Beruflich Dokumente

Kultur Dokumente

Etd820s Lab 1 2018

Hochgeladen von

TimoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Etd820s Lab 1 2018

Hochgeladen von

TimoCopyright:

Verfügbare Formate

ETD820S:

Electric Drives 415

Lab 1: Dynamic Simulation of a GTO Fed DC Motor Drive.

Objectives

To serve as an introduction to the Matlab’s drives library

To model and simulate a gto fed DC motor drive in Matlab/Simulink.

To investigate the response of the drive due to a change in the reference speed and load torque.

To obtain and display visual Torque and speed measurements in Matlab/Simulink.

Introduction & background theory

Simulink is a block diagram environment for multi-domain simulation and Model-Based Design. It supports

system-level design, simulation, automatic code generation, and continuous test and verification of embedded

systems. Simulink provides a graphical editor, customisable block libraries, and solvers for modelling and

simulating dynamic systems. It is integrated with MATLAB, enabling you to incorporate MATLAB algorithms

into models and export simulation results to MATLAB for further analysis.

Drives are found in everyday life applications such as drills, elevators, fans, robotics and many other systems

that require speed/motion control. Drives that use electric motors as their prime movers are known as

electrical drives. As such, in this experiment, you will build and simulate a dc motor drive system.

Procedure

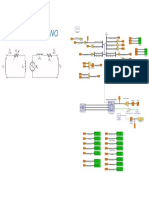

1. Open a new window and give it a name of your choice. Using Simulink, build a subsystem of the

following figure and name it ‘Current Controller’. Set the relay’s switch on point to h/2 and switch off

point to -h/2. Left click the controller and select mask subsystem and in the parameters column define

the hysteresis band and name it h. Now, double click the masked subsystem and set h to 2 A.

2

Ia

1

g

1 Relay

Iref

Figure 1 Current Controller

ETD820S Lab 1 Penti & P. Kumar Page 1

2. In the same window, build a subsystem of figure 2 and name it ‘Speed Controller’. Left click the

controller and select mask subsystem and in the parameters column define Kp, Ki and the current

limit. Double click the masked subsystem and set Kp to 1.6, Ki to 16 and current limit to 30 A.

Kp

1

1

Wm 1

Ki Iref

s

2

Wref

Figure 2 Speed Controller

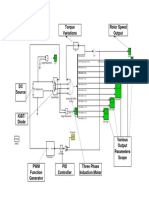

3. After you have built the two subsystems, build the main drive model shown in figure 3 and integrate

the current and speed controllers into the main model as shown below.

<Speed wm (rad/s)>

Speed Controller

Current Controller

Wm

Iref 120

Iref

Wref Ref Speed (rad /s)

g

Ia

Ref Speed

Selection Speed Step

<Armature current ia (A)>

Filter

<Electrical torque Te (n m)>

Scope

+ Torque (N.M)

v

- 5

Vd

Step Torque 5HP /240 V

Torque DC Motor

Selection

TL m

LS

g

k A+ dc A-

Gto F+ F-

Continuous 280 V Free wheeling

Vdc Diode

240 V

Vf

Figure 3 GTO fed dc motor drive model

ETD820S Lab 1 Penti & P. Kumar Page 2

4. Set the torque step as follows: Initial Value 5, Final value 50, sample time 0 and step time 1.2s.

5. Set the speed step as follows: step time 0.5, initial value 120, final value 200, and sample time 0.

Circuit Description

The DC motor is fed by the DC source through a chopper which consists of GTO thyristor and free-wheeling

diode D1. The motor drives a mechanical load characterised by inertia J, friction coefficient B (internal

parameters), and load torque TL. The hysteresis current controller compares the sensed current with the

reference and generates the trigger signal for the GTO thyristor to force the motor current to follow the

reference. The speed control loop uses a proportional-integral controller which produces the reference for the

current loop. Current and Voltage Measurement blocks provide signals for visualization purpose.

Simulation

Motor starting

Start the simulation. Observe the motor current, voltage, speed and torque during the starting on the scope. At

the end of the simulation time, the system has reached its steady-state operation point.

Response to a change in reference speed and load torque

The initial conditions to start with wm = 120 rad/s and TL = 5 N.m has been saved in the speed and torque

steps respectively.

Now, double click the Manual Switch block (Ref speed selection) to switch from the constant "Ref.

Speed (rad/s)” and restart the simulation and observe the drive’s response to successive changes in

speed reference (Save the scope graphs).

Set it back to constant Ref speed and double click the Manual Switch block (Torque selection) to

switch from the constant "Torque (N.m)” and Restart the simulation and observe the drive response to

successive changes in load torque (Save the scope graphs).

Finally, switch both of them from the Ref speed and torque selection points (simultaneously), restart

the simulation and observe the drive’s response to successive changes in speed reference and load

torque (Save the scope graphs).

Lab 1 Report Instructions

General rules about lab reporting (applicable to all following lab reports of this semester):

1. Please use a word processor to typeset your report.

2. Please write the following info on the front page of your report:

Course code & name

Experiment number & name

Your Programme of study

Your name and student ID

3. Your report should include at least the following sections:

Objectives

Introduction

Simulation results

ETD820S Lab 1 Penti & P. Kumar

Page 3

Analysis of results – Point out the effects of changing the Ref speed on torque and armature current,

voltage & the effects of change in load torque on the speed, armature current & voltage.

Conclusion

Helpful Tips

Q: How to copy the circuit diagram from Matlab/Simulink to MS Word?

A: Select the diagram using copy (Ctrl-C) and paste (Ctrl-V) into MS Word.

Q: How to copy output graph from Matlab/Simulink MS Word?

A: In the scope output window, copy (Ctrl-Print screen) and paste (Ctrl-V) into MS Word.

ETD820S Lab 1 Penti & P. Kumar Page 4

Das könnte Ihnen auch gefallen

- Torque Variations Rotor Speed Output: Three - Phase Asynchronous MachineDokument1 SeiteTorque Variations Rotor Speed Output: Three - Phase Asynchronous MachineJaved Ahmed LaghariNoch keine Bewertungen

- Lab 3 Field Speed Control of DC Motors: 1. ObjectiveDokument7 SeitenLab 3 Field Speed Control of DC Motors: 1. ObjectiveErgin ÖzdikicioğluNoch keine Bewertungen

- Gearless Mill Drive - Operation and Maintenance: CycloconverterDokument21 SeitenGearless Mill Drive - Operation and Maintenance: CycloconverterIrving Dirzo Carrillo100% (1)

- 2018 PI Exam SolutionDokument9 Seiten2018 PI Exam SolutionAhmed AliNoch keine Bewertungen

- Enric Pardo, Mike Staines, Zhenan Jiang, Neil Glasson, Bob BuckleyDokument1 SeiteEnric Pardo, Mike Staines, Zhenan Jiang, Neil Glasson, Bob BuckleymikeNoch keine Bewertungen

- Motor SincronoDokument1 SeiteMotor Sincronosamuel sedanoNoch keine Bewertungen

- Modelling & S Imulation of BLDC Motor Characterstics: 1999 SpeedDokument1 SeiteModelling & S Imulation of BLDC Motor Characterstics: 1999 SpeedTanmay SuryawanshiNoch keine Bewertungen

- Imc 35 MLD Dep Ee Dat 08 r2Dokument4 SeitenImc 35 MLD Dep Ee Dat 08 r2Electrical RadicalNoch keine Bewertungen

- Half BridgeDokument44 SeitenHalf BridgeVenkatesh ShastryNoch keine Bewertungen

- Sourav Dutta: Dynamic Braking Operation of An Induction Motor Using MatlabDokument4 SeitenSourav Dutta: Dynamic Braking Operation of An Induction Motor Using MatlabSourav DuttaNoch keine Bewertungen

- Power Factor Correction: Current Lagging ReactiveDokument4 SeitenPower Factor Correction: Current Lagging ReactiveZubairAfzalNoch keine Bewertungen

- Ew412 - Ew512Dokument2 SeitenEw412 - Ew512Carlos PosadaNoch keine Bewertungen

- Catalogo Servo 1FK7Dokument6 SeitenCatalogo Servo 1FK7José Manuel GonzálezNoch keine Bewertungen

- Relay Coordination Preliminary Report Draft-BDokument4 SeitenRelay Coordination Preliminary Report Draft-Bramesh1950Noch keine Bewertungen

- Product Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsDokument60 SeitenProduct Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsMisko PiskoNoch keine Bewertungen

- A.01 Ac Motors Operation ConceptsDokument11 SeitenA.01 Ac Motors Operation ConceptsRamez YassaNoch keine Bewertungen

- Em Lab 2Dokument22 SeitenEm Lab 2abhishek kolseNoch keine Bewertungen

- Product Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsDokument76 SeitenProduct Catalog & Design Guide: Gas Discharge Tube (GDT) ProductsSantiago BNoch keine Bewertungen

- Turbine-Less Ducted Fan Jet Engine: Subsonic PropulsionDokument25 SeitenTurbine-Less Ducted Fan Jet Engine: Subsonic PropulsionزهديابوانسNoch keine Bewertungen

- DCMT .AnDokument47 SeitenDCMT .AnastridyoungtheoNoch keine Bewertungen

- CTAN160 - 4-20ma Current Loop ControlDokument3 SeitenCTAN160 - 4-20ma Current Loop ControlSam eagle goodNoch keine Bewertungen

- DC MotorsDokument68 SeitenDC MotorsakshatNoch keine Bewertungen

- Sboa 247Dokument5 SeitenSboa 247Surafel DestawNoch keine Bewertungen

- TI Intro To FOCDokument55 SeitenTI Intro To FOCName24122021Noch keine Bewertungen

- InductionGenerator GridConnectedDokument2 SeitenInductionGenerator GridConnectedtemp tempNoch keine Bewertungen

- Instruction Manual & Observation Book: Clrr10-Applied Electrical and Electronics Engineering LaboratoryDokument9 SeitenInstruction Manual & Observation Book: Clrr10-Applied Electrical and Electronics Engineering LaboratoryAditi PatilNoch keine Bewertungen

- LM555 Single Timer: Features DescriptionDokument14 SeitenLM555 Single Timer: Features DescriptionDanilson GasparNoch keine Bewertungen

- Induction Motor DrivesDokument70 SeitenInduction Motor DrivesAshwin Gopinath80% (5)

- AT33 IND Software Most RecentDokument2 SeitenAT33 IND Software Most RecentENRIQUENoch keine Bewertungen

- AT33 IND Software Most RecentDokument2 SeitenAT33 IND Software Most RecentENRIQUENoch keine Bewertungen

- BUCK DC - 5PAPER - Edited 23.10.25Dokument8 SeitenBUCK DC - 5PAPER - Edited 23.10.25doanminhtien030903Noch keine Bewertungen

- Ecma L1221BR3 PD02 05172016Dokument2 SeitenEcma L1221BR3 PD02 05172016Anil JindalNoch keine Bewertungen

- sjpw-t4 Ds enDokument8 Seitensjpw-t4 Ds enPalinda BandaraNoch keine Bewertungen

- 3827-E10-063 - Modulating Control Valve - EDokument6 Seiten3827-E10-063 - Modulating Control Valve - EMohamed Elsaid El ShallNoch keine Bewertungen

- Generator Operation & ControlDokument21 SeitenGenerator Operation & ControlAsep HermanNoch keine Bewertungen

- BrushlessDC BasicsDokument1 SeiteBrushlessDC BasicsJimNoch keine Bewertungen

- Fsd2u2p14 01 PDFDokument1 SeiteFsd2u2p14 01 PDFPhan AnNoch keine Bewertungen

- Fsd2u2p14 01 PDFDokument1 SeiteFsd2u2p14 01 PDFPhan AnNoch keine Bewertungen

- Full Wave Rectifier: Instruction CircuitDokument1 SeiteFull Wave Rectifier: Instruction CircuitAtharv LokhandeNoch keine Bewertungen

- Speed Control of DC MotorDokument8 SeitenSpeed Control of DC MotorsubhamNoch keine Bewertungen

- Electric Motor Drive PDFDokument20 SeitenElectric Motor Drive PDFMoaz ShafiNoch keine Bewertungen

- Tabela Coordenação Tipo 1 Soft Start SMC50Dokument1 SeiteTabela Coordenação Tipo 1 Soft Start SMC50elclopesNoch keine Bewertungen

- Ee 491 Machine 1Dokument30 SeitenEe 491 Machine 1swagato deyNoch keine Bewertungen

- Acs 01Dokument12 SeitenAcs 01satya prakashNoch keine Bewertungen

- ECE461 - Motor Lab - Experiment5 PDFDokument13 SeitenECE461 - Motor Lab - Experiment5 PDFengshimaaNoch keine Bewertungen

- 2019ee30598 Exp 5Dokument6 Seiten2019ee30598 Exp 5Prashant KumarNoch keine Bewertungen

- Is The Time Constant of G: T T P P P T RDokument5 SeitenIs The Time Constant of G: T T P P P T Romer1299Noch keine Bewertungen

- SLA707xM Series: 2-Phase Unipolar Stepper Motor DriverDokument20 SeitenSLA707xM Series: 2-Phase Unipolar Stepper Motor DriverKatherine EsperillaNoch keine Bewertungen

- Lecture DC MachinesDokument40 SeitenLecture DC MachinesPrathap VuyyuruNoch keine Bewertungen

- World's Largest Science, Technology & Medicine Open Access Book PublisherDokument23 SeitenWorld's Largest Science, Technology & Medicine Open Access Book PublisherrahouaNoch keine Bewertungen

- Calculating Size of Transformer and Voltage Drop Due To Starting of Large Size MotorDokument8 SeitenCalculating Size of Transformer and Voltage Drop Due To Starting of Large Size MotorgebreNoch keine Bewertungen

- Solar Cell I-V Cuk ConverterDokument1 SeiteSolar Cell I-V Cuk ConverterKORAKRIT ANANTA-AUOYPORNNoch keine Bewertungen

- FFB 2907 - FairchildDokument13 SeitenFFB 2907 - FairchildStevenNoch keine Bewertungen

- Features: Schottky Barrier DiodeDokument3 SeitenFeatures: Schottky Barrier Diodeahmad sulaimanNoch keine Bewertungen

- L011516 - EMG-10APB Servo MotorDokument3 SeitenL011516 - EMG-10APB Servo MotorReginaldo KrothNoch keine Bewertungen

- Optimize Output Filter On D-CAP2™ For Stability Improvement: Application ReportDokument8 SeitenOptimize Output Filter On D-CAP2™ For Stability Improvement: Application ReportLeonardo SoaresNoch keine Bewertungen

- Relay CalcDokument12 SeitenRelay CalcMadhu Duraichamy100% (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Curriculum Vitae: Personal DetailsDokument2 SeitenCurriculum Vitae: Personal DetailsTimoNoch keine Bewertungen

- Economic AspectsDokument16 SeitenEconomic AspectsTimoNoch keine Bewertungen

- System ProtectionDokument35 SeitenSystem ProtectionTimoNoch keine Bewertungen

- 2 SlideDokument1 Seite2 SlideTimoNoch keine Bewertungen

- ETD 820S HomeworkDokument3 SeitenETD 820S HomeworkTimoNoch keine Bewertungen

- 11ee701 - Solid State Drives: Unit - I - Electric Drives Unit - I - SyllabusDokument2 Seiten11ee701 - Solid State Drives: Unit - I - Electric Drives Unit - I - SyllabusTimoNoch keine Bewertungen

- Speed Control of DC Motor: Lecture-11Dokument5 SeitenSpeed Control of DC Motor: Lecture-11TimoNoch keine Bewertungen

- Atm711s Lab 1Dokument4 SeitenAtm711s Lab 1TimoNoch keine Bewertungen

- Etd820s Lab 3 2018Dokument3 SeitenEtd820s Lab 3 2018TimoNoch keine Bewertungen

- Lecture-9: Load Equalization and Two Mark QuestionsDokument6 SeitenLecture-9: Load Equalization and Two Mark QuestionsTimoNoch keine Bewertungen

- 2013 BAC1100 Test 1Dokument8 Seiten2013 BAC1100 Test 1Timo100% (1)

- Unit-2 DC Drives: DC Motors and Their PerformanceDokument19 SeitenUnit-2 DC Drives: DC Motors and Their PerformanceTimoNoch keine Bewertungen

- CH Egg SolutionsDokument34 SeitenCH Egg SolutionsTimoNoch keine Bewertungen

- Etd820s Lab 2 2018Dokument4 SeitenEtd820s Lab 2 2018TimoNoch keine Bewertungen

- Question 2.21: What Are The Reasons of Using Load Equalisation in The Electric Drive? AnswerDokument1 SeiteQuestion 2.21: What Are The Reasons of Using Load Equalisation in The Electric Drive? AnswerTimoNoch keine Bewertungen

- Homwork - 1Dokument15 SeitenHomwork - 1TimoNoch keine Bewertungen

- Emc711s Electrical Machines 315 Lib Assign-2 May-2017 PaperDokument3 SeitenEmc711s Electrical Machines 315 Lib Assign-2 May-2017 PaperTimoNoch keine Bewertungen

- Introduction To Computer Networking ICN511S: Loini Iiyambo Department of Computer ScienceDokument30 SeitenIntroduction To Computer Networking ICN511S: Loini Iiyambo Department of Computer ScienceTimoNoch keine Bewertungen

- Factors For Power SystemsDokument3 SeitenFactors For Power SystemsTimoNoch keine Bewertungen

- True 63Dokument2 SeitenTrue 63stefanygomezNoch keine Bewertungen

- HT Motors Data SheetDokument3 SeitenHT Motors Data SheetSE ESTNoch keine Bewertungen

- Bridge Design Checklist Rev01Dokument7 SeitenBridge Design Checklist Rev01ingjcmv67% (3)

- Sts Lesson 6Dokument13 SeitenSts Lesson 6Ivy Joy BelzaNoch keine Bewertungen

- Tutorial 5 UpdatedDokument2 SeitenTutorial 5 UpdatedChiraag ChiruNoch keine Bewertungen

- Cs - cp56 64 74 Specalog (Qehq1241)Dokument20 SeitenCs - cp56 64 74 Specalog (Qehq1241)firman manaluNoch keine Bewertungen

- How-To Guide: Transaction Launcher (SAP CRM 7.0) .0Dokument22 SeitenHow-To Guide: Transaction Launcher (SAP CRM 7.0) .0Satish DhondalayNoch keine Bewertungen

- Ansi z245 2 1997Dokument31 SeitenAnsi z245 2 1997camohunter71Noch keine Bewertungen

- Digital Filter DesignDokument102 SeitenDigital Filter Designjaun danielNoch keine Bewertungen

- AssignmentDokument2 SeitenAssignmentPhước ĐặngNoch keine Bewertungen

- Bus & Cycle Signs & MarkingsDokument5 SeitenBus & Cycle Signs & MarkingsDaniel YitbarekNoch keine Bewertungen

- Mohana Krishnan KsDokument2 SeitenMohana Krishnan KsKanna MonishNoch keine Bewertungen

- أثر جودة الخدمة المصرفية الإلكترونية في تقوية العلاقة بين المصرف والزبائن - رمزي طلال حسن الردايدة PDFDokument146 Seitenأثر جودة الخدمة المصرفية الإلكترونية في تقوية العلاقة بين المصرف والزبائن - رمزي طلال حسن الردايدة PDFNezo Qawasmeh100% (1)

- Gold Kacha Flyer 2012Dokument2 SeitenGold Kacha Flyer 2012gustavus1Noch keine Bewertungen

- Husic GuideDokument3 SeitenHusic Guideth1mkNoch keine Bewertungen

- Computer 1Dokument8 SeitenComputer 1marce1909Noch keine Bewertungen

- Global Trends 2030 Preview: Interactive Le MenuDokument5 SeitenGlobal Trends 2030 Preview: Interactive Le MenuOffice of the Director of National Intelligence100% (1)

- Exedy 2015 Sports Clutch Catalog WebDokument80 SeitenExedy 2015 Sports Clutch Catalog WebfjhfjNoch keine Bewertungen

- History Desktop PublishingDokument16 SeitenHistory Desktop PublishingsanchezromanNoch keine Bewertungen

- Shyla Jennings Ebook FinalDokument17 SeitenShyla Jennings Ebook FinalChye Yong HockNoch keine Bewertungen

- IEPE Connector - 2021Dokument2 SeitenIEPE Connector - 2021Nguyen Ngoc TuanNoch keine Bewertungen

- CT ManualDokument543 SeitenCT ManualwindroidNoch keine Bewertungen

- Datapipe Fact SheetDokument1 SeiteDatapipe Fact SheetDeneme Deneme AsNoch keine Bewertungen

- Sewa bill-AED 559Dokument1 SeiteSewa bill-AED 559muhdazarNoch keine Bewertungen

- 2c - Types of Stone, Brick and Block MasonryDokument20 Seiten2c - Types of Stone, Brick and Block MasonryZeeshan ShoukatNoch keine Bewertungen

- User Manual For Online EC With QR Code For Portal Users PDFDokument13 SeitenUser Manual For Online EC With QR Code For Portal Users PDFkp pkNoch keine Bewertungen

- Checklist of E/OHS Activities For Asbestos Management: Name of Publication DateDokument20 SeitenChecklist of E/OHS Activities For Asbestos Management: Name of Publication DateidahssNoch keine Bewertungen

- Case Study ppt11Dokument25 SeitenCase Study ppt11WHATS APP STATUSNoch keine Bewertungen

- Azuma 2015 Metrologia 52 360Dokument17 SeitenAzuma 2015 Metrologia 52 360Rudolf KiraljNoch keine Bewertungen

- How To Draw Circuit DiagramDokument1 SeiteHow To Draw Circuit DiagramSAMARJEETNoch keine Bewertungen