Beruflich Dokumente

Kultur Dokumente

Reinforcing Loaded Steel Compression Members: J. H. Brown

Hochgeladen von

GürelBaltalıOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Reinforcing Loaded Steel Compression Members: J. H. Brown

Hochgeladen von

GürelBaltalıCopyright:

Verfügbare Formate

Reinforcing Loaded Steel

Compression Members

J. H. BROWN

Theoretically, it does not seem plausible that a column column has a post-buckUng capacity after the core has

which is reinforced under load will have the same ultimate failed. The additional capacity wifl be provided by the

capacity as a column reinforced in its unloaded state. Yet stiffness of the reinforcement. This results in a critical col-

there is a tendency to use the allowable stresses for the umn length Lj. The alternate assumption the reinforce-

geometry of the reinforced column for both cases. This ment will buckle first will result in a critical column length

question is examined in greater detail in this paper, where L2. The equations for determining Li and L2 are devel-

the analysis shows that both the geometry of the reinforce- oped in the paper, together with the way to calculate the

ment and initial load can affect column capacity. capacity of the reinforced column.

The paper develops a method to determine the capacity A typical reinforced column is shown in Fig. 1.

of a column reinforced under load based on AISC require- The reinforced column, modeled for analysis purposes,

ments. The analysis is appHcable to any kind of column is in Fig. 2.

and reinforcement, but has not been verified by testing.

Tests have been conducted by Nagaraja and TalP on a

W8x31 column with an LIr ratio of 48, which showed that

welding flange plates—while the column is subjected to a

load of 91.2 kips—produced results comparable to the W= Q

same column reinforced under no load. This paper would

confirm this, but shows this is not necessarily true for

larger LIr values of the same reinforced column.

If the effects of residual stresses from welding are ig-

nored, the following examples illustrate how the location

of the new reinforcement influences capacity.

Reinforcing Core Column

If a column is already carrying its full dead and live

A • Area of Reinforcing^

load, only the live load can be removed during reinforce-

I . » Moment of Inertia I^ * Moment of Inertia

ment. The dead load stresses will be frozen in the column

core after welding and can influence its capability to carry

additional load. The original column, hereafter is referred

to as the core.

The effects of residual stresses from welding have not

been considered in this paper and the reader should con-

sult other publications on the subject. ^"^'^

METHOD OF ANALYSIS

Inelastic Analysis for Buckling

The analysis will be based on the assumption a plastic

hinge will first form in the core column and the reinforced

Jack H. Brown, P.E., is Senior Research Associate, Research

& Development, The Austin Company, Cleveland, Ohio.

Figure 1

FOURTH QUARTER / 1988 161

The model consists of two separate columns connected Stage 1 with the assumed forces and displacements shown

by rigid links. This insures that both the core and the rein- in Fig. 3.

forcement follow the same axial deformation and have the No real column is perfectly straight and its initial crook-

same deflection curves. edness can be given as,

The model will have three stages of loading:

yo = aisin('nx/L) + a2sin{2'nx / L) +

. . . +anSm{mix/L) (3)

Stage 1 The reinforcement is welded to the loaded core.

The first term of the series is predominant and will be

Stage 2 A plastic hinge forms in the core at G.

used in the analysis to follow. The column C D , in Fig. 3a,

Stage 3 Failure occurs when the reinforcement is unable is assumed to have an initial bow. Using this assumption,

to stabilize the core. then,

y^ = flisin('iTJc/L) (4)

The loading in the core and reinforcement at Stage 1 is:

As the load Q increases, the initial bow will take the de-

Q = Qo (core column) (la)

flected shape given by y. This deflection will result in a

P= Q (reinforcement) (lb) load q on the reinforcement, shown in Fig. 3b. The rein-

forcem. nt will have a transverse loading of the same form

W=P+Q (combined) (2)

as the deflected core.

As the load W is increased, the core reaches its buckling q = FoSm(7Tx/L) (5)

load of Qcr, with both the core and the reinforcement car- where

rying loads up to Stage 2. q = the load per unit length.

When Stage 2 is reached, the core has reached its maxi-

mum load capacity. If strain-hardening is ignored, any fur- Fo = maximum force acting at L/2

ther load will be carried by the reinforcement. The mecha- The deflection^ for the beam CD is,

nism against failure at this stage is shown in Fig. 2b.

As the deflection of point G increases because of the in- y = Qa sm{Ttx/L)/('n^EIJL^-Q) (6)

creased load of W, the capacity of the core will approach The term ir^EI^ IL^ is Euler beam-column buckling load.

Qcr, while its resistance to rotation at G approaches zero. If this is replaced by Q^r, where Q^r = Fcr^c^ then Eq. (6)

As W increases, a plastic hinge will form at E and becomes.

the reinforcement loses its stiffness. This is the failure

stage of the reinforced column. The analysis will start at y = Qas.m{^xlL)l{Q,r-Q) (6a)

i 1

Reinf . ^ Core

Rigid Links Jr Plastic Hinge

(P = 0) Qo1

u «^cr

Initial Stage F a i l u r e of Core Failure

Figure 2a Figure 2b Figure 2c

162 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

The solution^ to the beam-column shown in Fig. 3b is, where

w = Fo{Lli:)h\n{i:xlL)l{iT^EIJL^-P) (7) P=iT^EIJL^ (12)

Similarly, if i^EIrlL^ is replaced by Per, where The corresponding deflection at the center of column CD

Per Pcr^r after the plastic hinge has formed, shown in Fig. 4b, is,

and Fcr is based on the stiffness of the reinforcement, then

Eq. 7 becomes: y = FLIAQe, (13)

w= F^iL/irfsmiTTx/Q/iPer-P) (7a)

Equating}' = w, then,

Critical Load on Reinforcement

F, = i^^Qa{Per-P)IL\Qcr-Q) (8) If the deflection y and w are equated, the maximum load

As {Qcr - Q)^0, (Per - P)>0, (from initial assumption). P can be determined using Eqs. 10 and 13 and equating

Rewriting Eq. (8) as, y = w, then.

F,= C(Per-P)/(Qcr-Q) (9)

As Q-^Qcr y Fo-^'^y whatever the value of C. So it can be con- P = G^,[tan(ML/2)/(wL/2)-l] (14)

cluded a plastic hinge will form at G in column CD, with

a mechanism similar to that shown in Fig. 4b. The force The solution of Eq. 14 is best solved by computer or by

F acts at the center of column CD, preventing it from col- successive approximations.

lapsing. A simpler but less accurate method for finding P is to

The force F also acts at the center of the reinforcement, use the approximation given by Eq. 13 and Eq. 11. Equat-

creating the beam-column shown in Fig. 4a. ing deflections.

The equation^ for the deflection center of the column

ABis, y—w

w = LF [tan(ML/2)/(wL/2)-l] lAP (10) then

where (15)

u^ = PIEIr

An approximation of Eq. 10 is: i'max = Pe- 0 . 8 2 2 (2cr (16)

w = FPeLV4SEIXPe-P) (11) P <P

-* max — -* c;

XQ = a s i n ( 7 r x / L )

is the i n i t i a l cur\'ature

Figure 3a

1/2 L/2

Loading curve r e s u l t i n g

r from d e f l e c t i o n y

?E

r^aT M i i ;TT^r^^',

q = F s i n ( 7 r x/L)

(a) (b)

Figure 3b Figure 4

FOURTH QUARTER / 1988 163

Critical Length of Reinforcement Load in reinforcement at load Q^is P = O. Load P in the

reinforcement at load Q^r is:

If Eq. 16 is equated to P^r, a critical length Lj results. This

is the maximum column length for which the properties P= (e,,-eo)A,E

of an unloaded reinforced column can be used, given as, P={Qcr-Qo)AJA, (19)

Li = V[7r^E/,/(P,,+0.822a.)] (17) The ultimate load F^ of the reinforced column is:

Similarly, if Eq. 15 is equated to zero, a critical length W=P, = F + a . (20)

L2 results. This is the minimum length of column for which

In no case should W exceed the buckhng strength of the

the reinforcement provides additional stiffness to the core.

reinforced column, with Q^ — 0.

For column lengths greater than L2, the column must be

designed for the elastic range as given by the next section. FACTOR OF SAFETY AND

CRITICAL BUCKLING STRESS

L2 = V(12EIJQ^) (18)

The factor of safety and critical inelastic buckling stress

Since Eqs. 17 and 18 give approximate values of Lj and should be based on AISC Specification Eq. 1.5-1.^ This

L2 sometimes it is necessary to make a second trial calcu- equation can be broken down into two parts: one is the

lation. factor of safety and the other the critical buckling stress.

Properties of core column W8x31.

Elastic Analysis

A, =9.12in.2

When the core column length is greater than L2, the col-

umn must be designed for elastic stresses only, with both ly =37.0 in.'*

the core and reinforcement working below the critical

buckling stress of the reinforced column. Vy = 2.02 in.

The following analysis derives the ultimate load for a re- L/r = 126/2.02 = 62.38

inforced column in this state.

Determine critical stress F^r by Eq. 23.

Eqs. 21 and 22 are given for the factor of safety and Q (Fy = 36 ksi) = 126.1, K = 1.0

Eqs. 23 and 24 give the critical buckling stresses.

i7^^= [l-(62.38/126.1)2/2]x36 = 31.60 ksi

The larger value of the reinforced or unreinforced L/r

should be used to calculate the factor of safety. Q,, = 31.60 X 9.12 = 288.19 kips

The factor of safety (F.S.) for Eq. 1.5-P is.

Case 1.

F.S. = 5/3+3{KL/r)/SC,-(KL/ry/8C,^ (21)

2 - 7-in. X yg-in. plates welded to the flanges.

and for Eq. 1.5-2^ is,

Reinforcement properties:

F.S. = 23/12, KL/r>C, (22)

Ar = 2 x 7 x 0 . 3 7 5 = 5.25 in.^

The critical stress /J^ for Eq. 1.5-1 is,

/, = 2 X .375 X 7^/12 = 21.44 in.^

ij, = [l-(KL/rf/2C,^]Fy, KLIr<C, (23)

r = V21.44/5.25 = 2.02in.

F,, = iT^EI{Llrf,KLIr>C, (24)

L/r = 126/2.02 = 62.38

where

Combined column properties

Q = V(2iT^'E/Fy)

A = 9 . 1 2 + 5.25 = 14.37 in.2

EXAMPLES / = 3 7 + 21.44 = 58.44 in.

r = VUA = V(58.44/14.37) = 2.02 in.

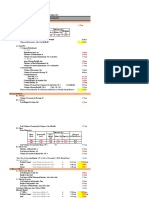

Three cases will be considered, each using L = 126 in. Ini-

tial dead load Q^ = 91.2 kips and the same W8x31 section L/r = 126/2.02 = 62.38

with the equivalent area of reinforcement of 2 - 7-in. x

F,r = [1 - (62.38/126.1)2/2] x 36 = 31.60 ksi

Ys-in. plates with Fy = 36 ksi.

Ultimate capacity with Qo = O.

Strain in the core column CD at load Q^ is e^ and the

strain at load Q^r is e^r- Strain in reinforcement at load P^ = 31.60 X 14.37 = 454.09 kips

Gcr is: F,r = [1 - (62.38/126.1)2/2] x 36 = 31.60 ksi

P,, = 31.60 X 5.25 = 165.9 kips

164 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Check critical length Lj for post buckling by Eq. 17, Shear on end of plate = MQ^/Ix

= 1157x11.5/210.7

Li = V[7r2x29000x21.44/(165.9+.822x288.19)] = 63.0 kips

= 123.4 in.

Length of yi6-in. fillet weld = 63.0/2.7 = 23.3 in.

Check critical length L for the elastic buckling by Eq.

18, Use 12-in. of yi6-in. fillet weld each side of plate with

1-in. return weld

L2 = V(12 X 29000 X 21.44/288.19) = 160.9 in.

Case 2.

The reinforced column is in the transition stage, since

Li<L<L2. Use Eq. 16 to calculate P. W8x31 with 2 - 10.5-in. x 1/4-in.flangeplates

P = P e - 0 . 8 2 2 G,, Properties of reinforcement

P, =iT^x 29000 X 21.44/126^ = 386.49 kips Ar =10.5 X .25 X 2 = 5.25 in.^

Q^r =288.19 kips / = 2x0.25x10.5^/12 = 48.23 in.^

P = 386.49 - .822 x 288.19 = 149.60 kips r = V(48.23/5.25) = 3.03 in.

P <P,, L/r =126/3.03 = 41.57

W = F ^ = ecr + ^ = 288.19-h 149.96 = 438.15 f^^ = [1 - (41.57/126.1)^/2] X 36 = 34.04 ksi

kips P,, = 34.04 X 5.25 = 178.71 kips

The factor of safety is given by Eq. 21 using the L/r ratio Combined properties

for the combined column properties,

A = 14.37 in.^

F.S. = 5/3+3x62.38/(8x126.1)-.125x(62.38/126.1)^

= 1.84 / = 3 7 + 48.234 = 85.23 in.^

ASD design load on reinforced column r =2.44 in.

F.S. = 438.15/1.84 = 238.5 kips L/r = 126/2.44 = 51.64

Fa =238.5/14.37 = 16.60 ksi F,r = [1 - (51.64/126.1)2/2] x 36 = 32.98 ksi

F, = 32.98 X 14.37 = 473.92 kips

Welds to reinforcement

Check critical length Lj by Eq. 17

Use E70XX electrodes

Using Lj = 182.25, Q.^ = 244.21 kips,

Shear flow Tb = VyQ^/I^

P,, =167.49 kips

e^ = (7 X .375) X (.75+8)/2 = 11.5

then

4 = 110 + [(.75-f 8)/2f X2.63x2=210.7 in.^

Li = V[7T2X29,000 X 48.23/(167.49+.822x244.21)]

S^ =210.7/4.375 = 48.2 in.3 = 193.6 in.

Allowable moment, M = 24x48.2 = 1156 kip-in. LJ > L, so the column can be designed for the rein-

Equivalent shear, Vy = 2M/L forced column properties with Qo = O.

= 2x1156/126 = 18.4 kips then.

Shear flow/in. = VyQJI^ P^ =473.92 kips

= 18.4x11.5/210.7=1.0 kips/in.

Spacing welds = 127/V^ = 127/V36 = 21.2 in. Case 3.

Limit spacing to 12-in. W8X31 with 2 - 6-in. x yi6-in. web plates

Capacity of yi6-in. fillet weld = 36x0.4x3/16 = Properties of reinforcement

2.7 kips/in.

A, =5.25in.2

Length of weld = 12x1/2.7 = 4.44 in.

/, = 2x6x.4382/12+5.25+(.438+.288)2/2

Use 2 - yi6-in. fillet x 2% long at 12-in. c. to c. = .774 in.^

End welds r = V(.774/5.25) = .384

FOURTH QUARTER / 1988 165

LIr = 126/.384 = 327.8 than Lj. For lengths up to point b, the column can be de-

signed as a normal column and the effects of the residual

F,, = TT^x29000/327.8^ = 2.66 ksi

load Qo can be ignored.

P^r = 2 . 6 6 x 5 . 2 5 = 14.0 kips From points b to c, there is a change in the curve as the

reinforcement provides post-buckling strength to the core

A = 14.37 in.^ column. This is the transition stage between inelastic

/ = 37.324 buckling to elastic buckHng and the column should be de-

signed using Eq. 16.

r = V37.324/14.37=1.61in. From points c to d, the column is completely dependent

L/r =126/1.61 = 78.16 on the initial loading Q^ and the strain of the core cannot

go beyond the first buckling load. The column should be

Far = [1 - (78.16/126.1)^/2] x 36 = 29.08 ksi designed as outlined by the section on Elastic Analsyis.

Ultimate capacity assuming Q^ = 0. The computer showed Eq. 16 slightly overestimates the

critical buckling of the reinforced column. If one desires

P^ = 29.08 X 14.37 = 417.88 kips to check the value of F by Eq. 14, then Eq. 16 can be used

Check critical length for elastic buckling using Eq. 18. as a starting point.

The ultimate capacity of the column should not exceed

L2 = V(12 X 29,000 X .776/288.19) = 30.6 in. the capacity of the reinforced column under no load condi-

The column is elastic; use Eq. 19 tion, i.e., Qo = 0.

The complexity of the failure modes is shown in Fig. 6

P = (288.19 - 91.2) X 5.25/9.12 = 113.4 kips curve (3), where the buckling load after L = 150 is based

Pu =Qcr + P = 288.19 + 113.4 = 401.59 kips on Eq. 24 with the properties of the reinforced column

If the column had been designed with the reinforced prop- and Qo = 0, rather than the method suggested in the Elas-

erties and load Qo = 0, then the column would be defi- tic Analysis of this paper. This is because the radius of gy-

cient by, ration of the reinforced column is less than the radius of

gyration of the core.

(417.88 - 401.59) x 100/401.6 = 4.06%

If the same column was carrying its full load at the time CONCLUSION

of reinforcement, then The method developed in this paper for calculating the ul-

timate capacity of a column reinforced under load is based

L/r = 62.38 on a rational analysis and is not substantiated by testing,

2^ = 17.2x9.12 =156.86 kips although the method does provide the same answer as

and Ref. 2 for a W8x31 column reinforced with 2 ft. - 7 in.

X 3/8 in. flange plates and an L/r = .48.

^u(eo=156.86) = (288.19-156.86)x5.25/9.12+288.19 The paper treats the reinforced column as a frame with

= 363.1 two members joined to each other by rigid links. The

% overstress = (417.88-363.1)x 100/363.1 = 15% members are the reinforcement and the unreinforced col-

umn. The reinforced column of length L has two critical

lengths LJ and L2 which define its behavior. The values

of LJ and L2 are dependent on the relative stiffness of the

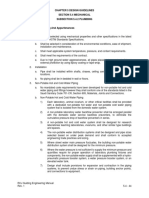

COMPUTER ANALYSIS AND RECOMMENDATIONS reinforcement and column.

A computer program was written to investigate the char- The design criteria for determining the capacity of the

acteristics of a W8x31 section reinforced as previously de- column is given by the following:

scribed for Cases 1, 2 and 3 in the Example section. The

1. L < LJ, the properties of the reinforced column can

behavior of the three cases is shown in Figs. 5 and 6. Also,

be used.

the computer analysis was used to check the validity of

using the approximate Eq. 16 instead of the more exact 2. L > L2, the column should be designed for elastic be-

Eq. 14. havior only, by Elastic Analysis section of this paper.

3. LJ < L < L2, the column uses the post-buckhng

Figure 6 shows the curves have a distinct discontinuity

strength of the reinforcement after the column core has

when a critical length Lj is reached for each type of rein-

failed. The critical load is given by Eq. 14.

forcement. This is best described by examining the curve

for Case 1.

From points a to b, the curve gives the ultimate capacity

of the column, based on the reinforced column properties.

The initial load on the column has no effect on the ulti-

mate capacity P^ of the column for column lengths less

166 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

7 X 3/8 PL 10.5 X 1/4 PL

"^ I I'

.6 X 7/16 PL

Test column failure Ref.2

COLUI^N REINFORCED UNDER NO LOAD

COLUMN REINFORCED UNDER 9.12 kips

.2 1

20 40 60 80 100 120

L/r

Figure 5

500

400

P

(kips)

300

200

KEY

100 COLUMN REINFORCED UNDER NO LOAD

COLUMN REINFORCED UNDER 91.2 kips

UNREINFORCED W 8 x 31

50 100 150 200 250 300

L (INS)

ALL CURVES END AT L/r 120

Figure 6

FOURTH QUARTER / 1988 167

REFERENCES M = Moment acting on reinforcement

P = Load on reinforcement

1. American Institute of Steel Construction, Inc.

Per = Critical load on reinforcement

Manual of Steel Construction, 8th Ed. 1980, Chicago,

P^ = Euler equation, Eq. 12

111.

P^ = Ultimate load on reinforced column

2. Nagaraja Rao, N.R. and L. Tall Columns Reinforced

q = Lateral force between core column and reinforce-

Under Load Welding Journal, Welding Research Sup-

ment

plement, April 1963, American Welding Society,

Q — Load on core column

Miami, Fla.

Qo - Load on core column at time of reinforcing

3. Johnston, Bruce C. Guide to Stability Design Criteria

Qcr = Critical load on core column

for Metal Structures, 3rd Ed. JohnWiley& Sons, New

r = Radius of gyration

York, N. Y.

W = Load on combined core column and reinforcement

4. Tall, L. Structural Steel Design The Ronald Press

w — Deflection of reinforcement, elastic range

Company 1964, New York, N. Y.

X = Distance along column, measured from support

5. Taucher, Theodore R, Energy Principles in Structural

y = Deflection of core column

Mechanics McGraw-Hill Inc., 1974, New York, N.Y.

y^ = Initial curvature of core column

6. Brush D.O. and B.O. Almmoth Buckling of Bars,

Plates and Shells McGraw-Hill, 1975, New York, u^ = PIEIr

€o = Strain in core column at time of reinforcing

N.Y.

e^r = Strain in core column at buckling

7. Allen, H.G. and P.S. Bulson Background to

Buckling McGraw-Hill, 1980, New York, N.Y.

NOMENCLATURE

A = Area of compression members

Ac = Area of core column k r i T L I OP F O i L I C A T I O N 2. DATE OF F I L I N G

C = Constant . F a i Q u i N C Y OF i s s u e

) ! 0 I l | 31 8 I 0 I 2 Dec.

k NO. OF ISSUES FUBLISHEOl 3B A N N U A L SUSSCRIF

2, 1987

Cc = Column slenderness ratio separating elastic and in- ANNUALLY

Four

PRICE

Sll.OO

elastic buckling . C O M ^ ( T ( M A I L I N Q A O O n t U OF KNOMN OFFICC OF FUBLICATION IS

400 North Michigan Avanua. Chicago, Illlnola 60611

E = Modulus of elasticity of steel i. d A M K T k M A I L I N O A O O M f S S of T H t H C A O a U A A T t n s 0 # C E N E n A t . SUSINtSS OFFICES OF TMt PUBLISM€B If

•ricsB Inac. of SCaal Conacruetlon, Inc.

F = Lateral force acting at center of column, between «• FULL N A M I S A N D C O < l > U t T t MAILII^O A O O W t a J F PUBLISHtW. SOITQW. J

core and reinforcement at failure of Staal Conatructlon, Inc.

Fa = Allowable compressive stress IOITONrMM«<iW

nan Avanua. Chicago, Ullnota 60611

Saorg* E. Uarpar Diraccor of Publlcaciona Aaarlcan Inaclci

Fcr = Critical buckling stress 400 North nichigan Avanua. Chicago, Illlnoti 60611

Sni IM6H ,sm^ ^ com,u» u

Fo = Maximum force between core and reinforcement,

elastic range

Fy = Specified minimum yield stress

COMPLETE MAILING AOOWBM

F.S. = Factor of safety A—rlcan Inatltuta of Staal Conatructlon. IncL 400 North Michigan Avanua, Chicago, IL 6 0 6 I 1 |

Ic = Moment of inertia of core column

/^ = Moment of inertia of reinforcement

K = Effective length factor for a prismatic member COMFLETg MAILING AOORf SS

L = Length of column

Li = First critical length, Eq. 17

•. Fon coMTtanoM av NONTWJFIT OWOANIZATIOMB AUTMOWIZIO TO MAIL AT SPECIAL HATES is-nm

L2 = Second critical length, Eq. 18

J M t f C I O I M O 17 M O M T H t

ACTUAL NO. COFIES OF SINGLE !

EXTENT ANO N A T V I « t OF C m c U L A T I O N ISSUE PUBLISHED NEAREST TO ;

F I L I N G OATE i

A. TOTAL NO. C O r t U / A

I . FAIO AHOIOm R E Q O I S T E D C m C U L A T I O N

i . TOTAL 0 I S T M i a u T t O N ^ » M « < C « i ^ O ;

Ft fmm 383S. OM. 1H5

168 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

Das könnte Ihnen auch gefallen

- The Mysterious One-Third Stress IncreaseDokument3 SeitenThe Mysterious One-Third Stress Increaseprozoam21Noch keine Bewertungen

- Recommendations for Shear Lag Factors for Longitudinally Welded Tension MembersDokument22 SeitenRecommendations for Shear Lag Factors for Longitudinally Welded Tension MembersSergioAlcantaraNoch keine Bewertungen

- S16-14 Changes You Need to KnowDokument141 SeitenS16-14 Changes You Need to KnowMG Xie0% (1)

- Field WeldingDokument16 SeitenField WeldingIngeniero EstructuralNoch keine Bewertungen

- A Design Guide For Bracing Cold-Formed Steel StructuresDokument10 SeitenA Design Guide For Bracing Cold-Formed Steel StructuresSaravanan SilambanNoch keine Bewertungen

- Practical Compactness and Bracing Provisions For The Design of Single Angle BeamsDokument7 SeitenPractical Compactness and Bracing Provisions For The Design of Single Angle Beamsbruno_alqNoch keine Bewertungen

- Design Method For The Bolts in Bearing-Type Connections With FillersDokument7 SeitenDesign Method For The Bolts in Bearing-Type Connections With FillersAnonymous 7MdZQn1Noch keine Bewertungen

- Biaxial Bending of Steel Angle Section PDFDokument3 SeitenBiaxial Bending of Steel Angle Section PDFImam NakhrowiNoch keine Bewertungen

- Ch11 Stability of Angle MembersDokument38 SeitenCh11 Stability of Angle MembersErnie ErnieNoch keine Bewertungen

- CICIND Commentary PDFDokument36 SeitenCICIND Commentary PDFxufafruitjuiceNoch keine Bewertungen

- Steel StacksDokument44 SeitenSteel StacksNitish saini100% (1)

- The Effective Length of Columns in Unbraced FramesDokument6 SeitenThe Effective Length of Columns in Unbraced FramesMa Khristina Cassandra PacomaNoch keine Bewertungen

- Torsion of Rolled Sections in Building StructuresDokument27 SeitenTorsion of Rolled Sections in Building StructuresrilopiyNoch keine Bewertungen

- The Effective Length of Cantilevers As Goverened by Lateral BucklingDokument8 SeitenThe Effective Length of Cantilevers As Goverened by Lateral Bucklingjst8089372Noch keine Bewertungen

- Introduction of Concentrated Loads in Plates and ShellsDokument38 SeitenIntroduction of Concentrated Loads in Plates and ShellsAscanio Barbosa100% (1)

- Brace ConfigDokument1 SeiteBrace ConfigmrmerajNoch keine Bewertungen

- The Application of Flexural Methods To Torsional Analysis of Thin-Walled Open SectionsDokument10 SeitenThe Application of Flexural Methods To Torsional Analysis of Thin-Walled Open SectionsRm1262100% (1)

- Discussion - The Importance of Tension Chord BracingDokument2 SeitenDiscussion - The Importance of Tension Chord BracingKeaten ClaneyNoch keine Bewertungen

- Piglet 6-2 Manual-June 2021Dokument44 SeitenPiglet 6-2 Manual-June 2021LIM TECK THONGNoch keine Bewertungen

- DIRECT STRENGTH DESIGN OF COLD FORMED STEEL MEMBERS WITH PERFORATIONS - Report - RP09-1 PDFDokument564 SeitenDIRECT STRENGTH DESIGN OF COLD FORMED STEEL MEMBERS WITH PERFORATIONS - Report - RP09-1 PDFAravind BhashyamNoch keine Bewertungen

- Galambos 2001 Q2Dokument13 SeitenGalambos 2001 Q2bobmarley20161934Noch keine Bewertungen

- Masonry Structures 1921 PDFDokument424 SeitenMasonry Structures 1921 PDFGabriel MedinaNoch keine Bewertungen

- Cyclic Behavior of Steel Gusset Plate Connections PDFDokument165 SeitenCyclic Behavior of Steel Gusset Plate Connections PDFliron4349Noch keine Bewertungen

- Transverse Plate-To-squarerectangular Hss ConnectionsDokument7 SeitenTransverse Plate-To-squarerectangular Hss Connectionsdeepak_dce_meNoch keine Bewertungen

- AISC/MBMA Guide for Flush & Extended Multiple-Row Moment End-Plate ConnectionsDokument14 SeitenAISC/MBMA Guide for Flush & Extended Multiple-Row Moment End-Plate Connectionsอภิรักษ์ มานะกิจศิริสุทธิ100% (3)

- Truss Connections AISC ManualDokument8 SeitenTruss Connections AISC ManualBun KunNoch keine Bewertungen

- Buckling of Beams With YuraDokument20 SeitenBuckling of Beams With YuraMario JacomeNoch keine Bewertungen

- End Restraints in Single - and Double - Bolted AngDokument7 SeitenEnd Restraints in Single - and Double - Bolted AngJonatan ViloriaNoch keine Bewertungen

- Gusset Plate Connection To Round HSS Tension MembersDokument7 SeitenGusset Plate Connection To Round HSS Tension MembersSergioAlcantaraNoch keine Bewertungen

- Lateral Support For Tier Building FramesDokument4 SeitenLateral Support For Tier Building Framesuhu_plus6482Noch keine Bewertungen

- Parametric Study On Double Wall Freestanding Steel StackDokument5 SeitenParametric Study On Double Wall Freestanding Steel StacknehaNoch keine Bewertungen

- NCh2369.Of2003 (English April 25 2005) Seismic Design of Industrial Struct and FacilDokument131 SeitenNCh2369.Of2003 (English April 25 2005) Seismic Design of Industrial Struct and FaciliagpconceNoch keine Bewertungen

- Fundamentals of Beam Bracing PDFDokument16 SeitenFundamentals of Beam Bracing PDFGautham AllimuthuNoch keine Bewertungen

- Meet The Experts - Steel JoistsDokument2 SeitenMeet The Experts - Steel Joistsseth_gzbNoch keine Bewertungen

- 2 Lateral-Load-Transfer Session-2 2perDokument56 Seiten2 Lateral-Load-Transfer Session-2 2perLuis CortesNoch keine Bewertungen

- Evolution of Shear Lag and Block Shear Provisions in The AISC SpecificationDokument4 SeitenEvolution of Shear Lag and Block Shear Provisions in The AISC SpecificationSergioAlcantaraNoch keine Bewertungen

- NBC 2010 - Commentaries - Section IDokument24 SeitenNBC 2010 - Commentaries - Section IRick HenbidNoch keine Bewertungen

- Wood Shear Wall Design Examples For WindDokument4 SeitenWood Shear Wall Design Examples For WindAbdurrahman ÇINARNoch keine Bewertungen

- A Model For Predicting The Fire-Resisting Performance of Small-Scale Cavity Walls in Realistic FiresDokument9 SeitenA Model For Predicting The Fire-Resisting Performance of Small-Scale Cavity Walls in Realistic FiresjeccoNoch keine Bewertungen

- Beam Deflection Tables - MechaniCalcqweqdsdDokument9 SeitenBeam Deflection Tables - MechaniCalcqweqdsdKenneth LuceroNoch keine Bewertungen

- Torsion of Noncircular Prismatic Bars - Extract From Craig Mechanics of MaterialsDokument5 SeitenTorsion of Noncircular Prismatic Bars - Extract From Craig Mechanics of MaterialsAlmudena9Noch keine Bewertungen

- CHS CorusDokument13 SeitenCHS Corusfrog15Noch keine Bewertungen

- Old Paper On Vierendeel TrussDokument20 SeitenOld Paper On Vierendeel TrusssmwassyNoch keine Bewertungen

- Working Design of Single AnglesDokument2 SeitenWorking Design of Single AnglesAnonymous 1BdR0EQgbu100% (1)

- Tubular Brace MemberDokument8 SeitenTubular Brace MemberRegina MillerNoch keine Bewertungen

- A Comparative Study On Wind Loads Between Design Standards For The Design of Pipe-Rack StructuresDokument8 SeitenA Comparative Study On Wind Loads Between Design Standards For The Design of Pipe-Rack Structuresvirat_daveNoch keine Bewertungen

- Shelf Angles For Masonry VeneerDokument17 SeitenShelf Angles For Masonry VeneerJudian DuranNoch keine Bewertungen

- 1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsDokument6 Seiten1992 - 06 What Design Engineers Can Do To Reduce Fabrication CostsHenry HoyosNoch keine Bewertungen

- Shear Behavior of Headed Anchors With Large Diameters and Deep Embedments - Discussion Title 107-S14 - Mar-Apr 2010Dokument6 SeitenShear Behavior of Headed Anchors With Large Diameters and Deep Embedments - Discussion Title 107-S14 - Mar-Apr 2010ehab.attalaNoch keine Bewertungen

- Anchor Bolts Design of Headed Anchor BoltsDokument12 SeitenAnchor Bolts Design of Headed Anchor BoltsDoug LambNoch keine Bewertungen

- A Ramset SRB Ed3 Full EditionDokument312 SeitenA Ramset SRB Ed3 Full Editionchancer2Noch keine Bewertungen

- Asce 7-22 CH 29com - For PCDokument22 SeitenAsce 7-22 CH 29com - For PCsharethefilesNoch keine Bewertungen

- Structural Details To Increase Ductility of ConnectionsDokument12 SeitenStructural Details To Increase Ductility of ConnectionsNicușor SfârleaNoch keine Bewertungen

- AISI S211-07 (Raffirmed 2012) - E1Dokument2 SeitenAISI S211-07 (Raffirmed 2012) - E1Jon JacobsNoch keine Bewertungen

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionVon EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNoch keine Bewertungen

- 11-Stability of ColumnsDokument41 Seiten11-Stability of Columnsali381Noch keine Bewertungen

- THE STABILITY OF FOUNDATION PILES AGAINST BUCKLINGDokument8 SeitenTHE STABILITY OF FOUNDATION PILES AGAINST BUCKLINGCharles-Antoine BordeleauNoch keine Bewertungen

- Civil Engineering Department, I.I.T., Kharagpur Assignment - 12 M.Tech (I) & Dual DegreeDokument4 SeitenCivil Engineering Department, I.I.T., Kharagpur Assignment - 12 M.Tech (I) & Dual DegreeAravind KumarNoch keine Bewertungen

- Optimum Design of Geodesic Steel Domes Using MetaheuristicsDokument16 SeitenOptimum Design of Geodesic Steel Domes Using MetaheuristicsVinayak PotdarNoch keine Bewertungen

- Two Way Joist Concrete Waffle Slab Floor Design DetailingDokument86 SeitenTwo Way Joist Concrete Waffle Slab Floor Design DetailingHung NguyentheNoch keine Bewertungen

- 65487Dokument52 Seiten65487Christine SarigumbaNoch keine Bewertungen

- Pile Cap DesignDokument12 SeitenPile Cap DesignBhaskar Jyoti Das100% (2)

- SimmonsDokument12 SeitenSimmonsGürelBaltalıNoch keine Bewertungen

- Guideline Floors - VibrationDokument43 SeitenGuideline Floors - VibrationDawit SolomonNoch keine Bewertungen

- Design and Construction of Jetties: ,' .E!.tyllDokument19 SeitenDesign and Construction of Jetties: ,' .E!.tyllGeorge Opar100% (3)

- Building Vibrations From Human ActivitiesDokument12 SeitenBuilding Vibrations From Human ActivitiesGürelBaltalıNoch keine Bewertungen

- UPVC Litaflex Conduit & FittingDokument10 SeitenUPVC Litaflex Conduit & FittingSara NuonNoch keine Bewertungen

- Proposed waiting shed in Lumbia, Cagayan de Oro CityDokument7 SeitenProposed waiting shed in Lumbia, Cagayan de Oro CityMac KYNoch keine Bewertungen

- Wide-Lite Spectra VI Commercial Indoor Bulletin 1989Dokument4 SeitenWide-Lite Spectra VI Commercial Indoor Bulletin 1989Alan MastersNoch keine Bewertungen

- Rheology Book PDFDokument268 SeitenRheology Book PDFPaulo SouzaNoch keine Bewertungen

- Disperse DyeDokument8 SeitenDisperse DyeSifat RaihanNoch keine Bewertungen

- Furadur Kittloesung 20120416 en SD 91070119 PDFDokument9 SeitenFuradur Kittloesung 20120416 en SD 91070119 PDFBarbara Andreina Sanchez AmayaNoch keine Bewertungen

- Lesson 1 Electron Configuration and Octet RuleDokument23 SeitenLesson 1 Electron Configuration and Octet RuleAngel CapinpinNoch keine Bewertungen

- Cooling TowerDokument12 SeitenCooling Towernhalieza1067Noch keine Bewertungen

- Red Oxide Primer QD JotunDokument4 SeitenRed Oxide Primer QD JotunDebNoch keine Bewertungen

- 2015 JMR SoftRobotHandDokument9 Seiten2015 JMR SoftRobotHandsaqlain saqiNoch keine Bewertungen

- Chapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingDokument4 SeitenChapter 5 Design Guidelines Section 5.4 Mechanical Subsection 5.4.2 PlumbingkapsarcNoch keine Bewertungen

- Building The Formula For Calculating The Vapor of The LPG Liquid Generating in The Explosion Risk of LPG TankDokument3 SeitenBuilding The Formula For Calculating The Vapor of The LPG Liquid Generating in The Explosion Risk of LPG TankLy Ngoc MinhNoch keine Bewertungen

- Me F211 1083 PDFDokument3 SeitenMe F211 1083 PDFPranjal SrivastavaNoch keine Bewertungen

- 2021 H2 JC1 Promo Section C QnsDokument16 Seiten2021 H2 JC1 Promo Section C QnsFelysia DianniNoch keine Bewertungen

- 8-2 Salt CementDokument23 Seiten8-2 Salt CementLenin DiazNoch keine Bewertungen

- Insulating Flange Kits DatasheetDokument4 SeitenInsulating Flange Kits DatasheetAndry RimanovNoch keine Bewertungen

- Deaerators: Technical BackgroundDokument8 SeitenDeaerators: Technical Backgroundกี๋ แต่งงามNoch keine Bewertungen

- Data Sheet Schott® Borofloat: Chemical PropertiesDokument2 SeitenData Sheet Schott® Borofloat: Chemical PropertiesDiego SaenzNoch keine Bewertungen

- Waterproofing: Part - 8 Waterproofing and Low Energy Consumption Roofing SystemsDokument20 SeitenWaterproofing: Part - 8 Waterproofing and Low Energy Consumption Roofing SystemsVaishamNoch keine Bewertungen

- SOW - Improvement of Twelve (12) Units StaffhousesDokument14 SeitenSOW - Improvement of Twelve (12) Units StaffhousesKathleen A. PascualNoch keine Bewertungen

- SOBM Calculation SheetDokument15 SeitenSOBM Calculation SheetChintan GohelNoch keine Bewertungen

- Safety Data Sheet X-CIDE 105: 1. Identification of The Substance/Preparation and The CompanyDokument5 SeitenSafety Data Sheet X-CIDE 105: 1. Identification of The Substance/Preparation and The Company123456ccNoch keine Bewertungen

- TCE Babbitt 18391-2Dokument2 SeitenTCE Babbitt 18391-2paulo cesar hernandez mijangosNoch keine Bewertungen

- Chemistry: Pearson EdexcelDokument36 SeitenChemistry: Pearson EdexcelSanti DiazNoch keine Bewertungen

- Us5591802 PDFDokument7 SeitenUs5591802 PDFAl Saraaf MohammedNoch keine Bewertungen

- THEORITICAL RAW MIX DESIGNDokument3 SeitenTHEORITICAL RAW MIX DESIGNVaibhav Khodake100% (4)

- Forged Engineering DataDokument4 SeitenForged Engineering DataretrogradesNoch keine Bewertungen

- Conservation of An Amphora of The Spatheion TypeDokument2 SeitenConservation of An Amphora of The Spatheion TypeJaime Mujica SallesNoch keine Bewertungen

- HE Design CalculationsDokument166 SeitenHE Design CalculationsdinakaranpatelNoch keine Bewertungen

- Glass Chap 5: Structure and PropertiesDokument80 SeitenGlass Chap 5: Structure and PropertiesIka Safitri RachmawatiNoch keine Bewertungen