Beruflich Dokumente

Kultur Dokumente

Bohler Dcms T-MC

Hochgeladen von

Flaviu-Andrei AstalisOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bohler Dcms T-MC

Hochgeladen von

Flaviu-Andrei AstalisCopyright:

Verfügbare Formate

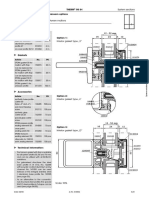

BOHLER PCMS T-MC

bohler welding

by v o e sta lp ire

M etal cored w ire, seam less, cre e p re sista n t

Classifications

EN ISO 17634-A EN ISO 17634-B AWS A5.36 AWS A5.36M

T CrM ol M M21 1 T55T15-1M21-1CM- E80T15-M21PY-B2-H4 E550T15-M21PY-B2-H4

H5 H5

Characteristics and typical fields of application

Seamless, Cr-Mo alloyed, metalcored wire for single- or multilayer welding of creep resistant steels

up to 500°C with A r-C 0 2shielding gas.

Features include: high yield, good weldability, excellent bead appearance, very low spatter losses.

Wire with very low amount of diffusible hydrogen (< 3ml/100g) that reduces the risk of cracks.

Base materials

1.7335 13CrMo4-5, 1.7262 15CrMo5, 1.7728 16CrMoV4, 1.7218 25CrMo4, 1.7225 42CrMo4,

1.7258 24CrMo5, 1.7354 G22CrMo5-4, 1.7357 G17CrMo5-5

ASTM A 182 Gr. F12; A 193 Gr. B7; A 213 Gr. T12; A 217 Gr. WC6; A 234 Gr. W P 11;

A335 Cr. P11, P12; A 336 Gr. F11, F12; A 426 Gr. CP12

Typical analysis of aH-weid metal (wt.-%)

Gas C Si Mn Cr Mo

wt-% M21 0.06 0.40 1.10 1.20 0.50

Mechanical properties of all-weld metal

Condition Yield strength Tensile strength Elongation Impact work

Rpo^ Rm A (L0=5d0) ISO-V KV J

MPa MPa % +20°C -10°C -20°C

a 520 (>470) 620 (550-690) 22 (>20) 110 (>47) 90 80

a annealed 690°C / 60min - shielding gas M21

Operating data

Polarity: Shielding gas: 0 (mm)

L

M - DC ( + ) (EN ISO 14175) M21 1.0

1.2

/ \ i r. 1.4

1.6

Welding with standard GMAW power source possible

Approvals

TUV, DB, CE

AII information provided is based upon careful investigation and intensive research. 09/2015

However, v/e do not assum e a n y liabiiiîy fo r correctness and information is subject to change without notice. VAvw .voestalpine.com /w elding

Das könnte Ihnen auch gefallen

- Metric Grease Fittings - Metric Zerk Fittings - Metric Grease FittingsDokument6 SeitenMetric Grease Fittings - Metric Zerk Fittings - Metric Grease FittingsUdayan BasuNoch keine Bewertungen

- Data Sheet PR 6201Dokument4 SeitenData Sheet PR 6201Zarra FaktNoch keine Bewertungen

- Format BBSDokument8 SeitenFormat BBSArmida ShareNoch keine Bewertungen

- Form Deffect ListDokument2 SeitenForm Deffect ListWahyu Rohmad DiantoNoch keine Bewertungen

- Kabel MetalDokument2 SeitenKabel Metalsri haryadiNoch keine Bewertungen

- Welded Wire Mesh 50 X 50 X 1 6mm MSDSDokument3 SeitenWelded Wire Mesh 50 X 50 X 1 6mm MSDSMounir BoutaghaneNoch keine Bewertungen

- Uraian Analisa Harga SatuanDokument6 SeitenUraian Analisa Harga Satuandwi istNoch keine Bewertungen

- Davidi Int - Company Profile Sept 2014 - PotraitDokument28 SeitenDavidi Int - Company Profile Sept 2014 - PotraitChaidir TransmissionNoch keine Bewertungen

- Lighting Solutions Lighting Solutions: AmorisDokument51 SeitenLighting Solutions Lighting Solutions: AmorisjohanNoch keine Bewertungen

- Rencana Keselamatan Kesehatan Kerja & Lingkungan: ProyekDokument15 SeitenRencana Keselamatan Kesehatan Kerja & Lingkungan: ProyekSilvester LamanepaNoch keine Bewertungen

- MU-Weber General Presentation New (Key Account)Dokument97 SeitenMU-Weber General Presentation New (Key Account)syahrulNoch keine Bewertungen

- Socla Katalog CZ - 3Dokument28 SeitenSocla Katalog CZ - 3Anugrah Prihantoro Amd TNoch keine Bewertungen

- PT Inter World Steel MillsDokument20 SeitenPT Inter World Steel Millssugiarto budiNoch keine Bewertungen

- BaskomDokument8 SeitenBaskomKrisnandha RahardianNoch keine Bewertungen

- Rencana Pembangunan Bendungan Cibeet Kabupaten Bogor: NorthDokument1 SeiteRencana Pembangunan Bendungan Cibeet Kabupaten Bogor: NorthEdi AriyantoNoch keine Bewertungen

- Invoice: Mr. Edy Jl. Jakarta Blok CF No 8 SamarindaDokument1 SeiteInvoice: Mr. Edy Jl. Jakarta Blok CF No 8 Samarindaone borneo100% (1)

- Colour Card Multi-PoxDokument4 SeitenColour Card Multi-PoxGunawan MuhamadNoch keine Bewertungen

- Break Down Quotation Asti-A Rev. 03Dokument2 SeitenBreak Down Quotation Asti-A Rev. 03Kholer Burgman67% (3)

- SPINDO Catalogue New PDFDokument56 SeitenSPINDO Catalogue New PDFTitus Deus PrizfelixNoch keine Bewertungen

- Standard Non-Inverter CS/CU-YN18WKJ: Air Conditioners Single SplitDokument1 SeiteStandard Non-Inverter CS/CU-YN18WKJ: Air Conditioners Single SplitBoy KailimangNoch keine Bewertungen

- RAB & Spek IGMDokument2 SeitenRAB & Spek IGMfatwa1985Noch keine Bewertungen

- Daikin VRV FXMQ Medium Static Concealed Ducted Indoor Unit BrochureDokument1 SeiteDaikin VRV FXMQ Medium Static Concealed Ducted Indoor Unit BrochureChuy Cantú100% (1)

- Brosur Lampu PJU SHT 30WDokument1 SeiteBrosur Lampu PJU SHT 30WRahmat HidayatNoch keine Bewertungen

- Brosur+Len+200+Wp 24V+MonocrystallineDokument2 SeitenBrosur+Len+200+Wp 24V+Monocrystallineeric_agustianNoch keine Bewertungen

- Daily Report, Selasa 21 Januari 2020 PDFDokument2 SeitenDaily Report, Selasa 21 Januari 2020 PDFAndika AndikaNoch keine Bewertungen

- Reel No672 - 36mm X 1500m 35x7 (Wa) Galv RHLL KW Mill & GL CertDokument3 SeitenReel No672 - 36mm X 1500m 35x7 (Wa) Galv RHLL KW Mill & GL CertNg Thiam YongNoch keine Bewertungen

- 1 Site Plan Komplek SATPAS OKI by Iskandar Ilyas Semendawai 085267069867Dokument1 Seite1 Site Plan Komplek SATPAS OKI by Iskandar Ilyas Semendawai 085267069867Arsitek Iskandar Ilyas SemendawaiNoch keine Bewertungen

- Project: RDMP-JO-Building PKG 1 Title: Bar Bending Schedule A B C D Dia. Length (M) QTY Unit Weight (KG/M) Total Length (M) Total Weight (KG)Dokument2 SeitenProject: RDMP-JO-Building PKG 1 Title: Bar Bending Schedule A B C D Dia. Length (M) QTY Unit Weight (KG/M) Total Length (M) Total Weight (KG)hendra efendiNoch keine Bewertungen

- Form RFIDokument1 SeiteForm RFIJosep SuryaNoch keine Bewertungen

- Windrose - Dry Season (Apr-Oct)Dokument1 SeiteWindrose - Dry Season (Apr-Oct)Edi AriyantoNoch keine Bewertungen

- Penetrant Test Report - ContohDokument2 SeitenPenetrant Test Report - ContohSmksore PasNoch keine Bewertungen

- Katalog TSP PT PDFDokument24 SeitenKatalog TSP PT PDFdeniNoch keine Bewertungen

- Seal Weld Activ 8Dokument23 SeitenSeal Weld Activ 8Mostafa NabilNoch keine Bewertungen

- CV. Batu Penjuru - Doc Penaw Kolang Paket 1 Bag2Dokument10 SeitenCV. Batu Penjuru - Doc Penaw Kolang Paket 1 Bag2Sudarma SibagariangNoch keine Bewertungen

- Jotamastic 80: Technical Data SheetDokument14 SeitenJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANNoch keine Bewertungen

- Rab PacingDokument1 SeiteRab PacingRosyadNoch keine Bewertungen

- Drawing List For ConstructionDokument3 SeitenDrawing List For Constructionkere_hore007Noch keine Bewertungen

- 3'' K Ill W ATE RLI NE: 4'' C VC Li NEDokument2 Seiten3'' K Ill W ATE RLI NE: 4'' C VC Li NEArdy Chidy ArismanNoch keine Bewertungen

- Belawan Port SituationDokument5 SeitenBelawan Port SituationAde YudiarsyahNoch keine Bewertungen

- Extract Pages From Tower Triangle 20 M - Revisi 1Dokument2 SeitenExtract Pages From Tower Triangle 20 M - Revisi 1Sholahuddin DiinNoch keine Bewertungen

- 01.01.02.01 Spesifikasi-Soilfelt LSDokument2 Seiten01.01.02.01 Spesifikasi-Soilfelt LSjogja raya100% (1)

- Katalog SevenDokument19 SeitenKatalog SevenAn ZizNoch keine Bewertungen

- Visio-Pondasi Jembatan Timbang 100 Ton (16m)Dokument17 SeitenVisio-Pondasi Jembatan Timbang 100 Ton (16m)Lalu Aditiya MardinatalNoch keine Bewertungen

- H D I y LDokument7 SeitenH D I y LCoklatabis CokicokiNoch keine Bewertungen

- Draft Justek V.O 07 Partial Taking OverDokument14 SeitenDraft Justek V.O 07 Partial Taking OverFahmi PratamaNoch keine Bewertungen

- SPHC, SPHDDokument2 SeitenSPHC, SPHDMihai Condeescu100% (1)

- Datasheet For Overcurrent Protection Devices ACB 2000A 50 Ka MVS20N3MF2ADokument12 SeitenDatasheet For Overcurrent Protection Devices ACB 2000A 50 Ka MVS20N3MF2AAli Mahdy ArrosikhNoch keine Bewertungen

- Test Certificate: Hex Bolt, Nut & Plain WasherDokument1 SeiteTest Certificate: Hex Bolt, Nut & Plain WasherQC Konart steelNoch keine Bewertungen

- SKT TKG Las - RudolfDokument4 SeitenSKT TKG Las - RudolfRifalMkNoch keine Bewertungen

- Aliva 264Dokument2 SeitenAliva 264Bambang SupriyantoNoch keine Bewertungen

- Weekly Report JAS EPC SP WKSAI 13 - 20 Januari 2023 PT. Odira (ANSI, API & Crude Oil Pump)Dokument10 SeitenWeekly Report JAS EPC SP WKSAI 13 - 20 Januari 2023 PT. Odira (ANSI, API & Crude Oil Pump)Andy ArdianNoch keine Bewertungen

- Rencana Anggaran Biaya (Rab)Dokument4 SeitenRencana Anggaran Biaya (Rab)D'wansaGrazzanoNoch keine Bewertungen

- DayeDokument2 SeitenDayeJosip JurčićNoch keine Bewertungen

- 017 - Test Report of Quality TGL 25 Sept 2023 - BIOSOLAR B35Dokument1 Seite017 - Test Report of Quality TGL 25 Sept 2023 - BIOSOLAR B35moehammadsaliem7Noch keine Bewertungen

- Spesifikasi Mobil Derek Dutro 130 HD PDFDokument3 SeitenSpesifikasi Mobil Derek Dutro 130 HD PDFKenny ELtorNoch keine Bewertungen

- Drilling Log: Soil or Rock Material DescriptionDokument1 SeiteDrilling Log: Soil or Rock Material DescriptionYosep AlianduNoch keine Bewertungen

- Acg080 PDFDokument1 SeiteAcg080 PDFSonia Liset Mamani HuamaniNoch keine Bewertungen

- Extrana Product CatalogDokument78 SeitenExtrana Product CatalogBaswara SadewaNoch keine Bewertungen

- Draft Material RequestDokument3 SeitenDraft Material Requestbang awiNoch keine Bewertungen

- Boehler NiCu1 Ti T-FD - CWDokument1 SeiteBoehler NiCu1 Ti T-FD - CWbrayanNoch keine Bewertungen

- S51 - S62Dokument12 SeitenS51 - S62Flaviu-Andrei AstalisNoch keine Bewertungen

- Tipuri de Sarma Procedeu Material Sarma DenumireDokument1 SeiteTipuri de Sarma Procedeu Material Sarma DenumireFlaviu-Andrei AstalisNoch keine Bewertungen

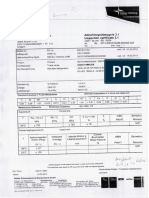

- Inspection Certificate Welding Wire TysweldDokument1 SeiteInspection Certificate Welding Wire TysweldFlaviu-Andrei AstalisNoch keine Bewertungen

- Inspection Certificate Welding Wire - Union NiMoCrDokument1 SeiteInspection Certificate Welding Wire - Union NiMoCrFlaviu-Andrei AstalisNoch keine Bewertungen

- Mil S 5059DDokument12 SeitenMil S 5059DMichael SkrableNoch keine Bewertungen

- Ta 201 A Laboratory ManualDokument22 SeitenTa 201 A Laboratory ManualSunitNoch keine Bewertungen

- 251-260 GregurekDokument10 Seiten251-260 GregurekAlexander SledzNoch keine Bewertungen

- Flotation Li Minerals - Lombe - WC - 1983 - PHD - ThesisDokument259 SeitenFlotation Li Minerals - Lombe - WC - 1983 - PHD - ThesisMaria José FuturoNoch keine Bewertungen

- BMP (Class 06-Class 07) Casting 01-6-7Dokument28 SeitenBMP (Class 06-Class 07) Casting 01-6-7Asesh PramanikNoch keine Bewertungen

- Lamara2018 PDFDokument13 SeitenLamara2018 PDFUmer HayatNoch keine Bewertungen

- WoW Mining and Smithing RP ResourceDokument11 SeitenWoW Mining and Smithing RP ResourceIcarusATBNoch keine Bewertungen

- Astm A666 - StainlesssteelDokument8 SeitenAstm A666 - StainlesssteelPeter MohabNoch keine Bewertungen

- Geopolymer Camp 2019-Ferro-Sialate GeopolymerDokument16 SeitenGeopolymer Camp 2019-Ferro-Sialate GeopolymerAlviona KabanNoch keine Bewertungen

- 2024 Aluminium Alloy - WikiDokument2 Seiten2024 Aluminium Alloy - WikiSamto Oi SelaluNoch keine Bewertungen

- IRSM-46-13 With Amendment 2016Dokument29 SeitenIRSM-46-13 With Amendment 2016Våïbhäv Çhåühåñ100% (1)

- VSP BrochureDokument33 SeitenVSP BrochuresudhakarrrrrrNoch keine Bewertungen

- BrazingDokument9 SeitenBrazingDennis DaleNoch keine Bewertungen

- Asme Marking-And-Mechanical-Properties-Of-Steel-FastenersDokument3 SeitenAsme Marking-And-Mechanical-Properties-Of-Steel-Fastenersjyoti prakash singhNoch keine Bewertungen

- LoveUrns® 2014 HumanDokument29 SeitenLoveUrns® 2014 HumanshimacherNoch keine Bewertungen

- Astm Standards For Coated Sheet Products: GalvinfonoteDokument3 SeitenAstm Standards For Coated Sheet Products: GalvinfonoteKYAW SOENoch keine Bewertungen

- Gazette No 67 DT 15-5-15Dokument4 SeitenGazette No 67 DT 15-5-15Tushar ShewaleNoch keine Bewertungen

- Basic Mettalurgy of The Precious Metal Part IDokument38 SeitenBasic Mettalurgy of The Precious Metal Part ILinda LindawatiNoch keine Bewertungen

- The Refractory Beat (Cement) - November 2019Dokument3 SeitenThe Refractory Beat (Cement) - November 2019khalil MoussaouiNoch keine Bewertungen

- Abrasive Machining and Finishing OperationsDokument27 SeitenAbrasive Machining and Finishing Operationsfazli98418Noch keine Bewertungen

- Pre-Fused vs. Blended Fluxes: Their Impact On Cleanliness of Low-Carbon Low-Alloy SteelDokument10 SeitenPre-Fused vs. Blended Fluxes: Their Impact On Cleanliness of Low-Carbon Low-Alloy SteelJJNoch keine Bewertungen

- Engleski 6 PrevodDokument25 SeitenEngleski 6 PrevodAnonymous YMhnrbmvaNoch keine Bewertungen

- Mil HDBK 735Dokument508 SeitenMil HDBK 735NicolasSuchNoch keine Bewertungen

- Item Code Opening FormDokument16 SeitenItem Code Opening FormAbhiNoch keine Bewertungen

- Species 20sept 202010 1Dokument12 SeitenSpecies 20sept 202010 1Andre NetcatshellNoch keine Bewertungen

- 02 CE134P-2 Section Properties of Hot Rolled Structural SteelDokument6 Seiten02 CE134P-2 Section Properties of Hot Rolled Structural SteelPzynae FlorentinoNoch keine Bewertungen

- Zone RefiningDokument21 SeitenZone RefiningHảo Vũ ĐứcNoch keine Bewertungen

- Astm A794-97Dokument3 SeitenAstm A794-97FeteneNoch keine Bewertungen

- Electrode Booklet F Web 8Dokument1 SeiteElectrode Booklet F Web 8satnamNoch keine Bewertungen

- Engineering Materials: Metals and Their Alloys Ceramics Polymers CompositesDokument53 SeitenEngineering Materials: Metals and Their Alloys Ceramics Polymers CompositesSyed Muhammad AliNoch keine Bewertungen