Beruflich Dokumente

Kultur Dokumente

Masterkure 300CR

Hochgeladen von

Doby YuniardiOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Masterkure 300CR

Hochgeladen von

Doby YuniardiCopyright:

Verfügbare Formate

MASTERKURE 300CR Interim Datasheet

Formerly Masterseal S

Sprayable, chlorinated rubber based, curing and sealing compound

DESCRIPTION The surface may be damp but with no free water on it. In

the case of formed concrete, apply immediately after

MASTERKURE 300CR is a clear, ready to use, striking the formwork.

chlorinated rubber based curing membrane and sealing Delaying the application until the next day will allow

compound. substantial loss of moisture reducing the effectiveness of

the curing membrane.

RECOMMENDED FOR For best results, apply an even coat by airless spray at a

pressure of 110 - 160 kg/cm2 using a nozzle with tip size

MASTERKURE 300CR is recommended for curing 0.43 - 0.48 mm. It can also be applied with a wide short

freshly placed concrete floors and vertical surfaces nap roller, or brush to the recommended thickness.

where after curing, the concrete surface has also to be Avoid too thick an application to prevent blisters and

protected from staining caused by spillage of mild debonding caused by solvent entrapment. With all

chemicals, mineral oils and grease. Areas of application methods, take adequate care to prevent marring of

include curing of, concrete surface.

• workshop floors, beam and columns, For curing only, a single coat is recommended. For

• cementitious toppings and surface hardening curing and sealing, apply one further coat after the first

finishes such as Mastertop 100, Mastertop 200, coat has dried.

Mastertop 210 and Mastertop 103.

• cementitious grouts and mortars. EQUIPMENT

FEATURES AND BENEFITS Airless spray machine, short nap mohair roller and

brush.

Effective moisture Facilitates complete hydration of

retention in cement resulting in greater CLEANING

concrete strength and superior wear

Clean tools and equipment using a hydrocarbon based

resistance.

solvent such as xylene.

Seals surface Protects concrete from staining

and ingress of liquids. Also ESTIMATING DATA

minimises dusting.

Bonds to non No need to remove membrane Consumption depends on the surface profile, porosity

cement based tile before laying ceramic or vinyl and method of application. When applied with a roller

adhesives tiles. onto a smooth, dense surface, MASTERKURE 300CR

2

gives a typical coverage of 5 m /L per coat.

2

PROPERTIES Therefore, material requirement will be 0.20 L/m per

coat on a dense smooth surface.

Supply form : Viscous liquid

Colour : Clear PACKAGING

MASTERKURE 300CR will yellow with prolonged MASTERKURE 300C is available in 20 L pails and 205

exposure to UV light but this will not affect its curing L drums.

efficiency.

STORAGE

APPLICATION

Store away from sources of heat and ignition in a

Use MASTERKURE 300CR as supplied without dilution. shaded, dry, well enclosed area at moderate

Stir the contents of the container using a slow speed temperatures.

(600 rpm) electric drill fitted with a wing type paddle,

before applying. SHELF LIFE

It should be applied after the final finishing operation as

soon as the concrete or mortar surface has hardened MASTERKURE 300CR can be stored in tightly sealed

sufficiently to prevent marring. original containers for 12 months when stored as

recommended.

Head Office Factories Representative Offices

Plaza GRI 10th & 11th Floor Jl. Daan Mogot Km.14 Jl. Jababeka V Blok I-1 Grand Residence Office Park, Komp. Pertokoan Royal Sunggal

Jl. HR Rasuna Said Blok X-2 No.1 Cengkareng, Cikarang Industrial Estate 1st Floor Jl. Gagak Hitam No. A-12

Jakarta 12950 Jakarta 11750 Bekasi 17530 Jl. Darmo Harapan Complex 1 Ring Road – Sunggal

Tel.: (6221) 5262481, 5262505 Tel.: (6221) 6190007 Tel.: (6221) 8934339 Surabaya 60187 Medan, Sumatera Utara 20128

Fax: (6221) 5262493, 5262515 Fax: (6221) 6190741 Fax: (6221) 8934342 Tel.: (6231) 7326705 Tel.: (6261) 8447110

Fax: (6231) 7326730 Fax: (6261) 8444072

MASTERKURE 300CR Interim Datasheet

PRECAUTIONS OTHER USEFUL PRODUCTS

Health : MASTERKURE 300CR contains certain Masterkure 181 : Acrylic based concrete curing

chemicals which can cause skin irritation if exposed and compound for outdoor and indoor application.

respiratory reaction if inhaled. Masterkure 148 : Membrane forming, wax based curing

Safety : Wear gloves and masks while handling the compound for concrete.

product. Wash thoroughly after handling. Barra repair system : Includes corrosion protective

coating for steel, polymer bonding agents, and Barra

Should spillage occur on clothes, remove the range of polymer modified repair mortars for anchoring,

contaminated clothing and wash exposed skin using surface levelling, high build in vertical & over head

soap and water. situations.

In case of accidental eye contact wash with copious Emaco : A range of high performance structural repair

amount of water and seek medical help. mortars available in pourable, pumpable and sprayable

If ingested drink a glass of water and do not induce grades, for high build (up to 120 mm ) and medium build

vomiting. Consult doctor immediately. (up to 40 mm) applications.

Concresive : Resin based mortars for chemical

Fire : The vapours of certain ingredients in resistance and exceptional strengths.

MASTERKURE 300CR are flammable. Avoid exposure Mastertop : A range of industrial flooring products that

to naked flame while handling the product. Do not includes resin based floor screeds and coatings, dry

smoke. shake iron aggregate based floor hardeners and iron

Flash Point : 42°C. aggregate based floor screed.

I Mk300CR/3/0602

The technical information and application advice given in this BASF Construction Chemicals

publication are based on the present state of our best scientific and practical knowledge. As the

STATEMENT OF information herein is of a general nature, no assumption can be made as to a product's suitability for a

RESPONSIBILITY particular use or application and no warranty as to its accuracy, reliability or completeness either

expressed or implied is given other than those required by law. The user is responsible for checking the

suitability of products for their intended use.

Field service where provided does not constitute supervisory responsibility. Suggestions made by

BASF Construction Chemicals either orally or in writing may be followed, modified or rejected by the

NOTE owner, engineer or contractor since they, and not BASF Construction Chemicals, are responsible for

carrying out procedures appropriate to a specific application.

Das könnte Ihnen auch gefallen

- Formulir Metode Taksiran Visual Skala ComstockDokument1 SeiteFormulir Metode Taksiran Visual Skala Comstockrini dwi puryaningtiasNoch keine Bewertungen

- Domain Diagnosa Gizi-Intake 2013-4Dokument58 SeitenDomain Diagnosa Gizi-Intake 2013-4Ilmi Dewi A100% (1)

- Standar Diet CairDokument1 SeiteStandar Diet CairrahmadiNoch keine Bewertungen

- Ketepatan Pemorsian Sayur Terhadap Standar Porsi MDokument9 SeitenKetepatan Pemorsian Sayur Terhadap Standar Porsi MJhoe kurniawanNoch keine Bewertungen

- Contoh Soal ComstockDokument6 SeitenContoh Soal ComstockolifiaNoch keine Bewertungen

- Food CostDokument14 SeitenFood CostErniRukmanaNoch keine Bewertungen

- Soal 1Dokument7 SeitenSoal 1shofiNoch keine Bewertungen

- Diet Pada Anemia, Kva, GakiDokument39 SeitenDiet Pada Anemia, Kva, GakiYanuarti PetrikaNoch keine Bewertungen

- NCP Luka BakarDokument10 SeitenNCP Luka BakarviandaVNNoch keine Bewertungen

- Template Daily SPVDokument25 SeitenTemplate Daily SPVrahmansetiadixshot xshotNoch keine Bewertungen

- Idnt 1300 2018Dokument14 SeitenIdnt 1300 2018api-335577439Noch keine Bewertungen

- Comparative StandarDokument3 SeitenComparative StandaryesiNoch keine Bewertungen

- Draf Leaflet DBMPDokument2 SeitenDraf Leaflet DBMPWildaniaNurinIzzati100% (1)

- Skor Asam AminoDokument7 SeitenSkor Asam Aminomutiara putriNoch keine Bewertungen

- (Spmi) KELOMPOK 1 - Menu Panti AsuhanDokument12 Seiten(Spmi) KELOMPOK 1 - Menu Panti Asuhanputri n.kNoch keine Bewertungen

- Food Frequency Questionnaire (FFQ)Dokument23 SeitenFood Frequency Questionnaire (FFQ)Novita SariNoch keine Bewertungen

- Daftar Komposisi Bahan MakananDokument10 SeitenDaftar Komposisi Bahan MakananTiara Tia AraNoch keine Bewertungen

- Modifikasi Formula Enteral Rumah Sakit Siap SeduhDokument8 SeitenModifikasi Formula Enteral Rumah Sakit Siap SeduhAsfi Ni'amNoch keine Bewertungen

- Diet OsteoporosisDokument20 SeitenDiet OsteoporosiserikNoch keine Bewertungen

- Manajemen Penerimaan Bahan Makanan Di inDokument11 SeitenManajemen Penerimaan Bahan Makanan Di inOki VimaNoch keine Bewertungen

- Blendera VS PROTENDokument2 SeitenBlendera VS PROTENAjeng Sekar ProboriniNoch keine Bewertungen

- Jurnal Sisa Makanan PasienDokument5 SeitenJurnal Sisa Makanan PasienDaraa Ananda100% (1)

- Kadar Kalium Pada Bahan Makanan: G. Lain - LainDokument3 SeitenKadar Kalium Pada Bahan Makanan: G. Lain - LainRaja Nurul TaniaNoch keine Bewertungen

- Tabel Food Recall 24 Jam SilviaDokument1 SeiteTabel Food Recall 24 Jam SilviaWiwik SeftafianiNoch keine Bewertungen

- Modifikasi Resep Brownis Untuk Makanan Selingan Penderita Diabetes MellitusDokument5 SeitenModifikasi Resep Brownis Untuk Makanan Selingan Penderita Diabetes MellitusRegitaand PutNoch keine Bewertungen

- Contekan Kuis Xo MabinogiDokument12 SeitenContekan Kuis Xo MabinogishiraikenNoch keine Bewertungen

- T-Test: T-Test Groups Kota (1 2) /missing Analysis /variables Kariayam Godas /CRITERIA CI (.95)Dokument38 SeitenT-Test: T-Test Groups Kota (1 2) /missing Analysis /variables Kariayam Godas /CRITERIA CI (.95)Ash RoryNoch keine Bewertungen

- Pasien Critical IllDokument151 SeitenPasien Critical IllUlfah TriTaNoch keine Bewertungen

- Menu Sehari Pasien Asam UratDokument1 SeiteMenu Sehari Pasien Asam UratpipitNoch keine Bewertungen

- Jurnal Haccp Bakpia Pathuk 25Dokument7 SeitenJurnal Haccp Bakpia Pathuk 25Rizka DhNoch keine Bewertungen

- Master Tabel SpssDokument3 SeitenMaster Tabel SpssIrene Sri Malem SembiringNoch keine Bewertungen

- Perhitungan Comparative StandartDokument4 SeitenPerhitungan Comparative StandartEva MutiarasariNoch keine Bewertungen

- Perhitungan Kebutuhan Gizi StrokeDokument2 SeitenPerhitungan Kebutuhan Gizi StrokeNauchi FebyNoch keine Bewertungen

- Brosur Diet Rendah KaloriDokument3 SeitenBrosur Diet Rendah KalorihildaNoch keine Bewertungen

- Patobiologi Gizi: Prof - Dr.Ambar Mudigdo, DR - Sp.PA (K)Dokument13 SeitenPatobiologi Gizi: Prof - Dr.Ambar Mudigdo, DR - Sp.PA (K)DewiNoch keine Bewertungen

- TM 1 - Formulasi & Fortifikasi Gizi AJDokument91 SeitenTM 1 - Formulasi & Fortifikasi Gizi AJKyoumi OfficialNoch keine Bewertungen

- Makanan Cair Jernih Melena PDFDokument2 SeitenMakanan Cair Jernih Melena PDFMasYonkuroNoch keine Bewertungen

- 2004 - Mackenzie - Ruler Drop TestDokument5 Seiten2004 - Mackenzie - Ruler Drop TestHerdiantri SufriyanaNoch keine Bewertungen

- Standar Diet RSU Dr. MoewardiDokument26 SeitenStandar Diet RSU Dr. MoewardiMathali' MonesiaNoch keine Bewertungen

- Nutrition Counseling During Pregnancy On Maternal Weight GainDokument4 SeitenNutrition Counseling During Pregnancy On Maternal Weight GainAbha AyushreeNoch keine Bewertungen

- Jurnal Sisa MakananDokument10 SeitenJurnal Sisa MakananRifky FaishalNoch keine Bewertungen

- NCP PebDokument7 SeitenNCP Pebdesitameiikalia7835Noch keine Bewertungen

- 3458 7242 1 SM PDFDokument9 Seiten3458 7242 1 SM PDFJuhariah Aring RNoch keine Bewertungen

- Homework Probstat PreuasDokument3 SeitenHomework Probstat PreuasTsabita fidinillahNoch keine Bewertungen

- Nilai Lab NormalDokument3 SeitenNilai Lab Normalraa_zhraNoch keine Bewertungen

- Toxi Medik-2Dokument39 SeitenToxi Medik-2Wahyu MargariniNoch keine Bewertungen

- Audit GiziDokument2 SeitenAudit Gizielis fitriaNoch keine Bewertungen

- Artikel MelaDokument14 SeitenArtikel MelaRobi UcibeNoch keine Bewertungen

- Kuliah Nutrisi ParenteralDokument31 SeitenKuliah Nutrisi ParenteralNicholas PetrovskiNoch keine Bewertungen

- Nutrisi Aplikasi 21 Macam Diet - Dr. Sri Murtiwi, Sp. PDDokument14 SeitenNutrisi Aplikasi 21 Macam Diet - Dr. Sri Murtiwi, Sp. PDbloadyroarNoch keine Bewertungen

- NCP InterventionDokument17 SeitenNCP InterventionNurul Huda HekmutiarNoch keine Bewertungen

- Flavours of Malaysia: The Norman Musa Collection 2014Dokument29 SeitenFlavours of Malaysia: The Norman Musa Collection 2014waiwaibabyNoch keine Bewertungen

- KONSELING GIZI PARIWISATA 2 OrgDokument6 SeitenKONSELING GIZI PARIWISATA 2 OrgSintia AriyuniNoch keine Bewertungen

- Metabolisme Zat BesiDokument33 SeitenMetabolisme Zat BesiFetria MelaniNoch keine Bewertungen

- Rab HansipDokument2 SeitenRab HansipsutrisnoNoch keine Bewertungen

- Procedure How To Make Cassava GetukDokument2 SeitenProcedure How To Make Cassava GetukHanyf WindyNoch keine Bewertungen

- DMT2Dokument15 SeitenDMT2Rimaya Erdhini FNoch keine Bewertungen

- Strong KidsDokument2 SeitenStrong Kidsisabella silaenNoch keine Bewertungen

- Pengaruh Penambahan Tepung Daun Kelor Terhadap Daya Terima Dan Kadar Protein Mie BasahDokument6 SeitenPengaruh Penambahan Tepung Daun Kelor Terhadap Daya Terima Dan Kadar Protein Mie BasahVina SoumokilNoch keine Bewertungen

- MasterProtect 300Dokument3 SeitenMasterProtect 300Gavriel NgNoch keine Bewertungen

- Nitoplate FRC: Constructive SolutionsDokument2 SeitenNitoplate FRC: Constructive SolutionsDoby YuniardiNoch keine Bewertungen

- Mastertop 102: Natural Aggregate Concrete Surface HardenerDokument2 SeitenMastertop 102: Natural Aggregate Concrete Surface HardenerDoby YuniardiNoch keine Bewertungen

- Intercure 99Dokument4 SeitenIntercure 99Doby YuniardiNoch keine Bewertungen

- ) Fi Puoqqsnrg: LZVX LselduocDokument2 Seiten) Fi Puoqqsnrg: LZVX LselduocDoby YuniardiNoch keine Bewertungen

- Mastertop 566: Self Smoothing Cementitious Based Floor LevellerDokument2 SeitenMastertop 566: Self Smoothing Cementitious Based Floor LevellerDoby YuniardiNoch keine Bewertungen

- Masterflex 3000Dokument2 SeitenMasterflex 3000Doby YuniardiNoch keine Bewertungen

- Mastertop 1240 AseanDokument2 SeitenMastertop 1240 AseanDoby YuniardiNoch keine Bewertungen

- Mastertop 1220 AseanDokument3 SeitenMastertop 1220 AseanDoby YuniardiNoch keine Bewertungen

- Mastertop 564Dokument2 SeitenMastertop 564Doby YuniardiNoch keine Bewertungen

- Intergard 774Dokument4 SeitenIntergard 774Doby YuniardiNoch keine Bewertungen

- Preco EAC-SDokument2 SeitenPreco EAC-SDoby YuniardiNoch keine Bewertungen

- Masterkure 128: Polymeric Emulsion Based, Concrete Curing CompoundDokument2 SeitenMasterkure 128: Polymeric Emulsion Based, Concrete Curing CompoundDoby YuniardiNoch keine Bewertungen

- Renderoc HB25: Constructive SolutionsDokument4 SeitenRenderoc HB25: Constructive SolutionsDoby YuniardiNoch keine Bewertungen

- Pds - Glenium C 317Dokument2 SeitenPds - Glenium C 317Doby YuniardiNoch keine Bewertungen

- Nitoflor Fc241: Constructive SolutionsDokument2 SeitenNitoflor Fc241: Constructive SolutionsDoby YuniardiNoch keine Bewertungen

- Mastertop 1324Dokument3 SeitenMastertop 1324Doby YuniardiNoch keine Bewertungen

- Glass - Fitting Calculation SheetDokument8 SeitenGlass - Fitting Calculation SheetyosNoch keine Bewertungen

- Special Steels, Superalloys, Aluminum and Titanium Alloys For The Space IndustryDokument6 SeitenSpecial Steels, Superalloys, Aluminum and Titanium Alloys For The Space Industrychetan_thakur4278Noch keine Bewertungen

- Chapter 2 MahoganyDokument2 SeitenChapter 2 MahoganyRichelle DandoNoch keine Bewertungen

- A Review On Exploring The Behavior of Multi-Layer Composite Structures Under Dynamic LoadingDokument9 SeitenA Review On Exploring The Behavior of Multi-Layer Composite Structures Under Dynamic LoadingRafael ZanettiNoch keine Bewertungen

- E305 Metallurgy and Material Science Set1 1Dokument2 SeitenE305 Metallurgy and Material Science Set1 1NAGA16100% (1)

- Vistalon Bimodal Rubber - Nov 18th 2010Dokument24 SeitenVistalon Bimodal Rubber - Nov 18th 2010Aryan ShahNoch keine Bewertungen

- Diagram Cat Jake BrakeDokument7 SeitenDiagram Cat Jake BrakeMarc Maxime100% (1)

- NEMA WC-71-1999-icea-71-1999icea-s-96-659-1999Dokument10 SeitenNEMA WC-71-1999-icea-71-1999icea-s-96-659-1999jan carlos martinezNoch keine Bewertungen

- Color Powder Color ChartDokument4 SeitenColor Powder Color ChartArif RusyanaNoch keine Bewertungen

- Iso 12473 2017Dokument13 SeitenIso 12473 2017testing castcoNoch keine Bewertungen

- Unit 3Dokument74 SeitenUnit 3ronnie199288% (8)

- Material SpecificationDokument12 SeitenMaterial SpecificationmehrNoch keine Bewertungen

- DR Fixit Pidipoxy MI EP Jan 2020Dokument3 SeitenDR Fixit Pidipoxy MI EP Jan 2020rakeshNoch keine Bewertungen

- Introduction To Carbon FiberDokument48 SeitenIntroduction To Carbon Fiberairbuk doeingNoch keine Bewertungen

- Transformer - CFPT PDFDokument16 SeitenTransformer - CFPT PDFTawan FindsoulNoch keine Bewertungen

- Course Outline For Reinforced Concrete IDokument2 SeitenCourse Outline For Reinforced Concrete ITefera TemesgenNoch keine Bewertungen

- Strength Properties of Adhesives in Shear by Tension Loading of Single-Lap-Joint Laminated AssembliesDokument4 SeitenStrength Properties of Adhesives in Shear by Tension Loading of Single-Lap-Joint Laminated AssembliesMarceloNoch keine Bewertungen

- IRC 112 - Oct 2013 Amendments PDFDokument3 SeitenIRC 112 - Oct 2013 Amendments PDFSiva Prasad MamillapalliNoch keine Bewertungen

- Tencord KB (E 42 4 Z B 42 h5)Dokument1 SeiteTencord KB (E 42 4 Z B 42 h5)brunizzaNoch keine Bewertungen

- Upper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Dokument15 SeitenUpper Zakum 750 Islands Surface Facilities Project - EPC2 PROJECT No. P7512Anonymous xyZH2OaUVNoch keine Bewertungen

- CeramTec SemiCon Data SheetDokument6 SeitenCeramTec SemiCon Data SheetЧжэньаоNoch keine Bewertungen

- BrederoShaw PDS 3LPPDokument2 SeitenBrederoShaw PDS 3LPPdipankarbasakNoch keine Bewertungen

- Roofcoat V1Dokument2 SeitenRoofcoat V1COONoch keine Bewertungen

- Industrial Coatings: Sasol Performance ChemicalsDokument6 SeitenIndustrial Coatings: Sasol Performance ChemicalsMaximiliano MackeviciusNoch keine Bewertungen

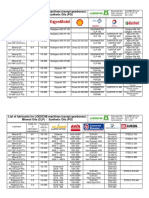

- List of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)Dokument8 SeitenList of Lubricants For LOESCHE-machines (Except Gearboxes) : Mineral Oils (CLP) / Synthetic Oils (PG)MossaabSelaimiaNoch keine Bewertungen

- Astm A320mDokument4 SeitenAstm A320mSHYAM SINGHNoch keine Bewertungen

- Heat Treatment Assignment My-005Dokument10 SeitenHeat Treatment Assignment My-005HANZALAH AHMEDNoch keine Bewertungen

- 3 Information Series The Welding of Stainless Steel MaterialDokument6 Seiten3 Information Series The Welding of Stainless Steel MaterialRamzi BEN AHMEDNoch keine Bewertungen

- Ch-27.8 PlasticsDokument98 SeitenCh-27.8 PlasticsasjfgauojfgfNoch keine Bewertungen

- Field Validation of A Coiled Tubing Fatigue Model: April 2003Dokument7 SeitenField Validation of A Coiled Tubing Fatigue Model: April 2003moorpvrNoch keine Bewertungen