01/14/18

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

(DCC) NO. _____________________

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 4

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

5 DEFINITIONS & ABBREVIATIONS

TBD

ABBREVIATION

ENGG CERT

IAD

ALARP As Low as Reasonably Practicable

BPCS Basic Process Control System

MSA

CCPS Center for Chemical Process Safety

C&E Cause and Effect

E/E/PES Electrical/Electronic/Programmable Electronic Systems

ESD Emergency Shutdown

FCV Flow Control Valve

ISSUED FOR REVIEW

HAZOP Hazard and Operability

DESCRIPTION

IEC International Electro technical Commission

IPL Independent Protection Layer

ISO International Standard Organization

LALL Level Alarm Low Low

LAHH Level Alarm High High

LCV Level Control Valve

NA Not Applicable

PALL Pressure Alarm Low Low

PAHH Pressure Alarm High High

JO/EWO

10-01978

PFD Probability of Failure on Demand

P&ID Piping and Instrumentation Diagram

RRF Risk Reduction Factor

01/14/18

DATE

SDV Shutdown Valve

SIF Safety Instrumented Function

NO.

REV

SIL Safety Integrity Level

A

DISCIPLINE

ENGINEER

SIS Safety Instrumented System

MSA TAHH Temperature Alarm High High

DATE:

01/14/18 ZV Remote Shut-Off Valve (or Emergency Isolation Valve)

PROJECT

ENGINEER

IAD

DATE:

01/14/18 DEFINITIONS

CERTIFIED

TBD

MTTR Mean Time to Restoration

04104/13

01/14/18

DATE: Mean Time to Restoration consists of mean time to repair logistical delay

CONSTRUCTION

AGENCY time and administrative delay time. Mean Time to Restoration is the total

TBD downtime used in availability calculations

01/14/18

DATE: Availability The probability that a device is operating successfully at a given moment

OPERATIONS

in time. This is a measure of the uptime and is defined in units of percent.

TBD

β Factor Beta Factor, Indicating Common cause susceptibility. The fraction of total

01/14/18

DATE: failure rate that is attributed to a single cause in common with other units

CONTROL NUMBER

in the group. A common cause failure will result in all units with the group

VERIFICATION

failing simultaneously.

EDSD

BPCS Basic Process Control System. IEC-61508 term used to describe the

DATE:

regulatory control system.

BY:

Diagnostic A measure of system’s ability to detect failures. This is a ratio between the

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

Coverage failure rates for detected failures to the failure rate for the all the failures in

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

the system.

(DCC) NO. _____________________

ESD Emergency Shut Down, a name used to describe a safety Instrumented

10-01091-0001-001

system.

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 5

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

Fault Ability of a functional unit to continue to perform a required function in the

TBD

Tolerance presence of faults or errors.

ENGG CERT

FE Final Element, This term included all the devices required for the purposes

IAD

of acting to remove of hazards.

Intermediate The frequency of the hazard outcome after IPL’s have been considered

MSA

Event but before any further protective function has been added. It is the

Frequency demand rate made on any additional safety functions required as a result

of analysis. Sometimes referred to unmitigated frequency.

IPF Instrumented Protective Function, A function comprising one or more

initiators, logic solver and one or more final element whose purposes is to

ISSUED FOR REVIEW

prevent mitigate hazardous situations.

DESCRIPTION

IPL Independent Protection Layer. This refers to various other methods of risk

reduction possible for a process. Examples include items such as rupture

disks and relief valves, which will independently reduce the likelihood of

the hazard escalating into a full accident with harmful outcome.

LOPA Layer of Protection Analysis. A modified event tree where only the single

hazard outcome and resulting occurrence of the consequence are of

interest. An initiating event cause is analyzed together with all effective

IPL’s. The resulting frequency is called the intermediate Event Frequency,

(for the single event cause).

JO/EWO

PFDavg Average Probability of Failure on Demand, This is the probability that a

10-01978

system will fail dangerously and not be able to perform its safety function

when required. IEC 61508/61511 uses PFDavg as the the system metric

01/14/18

DATE

upon which the SIL is defined.

PST Process Safety Time: This is the time within which the Safety

Instrumented Function (SIF) must, upon detection of hazard, act to

NO.

REV

DISCIPLINE prevent the occurrence of the consequence. The term is related to the

ENGINEER

MSA Fault Tolerant Time of the Process.

DATE:

01/14/18 Proof Test The periodic testing of the equipment, (usually SIF components and sub

PROJECT systems) to detect and correct any otherwise undetectable hardware

ENGINEER

IAD failures that would prevent the equipment form successfully operating on

01/14/18 demand.

DATE:

CERTIFIED PTC Proof Test Coverage: The percentage failures that are detected during the

TBD

servicing of the equipment. IEC-61508 allows people to assume that when

04104/13

DATE:

01/14/18

a proof test is performed any errors in the systems are detected and

CONSTRUCTION

AGENCY

corrected (100% proof test coverage); in practice, this is usually not the

TBD case.

DATE:

01/14/18

PTI Proof Test Interval: The time interval between servicing of the equipment.

OPERATIONS

TBD Redundancy Use of multiple elements or systems to perform the same function.

DATE:

01/14/18

Redundancy can be implemented by identical elements or diverse

elements. Redundancy is primarily used to improve reliability or

CONTROL NUMBER

VERIFICATION

availability.

EDSD

RRF Risk Reduction Factor: The inverse of PFDavg, so RRF=1/PFDavg

DATE:

BY:

SFF Safe Failure Fraction: The fraction of the overall failure rate of a device

REVISIONCERTIFICATION

that results in either a safe fault or diagnosed (detected) unsafe fault. The

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

safe failure fraction includes the detectable dangerous failures when those

(DCC) NO. _____________________

failures are annunciated and procedures for repair or shutdown are in

10-01091-0001-001

place.

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 6

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

SIF Safety Instrumented Function: A set of equipment intended to reduce the

TBD

risk due to a specific hazard (a safety loop).

ENGG CERT

SIL Safety Integrity Level: A quantitative target for measuring the level of

IAD

safety in a process. Defining a target SIL level for the process should be

based on the assessment of the likelihood that an incident will occur and

MSA

the consequence of the incident.

SIL PFDavg RRF

-5 to -4

4 ≥10 <10 >10,000 to ≤100,000

3 ≥10-4 to <10-3 >1,000 to ≤10,000

ISSUED FOR REVIEW

-3 to -2

2 ≥10 <10 >100 to ≤1,000

DESCRIPTION

-2 to -1

1 ≥10 <10 >10 to ≤100

SIS Safety Instrumented System: Implementation of one or more Safety

Instrumented Functions. A SIS is composed of any combination of

Sensor(s), Logic Solver(s), and final elements(s).

Spurious These unnecessary trips result from safe failures of sensors, logic solvers,

Trips and final shutdown elements. The STR value is used to quantify the

expected frequency of these trips.

STR Spurious Trip rate: This is the average frequency of safe process trips

JO/EWO

10-01978

caused by failure within the safety Instrumented Function (SIF).

TI Test Interval: same as Proof Test interval (PTI)

01/14/18

NO. DATE

REV

DISCIPLINE

ENGINEER

MSA

01/14/18

DATE:

PROJECT

ENGINEER

IAD

01/14/18

DATE:

CERTIFIED

TBD

04104/13

01/14/18

DATE:

CONSTRUCTION

AGENCY

TBD

01/14/18

DATE:

OPERATIONS

TBD

01/14/18

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

(DCC) NO. _____________________

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 7

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

6 APPLICABLE DOCUMENTS

TBD

6.1 PROJECT SPECIFIC DOCUMENTS

ENGG CERT

IAD

MSA

Sr. # Document number Description

1 TB048008-001 REV C C& E Diagrams

2 TE-049048 HAZOP REPORT

3 TA-049012.001 REV D P&IDs

ISSUED FOR REVIEW

DESCRIPTION

4 TA-049013.001 REV D P&IDs

5 TA-049014.001 REV D P&IDs

6.2 GENERAL REFERENCE DOCUMENTS

Sr. Document number Description

JO/EWO

10-01978

#

SAEP-250 (4th December 2012

1 Safety Integrity Level Assignment and Verification

01/14/18

revision)

DATE

Functional Safety of

2 IEC-61508;2010 Electrical/Electronic/Programmable Electronic

NO.

REV

Safety Related Systems

DISCIPLINE Functional Safety- Safety Instrumented Systems for

ENGINEER 3 IEC-61511:2003

MSA Process industry sector

01/14/18

DATE:

PROJECT

ENGINEER

IAD

01/14/18

DATE:

CERTIFIED

TBD

04104/13

01/14/18

DATE:

CONSTRUCTION

AGENCY

TBD

01/14/18

DATE:

OPERATIONS

TBD

01/14/18

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

(DCC) NO. _____________________

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 8

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

7 PROJECT DESCRIPTION

TBD

ENGG CERT

7.1 General

IAD

Marjan Field is currently producing 500 MBCD of AM crude oil. The 2017-2019 Business

MSA

Plan Crude Program calls for increasing the AM crude oil MSC target for Marjan field by

100 MBCD in January 2018. The present water handling facility at Tanajib Onshore Plant

will be inadequate due to the increased water cut and GOR until 2022.

ISSUED FOR REVIEW

DESCRIPTION

The purpose of the facilities is to support the corporate strategy to increase the MSC

target of Marjan field from 500 MBCD to 600 MBCD of AM crude by upgrading existing

water handling facilities at Tanajib Onshore Plant.

This upgrade will provide one (1) CPI separator, one (1) recovered oil pump, replacement

of three (3) existing level control valves of the dehydrators and flow elements at the

upstream of LCVs to handle the increase in the water cut and GOR until 2022. The

JO/EWO

10-01978

increase in the water cut and GOR after 2022 will be handled by Marjan Increment

Program.

01/14/18

NO. DATE

REV

DISCIPLINE

ENGINEER 7.2 PROCESS DESCRIPTION

MSA

01/14/18

DATE:

PROJECT

ENGINEER 7.3 Produced Water Handling System

IAD

DATE:

01/14/18 One (1) additional CPI Separator is required to meet the increase in this water cut. The

CERTIFIED

TBD new CPI Separator shall be placed next to the existing CPI separators and connected in

04104/13

01/14/18 parallel.

DATE:

CONSTRUCTION

AGENCY

TBD

01/14/18 7.4 Dehydrators Level Control Valves

DATE:

OPERATIONS

TBD In order to meet the forecasted water and crude rates increase, the three (3) existing Level

01/14/18 Control Valves (LCV-149/161/173) installed on produced water lines of three (3)

DATE:

Dehydrators (G80-D-5/6/7) will be replaced with new valves. Flow elements and flow

CONTROL NUMBER

VERIFICATION

transmitter (FE/FIT-138/150/162) will be also replaced to meet forecasted water flow rate.

EDSD

DATE:

BY:

7.5 Recovered Oil Pump

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

The capacity of each CPI separator is 58.700 MBOD. To treat 121.4 MBOD of produced

(DCC) NO. _____________________

water all three CPI separators will be in operation. Currently, there are three (3) recovered

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 9

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

oil pumps (G80-G-50/51/52) (2 operating, 1 standby). To control the level of oil in CPI

TBD

separator a dedicated pump is required for each CPI separator. Therefore, a new pump

ENGG CERT

will be added. . Now there will be four (4) pumps (3 operating, 1 standby).

IAD

MSA

8 SIL ASSIGNMENT METHODOLOGY

Safety life cycle approach as per IEC-61511 and Saudi Aramco Engineering Procedure

identified in SAEP-250 is used for the SIL assignment of the Safety instrumented function

ISSUED FOR REVIEW

under this project.

DESCRIPTION

9 SIL ASSIGNMENT:

The SIL assessment comprises an assessment of the plant process equipment and

systems to be protected by Safety Instrumented System, to identify potential hazards and

to assess the risk that is present for persons and the environment and assets.

This assessment is made on the basis that no protective systems are in place so that a

JO/EWO

10-01978

basic level of risk can be established for the equipment under control (EUC) or Process as

per IEC-61508 & IEC-61511 terminology.

01/14/18

DATE

Essentially the SIL derived rating is a measure of the performance availability that is

NO.

REV

DISCIPLINE

required to be achieved by the safety–related control system, in order that the residual risk

ENGINEER

MSA level is within acceptable limits, or, is as low as reasonably practical (ALARP) as defined in

01/14/18

DATE:

PROJECT

SAEP-250 in terms of target frequency.

ENGINEER

IAD

SIL assignment report contents follow the requirements of SAEP-250

01/14/18

DATE:

CERTIFIED

TBD The SIL rating shall be considered for the entire Safety integrated function i.e. from

04104/13

DATE:

01/14/18

initiating devices through the logic solvers / controllers to the final actuating elements in

CONSTRUCTION

AGENCY order that the system will adequately meet the design intent.

TBD

01/14/18

DATE:

SAEP-250 is used as the main data source (for initiating cause frequency/PFD of

OPERATIONS

TBD protection layers etc.)

01/14/18

DATE:

As per requirements of SAEP-250, LOPA methodology shall be used for SIL assessment.

CONTROL NUMBER

VERIFICATION

SIL Assignment will be carried out based on LOPA based on following steps

EDSD

DATE:

BY:

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

9.1.1 Identification of Hazardous Scenario

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

(DCC) NO. _____________________

HAZOP report, Cause and Effect shall be used for the identification/development of

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 10

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

hazardous scenario, additional scenarios can be listed through brain storming during SIL

TBD

session. Each scenario must have a unique initiating event/consequence pair. LOPA is

ENGG CERT

IAD

limited to evaluating a single cause-consequence pair as scenario.

MSA

9.1.2 Quantitative Risk Target Frequency

Quantitative risk target frequency shall be assigned for the hazardous event identified that

is protected by identified SIF. Appendix-H of Saudi Aramco standard SAEP-250 shall be

ISSUED FOR REVIEW

used as guideline for “Quantitative Risk Target Frequency” against each hazardous event/

DESCRIPTION

risk.

The consequences against each of the following category will be identified for each

hazard/risk and a target frequency will be assigned against each consequence as

identified below.

a- Personnel Safety

JO/EWO

10-01978

b- Environment safety

c- Asset Safety

d- Reputation

01/14/18

DATE

Note: SIL assignment is carried out against lowest “risk target frequency” as this will lead

NO.

REV

DISCIPLINE

to worst case scenario covering all the other categories.

ENGINEER

MSA

Refer to Appendix-C of this report for Saudi Aramco standard SAEP-250.

01/14/18

DATE:

PROJECT

ENGINEER 9.1.3 Initiating Event Frequency

IAD

01/14/18

DATE: For LOPA, each scenario has a single initiating event. The frequency of the initiating

CERTIFIED

TBD

event, causing the hazard, will be identified. Appendix-I of Saudi Aramco Standard SAEP-

04104/13

01/14/18

DATE:

CONSTRUCTION

250 shall be used as guideline for calculating initiating event frequencies. Expert

AGENCY

TBD judgment/operation experience and OREDA database will also be referred to identify the

01/14/18

DATE:

failure rate of some of the equipment that will be part of initiating cause of that hazard.

OPERATIONS

TBD Refer to Appendix-C of this report for referring Saudi Aramco standard SAEP-250

01/14/18

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

9.1.4 IPLs

One by one, all the IPLs (excluding SIF under evaluation) available were identified which

DATE:

BY:

are present to mitigate the consequences or reduce the frequency of the hazard event

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

An IPL is a device, system or action that is capable of preventing/mitigating a scenario

(DCC) NO. _____________________

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 11

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

from proceeding to its undesired consequence independent of the initiating event or the

TBD

action of any other layer of protection associated with the scenario. Independent

ENGG CERT

IAD

Protection Layers (IPL) , when applied to mitigate the hazard shall reduce the

MSA

Identified risk by a factor of 10 or more, shall be specific, independent, dependable and

auditable.

IPL risk reduction values shall be taken based on conservative approach from Appendix I

of Saudi Aramco standard SAEP-250

ISSUED FOR REVIEW

DESCRIPTION

9.1.5 Mitigated Event Frequency (MEF)

The risk reduction credit against each existing safeguard (protection layer) will be

assigned as per Appendix

Appendix-I of SAEP-250.

250. The mitigated event frequency is calculated by

multiplying the initiating event frequency by probabilities of all tthe

he IPLs failing to do their

intended function.. Conditional modifiers/Enabling conditions are also multiplied along with

other IPLs to calcuated the final MEF values

values.

JO/EWO

10-01978

01/14/18

NO. DATE

REV

DISCIPLINE

ENGINEER

MSA

01/14/18

DATE:

PROJECT

ENGINEER

IAD

01/14/18

DATE:

CERTIFIED

TBD

04104/13

01/14/18

DATE:

CONSTRUCTION

AGENCY

TBD

01/14/18

DATE:

OPERATIONS

9.1.6 RRF CALCULATION

TBD

DATE:

01/14/18 Risk Target Frequency for the SIF will be calculated by dividing the mitigated

mi risk with the

CONTROL NUMBER

target Risk (identified in step c) to identify the Risk Reduction Factor (RRF) required by the

VERIFICATION

EDSD

SIF loop.

DATE:

BY:

9.1.7 SIL/PFD CALCULATION

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

Inverse of RRF (i.e. 1/RRF) will lead to PFD of the SIF, against which SIL will be assigned

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

(DCC) NO. _____________________

for the SIF.

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-0490

049050 12

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111

09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

10 LOPA WORKSHOP ASSUMPTIONS & CONVENTIONS

TBD

ENGG CERT

IAD

• SIL study is conducted based on

MSA

a- the HAZOP findings and risk ranking ranked high in the HAZOP report &

b- the Safety instrumented functions listed in Cause & Effect diagram.

• The facility has been designed and engineered properly based on the Saudi Aramco

design/engineering codes, industry standards and good engineering practices.

ISSUED FOR REVIEW

DESCRIPTION

• SIL study has been conducted for the SIFs which are covered under the scope of this

project BI-10-09111-001

• Permissive & Maintenance Bypasses are not covered in the SIL assessment.

• All equipment will be well maintained.

• The SIFs with hand switches and push button (PB) as initiators are considered SIL 1

JO/EWO

10-01978

by default and are not studied during the SIL workshop (in accordance with SAEP-

250). Such manual initiators in a SIF require operator action that is used for both

01/14/18

DATE

prevention and mitigation of hazardous events, like total plant shutdown, unit

shutdown, equipment isolation and equipment protection systems shutdown.

NO.

REV

DISCIPLINE

ENGINEER • Alarms are considered as an IPL with a PFD of 0.1 provided the operator has clearly

MSA

DATE:

01/14/18 understood the alarm, Operator has more than specified time (15 minutes for control

PROJECT

ENGINEER room alarm ; 30 minutes for field alarms) to respond inorder to prevent the demand

IAD

01/14/18 occurring on the SIF. Also this credit shall only be given if the operator is trained and

DATE:

CERTIFIED

TBD regularly completes action as drilled exercise, has access to clear written procedures

DATE:

04104/13

01/14/18 and performs actions according to the appropriate procedures and operating.

CONSTRUCTION

AGENCY

TBD • CCPS “Approach A’ is followed, i.e., where BPCS is an Initiating Event (IE) for a

01/14/18

DATE: scenario, no credit for protection layer in the BPCS is taken.

OPERATIONS

TBD

• Independence between BPCS protection and initiating cause is taken in accordance

01/14/18

DATE:

with the requirement of IEC-61511-2 section 9.4.2.

CONTROL NUMBER

VERIFICATION

EDSD

• Team agreed to take credit for PZV-196/195 only on the condition that PZV is

adequately sized for blowby case as well as will be routed to the safe location.

DATE:

BY:

REVISIONCERTIFICATION

Team agreed that damage of water tank D-24 will result in stoppage of operation

APPROVAL/CERTIFICATION REQUIREMENTS,

•

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

resulting in production loss which will lead to significant enonomic loss.

(DCC) NO. _____________________

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 13

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

• Proponent confirmed that no dike at produced water tank D-24 to contain loss of

TBD

containment.

ENGG CERT

IAD

• SIL Committee agreed that due to low Process Safety Time in “Gas Blow by” case ;

MSA

operator action shall not be given any credit for risk reduction.

11 RESULTS & FINDINGS

11.1 WORKSHEET

ISSUED FOR REVIEW

DESCRIPTION

The SIL workshop results are depicted in the LOPA Worksheets attached in Appendix D

with this report.

11.2 LOPA SUMMARY

The results of the SIL determination /assessment workshop are summarized below:

The following is the list of target SILs for the SIF tags; One (1) SIFs was assigned as SIL--2

JO/EWO

10-01978

whereas the other one was assgined SIL-3.

SIF Description Target P&ID No. C&E No.

Numb SIL

01/14/18

DATE

er

Low Low oil Level (measured by

NO.

REV

LIT-2005) in CPI Separator G80-

TA-049014.001 REV

DISCIPLINE ZC-001 D-XXX1 resulting in Closure of SIL 3 TB048008.001 REV C

ENGINEER D

MSA ZV-2001 & shutdown of

Recovered Oil Pumps.

01/14/18

DATE:

PROJECT

ENGINEER Low Low water Level (measured

IAD by LIT-2008) in CPI Separator TA-049014.001 REV

ZC-002 SIL-2 TB048008.001 REV C

DATE:

01/14/18 G80-D-XXX1 resulting in Closure D

CERTIFIED of ZV-2002.

TBD

04104/13

01/14/18

DATE: Table 1: SIF tags SIL assignment

CONSTRUCTION

AGENCY

TBD Note: As the team developed LOPA scenarios, for some SIF tags there was no protection layer except the SIF

01/14/18

being studied, hence a PFD value ‘1’ was entered in the IPL column for the LOPA calculation.

DATE:

OPERATIONS

TBD

01/14/18

DATE: 12 RECOMMENDATIONS & ACTIONS

CONTROL NUMBER

VERIFICATION

EDSD

1. Both SIF Loops (which are assigned SIL-2 and SIL-3) shall be part of Safety

instrumented system which shall conform ot IEC-61511 requirements.

DATE:

BY:

REVISIONCERTIFICATION

2. PZV-195/196 shall be adequately sized for blowby case as well as will be routed to

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

the safe location.

(DCC) NO. _____________________

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 14

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Saudi Aramco 2616-ENG (03/99)

PMT OPRNS

TBD

SAUDI ARABIAN OIL COMPANY

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

3. As per IEC-61511 section 11.2.10; A device used to perform part of a safety

TBD

instrumented function shall not be used for basic process control purposes.

ENGG CERT

IAD

4. As per ISA-TR84.00.02 ;Frequently, multiple safety functions are included in a single

MSA

ESD logic solver. Generally, the safety function case with the highest SIL requirement

will be the case that determines whether the logic solver meets performance

requirements.

5. System architecture for each SIF shall be designed in accordance with the

ISSUED FOR REVIEW

DESCRIPTION

requirements of standards identified in section 6.2 of this document.

Note:Team members suggested design improvment that failure of LIC-2007 shall not result in the non-

availability of two CPI separators

13 .CONCLUSIONS

Safety instrumented functions designed for the safety of personal; assets /equipment

& enviornment are sufficient with the assigned SIL level to meet the required risk

JO/EWO

10-01978

target. Recommendations shall be implemented as per section 7 of this document.

01/14/18

DATE

14 APPENDICES

NO.

REV

DISCIPLINE Appendix A: Attendance Sheet

ENGINEER

MSA

01/14/18

Appendix B: Process & Instrumentation Diagrams.

DATE:

PROJECT

ENGINEER Appendix C : SAEP-250

IAD

01/14/18

Appendix D: LOPA Worksheets

DATE:

CERTIFIED

TBD

Appendix E: Cause & Effect

04104/13

01/14/18

DATE:

CONSTRUCTION

AGENCY

TBD

01/14/18

DATE:

OPERATIONS

TBD

01/14/18

DATE:

CONTROL NUMBER

VERIFICATION

EDSD

DATE:

BY:

REVISIONCERTIFICATION

APPROVAL/CERTIFICATION REQUIREMENTS,

THIS INDICATES THAT REV. NO.__________

CERTIFICATE

OF THIS DRAWING IS COVERED, FOR ALL

BY DRAWING COMPLETION CERTIFICATE

BA

(DCC) NO. _____________________

10-01091-0001-001

SIL STUDY REPORT DWG.TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

REVISION

DEBOTTLENECK TANAJIB WATER HANDLING DOC

476 A TE-049050 15

BERRI GAS PLANT OF A

BERRI SAUDI ARABIA JO / EWO: BI-10-09111-001 15

EDSD/2616-0399.doc

Das könnte Ihnen auch gefallen

- Wolves, Witches, and Werewolves - Lycanthropy and Witchcraft From 1423 To 1700 PDFDokument28 SeitenWolves, Witches, and Werewolves - Lycanthropy and Witchcraft From 1423 To 1700 PDFshotoshNoch keine Bewertungen

- Pipeline Wall Thickness ReportDokument22 SeitenPipeline Wall Thickness Reportgv gowrav100% (2)

- Sil Study Report: Na Capital Program ManagementDokument20 SeitenSil Study Report: Na Capital Program Managementsalman1111aNoch keine Bewertungen

- Sabp Z 076Dokument29 SeitenSabp Z 076Hassan Mokhtar100% (1)

- Pep 20081300Dokument300 SeitenPep 20081300imri ssNoch keine Bewertungen

- Classification of ComputersDokument2 SeitenClassification of Computerseduardo acuniaNoch keine Bewertungen

- C-104 - FS of HippsDokument9 SeitenC-104 - FS of HippsShakeel Ahmed100% (1)

- 3412 Timing CalibrationDokument4 Seiten3412 Timing CalibrationHrvoje Škarica100% (3)

- Integrating Hazop and Sil/Lopa Analysis: Best Practice RecommendationsDokument10 SeitenIntegrating Hazop and Sil/Lopa Analysis: Best Practice Recommendationsavinash_mokashi7073100% (1)

- Application HAZOP LOPA Figueroa 2015Dokument225 SeitenApplication HAZOP LOPA Figueroa 2015ravisankar100% (1)

- 32 Samss 010Dokument18 Seiten32 Samss 010naruto256Noch keine Bewertungen

- Polite Form and Verb Stems: Not Being Rude in JapanDokument84 SeitenPolite Form and Verb Stems: Not Being Rude in Japaneulea larkaroNoch keine Bewertungen

- Safety StudiesDokument37 SeitenSafety StudiesJagan Bose100% (1)

- My BookingDokument2 SeitenMy Bookingsalman1111a100% (1)

- SIL Study DragonDokument52 SeitenSIL Study DragonRomel RodriguezNoch keine Bewertungen

- R789977015 PDFDokument15 SeitenR789977015 PDFElie AouadNoch keine Bewertungen

- SIL MethodologyDokument16 SeitenSIL Methodologyhvananth100% (8)

- Hazop Sil Study Report For 6 Buy Back Gas PipelineDokument32 SeitenHazop Sil Study Report For 6 Buy Back Gas Pipelinealinor_tn100% (1)

- Saes J 505Dokument16 SeitenSaes J 505Irfan AliNoch keine Bewertungen

- 23 Samss 010Dokument66 Seiten23 Samss 010nadeem shaikhNoch keine Bewertungen

- Midas Manual PDFDokument49 SeitenMidas Manual PDFNishad Kulkarni100% (1)

- GU-513 - PDO - Guidelines For Alarm Management and Rationalization, Dec 2009Dokument45 SeitenGU-513 - PDO - Guidelines For Alarm Management and Rationalization, Dec 2009usebio64100% (2)

- Foundation Fieldbus Segment Drawing (FF Cable Schedule) - ModifDokument721 SeitenFoundation Fieldbus Segment Drawing (FF Cable Schedule) - ModifLakshman KaretiNoch keine Bewertungen

- Hazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDokument110 SeitenHazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDenstar Ricardo Silalahi94% (16)

- WPECC Response: Please Find Attached Missing MTO.: WorleyparsonsDokument12 SeitenWPECC Response: Please Find Attached Missing MTO.: Worleyparsonsrajum465Noch keine Bewertungen

- Saudi Aramco HAZOP Guidelines LOSS PREVE PDFDokument92 SeitenSaudi Aramco HAZOP Guidelines LOSS PREVE PDFPandhu100% (1)

- Active Doc ListDokument310 SeitenActive Doc Listsalman1111aNoch keine Bewertungen

- Functional Safety: Sil Assessment & Verification: Do Proof Test Practices Affect P&Ids?Dokument32 SeitenFunctional Safety: Sil Assessment & Verification: Do Proof Test Practices Affect P&Ids?Muhammad.SaimNoch keine Bewertungen

- Pep 20083221Dokument221 SeitenPep 20083221imri ssNoch keine Bewertungen

- Saep 250Dokument32 SeitenSaep 250brecht198075% (4)

- Marjan Development Program: Tanajib Gas Plant (TGP)Dokument7 SeitenMarjan Development Program: Tanajib Gas Plant (TGP)Maged GalalNoch keine Bewertungen

- IMPERFECT & Partial Valve Stroke Testing Impact On SIFDokument84 SeitenIMPERFECT & Partial Valve Stroke Testing Impact On SIFdavoodnasehiNoch keine Bewertungen

- Rek 85374012Dokument12 SeitenRek 85374012furqanNoch keine Bewertungen

- SK-A-YCC-021 Sales Gas Filtration System FSDDokument30 SeitenSK-A-YCC-021 Sales Gas Filtration System FSDtouseef88Noch keine Bewertungen

- Alarm RationalizationDokument23 SeitenAlarm RationalizationVASANHF1100% (2)

- LOPA and Human ReliabilityDokument26 SeitenLOPA and Human ReliabilityAyoun Ul Haque100% (1)

- Saep 1630Dokument10 SeitenSaep 1630faisalqr100% (1)

- ISO 18001 - Process Safety IndicatorsDokument22 SeitenISO 18001 - Process Safety IndicatorsStephen Groves100% (1)

- Safety Alarm RationalisationDokument21 SeitenSafety Alarm Rationalisationsasa1900sas100% (1)

- PROJECT STANDARDS and SPECIFICATIONS Instrumentation Safety Requirments Rev01Dokument7 SeitenPROJECT STANDARDS and SPECIFICATIONS Instrumentation Safety Requirments Rev01hiyeonNoch keine Bewertungen

- After The Alarm Rationalization - Managing The DCS Alarm SystemDokument16 SeitenAfter The Alarm Rationalization - Managing The DCS Alarm SystemPandharNoch keine Bewertungen

- Saes B 058Dokument15 SeitenSaes B 058Rashid ArshadNoch keine Bewertungen

- Impact Force CalculationDokument3 SeitenImpact Force CalculationphamvanlaiNoch keine Bewertungen

- Sabp Z 072Dokument20 SeitenSabp Z 072Hassan MokhtarNoch keine Bewertungen

- Saes Z 003Dokument10 SeitenSaes Z 003salic2013Noch keine Bewertungen

- 000-SA-E-050026 MR Analyzer Shelter & Process AnalyzersDokument57 Seiten000-SA-E-050026 MR Analyzer Shelter & Process Analyzerszizu1234Noch keine Bewertungen

- Saes Z 004Dokument40 SeitenSaes Z 004nadeem100% (1)

- 7s92 06011 0000 SHR 004a r3 - Sil Classification ReportDokument65 Seiten7s92 06011 0000 SHR 004a r3 - Sil Classification ReportDucViking100% (1)

- Engineering Report: Process Automation Systems 2014 Reliability ReportDokument54 SeitenEngineering Report: Process Automation Systems 2014 Reliability ReportHassan MokhtarNoch keine Bewertungen

- Pre Safety ReviewDokument27 SeitenPre Safety ReviewMagesh KumarNoch keine Bewertungen

- QP Guideline For Safety Integrity Level ReviewDokument32 SeitenQP Guideline For Safety Integrity Level Reviewjeeva438475% (4)

- HAZOP ReportDokument27 SeitenHAZOP ReportMuhammad.Saim100% (3)

- Sabp Z 075Dokument22 SeitenSabp Z 075Hassan MokhtarNoch keine Bewertungen

- Probability of Ignition Probability of Personnel in Affected Area Probability of Fatal Injury OthersDokument1 SeiteProbability of Ignition Probability of Personnel in Affected Area Probability of Fatal Injury OthersTFattahNoch keine Bewertungen

- Using ESD Valves As SafeguardsDokument11 SeitenUsing ESD Valves As SafeguardsHector Javier Cruz CampaNoch keine Bewertungen

- Loads Dead Loads Imposed Loads Floor Roof Determining Load Per M and m2 WindDokument58 SeitenLoads Dead Loads Imposed Loads Floor Roof Determining Load Per M and m2 Windwaheedopple3998Noch keine Bewertungen

- QP GDL S 030 1 PDFDokument32 SeitenQP GDL S 030 1 PDFAnonymous U0LPhn6EjA100% (1)

- Sis Training Course 1Dokument8 SeitenSis Training Course 1santoshjshinde100% (1)

- IEC 61508 - IEC 61511 Presentation: G.M. International S.R.LDokument56 SeitenIEC 61508 - IEC 61511 Presentation: G.M. International S.R.Lkin_Noch keine Bewertungen

- SIL Rating For F&G System HardwareDokument8 SeitenSIL Rating For F&G System HardwareJames GreenNoch keine Bewertungen

- 17 CASS TOES For FSM Assessment From IEC 61511-1 2016 v1Dokument7 Seiten17 CASS TOES For FSM Assessment From IEC 61511-1 2016 v1didikpramujiNoch keine Bewertungen

- Layer of Protection AnalysisDokument9 SeitenLayer of Protection Analysiscera211164Noch keine Bewertungen

- Chastainw Advancesinlayerofprotectionanalysis PDFDokument37 SeitenChastainw Advancesinlayerofprotectionanalysis PDFanon_770350620100% (1)

- Safety Instrumented Systems SIS SILDokument19 SeitenSafety Instrumented Systems SIS SILfloredaNoch keine Bewertungen

- 510006-MR-011 ESD - MR ChecklistDokument2 Seiten510006-MR-011 ESD - MR Checklistsalman1111a100% (1)

- Hazop ReportDokument60 SeitenHazop ReportPrasanna KumarNoch keine Bewertungen

- 1oo1, 1oo2, 2oo2, 2oo3 Voting Logics in Safety Instrumented System (SIS) - Safety Instrumented System - SIS - Instrumentation Forum PDFDokument2 Seiten1oo1, 1oo2, 2oo2, 2oo3 Voting Logics in Safety Instrumented System (SIS) - Safety Instrumented System - SIS - Instrumentation Forum PDFNadi Jothidan KLNoch keine Bewertungen

- 1 Te 498623Dokument5 Seiten1 Te 498623salman1111aNoch keine Bewertungen

- 2018SNE2714601999 VDL Rev00Dokument4 Seiten2018SNE2714601999 VDL Rev00salman1111aNoch keine Bewertungen

- CRS - 2018SNE2714601103 Mechanical Seal CRSDokument9 SeitenCRS - 2018SNE2714601103 Mechanical Seal CRSsalman1111aNoch keine Bewertungen

- NMR Comment Review Sheet-SLFE-masterDokument1 SeiteNMR Comment Review Sheet-SLFE-mastersalman1111aNoch keine Bewertungen

- Hardness Test Procedure: 1 of 8 DE3511.006/EDokument8 SeitenHardness Test Procedure: 1 of 8 DE3511.006/Esalman1111aNoch keine Bewertungen

- CRS - 2018SNE2714601137 - LCP Wiring Diagram - Rev02 CRSDokument5 SeitenCRS - 2018SNE2714601137 - LCP Wiring Diagram - Rev02 CRSsalman1111aNoch keine Bewertungen

- Appendix A - Attendance SheetDokument1 SeiteAppendix A - Attendance Sheetsalman1111aNoch keine Bewertungen

- Mxa Sil Guidance and Certification: SIL 3 Capable For Critical ApplicationsDokument6 SeitenMxa Sil Guidance and Certification: SIL 3 Capable For Critical Applicationssalman1111aNoch keine Bewertungen

- Open Path Gas DetectorsDokument4 SeitenOpen Path Gas Detectorssalman1111aNoch keine Bewertungen

- Saudi Arabian Oil Company: 5.5 TANK H45-D-8B Fire Detection & Foam Skid H45-U-0104 ActivationDokument2 SeitenSaudi Arabian Oil Company: 5.5 TANK H45-D-8B Fire Detection & Foam Skid H45-U-0104 Activationsalman1111aNoch keine Bewertungen

- Replace Crude Oil Samplers at Yanbu North TerminalDokument5 SeitenReplace Crude Oil Samplers at Yanbu North Terminalsalman1111aNoch keine Bewertungen

- WPR - Week Ending Apr 11 2020Dokument5 SeitenWPR - Week Ending Apr 11 2020salman1111aNoch keine Bewertungen

- Top View Cable Stub-Up Plan: 117mm (TYP 2)Dokument1 SeiteTop View Cable Stub-Up Plan: 117mm (TYP 2)salman1111aNoch keine Bewertungen

- 1 Te 498623Dokument5 Seiten1 Te 498623salman1111aNoch keine Bewertungen

- 1 Te 4222Dokument5 Seiten1 Te 4222salman1111aNoch keine Bewertungen

- Tanajib TMS NMR601 (ESD) Comments Item# Document/File Description ReviewerDokument4 SeitenTanajib TMS NMR601 (ESD) Comments Item# Document/File Description Reviewersalman1111aNoch keine Bewertungen

- SCIENCE and EDUCATION A NEW DIMENSION HUMANITIES and SOCIAL SCIENCE Issue 223Dokument93 SeitenSCIENCE and EDUCATION A NEW DIMENSION HUMANITIES and SOCIAL SCIENCE Issue 223seanewdimNoch keine Bewertungen

- PF Chang's Health Inspection 6-21-19Dokument2 SeitenPF Chang's Health Inspection 6-21-19Jimmy BentleyNoch keine Bewertungen

- PIC16F1946Dokument448 SeitenPIC16F1946madhavaNoch keine Bewertungen

- Atex Flow ChartDokument1 SeiteAtex Flow ChartMohammad KurdiaNoch keine Bewertungen

- Digital Citizenship E-Portfolio AssignmentDokument4 SeitenDigital Citizenship E-Portfolio AssignmentJordanne ChristieNoch keine Bewertungen

- Tilt-Up Building Seismic Design - Precast or Cast-In PlaceDokument3 SeitenTilt-Up Building Seismic Design - Precast or Cast-In PlacealexitomichaelNoch keine Bewertungen

- Tech Bull 3 - Free Fall of ConcreteDokument4 SeitenTech Bull 3 - Free Fall of ConcreteJoel TorcuatorNoch keine Bewertungen

- Maximum Remaining - CodeChefDokument3 SeitenMaximum Remaining - CodeChefShubhi SinghNoch keine Bewertungen

- Course On Fracture Mechanics - IIT RoparDokument248 SeitenCourse On Fracture Mechanics - IIT RoparSumit BasuNoch keine Bewertungen

- Graded Worksheet D3Dokument1 SeiteGraded Worksheet D3Jacob DziubekNoch keine Bewertungen

- Mom MF-1Dokument79 SeitenMom MF-1AnbuNoch keine Bewertungen

- Physics Chapter 3 Practice TestDokument2 SeitenPhysics Chapter 3 Practice TestVanessa Bugarin MananzanNoch keine Bewertungen

- CS604 - Operating SystemsDokument11 SeitenCS604 - Operating SystemsAsadNoch keine Bewertungen

- Tableau VM Tuning and Best PracticesDokument6 SeitenTableau VM Tuning and Best Practicessrikanth_4allNoch keine Bewertungen

- Kaizen MR - Final PDFDokument65 SeitenKaizen MR - Final PDFbhatiaharryjassiNoch keine Bewertungen

- C-Code Software Routines For Using The SPI Interface On The MAX7456 On-Screen DisplayDokument9 SeitenC-Code Software Routines For Using The SPI Interface On The MAX7456 On-Screen DisplayVinay Ashwath100% (2)

- WebSphere Application Server AMI Cheatsheet For DemoDokument2 SeitenWebSphere Application Server AMI Cheatsheet For DemoYakura CoffeeNoch keine Bewertungen

- PIT Error Overview - ParetoDokument208 SeitenPIT Error Overview - ParetoHariharan Yelomalei50% (2)

- Caillau, Guillon. S. Ephræm. Opera Omnia. 1832. Volume 7.Dokument540 SeitenCaillau, Guillon. S. Ephræm. Opera Omnia. 1832. Volume 7.Patrologia Latina, Graeca et OrientalisNoch keine Bewertungen

- Olympic Message SystemDokument16 SeitenOlympic Message Systemtrevor randyNoch keine Bewertungen

- Western Underground - HV and Ehv Cables-CmeDokument38 SeitenWestern Underground - HV and Ehv Cables-CmeA. Hassan100% (2)

- Leadership in Innovation 1194529453608858 3Dokument22 SeitenLeadership in Innovation 1194529453608858 3shashi4u.kumar5817Noch keine Bewertungen

- Epilogue Magazine, March 2010Dokument56 SeitenEpilogue Magazine, March 2010Epilogue MagazineNoch keine Bewertungen