Beruflich Dokumente

Kultur Dokumente

MAN002 FDE InventoryManagementCockpit v3.4

Hochgeladen von

bearpanzaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MAN002 FDE InventoryManagementCockpit v3.4

Hochgeladen von

bearpanzaCopyright:

Verfügbare Formate

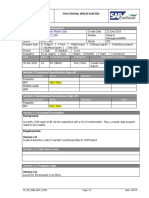

EBM Functional Design - Report

Manufacturing

Inventory Management Cockpit

Version 3.1

March 2013

Holcim Services EMEA

EBM Functional Design – Inventory Management Cockpit

EBM Blueprint template – Functional Design - Report 2/43

EBM Functional Design – Inventory Management Cockpit

Document Control

Document Information

Document name: MAN002_FDE_Inventory Management Cockpit.doc

Authors: Beat Thalmann

Contributors: Laura de la Arena

Owner: Laura de la Arena

Document status: Definitive

Associated documentation:

Document History

Release Section

Version RFC id Reason for change Authors

Date affected

0.0 06.04.2011 Initial version All BTH

1.0 26.04.2011 Data from Info 3.1.5 Report BTH

Records included output fields

1.1 29.04.2011 Input from matching 3.1.5 Report BTH

with ZMM_ALM output fields

Report

2.0 17.01.2012 Updated with all the All LAR

bug-fixing

performed during

the FBNL tests.

3.0 01.09.2012 Report All AIH

Enhancement

Bug-fixing (Incident 4.1.5 Report JEC

239884) output fields

3.1 12.03.2013 CR790 Include Currency on 4.1.5.5 RPI

the Inventory tab Inventory tab

(pg. 18)

3.2 14.10.2013 CRQ37377 Do not display 4.1.5.5 LCO

project stock when Inventory tab

it’s 0 (pg. 19)

3.3_1 13.10.2015 CHG0039586 Insert MAT 3.2 Material MLE

description and EQ documents

description on tab (pag. 20)

“Materials

documents”

3.3_2 13.10.2015 CHG0039586 Insert Purchasing 4. Purchasing MLE

document number (pag. 21-22)

EBM Blueprint template – Functional Design - Report 3/43

EBM Functional Design – Inventory Management Cockpit

on tab “Purchasing”

3.4 New AFR moving GLI

Price determination

Document Approval

BUSINESS SIGN-OFF

Name Project Role Date Signature

IT SIGN-OFF

Name Project Role Date Signature

Laura de la Arena IT Project Manager AFR 29.04.2011 Sign-off v1.1 by LAR

Laura de la Arena IT Project Manager AFR 17.01.2012 Sign-off v2.0 by LAR

Distribution List

Name Role OpCo

EBM Blueprint template – Functional Design - Report 4/43

EBM Functional Design – Inventory Management Cockpit

Table of Contents

EBM Functional Design - Report

Manufacturing

Inventory Management Cockpit

1 Introduction

1.1 Objective and scope of the document

2 Executive Overview

3 Overview and Scope

3.1 Functional Description

3.2 Scope

3.3 Dependencies/Constraints

3.4 Assumptions

3.5 Security and Authorization

4 Detailed Functional Requirements

4.1 Functional Specification

4.1.1 General description of the logic of the program

4.1.2 AS-IS program

4.1.3 Access

4.1.4 Selection Screen

Description of selection fields:

4.1.5 Report Output fields

4.1.6 General report functions

4.2 Process Flow Diagram

4.3 Initiating Process / Transaction / Program

4.4 Selection Criteria

4.5 Report Layout

4.6 Report Fields

4.7 Main Heading

4.8 Sub Heading

4.9 Totalling

4.10 Sorting

4.11 Page Break

4.12 Stationery

4.13 Existing Sample Reports

4.14 Processing and Operational Considerations

4.14.1 Performance

4.14.2 Processing Type

4.14.3 Batch Requirements

4.14.4 Expected Transaction Volumes

4.14.5 Output Type

4.14.6 Error Handling

4.15 Change Management Requirements

5 Testing Requirements

5.1 Key Business Test Conditions

5.2 Technical Test Conditions

5.3 Risk and Controls Test Conditions

5.4 Testing Considerations/Dependencies

6 Design Alternatives

7 Outstanding Issues

8 Appendix

8.1 EBM IT Design Principles

EBM Blueprint template – Functional Design - Report 5/43

EBM Functional Design – Inventory Management Cockpit

1 Introduction

1.1 Objective and scope of the document

This document is part of the global EBM Blueprint.

Objective of the EBM Blueprint:

The EBM Blueprint is a detailed description of the EBM business processes and

system requirements. It is the key deliverable of the EBM Project.

The main objectives of the EBM Blueprint are:

- to describe the targeted (To-Be) EBM processes and PPIs;

- to define in detail all the requirements that the solution must fulfill (master

data, structural data, process flows, reporting, data migration, service level

requirements).

The EBM Blueprint is the major input for the design of the solution that will support

the targeted business processes. All the specifications that are required for designing

the solution must be included in this document.

The EBM Blueprint will as well support the scope management during the project.

The document will be frozen once it is signed-off by all the relevant stakeholders. If

any additional requirement needs to be added to the project, it will have to be

approved following the established Change Management process.

Scope of this document:

This document is part of the EBM IT Blueprint.

The objective of this document is to describe the detailed business requirements for

the development of the EBM report “Inventory Management Cockpit”.

Version 3 Enhancement:

● Capitalizable spare part to be taken in account in several tabs

● Material W/O BOM tab enhancement

EBM Blueprint template – Functional Design - Report 6/43

EBM Functional Design – Inventory Management Cockpit

EBM Blueprint template – Functional Design - Report 7/43

EBM Functional Design – Inventory Management Cockpit

2 Executive Overview

In the EBM design phase, it was decided to develop an Inventory Management

Cockpit/Report with the most relevant information of the materials, structured as

follows:

- Basic and MRP (material master data)

- Equipment BOMs

- Materials without BOM

- Purchasing (vendor info-records)

- Inventory (at plant and at storage location level)

- Inventory Storage Location

Two main sources were assessed for the definition of the IM report:

- Developed report in NASC: ZMM_INVENT

- Current ZMM_ALM report in EMEA

Final decision was to copy the ZMM_INVENT report from NASC and adapt it to

EMEA by:

- Enhancing the inventory tabs with the info that is today in ZMM_ALM

- Remove the Warehouse Mgmt information, as it is not used in EMEA

- Add additional business requirements: info-records instead of source lists in

the Purchasing tab, etc.

The objective of this document is to explain how to adapt the transaction

ZMM_INVENT for the EBM.

EBM Blueprint template – Functional Design - Report 8/43

EBM Functional Design – Inventory Management Cockpit

3 Overview and Scope

3.1 Functional Description

Described in section 4.1

● Capitalizable spare part to be taken in account in Inventory and Merge tabs:

Materials under project on Stock should to be taken in account in the

following tabs: Inventory and Data Merge tabs

● Material W/O BOM tab enhancement

This tab should show the lines per material movements instead of grouped

(as is now). Also some columns need to be added.

3.2 Scope

The scope of this report covers all EMEA OpCos and all Holcim business

segments.

3.3 Dependencies/Constraints

N/A

3.4 Assumptions

N/A

3.5 Security and Authorization

Authority check by plant.

EBM Blueprint template – Functional Design - Report 9/43

EBM Functional Design – Inventory Management Cockpit

4 Detailed Functional Requirements

The IT Design Principles are described in the Appendix (section 7.1) of this

document.

The changes required to adapt the NASC report to EMEA are marked in blue

color

4.1 Functional Specification

4.1.1 General description of the logic of the program

Selection of all the materials and inventory data which fulfil the criteria indicated

in the selection screen and display it split into the following tabs:

4.1.2 AS-IS program

AS-IS program from NASC o be copied and adapted:

- AS-IS transaction code: ZMM_INVENT

- AS-IS name of the Program: Z_MMR_INVENT

- AS-IS ABAP code:

EBM Blueprint template – Functional Design - Report 10/4

3

EBM Functional Design – Inventory Management Cockpit

4.1.3 Access

New transaction code to be created to access to the report: ZMM003

4.1.4 Selection Screen

In the selection screen, you can enter the criteria you want to use in order to

delimit the output of the report:

Description of selection fields:

EBM Blueprint template – Functional Design - Report 11/4

3

EBM Functional Design – Inventory Management Cockpit

The changes required to adapt the NASC report to EMEA are marked in blue color

Material: Enter a specific material numbers, or number ranges

Status Code: This code refers to the material master status that set at the client

level for all plants on the “Basic Data 1” tab (“X-plant matl status“

field). To be replaced for EMEA by the “plant-specific material

status” field set on the “Purchasing” tab.

Valuation type: To be used for materials with split-valuation (New, Used,

Refurbished)

IMPORTANT:

Restricting the report to specific valuation types will prevent the

High Stock from being calculated (since its calculation requires all

valuation types to be included). An information message will be

displayed when you enter a selection in this field and press

ENTER or execute the report:

Storage Location: This is the inventory management (IM) storage location of the

material

Storage bin: This is the Inventory Management (IM) storage bin found in the

material master on the “Plant data / Stor. 1 tab”

Material type: A specific material type can be entered

Material group: A specific material group (PCS code) can be entered.

MRP Type: Enter a specific MRP Type.

MRP Group: The MRP Group is assigned in the material master on the “MRP 1”

tab.

MRP Controller: The MRP Controller also comes from the material master on the

“MRP 1” tab

Lot Size: The Lot Size is found on the “MRP 1” tab in the material master.

EBM Blueprint template – Functional Design - Report 12/4

3

EBM Functional Design – Inventory Management Cockpit

Plant: This is a REQUIRED field (an entry must be made). The report

can be executed for a single plant or for multiple plants. For

EMEA, to be moved to the top of the selection screen (just after

the “Material”).

Last G/I (Date): By entering a date in this field, only materials that had their last

goods issue posted on this date will be displayed.

Last G/R (Date): By entering a date in this field, only materials that had their last

goods receipt posted on this date will be displayed.

Equipment No.: If an equipment number (or several numbers) are selected, then

the report will only display materials that exist in the equipment bill

of material (BOM). If any material numbers are entered in the

material number selection field, then a message will appear when

you execute the report:

This means that the numbers entered in the material selection will

not be included in the report (unless they belong to the selected

equipment BOM).

Year for Analysis: This is a REQUIRED field (an entry must be made). The year

entered in this field becomes the “Current Year (C.Y.)” for the data

on the “Inventory tab” in the report. The “Previous Year (P.Y.)” will

be the year prior to the selected year.

WM Storage Type:

WM Storage Bin: These two selection fields must be removed, since the WM

(Warehouse Management) functionality is not used in EMEA.

No zero stock lines: Selecting this option will eliminate materials that have zero total

stock (total stock = own stock + consignment stock) from the

“Inventory” tab only (i.e. materials with zero stock will still appear

on the other report tabs).

Ind. for Critical Part: This selection fields must be removed, since it is not used in

EMEA.

EBM Blueprint template – Functional Design - Report 13/4

3

EBM Functional Design – Inventory Management Cockpit

Materials w/o BOMs only: Selecting this option will only display materials that do not

belong to equipment BOMs.

Stock levels exceeding the MAX: Select this option to display only materials whose

stock levels exceed the maximum specified level (see the section

below regarding the Basic and MRP data tab for more information

regarding the high stock calculation).

Materials with transfers only: By selecting this option, only materials that have had a

material-to-material transfer will be displayed in the report.

Deletion Flag:

All materials: All materials are included in the report

Deleted materials only: Only materials flagged for deletion will be included.

Active materials only: Only materials not flagged for deletion will be

included. Description to be changed for EMEA to

“Non-deleted materials only”, since “active” does not

mean the same as “non-deleted”.

Once you have update the selection screen with the desired criteria, press the button

in order to list the entries found by the report.

NOTE that the only REQUIRED selection fields are the “Plant” and the “Year for

Analysis”.

EBM Blueprint template – Functional Design - Report 14/4

3

EBM Functional Design – Inventory Management Cockpit

4.1.5 Report Output fields

The report is comprised of 6 7 separate tabs, each of which contains different

information for the materials selected:

1. BASIC AND MRP TAB:

It contains data from mainly the material master record (basic, purchasing and MRP

tabs):

Reporting Display Structure:

Field Positi Data Data

Length Short Description

name on element Type

MATNR 1 MATNR CHAR 18 Material Number

WERKS 2 WERKS_D CHAR 4 Plant

MAKTX 3 MAKTX CHAR 40 Material Description (Short Text)

MTART 4 MTART CHAR 4 Material Type

MEINS 5 MEINS UNIT 3 Base Unit of Measure

MATKL 6 MATKL CHAR 9 Material Group

MMSTA 7 MMSTA CHAR 2 Plant-Specific Material Status

MTSTB 8 MTSTB CHAR 25 Description of material status

MAABC 9 MAABC CHAR 1 ABC Indicator

DISPO 10 DISPO CHAR 3 MRP Controller (Materials Planner)

DISGR 11 DISGR CHAR 4 MRP Group

DISMM 12 DISMM CHAR 2 MRP Type

MINBE 13 MINBE QUAN 13 Reorder Point

DISLS 14 DISLS CHAR 2 Lot size (materials planning)

BSTMA 15 BSTMA QUAN 13 Maximum Lot Size

BSTMI 16 BSTMI QUAN 13 Minimum Lot Size

BSTFE 17 BSTFE QUAN 13 Fixed lot size

EISBE 18 EISBE QUAN 13 Safety Stock

MABST 19 MABST QUAN 13 Maximum stock level

PLIFZ 20 PLIFZ DEC 3 Planned Delivery Time in Days

WEBAZ 21 WEBAZ DEC 3 Goods Receipt Processing Time in Days

BOMLK 22 ZZBOMLK CHAR 1 Material assigned to Equipment

EBM Blueprint template – Functional Design - Report 15/4

3

EBM Functional Design – Inventory Management Cockpit

BISMT 23 BISMT CHAR 18 Old material number*

ERSDA 24 ERSDA DATS 8 Created On

LVORM_ LVOMA CHAR 1 Flag Material for Deletion at Client Level

25

MARA

LVORM 26 LVOWK CHAR 1 Flag Material for Deletion at Plant Level

LIQDT 27 LIQDT DATS 8 Deletion date

HIGH_STO ZZMM_INVENT QUAN 13 High Stock

CK 28 _HIGH_STOCK

OVERSTK 29 ZZOVERSTK CURR 13 OverStock

ZMAKTX_NC 30 ZMAKTX_NC CHAR 40 Material Description (Naming Convention)

KZKRI KZKRI CHAR 1 Indicator: Critical part

EBM Blueprint template – Functional Design - Report 16/4

3

EBM Functional Design – Inventory Management Cockpit

By clicking on the material number, the user is able to access to the transaction

MM03 (material display).

HIGH STOCK:

If the maximum stock level has been exceeded then the HIGH STOCK will contain

the quantity by which the maximum level has been exceeded (the difference between

the stock on hand and the maximum level). If the stock level is less than or equal to

the maximum, then HIGH STOCK will contain zero.

Maximum Stock Level determination:

The maximum stock levels are determined based on the MRP Lot Size indicated on

the MRP 1 tab of the material master.

● If MRP Lot Size = EX (Lot-for-lot order quantity) then the maximum stock

level = safety stock quantity (from MRP 2 tab).

● If MRP Lot Size = HB (Replenish to maximum stock level) then the maximum

stock level = Maximum Stock Level quantity (from the MRP 1 tab).

Total Stock = Own Stock + Consignment Stock

Overstock:

The “Overstock” is the value of the stock that is exceeding the reorder point. It is

calculated as: [ Total Stock – Reorder Point) * Material Price ]

* Version 3.1

The field “old matl number” in report ZMM003 is showing a wrong number.

This happens when the program does not find a value for the field

MATNR_OLD in table ZTMM_CONV_MATNR. In this case the report is

showing the same value than in the previous line.

Example in DR1-300:

Execute ZMM003 for material 10000353

EBM Blueprint template – Functional Design - Report 17/4

3

EBM Functional Design – Inventory Management Cockpit

There is no Old Material Number for this material:

Then we execute the ZMM003 for materials 10000353 and 10000348.

In this case The Old Material Number for material 10000353 is the same than

in the previous line.

EBM Blueprint template – Functional Design - Report 18/4

3

EBM Functional Design – Inventory Management Cockpit

2. EQUIPMENT BOM TAB:

This tab displays equipment BOM information for selected materials that belong to an

equipment BOM.

If a material belongs to an assembly, and that assembly belongs to an equipment

BOM, then the material will appear on this tab, and the assembly number will be

displayed.

Reporting Display Structure:

Field Positi Data Data

Length Short Description

name on element Type

WERKS 1 WERKS_D CHAR 4 Plant

EQUNR 2 EQUNR CHAR 18 Equipment Number

MATNR 3 MATNR CHAR 18 Material Number

EQKTX 4 KTX01 CHAR 40 Description of technical object

EBM Blueprint template – Functional Design - Report 19/4

3

EBM Functional Design – Inventory Management Cockpit

TIDNR 5 TIDNR CHAR 25 Technical identification number

BAUTL 6 BAUTL CHAR 18 Assembly

BAUTX 7 BAUTX CHAR 40 Description of PM Assembly

MENGE 8 KMPMG QUAN 13 Component quantity

MEINS 9 KMPME UNIT 3 Component unit of measure

POSTP 10 POSTP CHAR 1 Item Category (Bill of Material)

LGORT 11 CSLGO CHAR 4 Issue location for production order

MAKTX 12 MAKTX CHAR 40 Material Description (Short Text)

By clicking on the material number, the user is able to access to the transaction

MM03 (material display).

3. MATERIALS W/O BOM TAB:

3.1. Materials w/o Bom Report (sub-tab)

This tab displays materials that do not belong to equipment BOMs.

If a material belongs to an assembly but the assembly does not belong to an

equipment BOM, then the assembly number will be displayed.

Reporting Display Structure:

Field Positi Data Data

Length Short Description

name on element Type

WERKS 1 WERKS_D CHAR 4 Plant

MATNR 2 MATNR CHAR 18 Material Number

MAKTX 3 MAKTX CHAR 40 Material Description (Short Text)

IDNRK 4 IDNRK CHAR 18 BOM component

KTEXT 5 KMPTX CHAR 40 Component description

MENGE 6 KMPMG QUAN 13 Component quantity

EBM Blueprint template – Functional Design - Report 20/4

3

EBM Functional Design – Inventory Management Cockpit

MEINS 7 KMPME UNIT 3 Component unit of measure

POSTP 8 POSTP CHAR 1 Item Category (Bill of Material)

UDATE 9 CDDATUM DATS 8 Creation date of the change document

By clicking on the material number, the user is able to access to the transaction

MM03 (material display).

3.2. Materials documents (sub-tab)

This tab displays materials movements related with PM orders.

If a material belongs to an assembly but the assembly does not belong to an

equipment BOM, then the assembly number will be displayed.

Field Posi Data Data

Length Short Description

name tion element Type

MATNR 1 MATNR CHAR 18 Material Number

MAKTX 2 MAKTX CHAR 40 Material Description (Short Text)

WERKS WERKS_ CHAR 4 Plant

3

D

LGORT LGORT_ CHAR 4 Storage Location

4

D

BWART 5 BWART CHAR 3 Movement Type

SOBKZ 6 SOBKZ CHAR 1 Special stocks

MBLNR 7 MBLNR CHAR 10 Material document

MJAHR 8 MJAHR NUMC 4 Material document year

ZEILE 9 MBLPO NUMC 4 Material doc. Item

BUDAT 10 BUDAT DATS 8 Posting date

EBM Blueprint template – Functional Design - Report 21/4

3

EBM Functional Design – Inventory Management Cockpit

ERFMG 11 ERFMG QUAN 13 Qty. in Un. of entry

ERFME 12 ERFME UNIT 3 Unit of entry

AUFNR 13 AUFNR CHAR 12 Order

EQUNR 14 EQUNR CHAR 18 Equipment

EQKTX 15 KTX01 CHAR 40 Equipment description

By clicking on the material number, the user is able to access to the transaction

MM03 (material display).

By clicking on the order number, the user is able to access to the transaction IW32

(Change order / Change maintenance preventive).

4. PURCHASING TAB:

Untill now, on this tab, we only show the info records purchasing data information.

Now, we will include the purchasing data information from the “contracts/agreements”

too.

For that, now on this “Purchasing” tab, will show the purchasing data information

from both (info records and “contracts/agreements).

For show purchasing data information from the info records:

● this tab needs to be adapted for EMEA, instead of displaying the source lists

(which are not used in EMEA), it must show the purchasing data of the info

records with NO deletion flag activated (EINA-LOEKZ=” “-blancs-).

For show purchasing data information from the "contracts / agreements":

● EKPO table with:

○ EKPO-MATNR field informed

○ EKPO-LOEKZ=” “-blancs-

● and join with table EKKO by filter:

○ on field EKKO-BSTYP=”K”

○ on field EKKO-BSART=”WK”

○ and SY-DATUM >= EKKO-KDATB

○ and SY-DATUM =< EKKO-KDATE

○ on field EKKO-LOEKZ=” “-blancs-

On this tab, sort all this information (info records and contracts/agreements) by

material number (MATNR).

EBM Blueprint template – Functional Design - Report 22/4

3

EBM Functional Design – Inventory Management Cockpit

Reporting Display Structure:

Field Positi Data Data

Length Short Description

name on element Type

WERKS 1 EWERK CHAR 4 Plant

MATNR 2 MATNR CHAR 18 Material Number

LIFNR 3 ELIFN CHAR 10 Vendor Account Number

EKORG 4 EKORG CHAR 4 Purchasing Organization

EBELN 5 EBELN CHAR 10 Purchasing document number

INFNR 6 INFNR CHAR 10 Number of Purchasing Info Record

NAME1 NAME1_G CHAR 35 Name 1

7

P

MAKTX 8 MAKTX CHAR 40 Material Description (Short Text)

IDNLF 9 IDNLF CHAR 35 Material Number Used by Vendor

ESOKZ 10 ESOKZ CHAR 1 Purchasing info record category

EKGRP 11 BKGRP CHAR 3 Purchasing Group

APLFZ 12 PLIFZ DEC 3 Planned Delivery Time in Days

MINBM 13 MINBM QUAN 13 Minimum Purchase Order Quantity

BSTMA 14 MAXBM QUAN 13 Maximum Purchase Order Quantity

NORBM 15 NORBM QUAN 13 Standard Purchase Order Quantity

UEBTO 16 UEBTO DEC 3 Overdelivery Tolerance Limit

UEBTK 17 UEBTK CHAR 1 Indicator: Unlimited Overdelivery Allowed

UNTTO 18 UNTTO DEC 3 Underdelivery Tolerance Limit

EBELP 19 EBELP NUMC 5 Item Number of Purchasing Document

DATLB DATLB DATS 8 Date of Last PO or Sched. Agreement

20

Document in Info Record

NETPR 21 IPREI CURR 11 Net Price in Purchasing Info Record

WAERS 22 WAERS CUKY 5 Currency Key

PEINH 23 EPEIN DEC 5 Price Unit

BPRME 24 BBPRM UNIT 3 Order Price Unit (Purchasing)

PRDAT 25 PRGBI DATS 8 Price Valid Until

EFFPR 26 EFFPR CURR 11 Effective Price in Purchasing Info Record

WEBRE 27 WEBRE CHAR 1 Indicator: GR-Based Invoice Verification

EBM Blueprint template – Functional Design - Report 23/4

3

EBM Functional Design – Inventory Management Cockpit

By clicking on the info-record number, the user is able to access to the transaction

ME12 (info record modification) or ME13 (info record display), depending on the

authorizations of the user.

By clicking on the Purchasing document number, the user is able to access to the

transaction ME33K (Display Contract / Agreement).

INVENTORY. El ALV se alimenta de

5. INVENTORY TAB:

This tab displays stock information as well as current year and previous year usage

and receipt information.

We are going to discriminate alternative fuels from the rest of material due to the

particular price calculation.

Reporting Display Structure: ZSMM_INVENT_ACCOUNT

Le

Posit Data

Field name Data element ngt Short Description

ion Type

h

BWKEY 1 BWKEY CHAR 4 Valuation Area

MATNR 2 MATNR CHAR 18 Material Number

BWTAR 3 BWTAR_D CHAR 10 Valuation Type

MAKTX 4 MAKTX CHAR 40 Material Description (Short Text)

BKLAS 5 BKLAS CHAR 4 Valuation Class

HIGH_STOCK ZZMM_INVENT_HIGH QUAN 13 High Stock

6 _STOCK

OVERSTK 7 ZZOVERSTK CURR 13 OverStock

TOT_STOCK ZZMM_INVENT_TOT QUAN 13 Total Stock

8 _STOCK

LBKUM 9 LBKUM QUAN 13 Total Valuated Stock

VPRSV 10 VPRSV CHAR 1 Price Control Indicator

VERPR 11 VERPR CURR 11 Mov.Average Price/Periodic Unit Price

PEINH 12 PEINH DEC 5 Price Unit

SALK3 13 SALK3 CURR 13 Value of Total Valuated Stock

SLABS 14 KLABS QUAN 13 Unrestricted-Use Consignment Stock

EBM Blueprint template – Functional Design - Report 24/4

3

EBM Functional Design – Inventory Management Cockpit

ZPTGI 15 ZZMM_INVENT_PTGI QUAN 13 Previous Year Total G/I

ZCTGI 16 ZZMM_INVENT_CTGI QUAN 13 Current Year Total G/I

ZPLGI 17 ZZMM_INVENT_PLGI QUAN 13 Previous Year Largest G/I

ZCLGI 18 ZZMM_INVENT_CLGI QUAN 13 Current Year Largest G/I

ZPSGI 19 ZZMM_INVENT_PSGI QUAN 13 Previous Year Smallest G/I

ZCSGI 20 ZZCSGI QUAN 13 Current Year Smallest G/I

ZPAGI 21 ZZPAGI QUAN 13 Previous Year Average G/I

ZCAGI 22 ZZCAGI QUAN 13 Current Year Average G/I

ZLGI 23 ZZMM_INVENT_LGI DATS 8 Last G/I (Date)

ZLGR 24 ZZMM_INVENT_LGR DATS 8 Last G/R (Date)

SPECIAL_MOV ZZMM_INVENT_SPE CHAR 1 Material Transfer (309)

25 CIAL_MOV

CONSUM01 26 ZZCONSUM01 QUAN 13 G/I Period 01

CONSUM02 27 ZZCONSUM02 QUAN 13 G/I Period 02

CONSUM03 28 ZZCONSUM03 QUAN 13 G/I Period 03

CONSUM04 29 ZZCONSUM04 QUAN 13 G/I Period 04

CONSUM05 30 ZZCONSUM05 QUAN 13 G/I Period 05

CONSUM06 31 ZZCONSUM06 QUAN 13 G/I Period 06

CONSUM07 32 ZZCONSUM07 QUAN 13 G/I Period 07

CONSUM08 33 ZZCONSUM08 QUAN 13 G/I Period 08

CONSUM09 34 ZZCONSUM09 QUAN 13 G/I Period 09

CONSUM10 35 ZZCONSUM10 QUAN 13 G/I Period 10

CONSUM11 36 ZZCONSUM11 QUAN 13 G/I Period 11

CONSUM12 37 ZZCONSUM12 QUAN 13 G/I Period 12

CONSUM01P 38 ZZCONSUM01P QUAN 13 G/I Period 01 Previous Year

CONSUM02P 39 ZZCONSUM02P QUAN 13 G/I Period 02 Previous Year

CONSUM03P 40 ZZCONSUM03P QUAN 13 G/I Period 03 Previous Year

CONSUM04P 41 ZZCONSUM04P QUAN 13 G/I Period 04 Previous Year

CONSUM05P 42 ZZCONSUM05P QUAN 13 G/I Period 05 Previous Year

CONSUM06P 43 ZZCONSUM06P QUAN 13 G/I Period 06 Previous Year

CONSUM07P 44 ZZCONSUM07P QUAN 13 G/I Period 07 Previous Year

CONSUM08P 45 ZZCONSUM08P QUAN 13 G/I Period 08 Previous Year

CONSUM09P 46 ZZCONSUM09P QUAN 13 G/I Period 09 Previous Year

CONSUM10P 47 ZZCONSUM10P QUAN 13 G/I Period 10 Previous Year

CONSUM11P 48 ZZCONSUM11P QUAN 13 G/I Period 11 Previous Year

CONSUM12P 49 ZZCONSUM12P QUAN 13 G/I Period 12 Previous Year

WAERS 50 WAERS CHAR 3 Currency Key

Alternatives fuel (valuation class: 2501/ 2502 / 1501) Material ZAFR

Column details:

Mov.Average Price/Periodic Unit Price = table ZTAFR_MEC_002 - VERPR

Total Stock = total of stock quantities allocated in diferent storage

location grouping by plant ( table MARD): all storage location in the last

EBM Blueprint template – Functional Design - Report 25/4

3

EBM Functional Design – Inventory Management Cockpit

period (it could be difente period in between the diferent storage location

where the AFR it’s allocated)

Own Stock = Total stock

Own Value = Own stock

Csgt. Stock = No consignament sotck

P.Y.T. G/I = Previous year total goods issues ( = sum of issues from stock

minus returns to stock for the previous year).

Rest of material or valuation class.

Column details:

- Total Stock = Own Stock + Consignment Stock

- Own Stock = total of all valuated stock quantities

- Own Value = value of Own Stock

- Csgt. Stock = Consignment Stock quantity

- P.Y.T. G/I = Previous year total goods issues ( = sum of issues from stock

minus returns to stock for the previous year).

- C.Y.T. G/I =Current year total goods issues ( = sum of issues from stock

minus returns to stock for current year-to-date).

- P.Y.L. G/I = Previous year largest G/I

- C.Y.L. G/I = Current year-to-date largest G/I

- P.Y.S. G/I = Previous year smallest G/I

- C.Y.S. G/I = Current year-to-date smallest G/I

- P.Y.A. G/I = Previous year average G/I

- C.Y.A. G/I = Current year average G/I

- Last G/I = Date of last goods issue. If no issues have occurred in the current

year, then it will contain the date of last G/I for the previous year. It will be

blank if no issues have been posted.

- Last G/R = Date of last goods receipt. If no receipts have occurred in the

current year, then it will contain the date of last G/R for the previous year. It

will be blank if no receipts have been posted.

- Matl Trnsf = A material-to-material transfer has occurred for this material. If a

309 movement has been posted for a material, then an “X” will appear in this

column. This will apply to both the sending and receiving materials.

- Currency Key = Currency of the material. This information is at Company

code level, and is available in the Table/field T001-WAERS

- Project stock: If the there is some record of project stock in table MSPR a

new line with WBS/project ID and project stock will be displayed. This line

should be removed if total project stock is 0. Total project stock = unrestricted

+ Quality inspection stock + blocked (PRLAB + PRINS + PRSPE) .

EBM Blueprint template – Functional Design - Report 26/4

3

EBM Functional Design – Inventory Management Cockpit

Goods Issue Calculation Details:

- Total goods issue = Sum of all non-cancelled issue and return movement

types: 201, 202, 221, 222, 241, 242, 261, 262, 281, 282, 291, 292

NOTE: Movement type ending in a “2” represent returns to inventory and

therefore those quantities are subtracted from the goods issues quantities

(movement types ending in a “1”)

- Largest goods issue = Largest quantity from non-cancelled issue movement

types: 201, 221, 241, 261, 281, 291.

- Smallest goods issue = Smallest quantity from non-cancelled issue

movement types: 201, 221, 241, 261, 281, 291.

- Average goods issue = Total goods issue divided by the number of non-

cancelled movement types: 201, 202, 221, 222, 241, 242, 261, 262, 281, 282,

291, 292

- Last Good Issue = The date of the last non-cancelled issue movement type:

201, 221, 241, 261, 281, 291.

- Last Good Receipt = The date of the last non-cancelled receipt movement

type: 101, 301, 501, 511, 561.

NOTE: The 301 movement is the plant-to-plant transfer movement. This

movement is considered as a goods receipt at the receiving plant. Therefore,

only the 301 movement with a debit/credit indicator = “S” (debit or increase)

is considered, not the 301 H movement (which occurs for the sending plant).

Movement type definitions:

Good issues:

- 201: Goods issue to a cost center, or cancellation of a 202

- 202: Return to inventory from a cost center, or cancellation of a 201

- 221: Goods issue to a project, or cancellation of a 222

- 222: Return to inventory from a project, or cancellation of a 221

- 241: Goods issue to an asset, or cancellation of a 242

- 242: Return to inventory from an asset, or cancellation of a 241

- 261: Goods issue to an order, or cancellation of a 262

- 262: Return to inventory from an order, or cancellation of a 261

- 281: Goods issue to a network, or cancellation of a 282

- 282: Return to inventory from a network, or cancellation of a 281

- 291: Goods issue to any account assignment, or cancellation of a 292

- 292: Return to inventory from any account assignment, or cancellation of 291

Good receipts:

- 101: Goods receipt for a purchase order

- 102: Cancellation of a 101

- 301: Plant-to-plant transfer

EBM Blueprint template – Functional Design - Report 27/4

3

EBM Functional Design – Inventory Management Cockpit

- 302: Cancellation of a 301

- 501: Goods receipt without a PO

- 502: Cancellation of a 501

- 511: Delivery without charge

- 512: Cancellation of a 511

- 561: Initial inventory input

- 562: Cancellation of a 561

Enhancement to be implemented for EMEA:

Not only the overall consumption per year is required, but also the consumptions per

month, for the current year and for the previous one. This info is needed for the

calculation of the MRP parameters, since we need to know if the consumption is

constant per month or has peaks depending on the season.

By clicking on the material number, the user is able to access to the transaction

MMBE (stock overview).

6. INVENTORY STORAGE LOCATION TAB:

The following storage information is provided for each storage location in which a

material is stored. Both own stock and consignment stock quantities are shown:

● Unrestricted own stock

● Quality inspection stock

● Restricted-use stock

● Blocked stock

EBM Blueprint template – Functional Design - Report 28/4

3

EBM Functional Design – Inventory Management Cockpit

Reporting Display Structure:

Field Positi Data Data

Length Short Description

name on element Type

WERKS 1 WERKS_D CHAR 4 Plant

MATNR 2 MATNR CHAR 18 Material Number

LGORT 3 LGORT_D CHAR 4 Storage Location

LGPBE 4 LGPBE CHAR 10 Storage Bin

MAKTX 5 MAKTX CHAR 40 Material Description (Short Text)

MEINS 6 MEINS UNIT 3 Base Unit of Measure

LABST 7 LABST QUAN 13 Valuated Unrestricted-Use Stock

INSME 8 INSME QUAN 13 Stock in Quality Inspection

EINME 9 EINME QUAN 13 Total Stock of All Restricted Batches

SPEME 10 SPEME QUAN 13 Blocked Stock

KLABS 11 KLABS QUAN 13 Unrestricted-Use Consignment Stock

KINSM 12 KINSM QUAN 13 Consignment Stock in Quality Inspection

KEINM 13 KEINM QUAN 13 Restricted-Use Consignment Stock

KSPEM 14 KSPEM QUAN 13 Blocked Consignment Stock

LVORM_ LVOMA CHAR 1 Flag Material for Deletion at Client Level

15

MARA

LVORM 16 LVOWK CHAR 1 Flag Material for Deletion at Plant Level

LVORM_ LVOLG CHAR 1 Flag Material for Deletion at Storage

17

MARD Location Level

NOTE: If a storage location has been flagged for deletion for a material but it still

contains stock, then it will be displayed on the report. However, if a storage location

has been flagged for deletion and no stock exists, then it will not be displayed on the

report.

By clicking on the material number, the user is able to access to the transaction

MMBE (stock overview).

7. WAREHOUSE MANAGEMENT STORAGE DATA TAB:

This tab must be removed for EMEA because the Warehouse Management (WM)

module is not used anymore.

7. DATA MERGE TAB (Inventory + MRP):

New tab that must be added for EMEA region.

EBM Blueprint template – Functional Design - Report 29/4

3

EBM Functional Design – Inventory Management Cockpit

It must contain all the columns of the tabs “Basic and MRP” and “Inventory”.

It has been requested by the users to be able to download to an excel file all the

relevant information that is needed to analyze and determine the MRP parameters of

the materials (basic data + MRP data + inventory data).

Without this tab, the users would need to download the info from two different tabs

and then apply formulas in excel to put all the info together, so it will save quite a lot

of time to the end users.

Reporting Display Structure:

Posit Data Len

Field name Data element gth

Short Description

ion Type

BWKEY 1 BWKEY CHAR 4 Valuation Area

MATNR 2 MATNR CHAR 18 Material Number

BWTAR 3 BWTAR_D CHAR 10 Valuation Type

MAKTX 4 MAKTX CHAR 40 Material Description (Short Text)

MTART 4 MTART CHAR 4 Material Type

MEINS 5 MEINS UNIT 3 Base Unit of Measure

MATKL 6 MATKL CHAR 9 Material Group

MMSTA 7 MMSTA CHAR 2 Plant-Specific Material Status

MTSTB 8 MTSTB CHAR 25 Description of material status

MAABC 9 MAABC CHAR 1 ABC Indicator

DISPO 10 DISPO CHAR 3 MRP Controller (Materials Planner)

DISGR 11 DISGR CHAR 4 MRP Group

DISMM 12 DISMM CHAR 2 MRP Type

MINBE 13 MINBE QUAN 13 Reorder Point

DISLS 14 DISLS CHAR 2 Lot size (materials planning)

BSTMA 15 BSTMA QUAN 13 Maximum Lot Size

BSTMI 16 BSTMI QUAN 13 Minimum Lot Size

BSTFE 17 BSTFE QUAN 13 Fixed lot size

EISBE 18 EISBE QUAN 13 Safety Stock

MABST 19 MABST QUAN 13 Maximum stock level

PLIFZ 20 PLIFZ DEC 3 Planned Delivery Time in Days

WEBAZ WEBAZ DEC 3 Goods Receipt Processing Time in

21

Days

BOMLK 22 ZZBOMLK CHAR 1 Material assigned to Equipment

BKLAS 5 BKLAS CHAR 4 Valuation Class

EBM Blueprint template – Functional Design - Report 30/4

3

EBM Functional Design – Inventory Management Cockpit

TOT_STOCK ZZMM_INVENT_TOT QUAN 13 Total Stock

8 _STOCK

LBKUM 9 LBKUM QUAN 13 Total Valuated Stock

HIGH_STOCK ZZMM_INVENT_HIGH QUAN 13 High Stock

6 _STOCK

OVERSTK 7 ZZOVERSTK CURR 13 OverStock

VPRSV 10 VPRSV CHAR 1 Price Control Indicator

VERPR 11 VERPR CURR 11 Mov.Average Price/Periodic Unit Price

PEINH 12 PEINH DEC 5 Price Unit

SALK3 13 SALK3 CURR 13 Value of Total Valuated Stock

SLABS 14 KLABS QUAN 13 Unrestricted-Use Consignment Stock

ZPTGI 15 ZZMM_INVENT_PTGI QUAN 13 Previous Year Total G/I

ZCTGI 16 ZZMM_INVENT_CTGI QUAN 13 Current Year Total G/I

ZPLGI 17 ZZMM_INVENT_PLGI QUAN 13 Previous Year Largest G/I

ZCLGI 18 ZZMM_INVENT_CLGI QUAN 13 Current Year Largest G/I

ZPSGI 19 ZZMM_INVENT_PSGI QUAN 13 Previous Year Smallest G/I

ZCSGI 20 ZZCSGI QUAN 13 Current Year Smallest G/I

ZPAGI 21 ZZPAGI QUAN 13 Previous Year Average G/I

ZCAGI 22 ZZCAGI QUAN 13 Current Year Average G/I

ZLGI 23 ZZMM_INVENT_LGI DATS 8 Last G/I (Date)

ZLGR 24 ZZMM_INVENT_LGR DATS 8 Last G/R (Date)

SPECIAL_MOV ZZMM_INVENT_SPE CHAR 1 Material Transfer (309)

25 CIAL_MOV

CONSUM01 26 ZZCONSUM01 QUAN 13 G/I Period 01

CONSUM02 27 ZZCONSUM02 QUAN 13 G/I Period 02

CONSUM03 28 ZZCONSUM03 QUAN 13 G/I Period 03

CONSUM04 29 ZZCONSUM04 QUAN 13 G/I Period 04

CONSUM05 30 ZZCONSUM05 QUAN 13 G/I Period 05

CONSUM06 31 ZZCONSUM06 QUAN 13 G/I Period 06

CONSUM07 32 ZZCONSUM07 QUAN 13 G/I Period 07

CONSUM08 33 ZZCONSUM08 QUAN 13 G/I Period 08

CONSUM09 34 ZZCONSUM09 QUAN 13 G/I Period 09

CONSUM10 35 ZZCONSUM10 QUAN 13 G/I Period 10

CONSUM11 36 ZZCONSUM11 QUAN 13 G/I Period 11

CONSUM12 37 ZZCONSUM12 QUAN 13 G/I Period 12

CONSUM01P 38 ZZCONSUM01P QUAN 13 G/I Period 01 Previous Year

CONSUM02P 39 ZZCONSUM02P QUAN 13 G/I Period 02 Previous Year

CONSUM03P 40 ZZCONSUM03P QUAN 13 G/I Period 03 Previous Year

CONSUM04P 41 ZZCONSUM04P QUAN 13 G/I Period 04 Previous Year

CONSUM05P 42 ZZCONSUM05P QUAN 13 G/I Period 05 Previous Year

CONSUM06P 43 ZZCONSUM06P QUAN 13 G/I Period 06 Previous Year

CONSUM07P 44 ZZCONSUM07P QUAN 13 G/I Period 07 Previous Year

CONSUM08P 45 ZZCONSUM08P QUAN 13 G/I Period 08 Previous Year

CONSUM09P 46 ZZCONSUM09P QUAN 13 G/I Period 09 Previous Year

CONSUM10P 47 ZZCONSUM10P QUAN 13 G/I Period 10 Previous Year

CONSUM11P 48 ZZCONSUM11P QUAN 13 G/I Period 11 Previous Year

CONSUM12P 49 ZZCONSUM12P QUAN 13 G/I Period 12 Previous Year

BISMT 23 BISMT CHAR 18 Old material number

EBM Blueprint template – Functional Design - Report 31/4

3

EBM Functional Design – Inventory Management Cockpit

ERSDA 24 ERSDA DATS 8 Created On

LVORM_MAR 25 LVOMA CHAR 1 Flag Material for Deletion at Client

A Level

LVORM 26 LVOWK CHAR 1 Flag Material for Deletion at Plant

Level

LIQDT 27 LIQDT DATS 8 Deletion date

ZMAKTX_NC 30 ZMAKTX_NC CHAR 40 Material Description (Naming

Convention)

By clicking on the material number, the user is able to access to the transaction

MMBE (stock overview).

4.1.6 General report functions

Updating Inventory Data:

Every night, an updating program runs to update the Inventory data (C.Y.T G/I, C.Y.L

G/I etc.) in a table, in order to improve the performance of the report.

It ensures that the report is accurate as of the end of the previous day.

However, you can update this data at anytime from the Basic and MRP tab by using

the button (“ZINV” in the NASC program).

First you must select the materials you wish to update.

You can select individual materials by clicking on the to the left of each line (hold

CTRL down to select multiple materials).

Or you can select all materials by clicking on the at the top left of the data grid

(clicking it again will deselect all).

After selecting materials, click on . The data on all tabs of the

report will be updated for the chosen materials.

EBM Blueprint template – Functional Design - Report 32/4

3

EBM Functional Design – Inventory Management Cockpit

ENHANCEMENT v3.0

● Capitalizable spare part to be taken in account in Inventory and Merge tabs:

As is fields key in Inventory Data report are Valuation Area, material, and valuation

type, with the modification also WBS (project on stock) where the stock is allocated

should to be taken in account.

As an example in PR1 system for 2012 material 30012429 now appear

In the future should appear a new column project on stock with the stock

value

Val Area Material Val. Type Project on Stock Total Stock

EBM Blueprint template – Functional Design - Report 33/4

3

EBM Functional Design – Inventory Management Cockpit

F102 30012429 N 0

R 0

U 0

N F102-T000-001-01 1

Materials can have or not valuation type independently of project on stock

Material can have several project on stocks under the same valuation type and also if

the material don’t have valuation type.

For some of the rest of the field of the tab , the value should we calculated based on

this new value (some of them are not project on stock dependant).

Same should apply for Data Merge tab.

● Material W/O BOM tab enhancement

Actually the report is showing material that doesn’t belong to an Equipment BOM.TO

BE should be show the material but also if the material has been issue (based on the

GI field selection criteria) should show the material document (so the same material

will appear in several lines, one per material document). Another column should be

added indicating the order (account assignment ;order number) if not order number

exits leave it blank. In case than order number exist two new columns should to be

populated (FL and Equipment of the order)

Instead of adding new columns in Material W/O BOM tab is possible to create

another tab with this functionality. (depend on development difficulty asset)

Example in DR1 300 for Capitalizable Spare Parts

Material 30000021

EBM Blueprint template – Functional Design - Report 34/4

3

EBM Functional Design – Inventory Management Cockpit

Example for Material W/O BOM

The system take all this materials

EBM Blueprint template – Functional Design - Report 35/4

3

EBM Functional Design – Inventory Management Cockpit

But only this ones has been used in Plant maintenance orders

4.2 Process Flow Diagram

N/A

4.3 Initiating Process / Transaction / Program

Described in section 4.1

4.4 Selection Criteria

Described in section 4.1

4.5 Report Layout

Described in section 4.1

EBM Blueprint template – Functional Design - Report 36/4

3

EBM Functional Design – Inventory Management Cockpit

4.6 Report Fields

Described in section 4.1

4.7 Main Heading

Described in section 4.1

4.8 Sub Heading

Described in section 4.1

4.9 Totalling

Described in section 4.1

4.10 Sorting

Described in section 4.1

4.11 Page Break

Described in section 4.1

4.12 Stationery

Described in section 4.1

4.13 Existing Sample Reports

Described in section 4.1

4.14 Processing and Operational Considerations

4.14.1 Performance

See section 4.1.6

4.14.2 Processing Type

Real time

4.14.3 Batch Requirements

N/A

4.14.4 Expected Transaction Volumes

Tbc

4.14.5 Output Type

Described in section 4.1

EBM Blueprint template – Functional Design - Report 37/4

3

EBM Functional Design – Inventory Management Cockpit

4.14.6 Error Handling

N/A

4.15 Change Management Requirements

N/A

EBM Blueprint template – Functional Design - Report 38/4

3

EBM Functional Design – Inventory Management Cockpit

5 Testing data for developer DR300

Case1:

Material : 1100228 plant: M118 MAVG price : 1€ in Ztable

Waiting result in ZMM003 transaction ( same as MB52 with enhacement for AFR)

Case2:

Material : 1100490 plant: M118 MAVG price : 1.853,13 € in Ztable

EBM Blueprint template – Functional Design - Report 39/4

3

EBM Functional Design – Inventory Management Cockpit

Waiting result in ZMM003 transaction ( same as MB52 with enhacement for AFR)

5.1 Key Business Test Conditions

To be completed once the testing system is installed

ID Condition Expected results Cycle Ref.

EBM Blueprint template – Functional Design - Report 40/4

3

EBM Functional Design – Inventory Management Cockpit

5.2 Technical Test Conditions

To be completed once the testing system is installed

ID Condition Expected results Cycle Ref.

5.3 Risk and Controls Test Conditions

N/A

ID Condition Expected results Cycle Ref.

5.4 Testing Considerations/Dependencies

N/A

6 Design Alternatives

N/A

7 Outstanding Issues

Issue Description Assigned To Status Impact Resolution

Number

EBM Blueprint template – Functional Design - Report 41/4

3

EBM Functional Design – Inventory Management Cockpit

8 Appendix

8.1 EBM IT Design Principles

Interfaces Principles:

- Unique interface design for: data flow, technical requirements, leading system

- SAP is the lead system for master data.

- All interfaces connect over PI system and not directly to the SAP systems

- Security considerations: insecure technologies like FTP are not to be used

anymore.

- Use of common interface technologies: Principal technology is XML over web

service.

- Sustainability / Fit for future: Legacy systems (like Business Connector for

middle ware) are not to be used anymore.

- Any interface that cannot comply to above principles has to be analyzed and

treated as exception.

SAP Standard:

- Use of standards: keep SAP standards in all areas where / if possible to

ensure we get full SAP support (e.g. transport workflow solution).

- Use latest functionality. Just because it worked in the old version does not

mean we have to replicate it exactly in the same way.

- Avoid system developments where possible and challenge the requirements

(RICEFW – Custom reports, interfaces, data conversions, system extensions;

e.g. new t-codes, custom forms, and workflow).

- If a program needs to be developed avoid “hard coding”.

- User-exits use to be avoided whenever possible. If and when they are used

promote single management across countries and segments.

- Use of common language strategy for all systems (e.g. activate local

language, but do not install libraries).

- Simplification: keep infrastructure components and their interconnection

simple and secure.

- Support packages strategy focused on legal and regulatory requirements (eg

for HRM and B2R).

- Release management strategy focused on maintaining the integrity of EBM

principles.

- Develop a robust technical SAP landscape and management to minimize

disruption to already live clusters in EBM environment during Rollouts.

Solution Design:

- Use SAP products whenever stated requirements can be fulfilled with the

corresponding SAP solution (strategic platform).

EBM Blueprint template – Functional Design - Report 42/4

3

EBM Functional Design – Inventory Management Cockpit

- Use solutions that are aligned with Holcim global strategy / CIT strategy

(where possible/available).

- Use as few solutions as possible for common functionalities / functionality

groups (e.g. for the doc mgmt. / archiving side).

- Implement solutions and corresponding Service Levels that are aligned with

actual business risks / continuity requirements. Do not gold-plate solutions.

EBM Blueprint template – Functional Design - Report 43/4

3

Das könnte Ihnen auch gefallen

- Remittance AdviceDokument30 SeitenRemittance AdviceSureshNoch keine Bewertungen

- Refinery ProcessDokument150 SeitenRefinery ProcessJennifer French100% (4)

- FS - MM-RP-001 - Quotation Comparison Statement - v0.3Dokument12 SeitenFS - MM-RP-001 - Quotation Comparison Statement - v0.3SUBHOJIT BANERJEENoch keine Bewertungen

- Process Design Document - V 30 30 03logistical ProductionDokument21 SeitenProcess Design Document - V 30 30 03logistical ProductionPramod ShettyNoch keine Bewertungen

- RFQ ComparisonDokument37 SeitenRFQ ComparisonGurinder Singh Singh GurinderNoch keine Bewertungen

- FC0007 ETDesign Cuenta16 17Dokument8 SeitenFC0007 ETDesign Cuenta16 17Kenny Junior Mercedes RojasNoch keine Bewertungen

- SAPScript Picking ListDokument13 SeitenSAPScript Picking ListSanjay PNoch keine Bewertungen

- Somasundaram Vedarathinam: E-Mail: MobileDokument5 SeitenSomasundaram Vedarathinam: E-Mail: Mobilesomujaz100% (2)

- Functional Specification TemplateDokument13 SeitenFunctional Specification TemplateSantosh BeheraNoch keine Bewertungen

- Cold Chain in PharmaDokument4 SeitenCold Chain in PharmaChandan Ahire100% (1)

- Inventory Reorder MethodsDokument26 SeitenInventory Reorder MethodsmragarwalNoch keine Bewertungen

- FS For Purchase Order OutputDokument23 SeitenFS For Purchase Order OutputSai Vaishnavi saddapalli100% (1)

- Concrete I Study GuideDokument8 SeitenConcrete I Study GuidecwcarusoNoch keine Bewertungen

- Functional Specification: FS - FI - VAT - Profit Center Jan - 18Dokument7 SeitenFunctional Specification: FS - FI - VAT - Profit Center Jan - 18Anonymous 0SLsR9Noch keine Bewertungen

- Manual On Civil Aviation Jet Fuel Supply ICAODokument46 SeitenManual On Civil Aviation Jet Fuel Supply ICAOtiualbert8729100% (6)

- Functional Spec Material Ageing ReportDokument8 SeitenFunctional Spec Material Ageing ReportKumar Ajit0% (1)

- Report - Vendor Payable Data ProgramDokument22 SeitenReport - Vendor Payable Data ProgramKishore Krishna100% (1)

- FS - MM-En-023 - Service PO For Transporters - Contractors and Other Overheads Pricing - v0.1Dokument8 SeitenFS - MM-En-023 - Service PO For Transporters - Contractors and Other Overheads Pricing - v0.1SUBHOJIT BANERJEENoch keine Bewertungen

- ENHC0039939 MB5L Enhancement FunctionalSpec v2Dokument17 SeitenENHC0039939 MB5L Enhancement FunctionalSpec v2Kush BhattNoch keine Bewertungen

- Functional SpecificationDokument4 SeitenFunctional SpecificationKirola SanjayNoch keine Bewertungen

- New Extractors For Transactional Data - V1Dokument15 SeitenNew Extractors For Transactional Data - V1geneNoch keine Bewertungen

- Continuous MinersDokument8 SeitenContinuous MinerssergioNoch keine Bewertungen

- Curtain WallsDokument23 SeitenCurtain Wallstwinkle4545Noch keine Bewertungen

- ITIL® Guide to Software and IT Asset Management - Second EditionVon EverandITIL® Guide to Software and IT Asset Management - Second EditionBewertung: 1 von 5 Sternen1/5 (1)

- Integrating Lean Thinking Into ISO 9001 - A First GuidelineDokument25 SeitenIntegrating Lean Thinking Into ISO 9001 - A First GuidelineakanddevNoch keine Bewertungen

- MM - Down Payment RequestDokument8 SeitenMM - Down Payment RequestSUBHOJIT BANERJEENoch keine Bewertungen

- Functional Specification: Specification No: Issue Date (Dd/mm/yyyy)Dokument8 SeitenFunctional Specification: Specification No: Issue Date (Dd/mm/yyyy)Gaurav Kumar MishraNoch keine Bewertungen

- 400.05.PM.03 - Predictive Maintenance - V - 0.1Dokument39 Seiten400.05.PM.03 - Predictive Maintenance - V - 0.1Neeraj TiwariNoch keine Bewertungen

- Phoenix - S4HANA - AP353 FD Report-RMC005-Report Daily Equipment Performance v1.00-xDokument36 SeitenPhoenix - S4HANA - AP353 FD Report-RMC005-Report Daily Equipment Performance v1.00-xsueb suebNoch keine Bewertungen

- GTCL - FS - RFI124-3 - MIS Income and Expenses Statement - 0.03Dokument15 SeitenGTCL - FS - RFI124-3 - MIS Income and Expenses Statement - 0.03MonalisaNoch keine Bewertungen

- MM - GR Blocked Stock ReportDokument9 SeitenMM - GR Blocked Stock ReportSUBHOJIT BANERJEENoch keine Bewertungen

- Functional Specification: Bajaj Power Generation BusinessDokument5 SeitenFunctional Specification: Bajaj Power Generation BusinessBipul KumarNoch keine Bewertungen

- Section 1: Document Information: SCM Report Master Data ZMM - Mat - VenDokument3 SeitenSection 1: Document Information: SCM Report Master Data ZMM - Mat - VenRicky リキNoch keine Bewertungen

- Mass Cahnge Enhancment TRDokument11 SeitenMass Cahnge Enhancment TRmaterial4abapNoch keine Bewertungen

- BRS Version 1.5Dokument11 SeitenBRS Version 1.5Dillip ParidaNoch keine Bewertungen

- PTT BRS Performance Manager v1.0Dokument43 SeitenPTT BRS Performance Manager v1.0De Firsta EpynoyaNoch keine Bewertungen

- RP50130 RTC 475 FS RP Production Tracking ReportDokument16 SeitenRP50130 RTC 475 FS RP Production Tracking Reportravi4920Noch keine Bewertungen

- FSD Ats Custom Form v1.0Dokument17 SeitenFSD Ats Custom Form v1.0Vinay ChughNoch keine Bewertungen

- Production Team 4/18/2011 Draft Specification, Development, Report, M-080, Sister ProductDokument26 SeitenProduction Team 4/18/2011 Draft Specification, Development, Report, M-080, Sister ProductPraveen KumarNoch keine Bewertungen

- TS1Dokument30 SeitenTS1Rajeeb Lochan SahooNoch keine Bewertungen

- FS-TS - SERP03 Email Address For Shipping NotificationDokument10 SeitenFS-TS - SERP03 Email Address For Shipping NotificationNguyễn Thành KếtNoch keine Bewertungen

- XXXXX 99999998888Dokument13 SeitenXXXXX 99999998888notion.io.83Noch keine Bewertungen

- Functional/Technical Specifications For: Inspection Vs Dispatch ReportDokument11 SeitenFunctional/Technical Specifications For: Inspection Vs Dispatch Reportaagg84Noch keine Bewertungen

- MD050 - GL - GENERATE GL Voucher Num - v1.0Dokument16 SeitenMD050 - GL - GENERATE GL Voucher Num - v1.0tran dangNoch keine Bewertungen

- 3 - IM - F - 004 - Customer Shipping Label FormDokument8 Seiten3 - IM - F - 004 - Customer Shipping Label FormAvinash MalladhiNoch keine Bewertungen

- Roject Nity: Project Unity Functional Specification - Process Order ConfirmationDokument32 SeitenRoject Nity: Project Unity Functional Specification - Process Order ConfirmationsowjanyaNoch keine Bewertungen

- Phoenix - S4HANA - AP353 FD Report-RMC004-Report Production All BUMA v1.00-xDokument11 SeitenPhoenix - S4HANA - AP353 FD Report-RMC004-Report Production All BUMA v1.00-xsueb suebNoch keine Bewertungen

- Unctional AND Echnical PecificationDokument26 SeitenUnctional AND Echnical PecificationPraveen KumarNoch keine Bewertungen

- APQP-PPAP (EN) - Feb 09Dokument34 SeitenAPQP-PPAP (EN) - Feb 09Fernando NavascuesNoch keine Bewertungen

- Application Function ServerDokument24 SeitenApplication Function ServerSurendar BheemreddyNoch keine Bewertungen

- RPT - OTC - Freight Cost App - V4Dokument21 SeitenRPT - OTC - Freight Cost App - V4ASHUTOSH MISHRANoch keine Bewertungen

- Functional Specification: LCNC Report For MaterialDokument7 SeitenFunctional Specification: LCNC Report For MaterialSUBHOJIT BANERJEENoch keine Bewertungen

- Roject Nity: Project Unity Functional Specification - Process Order ReleaseDokument38 SeitenRoject Nity: Project Unity Functional Specification - Process Order ReleasesowjanyaNoch keine Bewertungen

- CS Onsite Service ConfigDokument11 SeitenCS Onsite Service ConfigImtiaz KhanNoch keine Bewertungen

- SAP EAM Add-On For MRO 3.0 by HCL For SAP S4HANA 1709 EWI - UI5 - APP - Feature Scope DescriptionDokument95 SeitenSAP EAM Add-On For MRO 3.0 by HCL For SAP S4HANA 1709 EWI - UI5 - APP - Feature Scope DescriptionlymacsauokNoch keine Bewertungen

- FS-TS - SERP02 Drop Ship Reference FieldDokument11 SeitenFS-TS - SERP02 Drop Ship Reference FieldNguyễn Thành KếtNoch keine Bewertungen

- Part 3 18 IFSF POS To FEP V1 Interface Specification v1.53Dokument219 SeitenPart 3 18 IFSF POS To FEP V1 Interface Specification v1.53toovNoch keine Bewertungen

- TS - GT - Oracle India - Technical Spec - Integration - INT002Dokument28 SeitenTS - GT - Oracle India - Technical Spec - Integration - INT002Deepak KatiyarNoch keine Bewertungen

- FS - MM - Vendor Portal - Post Invoice DetailsDokument15 SeitenFS - MM - Vendor Portal - Post Invoice DetailsSUBHOJIT BANERJEENoch keine Bewertungen

- FC0007 ETDesign 0319Dokument9 SeitenFC0007 ETDesign 0319Kenny Junior Mercedes RojasNoch keine Bewertungen

- FS - EWM - Gate Pass Details To Vendor PortalDokument10 SeitenFS - EWM - Gate Pass Details To Vendor PortalSUBHOJIT BANERJEENoch keine Bewertungen

- MSNL FS PP Routing UploadDokument10 SeitenMSNL FS PP Routing UploadSandeep Kumar PraharajNoch keine Bewertungen

- Functional Specification DocumentDokument6 SeitenFunctional Specification DocumentJayabalaji GNoch keine Bewertungen

- Administer Product Master 4gDokument50 SeitenAdminister Product Master 4gAbhishek kumarNoch keine Bewertungen

- Detailed Performance Test Plan ExampleDokument13 SeitenDetailed Performance Test Plan Exampleameer143Noch keine Bewertungen

- Functional Specification: Bajaj Power Generation BusinessDokument5 SeitenFunctional Specification: Bajaj Power Generation BusinessBipul KumarNoch keine Bewertungen

- BPS6 - Report Engine Scalability and PerformanceDokument5 SeitenBPS6 - Report Engine Scalability and PerformanceLilyNoch keine Bewertungen

- HandbookDokument31 SeitenHandbookfrkmrd7955Noch keine Bewertungen

- Using Aspect-Oriented Programming for Trustworthy Software DevelopmentVon EverandUsing Aspect-Oriented Programming for Trustworthy Software DevelopmentBewertung: 3 von 5 Sternen3/5 (1)

- Kamen Steel Industries Sdn. BHD.: CertificateDokument6 SeitenKamen Steel Industries Sdn. BHD.: Certificatebiik0076153Noch keine Bewertungen

- Hammer MillDokument11 SeitenHammer MillLanre AfolabiNoch keine Bewertungen

- 2.processing Andd Manufacturing Industries in ZambaDokument2 Seiten2.processing Andd Manufacturing Industries in ZambaProf Samuel KashinaNoch keine Bewertungen

- FRP Grating ApplicationsDokument2 SeitenFRP Grating ApplicationsHindustan Fibre TechNoch keine Bewertungen

- Bulk Deformation ProcessDokument67 SeitenBulk Deformation ProcessJith ViswaNoch keine Bewertungen

- TM Egger Schichtstoff CPL HPL enDokument3 SeitenTM Egger Schichtstoff CPL HPL endarshak444Noch keine Bewertungen

- Acrylic DrillingDokument5 SeitenAcrylic DrillingBui Hoang DucNoch keine Bewertungen

- LPG Cylinder Market Player - Overview (Bangladesh)Dokument5 SeitenLPG Cylinder Market Player - Overview (Bangladesh)ABID REZA KhanNoch keine Bewertungen

- Is 6598 - 1972 Specification For Cellular Concrete For Thermal InsulationDokument12 SeitenIs 6598 - 1972 Specification For Cellular Concrete For Thermal InsulationPrapa KaranNoch keine Bewertungen

- Pet Market OjooDokument14 SeitenPet Market OjooJuan Pablo Fajardo SánchezNoch keine Bewertungen

- 2008 Abstract Booklet 9-12-08.FINALDokument63 Seiten2008 Abstract Booklet 9-12-08.FINALgladiolus86Noch keine Bewertungen

- CostconceptsDokument20 SeitenCostconceptsShobi DionelaNoch keine Bewertungen

- DMV5R5Dokument258 SeitenDMV5R5Pradeep MahalikNoch keine Bewertungen

- Arcelormittal CladDokument7 SeitenArcelormittal CladARNOUXNoch keine Bewertungen

- Porsche CasestudyDokument2 SeitenPorsche CasestudyAlexandra BotezatuNoch keine Bewertungen

- Bunshah - Mechanical Properties of Thin FilmsDokument10 SeitenBunshah - Mechanical Properties of Thin FilmsJulien MartegoutteNoch keine Bewertungen

- Jit PresentationDokument45 SeitenJit PresentationJasspreet Singh SraNoch keine Bewertungen

- 127FT L 015 FrictionDokument4 Seiten127FT L 015 FrictionMarijan JakovljevicNoch keine Bewertungen

- Design and Analysis of A Concrete Modular Housing System Constructed With 3D PanelsDokument80 SeitenDesign and Analysis of A Concrete Modular Housing System Constructed With 3D PanelsNeven Ahmed HassanNoch keine Bewertungen

- Types of CementDokument5 SeitenTypes of CementPeniel LuzonNoch keine Bewertungen

- Draft: Mechanical AssemblyDokument22 SeitenDraft: Mechanical Assemblysarath6725Noch keine Bewertungen